Preparation method of high-strength permeation-resistant aerated brick

A technology of anti-permeation and aerated bricks, applied in ceramic products, building components, applications, etc., can solve the problems of poor mechanical strength and poor anti-permeation performance of aerated bricks, and achieve corrosion prevention, compact internal structure, and increased strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

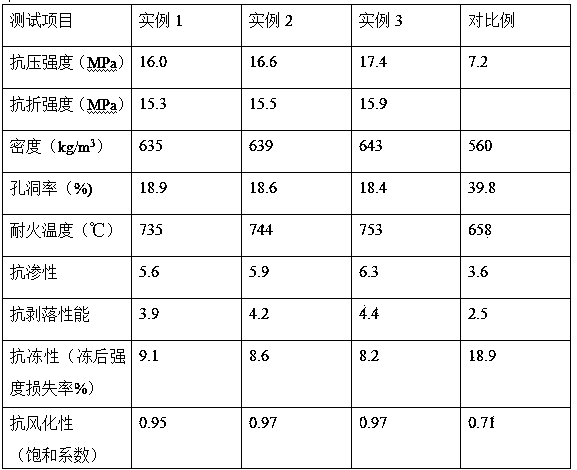

Examples

Embodiment Construction

[0032]In terms of parts by weight, weigh 40 to 50 parts of concentrated sulfuric acid with a mass fraction of 80 to 90%, 1 to 3 parts of sodium nitrate powder and 2 to 4 parts of graphite powder into a three-necked flask, and place the three-necked flask at a water bath temperature In a water bath at 0-5°C and stir with a stirrer at a speed of 300-350r / min for 10-15min, after stirring and mixing, add 5-8 parts of potassium permanganate powder and continue stirring for 10-15min, then raise the temperature of the water bath to 35 ~40°C, constant temperature reaction for 30-40min, to obtain a dark brown liquid; add deionized water with a mass of 200-240% of the above dark brown liquid into the three-necked flask, raise the temperature of the water bath to 88-92°C, and constant temperature reaction for 15-18min, To obtain the mixed solution, add 20-30% of the mixed solution to the mixed solution and add hydrogen peroxide with a mass fraction of 20-25%, keep the temperature of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com