A kind of large-scale aqueous phase prepares the method for graphene

A water-phase preparation, graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of difficult application and transportation, limited dispersion capacity, and lengthy process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Preparation technique of the present invention comprises the steps:

[0047] (1) Using flake graphite powder, natural graphite powder, synthetic graphite powder or expanded graphite powder as the starting material, it is intercalated by an oxidation intercalation method to prepare intercalated graphite;

[0048] The oxidation intercalation method described in step (1) can be sulfuric acid, nitric acid, perchloric acid, phosphoric acid, hydrogen peroxide, potassium permanganate, potassium dichromate, chromium trioxide, ammonium persulfate, formic acid, acetic acid, oxalic acid , bromine, chlorine, iodine chloride, iodine bromide, ozone, oxygen or any combination thereof. , but not limited to this.

[0049] The preparation process of intercalated graphite described in step (1) refers to completion at low temperature, the purpose is to avoid excessive oxidation of graphene sheets during the intercalation process, the preferred intercalation temperature is 0-60 o Between ...

Embodiment 1

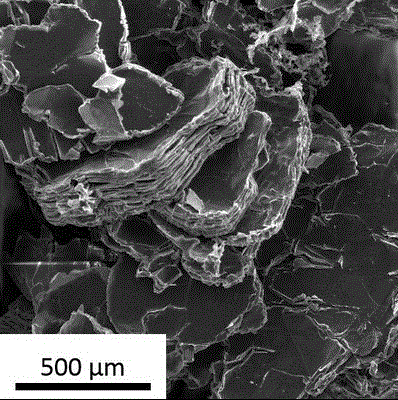

[0064] Mix 200 ml of concentrated sulfuric acid (98%) with 10 grams of potassium permanganate (purity>95%), 10 grams of flake graphite powder (particle diameter is 500 microns or 35 mesh, carbon content>95%), control the temperature of the system below 35 o C. After stirring continuously for 1 hour, slowly add it into 500 ml of ice water, and pay attention to remove the heat of mixing in time to avoid excessive temperature of the system. Then add 20 milliliters of hydrogen peroxide and stir for 5 minutes, and obtain sulfuric acid intercalated graphite intercalation compound after filtration.

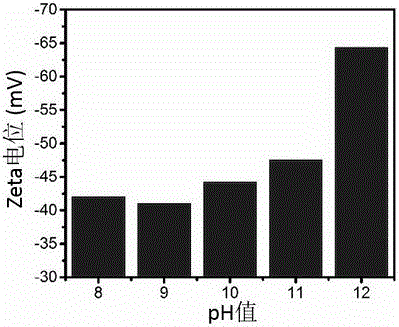

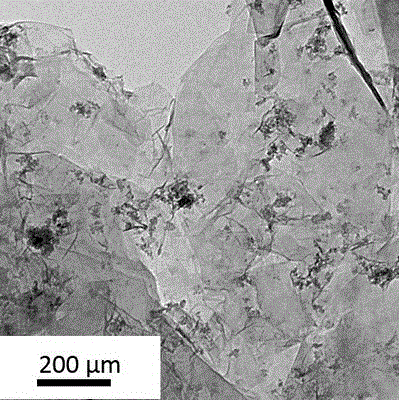

[0065] The filtered sulfuric acid-graphite intercalation compound (wet) was mixed with 10 g of sodium hydroxide and 250 ml of water. A black graphene suspension was obtained after 10 min using an ultrasonic probe (power 500 W, 95%). After the obtained black solution was centrifuged at 10,000 rpm for 10 minutes, the supernatant was poured off to obtain an aqueous phase paste with high s...

Embodiment 2

[0068] Evenly mix 100ml of oleum (containing 20% sulfur trioxide), 5ml of hydrogen peroxide and 10g of flake graphite powder (particle diameter is 500 microns), pay attention to control the temperature of the system below 35 o C, after continuous stirring for 1 hour, filter, then add to oxalic acid solution and soak for 1 hour, and filter again to obtain the intercalated graphite intercalation compound.

[0069] The filtered sulfuric acid-graphite intercalation compound (wet) was mixed with 10 g of sodium hydroxide and 250 ml of water. A black graphene suspension was obtained after 10 minutes using an ultrasonic probe (power 500W, 95%). After the obtained black solution was centrifuged at 10,000 rpm for 10 minutes, the supernatant was poured off to obtain an aqueous phase paste with high graphene content. Compared with graphite raw materials, the yield of graphene is greater than 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com