Photosensitive resin composition, photosensitive resin mixture and a corresponding printed circuit board

A technology of photosensitive resin and composition, applied in the field of printed circuit board and photosensitive resin composition, can solve the problems of insufficient resolution performance, insufficient resist adhesion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

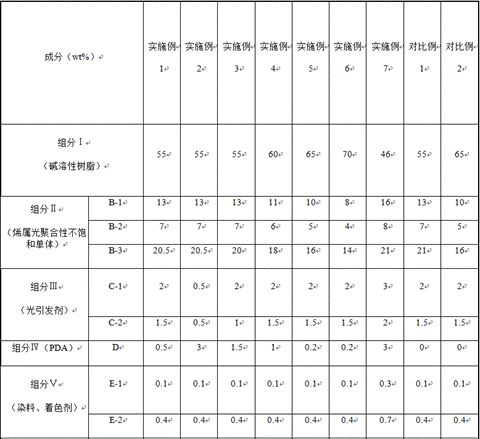

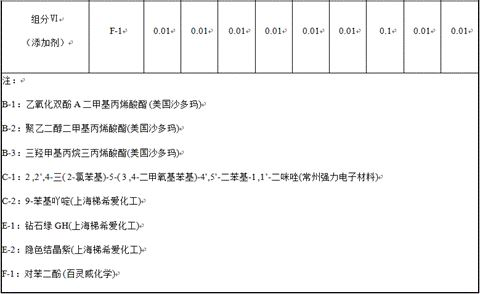

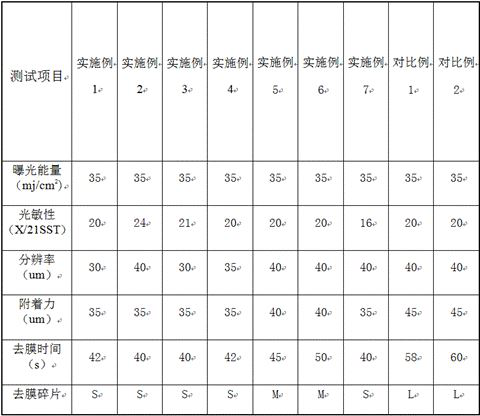

Method used

Image

Examples

Embodiment

[0056] 1. Synthesis of alkali-soluble polymer resin

[0057] Prepared by free radical solution polymerization, comprising the following steps:

[0058] Mix methacrylic acid, methyl methacrylate, butyl acrylate, styrene and hydroxyethyl methacrylate according to the mass ratio of 21 / 37 / 30 / 6 / 6, add initiator AIBN 0.5g, control The amount of solvent methyl ethyl ketone is configured as a mixed solution with a solid content of 37wt%, stirred and dissolved, and a mixed solution with a mass fraction of about 35% is added to a three-necked flask protected by nitrogen and equipped with a condensation reflux device through a peristaltic pump, and the oil bath is heated to 80 ℃, stirred for 1 hour, then slowly added the remaining mixed solution dropwise, and the addition was completed within 3 hours. After continuing the heat preservation reaction for 4 hours, the temperature was raised to 90°C, and 20 g of methyl ethyl ketone solution dissolved with 0.2 g of the initiator was added tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com