Patents

Literature

84results about How to "Achieve anti-static effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

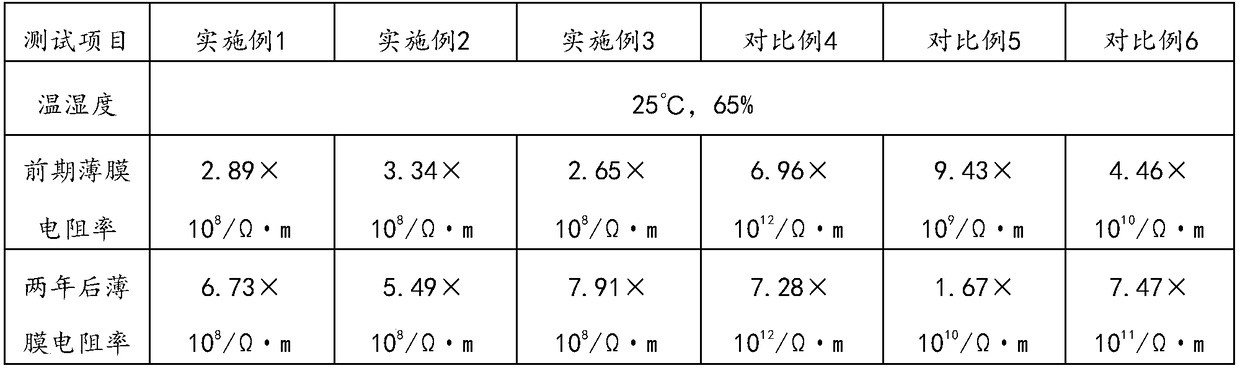

PVC (Poly Vinyl Chloride) thermal contraction printing film

The invention discloses a PVC (Poly Vinyl Chloride) thermal contraction printing film, which is characterized in that 0.8-1.2 parts by weight of cation quaternary ammonium salt or nonionic esters antistatic agent are added into components; the added antistatic agent is firstly coupled and processed by coupling agent adaptive to the antistatic agent; in the film preparation process, the cation quaternary ammonium salt or a nonionic esters antistatic agent solution layer are applied to the surface of the film; and therefore the surface resistivity of the film is 108-1010 omega. Two different applied antistatic agents are applied to successively perform action. On the premise that other performances of the PVC thermal contraction printing film are guaranteed to be substantially unchanged, static charges in the production process are effectively prevented or eliminated from generating and accumulating, and the shortage brought by the static charges is avoided, and pollution on printing because the antistatic agent is excessively separated out can be avoided.

Owner:YIXING GUANGHUI PACKAGE

Novel textile technology

InactiveCN105220302ARaise the gradeThe effect is smooth and plumpLiquid/gas/vapor removalHeating/cooling textile fabricsYarnSoft water

The invention discloses novel textile technology. The novel textile technology comprises following steps: utilizing a sectional warping machine to array plied yarns per inch plus conductive wires to a warp beam and utilizing a loom to weave, wherein plied yarns are twisted by a twisting device from pure cotton plied yarns and cotton yarns plus conductive wires; adding soft water into a water steam box and adding a detergent of 4 to 8g / L water into the water steam box at the water temperature ranging from 60 to 80 DEG C for steaming about 8 hours; and dehydrating and drying and adopting a dryer to dry washed textile fabric, placing dried textile fabric into a stenter for stentering, placing stentered textile fabric into a pre-shrinking machine for carrying out pre-shrinking operation and shaping the pre-shrank textile fabric. The novel textile technology has following advantages: fabric produced according to the technological requirement enables an overall effect of a cloth cover to be smooth and full so that the level of fabric is increased; better functional effect is achieved; anti-mildew, anti-bacteria, moisture-retentive, breathable, ultraviolet-proof and anti-static features are obtained; and threads are firmer and do not easily break.

Owner:NANTONG YUEDA KNITTING GARMENT

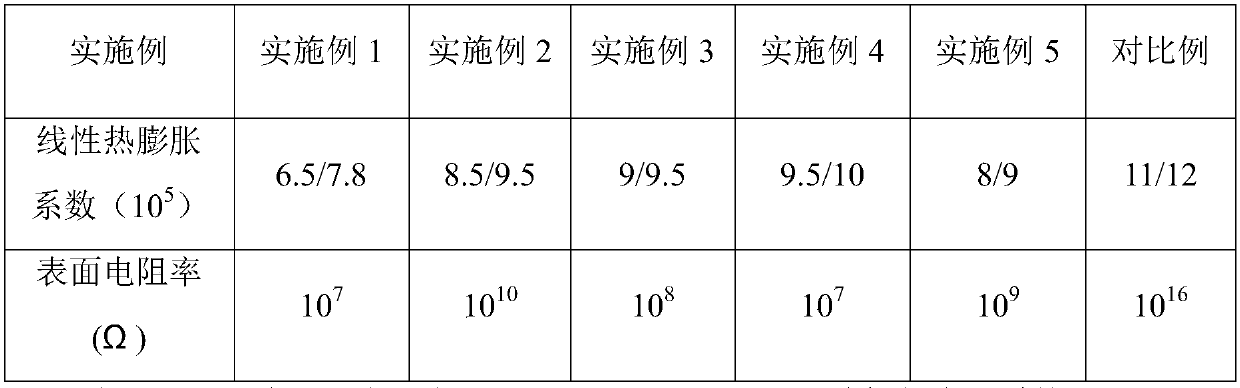

Antistatic spray-free polypropylene composite material with low linear thermal expansion coefficient and preparation method of antistatic spray-free polypropylene composite material

ActiveCN110408120AIncreased crystallinity and crystallization speedReduced after contractionAntioxidantWhiskers

The invention discloses an antistatic spray-free polypropylene composite material with low linear thermal expansion coefficient and a preparation method of the antistatic spray-free polypropylene composite material. The antistatic spray-free polypropylene composite material is prepared by mixing and extruding polypropylene, mineral filling, a toughening agent, a functional assistant, a metal pigment, a coupling agent, an antioxidant, a lubricant and a light stabilizer. The functional assistant is prepared by compounding wollastonite whisker and glyceryl monostearyl ester according to the mixing mass ratio of 1:1 to 4:1. According to the antistatic spray-free polypropylene composite material, the polypropylene is compounded with the mineral filling and the toughening agent, the strength, rigidity and toughness of the composite material are ensured, in addition, the crystallization velocity is shortened and the degree of crystallization of the material is increased by adding the functional assistant, the post shrinkage of the product is lowered, the forming period of the product is shortened, meanwhile a conductive network is formed in the material, the material has a certain conductive performance, the surface antistatic property of the material is improved, and thus the modified polypropylene composite material can be widely used in spray-free products.

Owner:HEFEI GENIUS NEW MATERIALS

Preparation process of antistatic organic glass

The invention provides a preparation process of antistatic organic glass. The preparation process sequentially comprises the steps of prepolymerized slurry preparation, antistatic agent addition, moldfilling, low temperature polymerization, high temperature polymerization, cooling and stripping and adsorption separation. An antistatic agent is a surfactant with hydrophilic lipophilic groups. Thestep of antistatic agent addition is added in the preparation process of the organic glass, so that the prepared organic glass contains the surfactant, the surfactant penetrates into the surface of the organic glass to form a smooth surfactant molecular layer, the friction coefficient on the surface of the organic glass is reduced, and the probability of static electricity generated by friction isreduced. At the same time, the hydrophilic groups arranged outwards on a surfactant molecular layer absorb trace water in the environment, and the trace water is adsorbed on the surface of the organic glass to form a conductive layer, the surface resistance of the organic glass is effectively reduced, electric charges are difficult to accumulate on the surface of the organic glass, and the antistatic effect can be achieved accordingly.

Owner:ANHUI XINTAO OPTOELECTRONICS TECH CO LTD

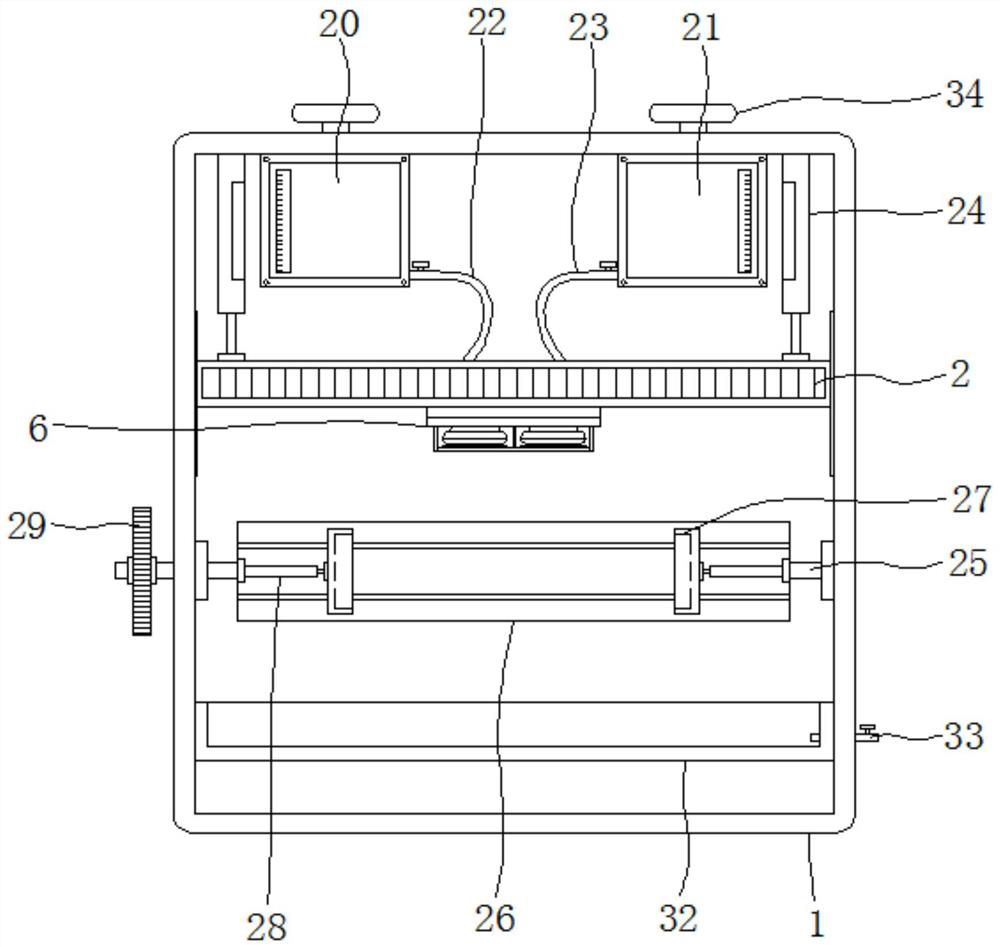

Plastic product processing spraying device with static electricity removing device

The invention provides a plastic product processing spraying device with a static electricity removing device. The plastic product processing spraying device with the static electricity removing device comprises a processing box, a fixing frame and two carrier rollers, wherein the two sides of the fixing frame are connected to the two sides of the interior of the processing box in a sliding manner, and the two ends of each of the two carrier rollers are rotationally connected to the two sides of the interior of the fixing frame. According to the plastic product processing spraying device withthe static electricity removing device, the plastic product is sprayed with anti-static liquid, so that the plastic product achieves the anti-static effect, and processing of subsequent links is facilitated; after spraying is completed, residual materials on a first sprayer are wiped away, and the situation that the residual materials drop on the parts in the processing box and cause certain contamination is avoided; and meanwhile, when the first sprayer is wiped, a second sprayer can also be wiped, so that the dust removal effect is achieved, dust is prevented from polluting spraying of a next link, and therefore the practicability of the device is improved.

Owner:YINGSHANG LONGYUYANG IND & TRADE

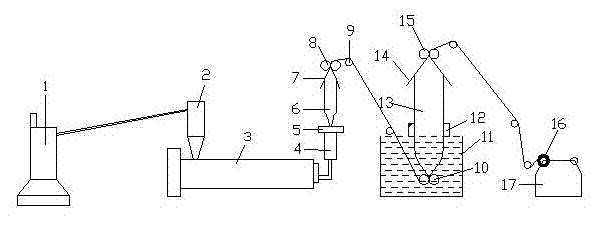

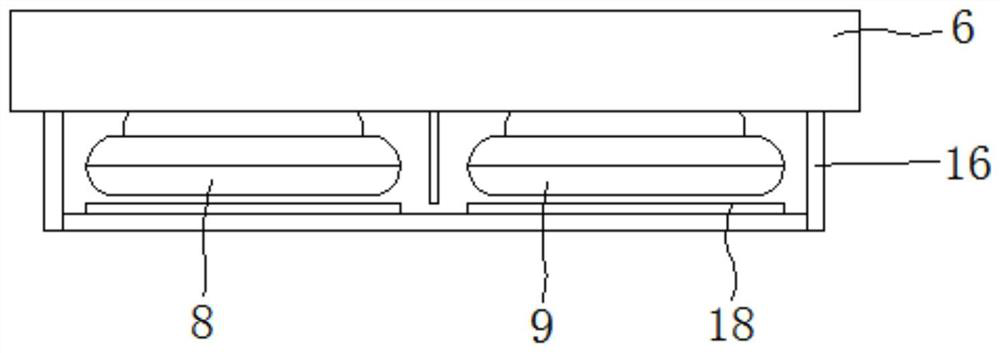

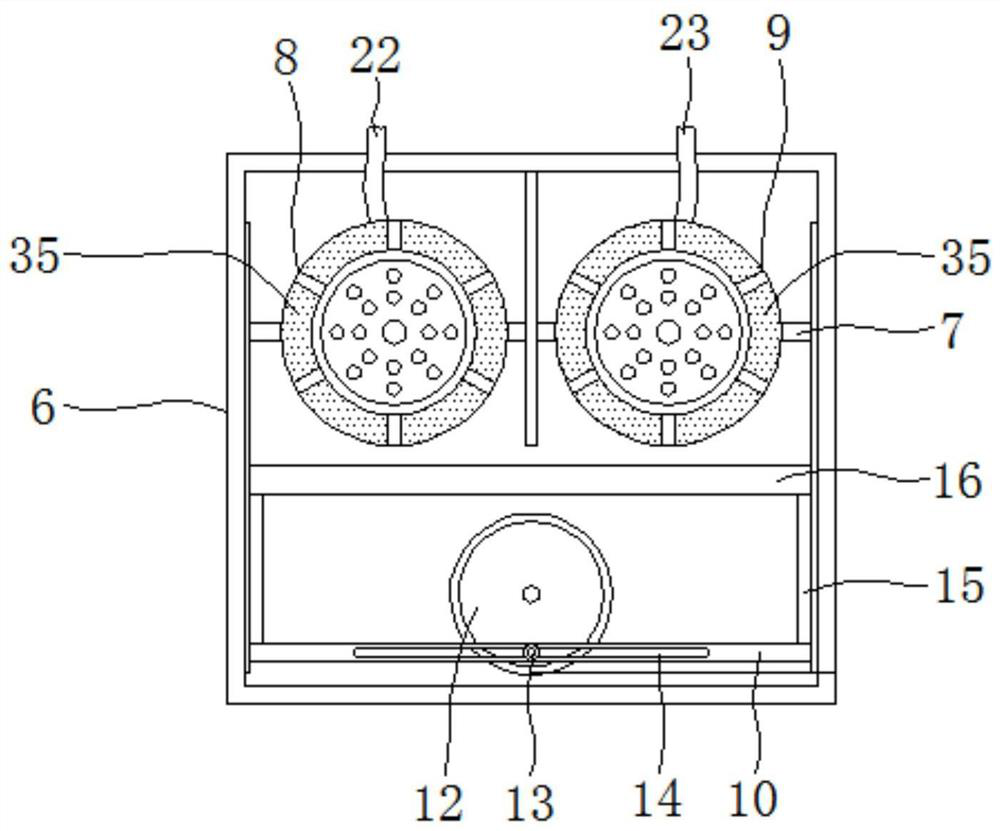

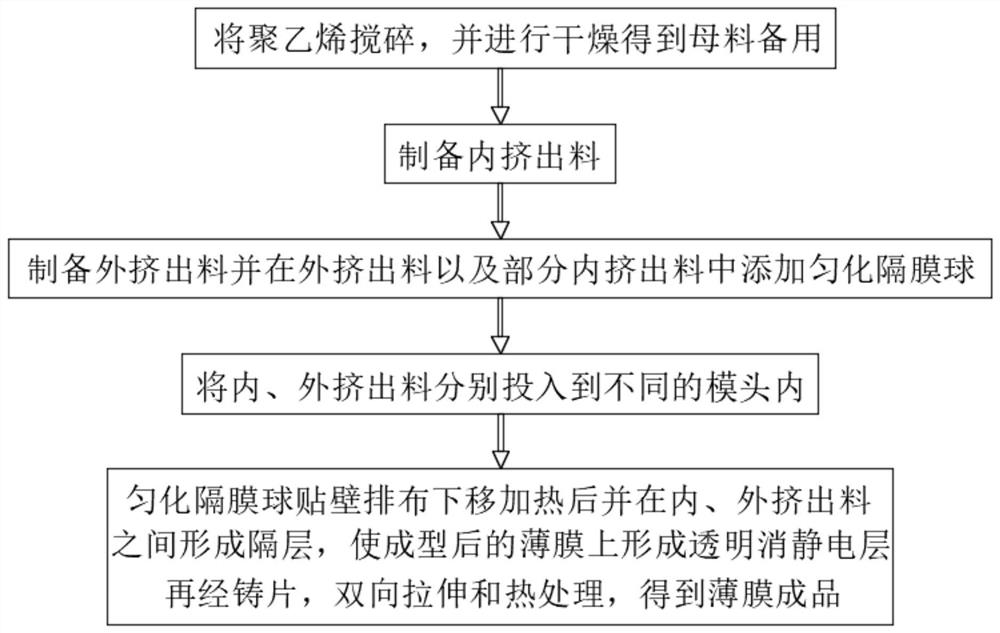

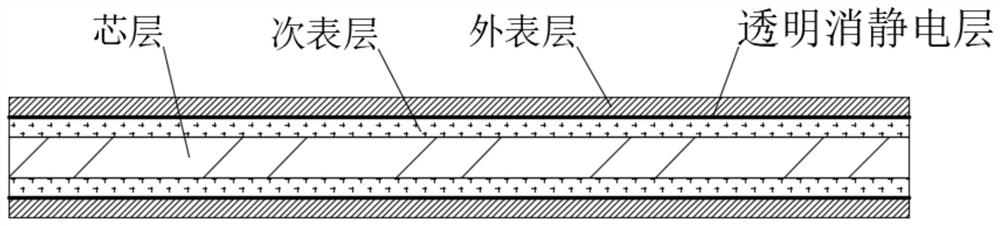

Multi-layer co-extrusion production technology for bidirectional tensile polyethylene antibacterial anti-fogging film

The invention discloses a multi-layer co-extrusion production technology for a bidirectional tensile polyethylene antibacterial anti-fogging film, and belongs to the field of films. According to the multi-layer co-extrusion production technology for the bidirectional tensile polyethylene antibacterial anti-fogging film, high production speed and high yield can be achieved, meanwhile, the film produced by the technology has the anti-fogging performance and the high mechanical and optical performance. In the production process, homogenizing diaphragm balls can be distributed at the inner walls of closer die heads in an attached mode and moved downwards, a homogenizing distributor is heated while the balls pass through the homogenizing distributor, and therefore an interlayer can be formed between an inner extrusion material and an outer extrusion material, and a transparent static electricity eliminating layer is formed between an outer surface layer and a secondary surface layer of theformed film. On one hand, static electricity of the finished film can be effectively eliminated so that use can be convenient. On the other hand, the connecting strength between the outer surface layer and the secondary surface layer can be effectively improved through the transparent static electricity eliminating layer, the mechanical property can be remarkably improved, and meanwhile the optical performance of the film can be effectively improved.

Owner:SUQIAN GETTEL PLASTIC IND

Moisture-wicking, antibacterial and antistatic multifunctional fabric and production method thereof

ActiveCN104389076BImprove wearing comfortGuaranteed antistatic functionWoven fabricsYarnYarnMoisture absorption

The invention discloses a multifunctional fabric with moisture absorption and perspiration, antibacterial and antistatic properties and a production method thereof. The multi-functional fabric is made of 95-99% multi-functional blended yarn and 1-5% stainless steel anti-static yarn or conductive anti-static yarn; the multi-functional blended yarn is made of moisture-wicking fiber 50-80%, cotton Fiber 15-45% and silver fiber 5-10% are blended; stainless steel antistatic yarn is made of moisture-wicking fiber 35-45%, cotton fiber 10-30%, silver fiber 3-7% and stainless steel fiber 25-40% % blended; conductive yarn antistatic yarn is twisted from 3-5% organic conductive yarn and 95-97% multifunctional blended yarn. The multifunctional fabric produced by the invention has antistatic function, moisture absorption and perspiration function and antibacterial function, which can not only ensure the antistatic function of the fabric, but also greatly improve the air permeability of the fabric, improve the wearing comfort of the fabric, and have good antibacterial function.

Owner:ZHENGZHOU NO 4 COTTON TEXTILE

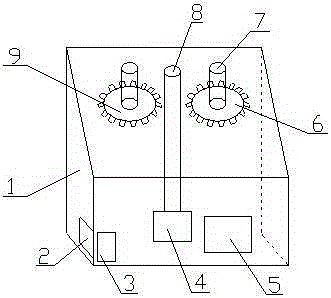

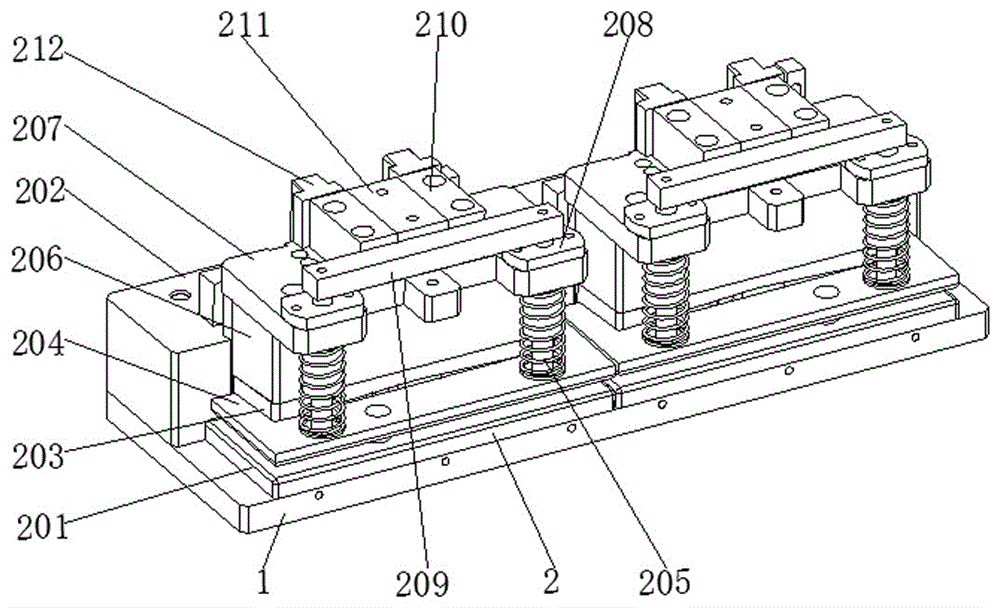

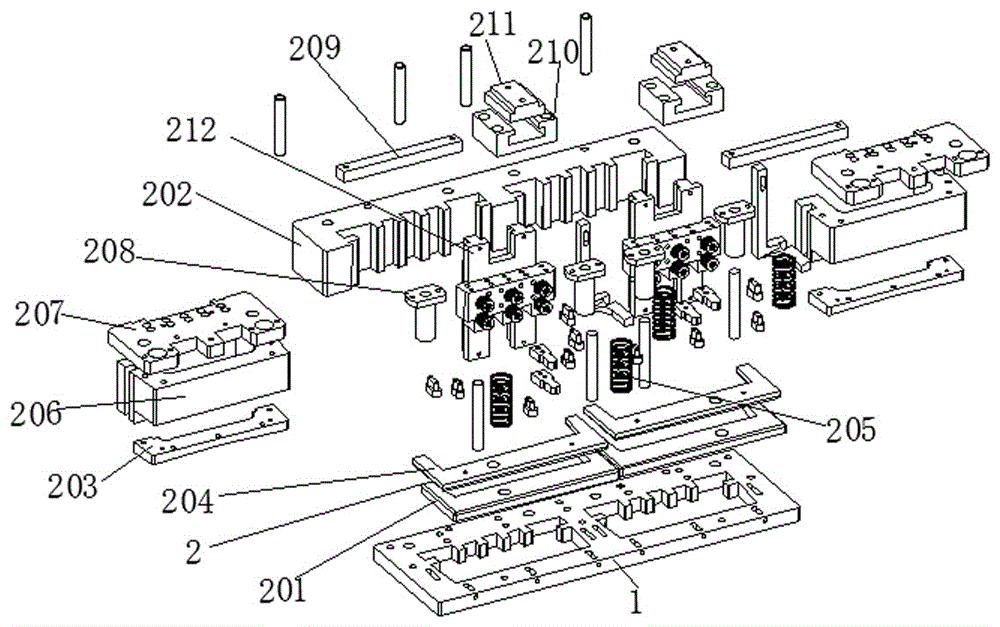

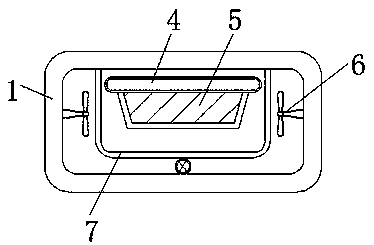

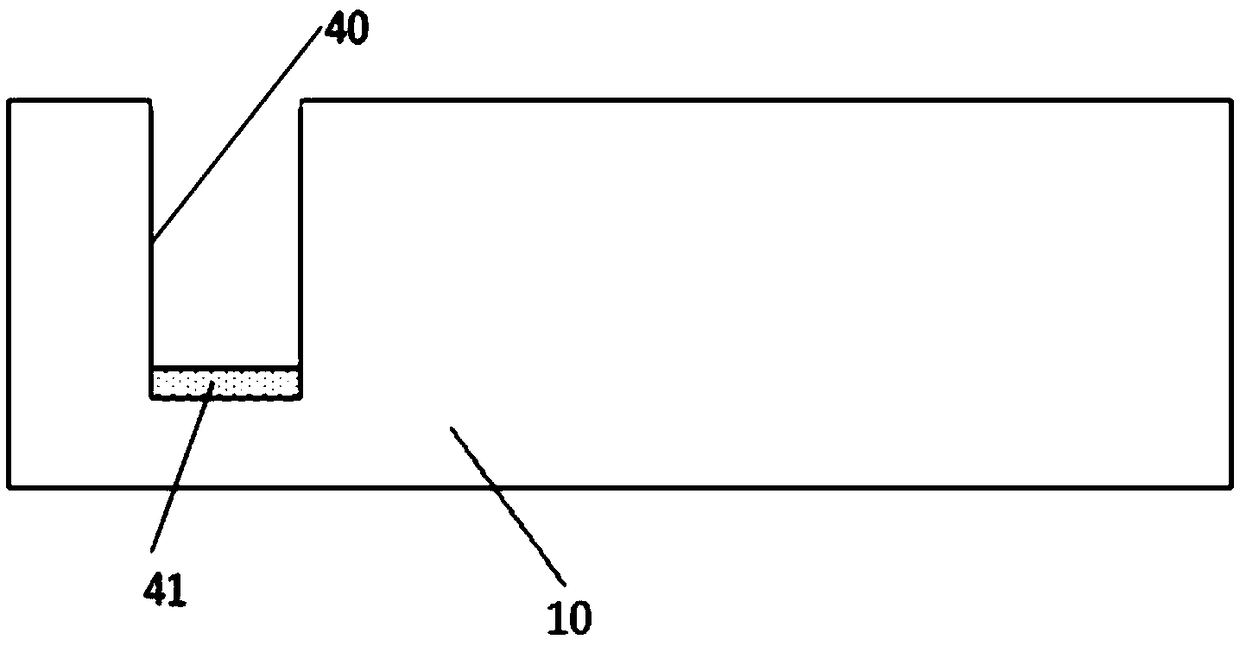

Lithium battery die-cutting machine punching die

The invention discloses a lithium battery die-cutting machine punching die. The lithium battery die-cutting machine punching die comprises a lower ceramic knife holder plate, and two punching devices are arranged at the top of the ceramic lower knife holder plate. Each punching device comprises an upper ceramic knife and an upper punch holder guide plate, wherein the upper ceramic knife and the upper punch holder guide plate are fixedly installed on the upper surface of the lower ceramic knife holder plate in sequence from front to back, a lower ceramic knife is fixedly installed at the top of the upper ceramic knife, a pressing plate is fixedly installed at the top of the lower ceramic knife, the top of the lower ceramic knife is fixedly connected with one ends of two pressing plate springs, the two pressing plate springs are located on the side away from the upper punch holder guide plate, an upper punch holder is fixedly installed at the top of the pressing plate, and the top of the upper punch holder is fixedly connected with the bottom of an upper punch holder clamping plate. According to the lithium battery die-cutting machine punching die, the efficiency is improved, a stabilizing effect is achieved, the problem of low stability is solved, durability is ensured, the service life is prolonged, and the effects of high-speed through cutting and static prevention are achieved.

Owner:东莞市金心自动化科技有限公司

Multifunctional synthetic leather

The invention relates to the technical field of artificial leather, and especially relates to multifunctional synthetic leather. An employed technical scheme is as follows: the multifunctional synthetic leather comprises a base cloth layer, a wet method PU layer which is formed on the base cloth layer and a dry method PU layer which is bonded on the wet method PU layer; a resin film layer for damping is formed on the upper surface of the dry method PU layer; a mite eliminating interlayer is arranged between the wet method PU layer and the dry method PU layer, the mite eliminating interlayer is a piece of non-woven fabric which is prepared from anti-microbial and mite eliminating fibers, and the non-woven fabric is bonded between the wet method PU layer and the dry method PU layer. The synthetic leather has the advantages of reasonable structure, good function, and good practicality; the synthetic leather is suitable for promotion and usage.

Owner:仲林

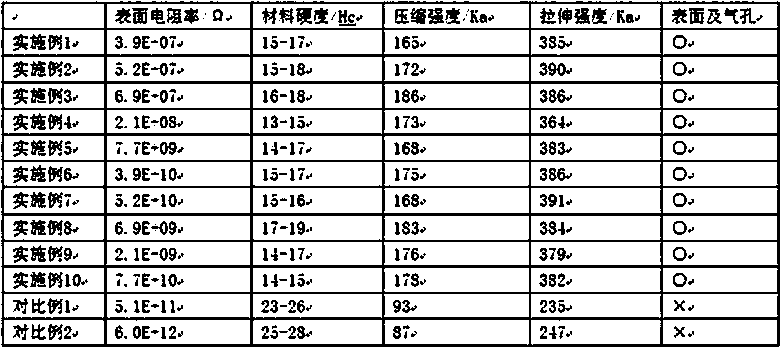

Foaming polyolefin anti-static material and preparation method thereof

ActiveCN103509204AEvenly distributedSolve uneven distributionElectrical resistance and conductancePolymer science

The invention relates to the field of high polymer materials and in particular relates to a foaming polyolefin anti-static material and a preparation method thereof. The material has the surface resistance of 10 <7-10> ohm, and comprises a foaming polyolefin base material and also comprises an anti-static fluid which exerts an anti-static effect and is sucked to the foaming polyolefin base material; an anti-static layer is formed by the anti-static fluid on the surface of the base material; the thickness of the anti-static layer is 0.1-1 micrometer. The preparation method comprises the following steps: (1) soaking the foaming polyolefin base material in a 1-5 mass percent of solution formed by adding water into the anti-static fluid, so that the solution is sucked to the base material; (2) performing primary draining; (3) allowing the anti-static fluid to be uniformly distributed inside and on the surface of the base material; (4) performing corona treatment on the surface of the base material. The obtained foaming polyolefin anti-static material is good and stable in physical performance and obvious in anti-static effect. The method for preparing the material is easy to operate and can be used for industrial production, the cost is reduced, and the environment is protected.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

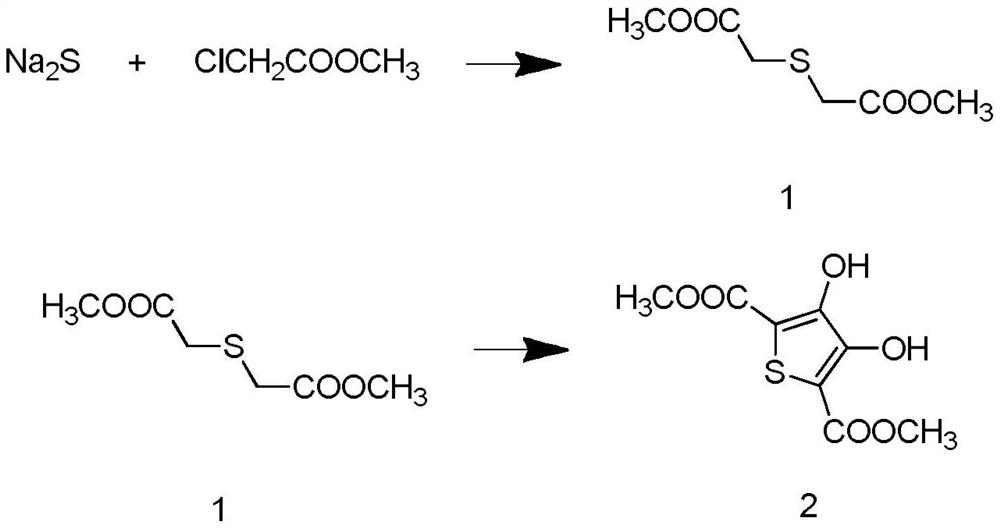

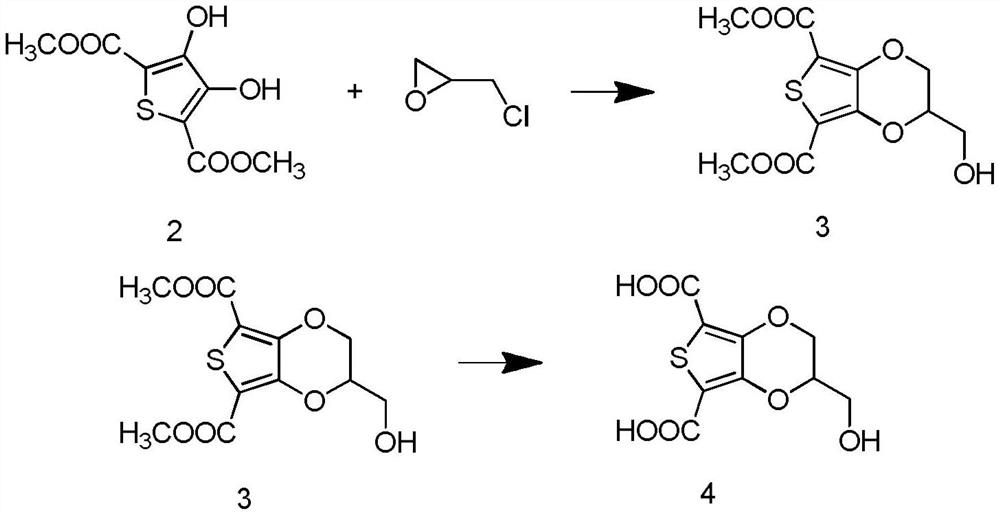

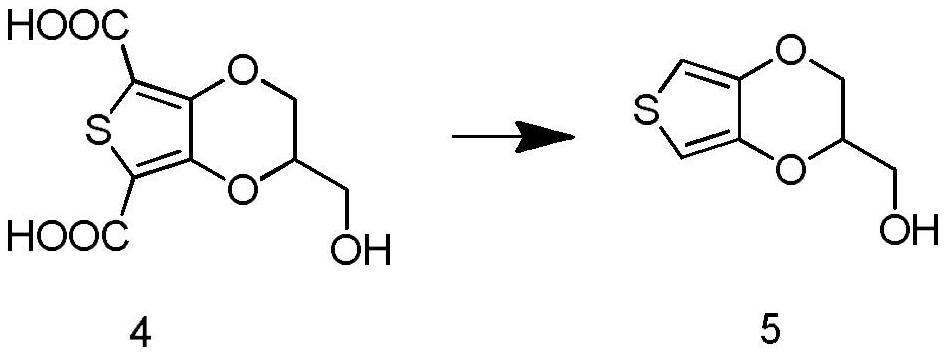

Breathable antistatic foam material and preparation method thereof

PendingCN112831115AIncreased bulk conductivityAchieve anti-static effectOrganic chemistryLow-density polyethyleneFoaming agent

The invention discloses a breathable antistatic foam material and a preparation method thereof. The foam material comprises the following raw materials in parts by weight: 100-120 parts of low-density polyethylene, 10-15 parts of glycerin monostearate, 3-8 parts of talcum powder, 3-5 parts of an antistatic agent, 1-3 parts of flame-retardant particles, 3-5 parts of a foaming agent and 1-3 parts of a nucleating agent. The antistatic agent and the flame-retardant particles are prepared in the preparation process, the antistatic agent is prepared by performing esterification reaction on an intermediate 5 and an intermediate 6 to prepare an intermediate 7 and polymerizing the intermediate 7, and the antistatic agent can increase the volume conductivity of the foamed plastic, so that static electricity accumulated in the foamed plastic can be conducted out in time, and theantistatic effect is thus achieved; the flame-retardant particles generate a coke layer on the surface of the material when the foamed plastic is combusted, and the coke layer can insulate oxygen and heat so as to extinguish flames.

Owner:罗伟才

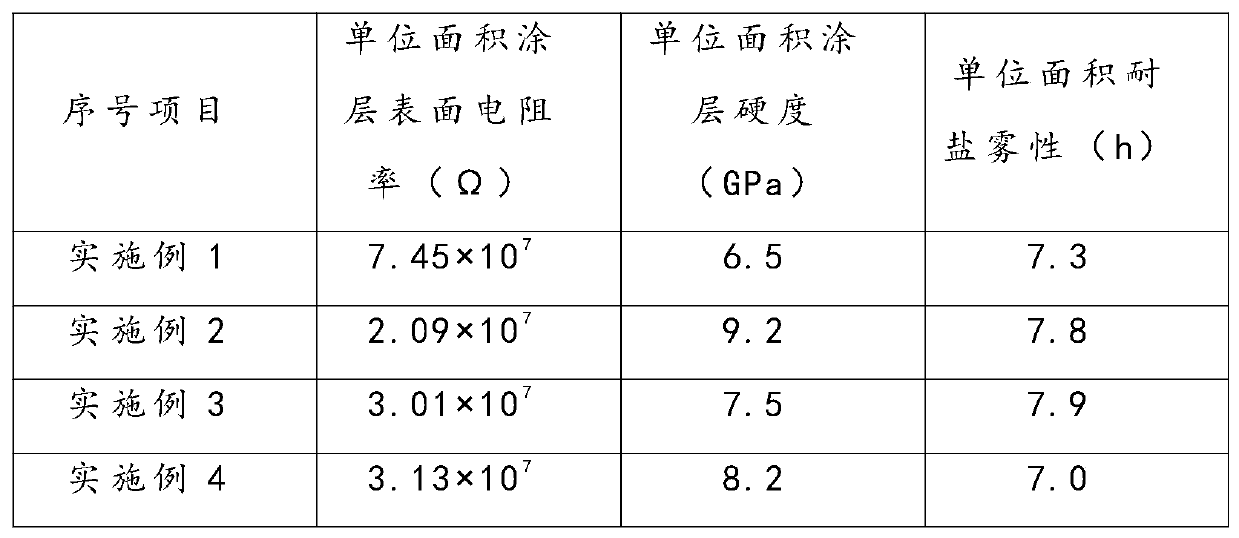

Self-cleaning coating material for car outer surface

InactiveCN110079133AWith self-cleaning effectNot easy to stickAntifouling/underwater paintsPaints with biocidesWear resistantSilicon dioxide

The invention relates to a self-cleaning coating material for a car outer surface, which consists of the following components in parts by weight: 50-70 parts of methyl alcohol, 21-25 parts of water, 1-5 parts of stannic oxide, 1.0-1.5 parts of platinum, 0.5-1.0 part of tungsten oxide and 6-9 parts of silicon dioxide. The preparation method of the self-cleaning coating material for the car outer surface includes the following steps: S1, preparing materials; S2, preparing a solution; S3, mixing. Compared with the prior art, the invention has the following advantages: the coating obtained throughthe formula has the self-cleaning effect, is not easy to adhere dust, and cannot form water drops or water curtain on the surface after being scoured by water, water stains can be removed and the coating can be further brushed and cleaned, so that the car washing frequency is reduced, the living cost is reduced, and the benefit of environmental protection is improved; besides, high hardness and chemical resistance are achieved, the surface is still wear resistant when the car is in high-speed motion, as a result, the service life is prolonged, the car body resistance is effectively reduced, and the antistatic effect is achieved.

Owner:苏州恒谊环保科技有限公司

Polyester fabric for dustproof garment and making method of fabric

InactiveCN109706538AAchieve anti-static effectAct as a dispersantElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentFiberPolyester

The invention provides a polyester fabric for a dustproof garment. A dustproof anti-static polyester fiber is used as a raw material. The dustproof anti-static polyester fiber comprises the raw materials of an anti-static modifier, a dustproof treatment agent, molybdenum disulfide and a polyester chip. A superfine copper wire is added into the fiber, the anti-static effect can be achieved, and compared with a common fiber blending mode, the addition amount is smaller than 1%; by mixing calcined shell powder with the superfine copper wire, the function of a dispersion agent can be achieved, themain component of the shell powder is calcium carbonate, after the shell powder is cleaned through a faintly acid detergent and then can be continuously and slightly dissolved, and it can be guaranteed that after the fabric is used for a long time, the anti-static effect is not weakened; by adding graphene, the addition number of the super-fine copper wire can be obviously lowered; by adding molybdenum dioxide, the dispersion effect of the anti-static modifier can be improved, and the addition number of the anti-static modifier is reduced; by adopting a special dustproof treatment agent of aninorganic, organic and catalyst combination mode, the good dustproof effect can be achieved.

Owner:湖州双林金辉船舶制造有限公司

Processing technology for sleep-facilitating and health-care textile fabric

InactiveCN105926108ARaise the gradePromote sleep and health careBiochemical fibre treatmentLiquid/gas/vapor removalYarnAdditive ingredient

The invention discloses a processing technology for sleep-facilitating and health-care textile fabric and belongs to the technical field of textile processing. The processing technology comprises the following steps: 1) four conductive filaments are added by a sectional warping machine to each inch of piled yarn twisted with pure cotton piled yarn and cotton yarn through twisting equipment, and the piled yarn is placed in a warp beam for weaving; 2) soft water is added to a water steaming box, the bath ratio of the soft water is 1:10, the temperature is 45 DEG C, a detergent is added to the water steaming box, the water temperature is 55 DEG C, the textile fabric is steamed for 4 h, a treating liquid is added to the water steaming box, the temperature is increased to 70 DEG C, and the textile fabric is steamed for 3 h at the constant temperature; 3) dehydration and drying are performed; 4) the dried textile fabric is put in a stenter for stentering and then put in a pre-shrinking machine for pre-shrinkage, and the pre-shrunk textile fabric is shaped finally; 5) finished products are packaged and put in storage. The textile fabric is immersed in the treating liquid containing traditional Chinese medicine ingredients and absorbs a tranquilization ingredient in Chinese medicinal materials, thereby being good for improving sleep quality of a user.

Owner:长兴恒远纺织有限公司

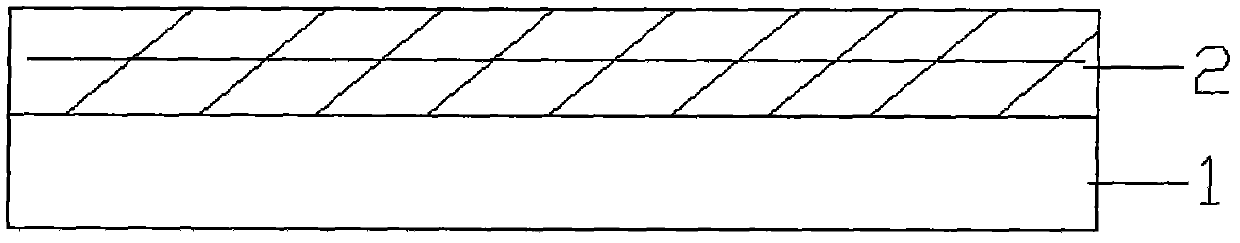

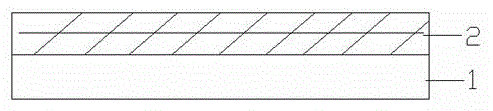

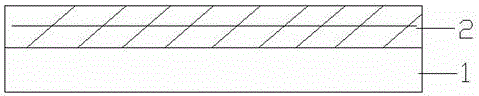

Anti-static artificial leather

InactiveCN103374836AHas the function of conducting electricityAchieve anti-static effectLayered productsTextiles and paperSurface layerCarbon fibers

The invention relates to artificial leather. The artificial leather comprises a base layer (1) and a plastic surface layer (2) which are bonded with each other, wherein a carbon fiber layer is embedded in the plastic surface layer (2) and is horizontally arranged in the plastic surface layer (2). The anti-static artificial leather has the beneficial effects that the carbon fiber layer is embedded in the plastic surface layer and is horizontally arranged in the plastic surface layer, and carbon fibers have electric conducting functions, thus achieving an anti-static effect.

Owner:赵小东

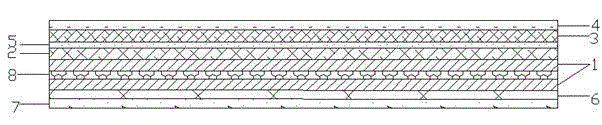

Antistatic and anti-oil polyester-mixed cotton cloth

PendingCN110271241AGood anti-static effectGood air permeabilitySynthetic resin layered productsMetal layered productsFiber layerCotton cloth

The invention discloses antistatic and anti-oil polyester-mixed cotton cloth which comprises a polyester-mixed cotton layer. An antibacterial layer is attached to the bottom of the polyester-mixed cotton layer through waterborne polyurethane. An antistatic layer is attached to the top of the polyester-mixed cotton layer through waterborne polyurethane. An anti-oil layer is attached to the top of the antistatic layer through waterborne polyurethane. A high-temperature-resistant layer is attached to the top of the anti-oil layer through waterborne polyurethane. The antistatic layer comprises a carbon black series conductive fiber layer and a metal series conductive fiber layer. The carbon black series conductive fiber layer is made of warp, and the metal series conductive fiber layer is made of weft. The carbon black series conductive fiber layer and the metal series conductive fiber layer are interwoven. By using the antistatic layer, the carbon black series conductive fiber layer, the metal series conductive fiber layer, the anti-oil layer, a bamboo fiber layer and a nano silica fiber layer in cooperation, the problem that existing polyester-mixed cotton cloth is poor in antistatic and anti-oil effect and not convenient to use is solved.

Owner:吴江市美林格纺织品有限公司

Antistatic interior wall coating and preparation method thereof

InactiveCN109468007ABoth conductiveMeet market demandElectrically-conductive paintsWater basedCoating system

The invention discloses an antistatic interior wall coating and a preparation method thereof. The antistatic interior wall coating is prepared from main components including deionized water, antistatic ionic liquid, ethylene glycol, cellulose, a dispersant, a wetting agent, a defoaming agent, carbon nanotubes, composite titanium dioxide, waterborne acrylic polyaniline and auxiliaries. The preparation method disclosed by the invention has the advantages that firstly, the waterborne acrylic polyaniline is adopted to replace a solvent type film-forming substance, and has the characteristic of static conductance while providing a proper system for a formula; in addition, the water-based environmental protection characteristic is in line with market demands; secondly, the composite titanium dioxide prepared by titanium dioxide for coating has the properties of a titanium dioxide pigment; besides, the production cost of the coating is reduced by using cheap filler as a core material; and meanwhile, the actual consumption of the titanium dioxide is reduced; thirdly, the added carbon nanotubes have the property that delocalized electron can spread along the axial direction in single-layergraphene, so that good electrical properties are achieved; by adding a small amount of the carbon nanotubes into a coating system, the antistatic interior wall coating is endowed with good electricalconductivity, so that an anti-static effect is achieved and the mechanical properties of the coating are improved.

Owner:广东顺德三和化工有限公司

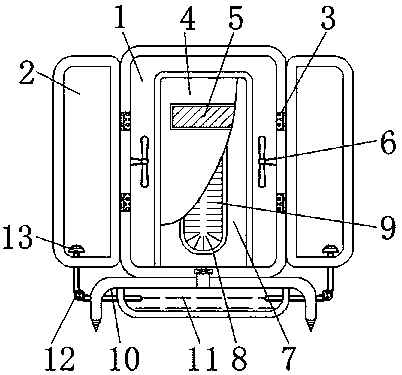

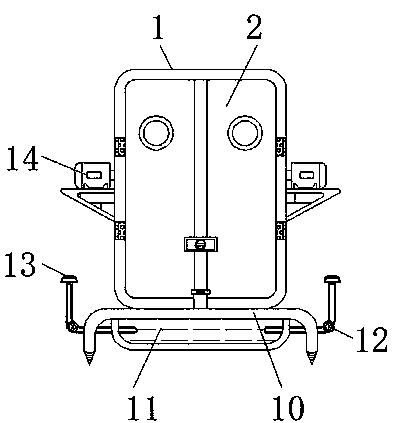

Anti-static dust removal device of electrical control cabinet

PendingCN107708354AWill not interfere with normal workAvoid excessive accumulationCasings/cabinets/drawers detailsCleaning using gasesElectrical controlElectric machinery

The invention discloses an anti-static dust removal device of an electrical control cabinet. The anti-static dust removal device comprises a device body, a base and a motor. The left side and the right side of the device body are connected with a cover body through hinges. The electrical control cabinet is fixed inside the device body. A control component is arranged above the electrical control cabinet. Suction fans are arranged on the two sides of the electrical control cabinet. A baffle plate is arranged between the suction fans. An adjusting window is arranged above the baffle plate. A through hole is formed above the baffle plate. A water tank is fixed at the bottom of the base. Water pumps are arranged on the two sides of the water tank. Atomizing nozzles are connected with the upperparts of the water pumps. The device body is arranged between the atomizing nozzles. The device body is arranged in the middle of the motor. The anti-static dust removal device of the electrical control cabinet is provided with the suction fans and is fixedly connected with the device body through the suction fans. Therefore, the control component arranged above the electrical control cabinet canbe subjected to dust removal under the effect of the suction fans.

Owner:CHANGSHU GENERAL ELECTRIC APPLIANCE FACTORY

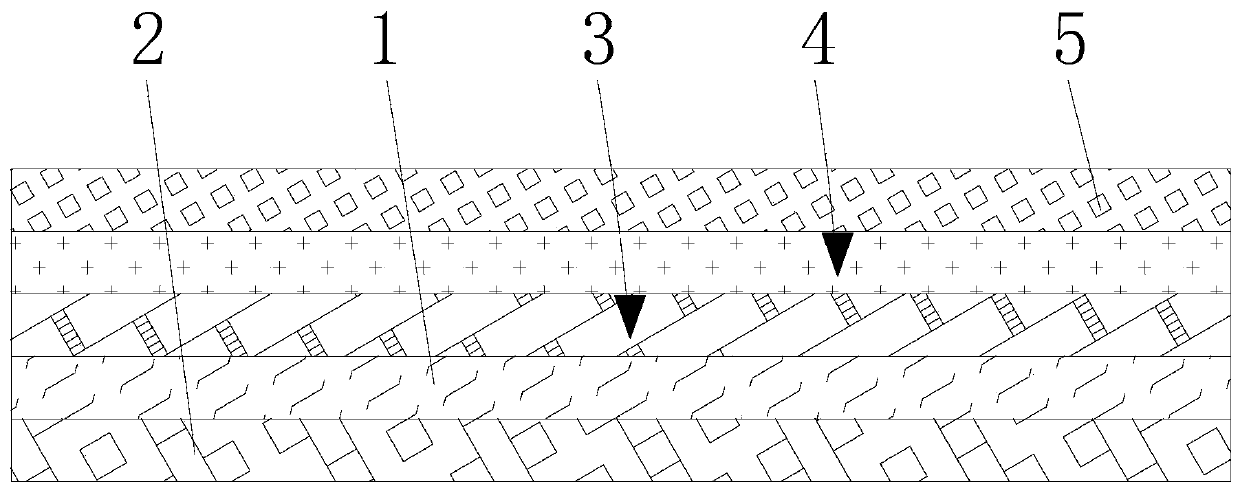

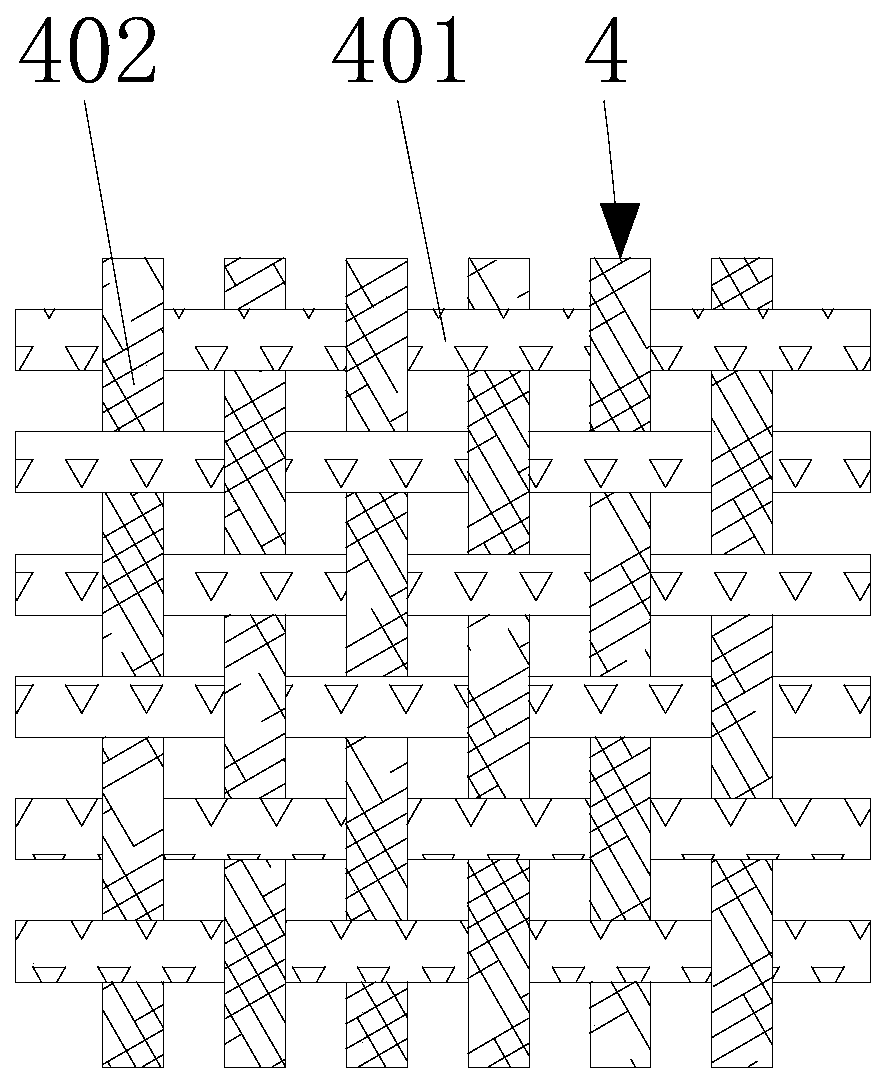

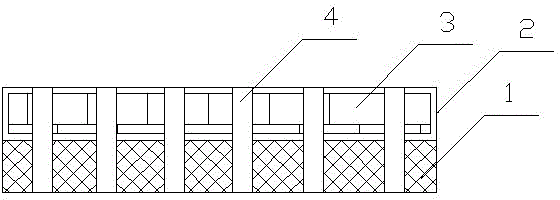

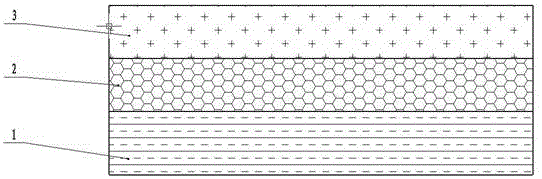

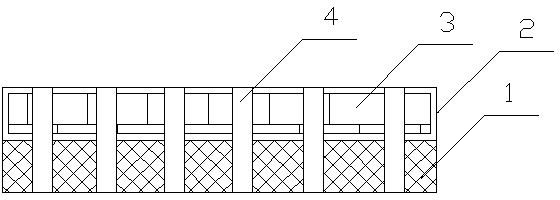

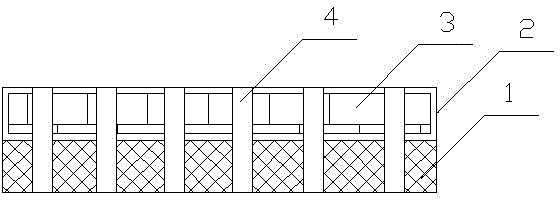

Antistatic breathable multifunctional artificial leather

InactiveCN104420275AHas the function of conducting electricityImprove breathabilitySynthetic resin layered productsTextiles and paperFiberPolymer science

The invention relates to antistatic breathable multifunctional artificial leather, the artificial leather comprises a base layer (1) and a plastic surface layer (2) which are mutually bonded, a carbon fiber layer (3) is embedded in the plastic surface layer (2), a breathable through hole (4) is arranged on the artificial leather, the base layer is made by fabrics, the fabrics comprise a fabrics body, the fabrics are made by interlacing warp yarn and weft yarn, conductive fiber is weaved in the warp yarn and the weft yarn, a fluorescent layer, a water proof layer and a moisture permeable flame-retardation layer are applied on the surface of the fabrics body in order, the fluorescent layer thickness is 0.1-1mm, the water proof layer is a transparent high-molecular water-proof membrane, and the thickness of the water proof layer is 0.1-2mm. The artificial leather has antistatic effect and can increase breathable effect of the artificial leather, the employed base material integrates four functions of waterproof and moisture permeable performance, flame retardation, fluorescence and antistatic performance, can satisfy the protection requirement of several special work, has good wearability, and can increase the work efficiency.

Owner:JIANGYIN YUEDA DYEING & PRINTING

Preparation method of anti-static silicone rubber O-shaped ring

The invention provides a preparation method of an anti-static silicone rubber O-shaped ring. The method sequentially comprises the following steps: S1, mixing, namely adding 100 parts by mass of methyl vinyl silicone rubber, 3-10 parts by mass of conductive carbon black, 10-15 parts by mass of wear-resistant carbon black, 5-8 parts by mass of iron oxide powder and 2-4 parts by mass of antistatic non-woven fabric fragments into an internal mixer, and mixing for 30 minutes at the temperature of 50-80 DEG C to obtain a rubber compound; and s2, performing forming vulcanization. Two conductive fillers of the conductive carbon black and the iron oxide powder are added into raw materials of a traditional silicone rubber O-shaped ring; and the filling amount of the filler reaches a threshold value, and the volume resistivity and the surface resistivity of the polymer are rapidly reduced, so that the O-shaped ring can simultaneously depend on volume conduction and surface conduction to carry out electrostatic dissipation, and an anti-static effect is achieved.

Owner:宁国天运橡塑制品有限公司

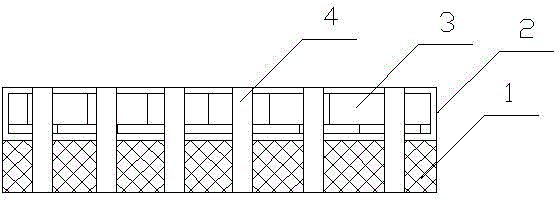

Antistatic breathable flame-retardant artificial leather

InactiveCN104420304AHas the function of conducting electricityImprove breathabilitySynthetic resin layered productsWoven fabricsPolymer scienceCarbon fibers

The invention relates to antistatic breathable flame-retardant artificial leather which includes a base material (1) and a plastic surface layer (2) which are bonded to each other. A carbon fiber layer is embedded in the plastic surface layer (2). Breathable pores (4) are formed in the artificial leather. The base material is manufactured from a fabric which is formed by warp yarns and weft yarns in an interweaving manner. The warp yarns are formed by cotton yarn threads and the weft yarn is formed by flame-retardant polyester filament yarn. The artificial leather has an antistatic effect and is improved in breathable performance. The base material is soft and comfort, is breathable and moisture-permeable, is free of pungent smells and is excellent in a flame-retardant performance.

Owner:JIANGYIN MINGPIN KNITTING

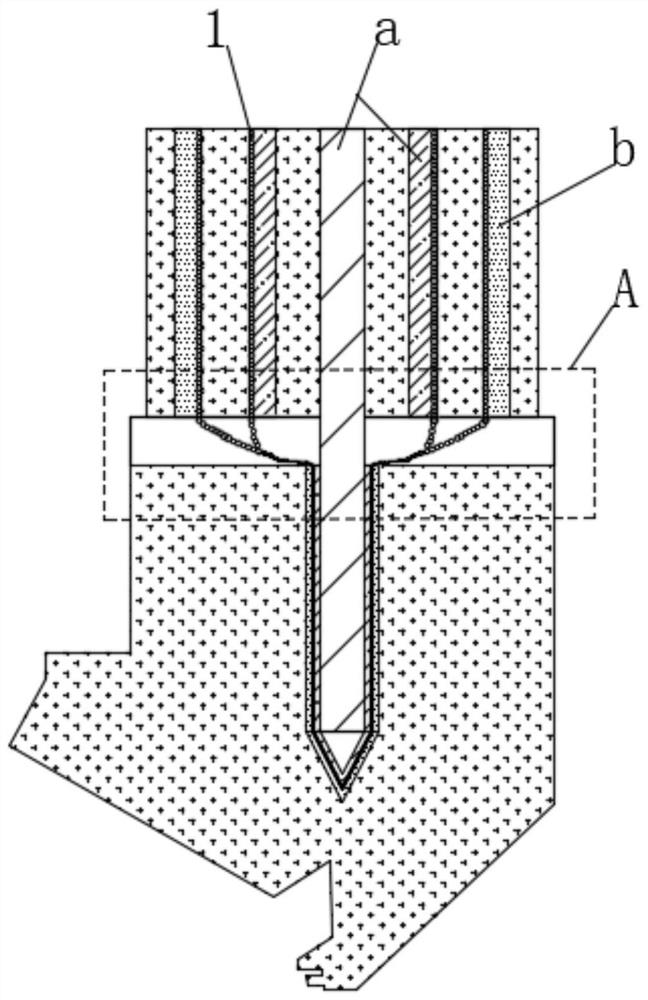

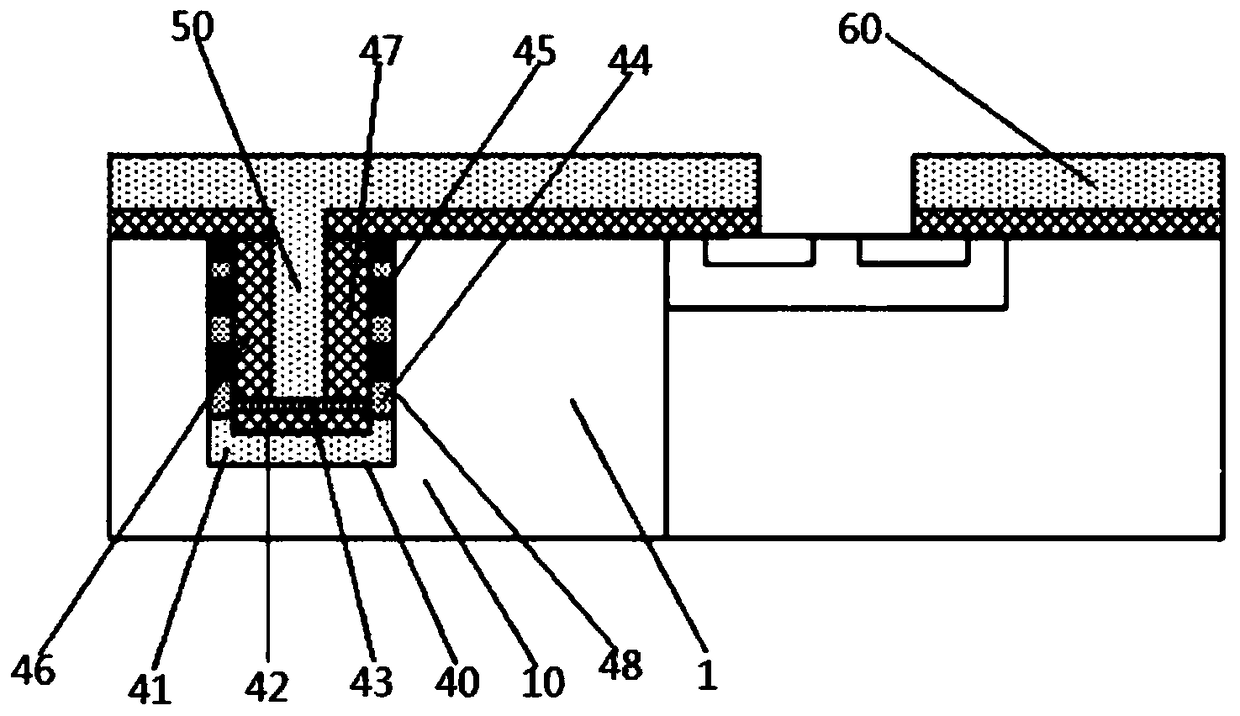

A semiconductor device and a manufacturing method thereof

ActiveCN109065533AAchieve anti-static effectSolid-state devicesDiodeSemiconductorSemiconductor device

A semiconductor device includes a substrate, a trench formed on the substrate, a compensation layer of a first conductivity type formed at the bottom of the trench, a first oxide layer formed on the compensation layer, a lead layer formed on the first oxide layer, at least one first injection region having a second conductivity type and at least one second injection region having a first conductivity type formed on the sidewall of the trench, a first electrode and a second electrode, wherein the first injection region is spaced apart from the second injection region, the top of the trench sidewall is a second injection region, the first electrode is electrically connected with the first injection region through the lead layer, and the second electrode is electrically connected with the compensation layer. The invention also provides a manufacturing method of a semiconductor device, which not only reduces waste of integrated area, enhances voltage withstand ability and reduces manufacturing cost, but also facilitates layout of the semiconductor device or circuit.

Owner:南京市臻坤智能科技有限公司

Plastic with anti-static and cooling properties for electronic product shell

The invention relates to the technical field of high polymer materials, in particular to a plastic with anti-static and cooling properties for an electronic product shell. The plastic is prepared fromABS resin, polycarbonate, conducting heat dissipation particles, glass fiber, ethylene propylene diene monomer, compatilizer, lubricant, antioxidant and a coupling agent, wherein the conducting heatdissipation particles are metal copper powder wrapped by gel, the fiber length of the glass fiber is 0.3-0.5 mm, the compatilizer is a mixture of nano calcium carbonate and maleic anhydride grafted polyolefin copolymer, the lubricant is zinc stearate or magnesium stearate, and the coupling agent is one of gamma-glycidyl oxypropyl trimethoxysilane, gamma-amino propyl triethoxysilane and gamma-chloropropyl trimethoxy silane. The resin material not only has high strength and hardness, but also can significantly improve the cooling property and the anti-static effect of the ABS resin material.

Owner:合肥奇呗数字科技有限公司

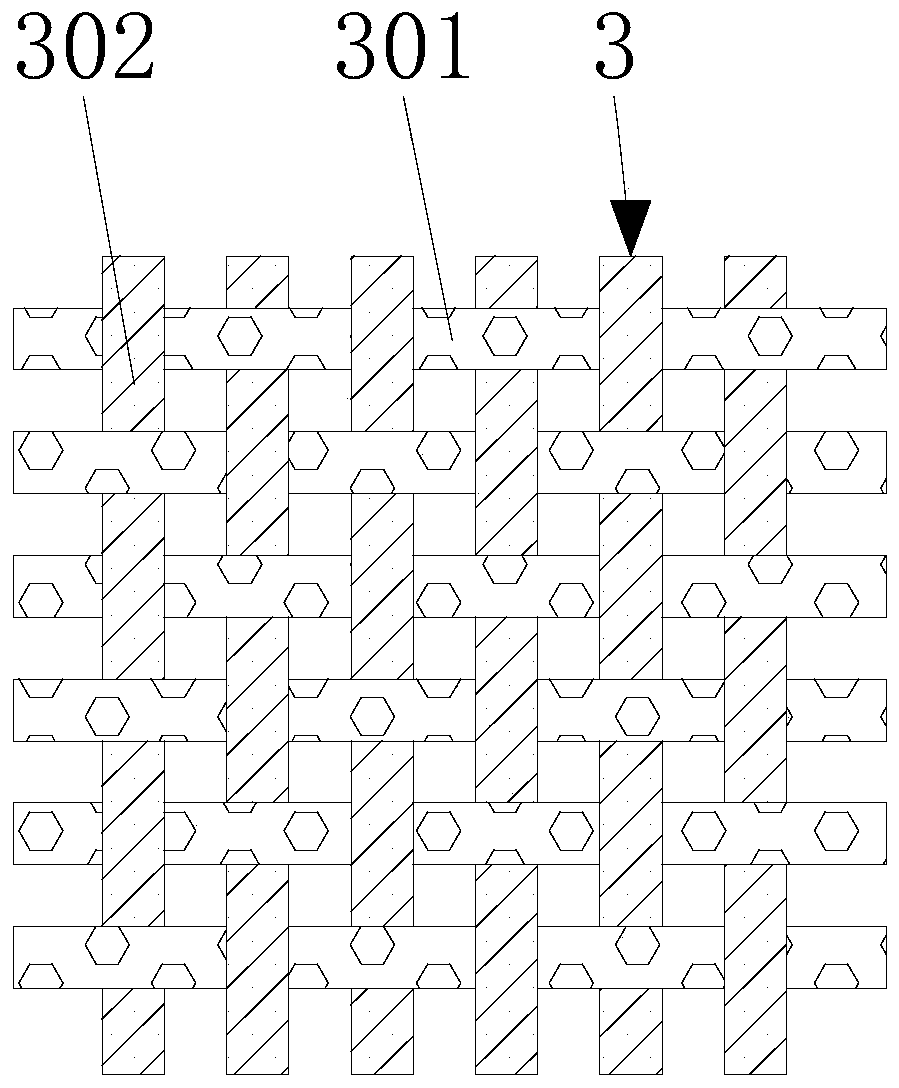

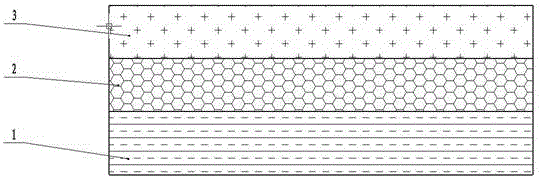

Anti-static fabric with waterproof, oil-proof and anti-fouling functions

InactiveCN106273777AImprove waterproof performanceGood oil resistanceSynthetic resin layered productsClothingsPolyesterMicrometer

The invention relates to an anti-static fabric with waterproof, oil-proof and anti-fouling functions. The fabric comprises an inner layer (1), and a base layer (2) and an electrostatic eliminating layer (3) are sequentially arranged outside the inner layer. The back face of the inner layer is provided with a lining fabric layer which comprises three layers, the outer layer is a teflon coating, the interlayer is a textile, the internal layer is a teflon coating, the textile is a nylon waterproof fabric or a polyester fabric, and the thickness of the teflon coating ranges from 10 micrometers to 13 micrometers. According to the anti-static fabric with the waterproof, oil-proof and anti-fouling functions, the service life of the fabric can be prolonged, and the fabric is washable and antistatic. The fabric has the waterproof, oil-proof and anti-fouling functions.

Owner:JIANGYIN GUORUN TEXTILE RAW MATERIALS SALES

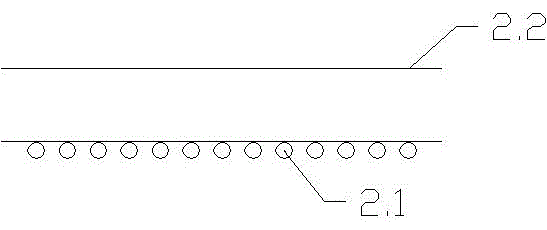

Anti-static synthetic leather capable of repelling mosquitoes

InactiveCN104988755AHas the function of conducting electricityAchieve anti-static effectSynthetic resin layered productsTextiles and paperFiberCarbon fibers

The invention relates to anti-static synthetic leather capable of repelling mosquitoes. The leather comprises a substrate (1) and a plastic surface layer (2) which are bonded to each other, the plastic surface layer (2) is composed of carbon fibers and PVC plastic, the carbon fibers are arranged inside the total synthetic leather vertically and horizontally, and the plastic surface layer (2) comprises a small-scale-shaped woven layer (2.1) which is arranged on the inner layer and a mosquito-proof protective layer (2.2) which is arranged on the outer layer. The anti-static synthetic leather capable of repelling the mosquitoes has the conductive function, thereby achieving the anti-static effect; the mosquito-proof addition agent is a non-toxic product and applied to the surface of the plastic surface layer, and the excellent effect of repelling winged insects such as the mosquitoes and flies or reptiles such as ants, dust mites and cockroaches is achieved.

Owner:JIANGYIN HUAHONG SYNTHETIC LEATHER FACTORY

Antistatic ventilating artificial leather capable of effectively preventing electromagnetic wave

InactiveCN104389182AImprove breathabilityGood radiation resistanceSynthetic resin layered productsWoven fabricsWeft yarnEngineering

The invention relates to antistatic ventilating artificial leather capable of effectively preventing electromagnetic wave. The antistatic ventilating artificial leather comprises a base material (1) and a plastic surface layer (2) which are adhered to each other. A carbon fiber layer (3) is embedded in the plastic surface layer (2). The artificial leather is provided with ventilating through-holes (4). The base material is prepared from fabric which is formed by interweaving warp yarns and weft yarns. The warp yarns are composed of nano-metal shield fiber yarns. The weft yarns are composed of tencel fiber yarns. According to the invention, an antistatic effect is achieved, and air permeability of the artificial leather is enhanced. The artificial leather provided by the invention has good radiation resistance and can effectively prevent human body from being harmed by electromagnetic wave.

Owner:JIANGYIN LICHEN IND

Evaporative heat loss preventing antistatic fabric

InactiveCN106273732AReduce discharge efficiencyImprove insulation effectSynthetic resin layered productsPolyesterHeat losses

The invention relates to an evaporative heat loss preventing antistatic fabric. The fabric comprises an inner layer (1). A basic layer (2) and a destaticizing layer (3) are sequentially arranged outside the inner layer. A lining fabric layer is arranged on the back side of the inner layer, is a compound fabric and is composed of a lining layer, a blocking layer and a fabric layer not prone to being wetted by water. The blocking layer is prepared from one of polyethylene, nylon, polyester, ethyl carbamate and polytetrafluoroethylene. The service life of the fabric can be prolonged, and the fabric is a washable and anti-static fabric. Evaporative heat loss is prevented.

Owner:JIANGYIN DUJUAN BEADED

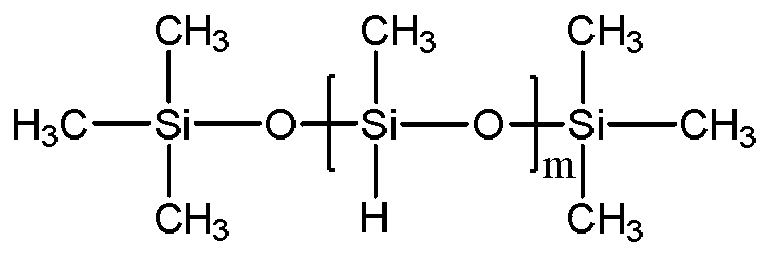

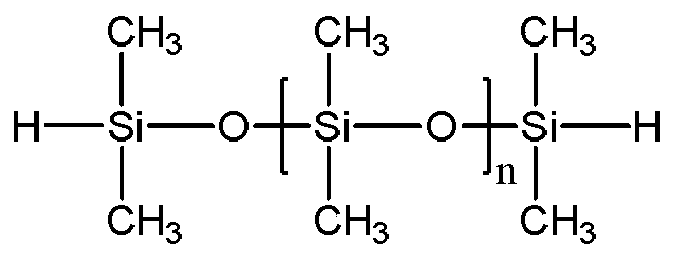

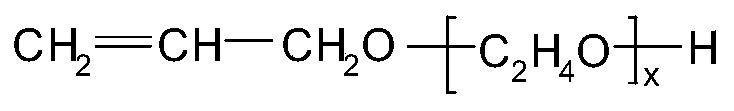

A kind of preparation method and application of organosilicon antistatic agent

The invention relates to the technical field of textiles, in particular to a preparation method and application of an organosilicone antistatic agent. The preparation method of the organosilicone antistatic agent comprises the following steps: adding low-hydrogen-content silicone oil and allyl alcohol polyoxyethylene ether into a reaction kettle provided with a reflux device; then adding a chloroplatinic acid solution; raising the temperature to 100-130 DEG C; performing a heat preservation reaction for 1-3 h after the system is transparent and clarified; and reducing the temperature and performing discharging, wherein the addition amount of chloroplatinic acid is 0.0005-0.0020% of the mass of the low-hydrogen-content silicone oil. As the low-hydrogen-content silicone oil is taken as the raw material to react with allyl alcohol polyoxyethylene ether with different activity, the reaction is complete, the conversion ratio is high, the product quality is stable, and such phenomena as polymerization and cross-linking are avoided. The organosilicone antistatic agent prepared by the preparation method has favorable hydrophilic hygroscopicity, the fiber surface specific resistance is greatly reduced, the antistatic effect is achieved, and the antistatic and washing-enduring requirements in the textile industry are satisfied.

Owner:SUZHOU BANGCEN TECH

Antistatic breathable layered artificial leather

InactiveCN104372662AHas the function of conducting electricityImprove breathabilitySynthetic resin layered productsTextiles and paperPolymer scienceCarbon fibers

The invention relates to an antistatic breathable layered artificial leather. The artificial leather comprises a substrate (1) and a plastic surface layer (2) which are bonded together, a carbon fiber layer (3) is embedded in the plastic surface layer (2), the artificial leather is provided with breathable through holes (4), the substrate is made of a fabric, the fabric comprises a fabric body, the surface of the fabric body is provided with a plurality of three dimensional stripes, the three dimensional strips are horizontally and equidistantly arranged, the cross section of each of the three dimensional strips is L-shaped, one of the three dimensional stripes is connected with the next adjacent one of the three dimensional stripes, the connection is at the bottom of the one of the three dimensional stripes and is fixed on the fabric body through a line, the backside of the three dimensional stripes is provided with a plurality of connection points, and the connection points are connected with the fabric body. The artificial leather has the advantages of antistatic effect, improved breathable performance, and enhancement of the layered sensation of the fabric by adopting the three dimensional stripes with the connection points.

Owner:JIANGYIN HOMEX TEXTILES

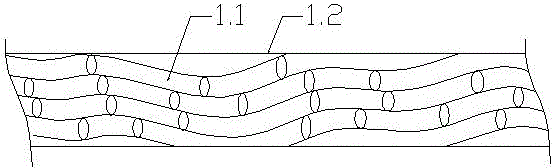

Dry and comfortable as well as peculiar-smell-free and aromatic antistatic synthetic leather

InactiveCN105951462AHas the function of conducting electricityAchieve anti-static effectLayered productsWoven fabricsFiberYarn

The invention relates to dry and comfortable as well as peculiar-smell-free and aromatic antistatic synthetic leather which comprises a basal layer (1) and a plastic surface layer (2), which are bonded with each other, wherein the plastic surface layer (2) is prepared from carbon fibers and PVC (polyvinyl chloride) plastic; the carbon fibers are longitudinally and transversely arranged in whole synthetic leather; a plurality of groups of miniature sachets (1.1) which are fixed by a bonding agent are arranged in clearances of the basal layer (1); outer sides of the miniature sachets in each group are all provided with waterproof layers; an external surface of the basal layer is also coated with a fragrance control layer (1.2) for controlling fragrance in the miniature sachets to volatilize. A lining layer is compounded on the back surface of the basal layer; the lining layer comprises a lining layer body; the lining layer body is formed by interweaving warp and weft; a plurality of covering yarns are arranged in the warp and the weft in an embedment manner; a plurality of bulges are arranged on an external surface of the lining layer body; the covering yarns comprise internal cores and superficial layers covering exteriors of the internal cores. The dry and comfortable as well as peculiar-smell-free and aromatic antistatic synthetic leather is dry, comfortable, peculiar-smell-free and aromatic.

Owner:JIANGYIN LONGSHENG PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com