Color filter photoresist stripping liquid composition

A color filter and composition technology, applied in the field of microelectronic materials, can solve the problems of long peeling time, serious taste, high operating temperature, and achieve no low-boiling organic volatiles, simple and convenient production process, and short peeling time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with specific embodiments:

[0018] The inorganic strong alkaline substance of the present invention may preferably be at least one of potassium hydroxide, sodium hydroxide and barium hydroxide, and the organic amine may preferably be hydroxylamine, monoethanolamine, N,N-dimethylethanolamine and diglycolamine The polar organic solvent may preferably be at least one of diethylene glycol monobutyl ether, dipropylene glycol monomethyl ether, benzyl alcohol, and propylene glycol phenyl ether.

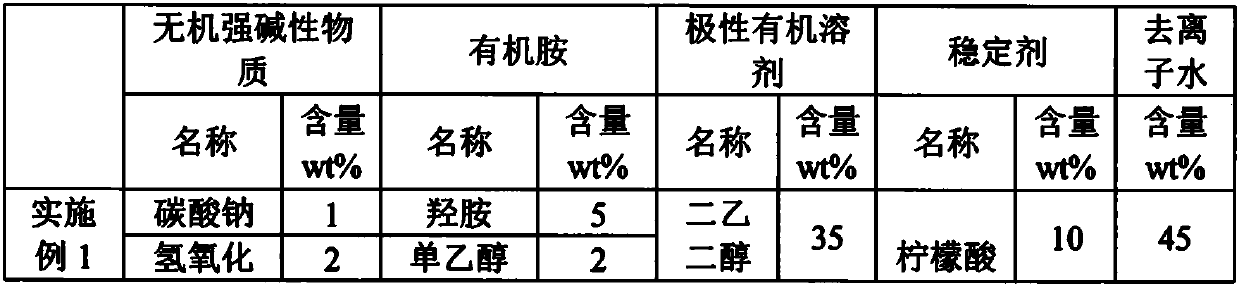

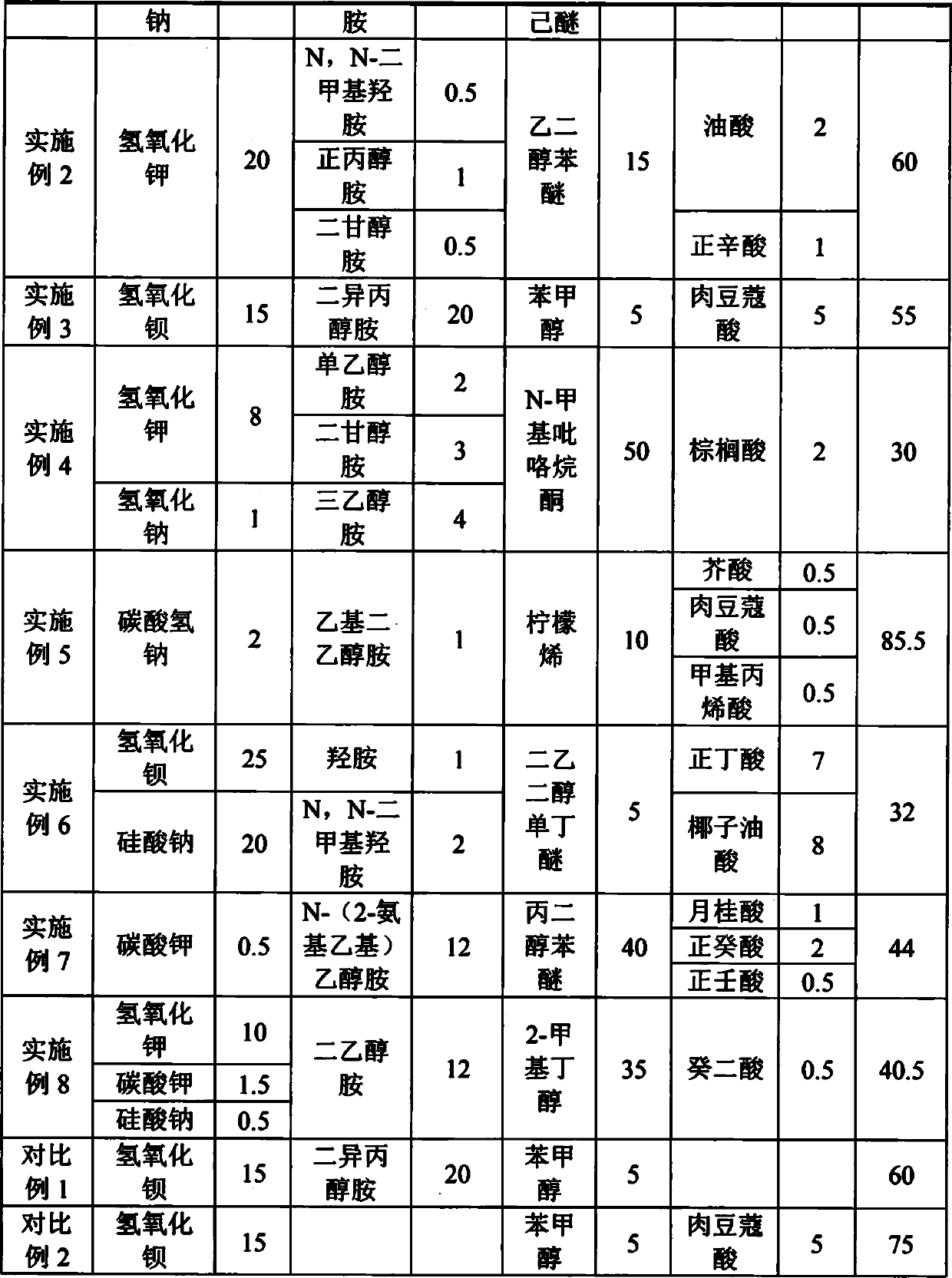

[0019] The following eight examples and two comparative examples are given. The components used in each of them and the amounts of each component are shown in Table 1 below:

[0020] Table 1 The dosage of each component of Examples 1-8 and Comparative Examples 1-2

[0021]

[0022]

[0023] It can be seen from the content in Table 1 above that the difference between Comparative Example 1 and Example 3 is that the stabiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com