A kind of method for preparing graphene

A graphene and ultrasonic technology, applied in the field of graphene, can solve the problems of increasing the volume of equipment, inconvenient use, and limiting the size of the tank, and achieve the effects of enhancing the peeling effect, reducing production costs, and reducing the peeling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

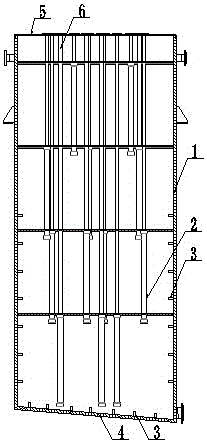

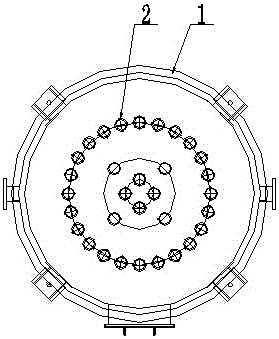

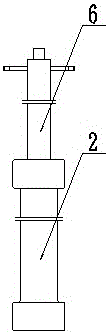

[0031] A method for preparing graphene includes a liquid phase expansion treatment process, an ultrasonic peeling process and a drying process. The liquid phase expansion treatment process is to place a graphite intercalation compound in an expansion solution to expand, and finally obtain a vermicular graphene aggregate The ultrasonic peeling process is to first add water and worm-like graphene aggregates at a mass ratio of 5:1 into the tank 1 provided with multiple ultrasonic vibrating rods 2, and then pass into the tank 1 Compressed air bubbling and stirring makes the worm-like graphene aggregates more uniformly dispersed and suspended in the stripping liquid, and then controls the ultrasonic vibration rod 2 with an ultrasonic frequency of 25KHz to ultrasonically oscillate for 0.5 hours, and finally obtain a flocculent graphene suspension; The drying step is to remove the moisture in the flocculent graphene suspension by flash drying or freeze drying, and finally obtain graphe...

Embodiment 2

[0033] A method for preparing graphene includes a liquid phase expansion treatment process, an ultrasonic peeling process and a drying process. The liquid phase expansion treatment process is to place a graphite intercalation compound in an expansion solution to expand, and finally obtain a vermicular graphene aggregate The ultrasonic peeling process is to first add the composite liquid and the worm-like graphene aggregates at a mass ratio of 5:1 into the tank 1 provided with multiple ultrasonic vibrating rods 2, and then pass to the tank 1 Into the compressed air bubbling and stirring to make the worm-like graphene aggregates more uniformly dispersed and suspended in the stripping liquid, and then control the ultrasonic vibrating rod with the ultrasonic frequency of 28KHz 2 ultrasonic vibration treatment for 1 hour, and finally obtain the flocculent graphene suspension The drying process is to use flash drying or freeze drying to remove the water in the flocculent graphene susp...

Embodiment 3

[0035] A method for preparing graphene includes a liquid phase expansion treatment process, an ultrasonic peeling process and a drying process. The liquid phase expansion treatment process is to place a graphite intercalation compound in an expansion solution to expand, and finally obtain a vermicular graphene aggregate The ultrasonic peeling process is to first add the composite liquid and the worm-like graphene aggregates at a mass ratio of 10:1 into the tank 1 provided with multiple ultrasonic vibrating rods 2, and then pass to the tank 1 Into the compressed air bubbling and stirring to make the worm-like graphene aggregates more uniformly dispersed and suspended in the stripping liquid, and then control the ultrasonic vibrating rod with an ultrasonic frequency of 30KHz 2 ultrasonic vibration treatment for 6 hours, and finally obtain a flocculent graphene suspension The drying process is to use flash drying or freeze drying to remove the water in the flocculent graphene suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com