Preparation method of moisture-absorbing, heat-generating and anti-bacterial yarn

A hygroscopic, heat-generating and antibacterial technology, applied in textiles and papermaking, one-component synthetic polymer rayon, chemical characteristics of fibers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

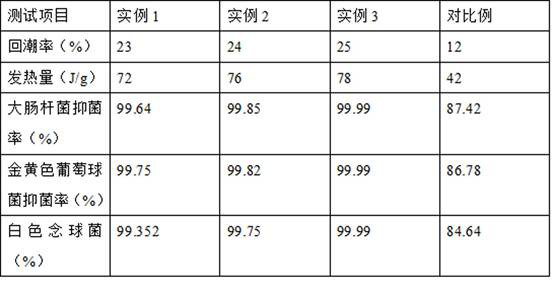

example 1

[0023] According to the mass ratio of 1:2, polyacrylonitrile and 15% sodium hydroxide solution were mixed in a beaker, hydrolyzed at a temperature of 85°C for 12 minutes, cooled and discharged to obtain a reaction solution, and then added to the reaction solution Add soybean protein with 7% of the mass of the reaction solution to the mixture, continue stirring and reacting for 35 minutes, and discharge to obtain a modified polyacrylonitrile hydrolyzate; weigh 20 g of crab shells and grind them for 10 minutes to obtain crab shell powder, and then add crab shell powder to the crab shell powder Yogurt with 0.5% shell powder mass is put into a fermenter, sealed and fermented at a temperature of 35°C for 6 days. The fermentation product of chitosan and the sodium hydroxide solution that mass fraction is 30% are mixed to be placed in the beaker, be frozen under the condition of-12 ℃ for 35min, obtain frozen liquid, finally freeze liquid and 2-chloroethanol by mass The ratio was 2:1 ...

example 2

[0025] According to the mass ratio of 1:2, polyacrylonitrile and 15% sodium hydroxide solution were mixed in a beaker, hydrolyzed at a temperature of 90°C for 14 minutes, cooled and discharged to obtain a reaction solution, and then added to the reaction solution Add soybean protein with a mass of 7% of the reaction solution, continue to stir and react for 40 minutes, and discharge to obtain a modified polyacrylonitrile hydrolyzate; weigh 25 g of crab shells and grind them for 11 minutes to obtain crab shell powder, and then add crab shell powder to the crab shell powder Yogurt with 0.5% shell powder mass is put into a fermenter, sealed and fermented at a temperature of 40°C for 7 days. The fermentation product of chitosan and the sodium hydroxide solution that mass fraction is 30% are mixed to be placed in the beaker, be frozen under the condition of-10 ℃ for 40min at a temperature, obtain frozen liquid, finally freeze liquid and 2-chloroethanol by mass The ratio was 2:1 and ...

example 3

[0027] According to the mass ratio of 1:2, polyacrylonitrile and 15% sodium hydroxide solution were mixed in a beaker, hydrolyzed at a temperature of 95°C for 16 minutes, cooled and discharged to obtain a reaction solution, and then added to the reaction solution Add soybean protein with a mass of 7% of the reaction solution to the mixture, continue to stir and react for 45 minutes, and discharge to obtain a modified polyacrylonitrile hydrolyzate; weigh 30 g of crab shells and grind them for 12 minutes to obtain crab shell powder, and then add crab shell powder to the crab shell powder Yogurt with 0.5% shell powder mass is put into a fermenter, sealed and fermented at a temperature of 45°C for 9 days. The fermentation product of chitosan and the sodium hydroxide solution that mass fraction is 30% are mixed to be placed in the beaker, be frozen 45min under the condition of -8 ℃ at temperature, obtain frozen liquid, finally freeze liquid and 2-chloroethanol by mass The ratio was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com