Method and equipment for stripping layered material nanosheet

A technology of nanosheets and peeling layers, applied in the field of nanomaterials, can solve problems such as difficult large-scale production, lack of universality, and large nanometer size, and achieve the effects of short peeling time, strong universality, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

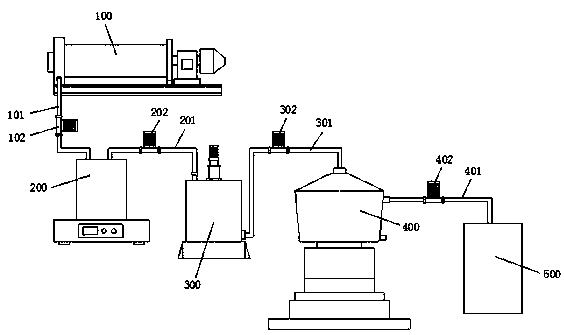

[0032] see figure 1 , the present invention provides the following technical solutions: a method for peeling off layered material nanosheets, comprising the following steps:

[0033] S1. Take out the layered crystal material, mix the layered crystal material with the liquid medium, and then place it in a wet grinding device for wet grinding, and obtain a wet grinding mixture after wet grinding;

[0034] S2. The wet-milled mixture obtained after wet-grinding in S1 is shaken in a vibrating device to achieve full mixing;

[0035] S3, adding the wet grinding mixture and organic solvent obtained after fully mixing in S2 into a high-pressure heating device, and peeling off to obtain a suspension solution formed by nanosheets and an organic solvent and unstripped crystal powder;

[0036] S4. The suspension solution formed by stripping the nanosheets obtained in S3 and an organic solvent and the unexfoliated crystal powder are added to a centrifugal separation device for solid-liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com