Method for improving moisture absorption and heating effects of pure cotton fabric

A technology of moisture absorption and heating, moisture absorption and heating yarn, applied in the direction of textiles and papermaking, fiber treatment, plant fiber, etc., can solve the problems of small temperature increase, low heating temperature, and heating effect not up to the standard, so as to reduce content and process The steps are simple, and the effect of enhancing the heating effect of the fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

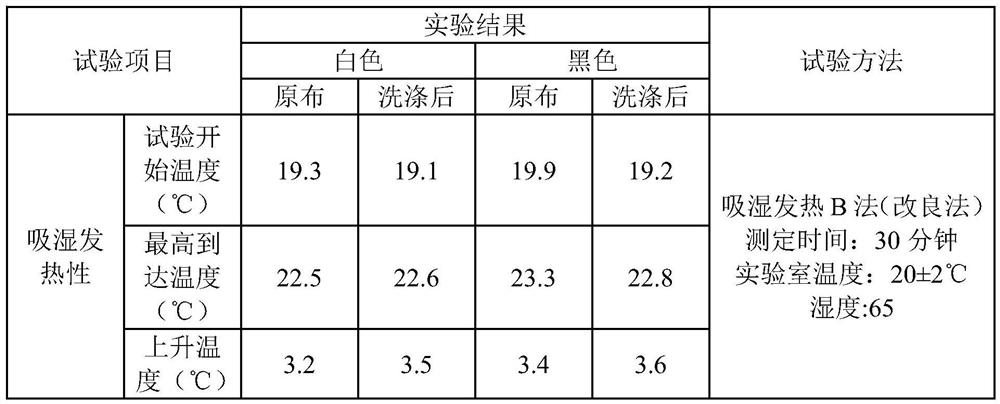

Examples

Embodiment 1

[0019] When processing the pure cotton moisture-absorbing and heat-generating knitted fabric in this embodiment, the method steps include refining, bleaching, and dyeing processes in sequence; several processes before dyeing are the same as the dyeing and finishing processes in the prior art, and will not be repeated here; After the dyed pure cotton fabric is subjected to normal soaping treatment, it is washed, and then heat treatment process is added.

[0020] The added exothermic processing procedure includes the following steps:

[0021] (1) Acid treatment: add 6g / L citric acid, treat at 40°C for 20 minutes; then wash with water at 30°C for 10 minutes;

[0022] (2) Alkali treatment: add 9g / L baking soda, treat at 40°C for 20min; then add 0.3g / L metal ion chelating dispersant SS-202 to it; finally wash with water at 30°C for 5min, wash with water The process is repeated twice.

Embodiment 2

[0024] The pure cotton fabric processing steps before the heating processing procedure are the same as in Example 1;

[0025] The heat treatment process includes the following steps:

[0026] (1) Acid treatment: add 3g / L citric acid, treat at 35°C for 15 minutes; then wash with water at 30°C for 8 minutes;

[0027] (2) Alkali treatment: add 6g / L baking soda, treat at 35°C for 15min; then add 0.1g / L metal ion chelating dispersant SS-202 to it; finally wash with water at 30°C for 3min, wash with water The process is repeated twice.

Embodiment 3

[0029] The pure cotton fabric processing steps before the heating processing procedure are the same as in Example 1;

[0030] The heat treatment process includes the following steps:

[0031] (1) Acid treatment: add 9g / L citric acid, treat at 45°C for 30min; then wash with water at 35°C for 15min;

[0032] (2) Alkali treatment: add 12g / L baking soda, treat at 45°C for 25min; then add 0.5g / L metal ion chelating dispersant SS-202 to it; finally wash with water at 35°C for 8min, wash with water The process was repeated four times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com