A semiconductor device and a manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, electrical solid devices, electrical components, etc., can solve the problems of area waste, unfavorable device or circuit layout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

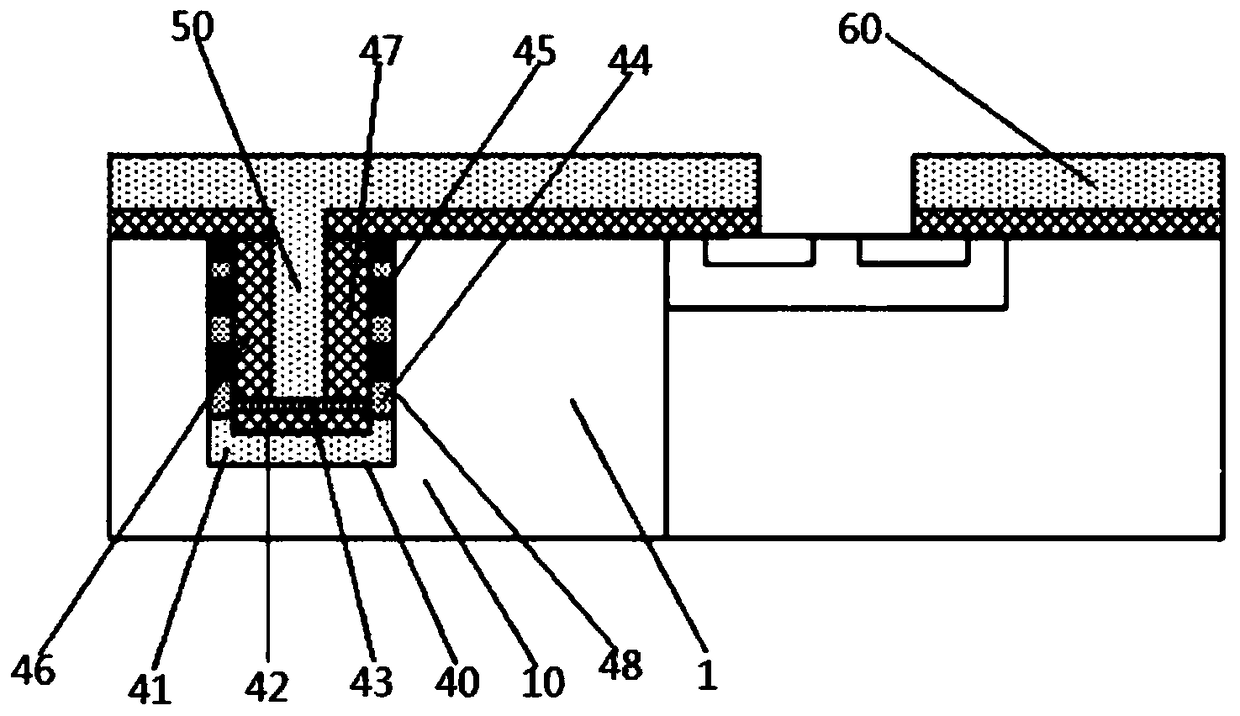

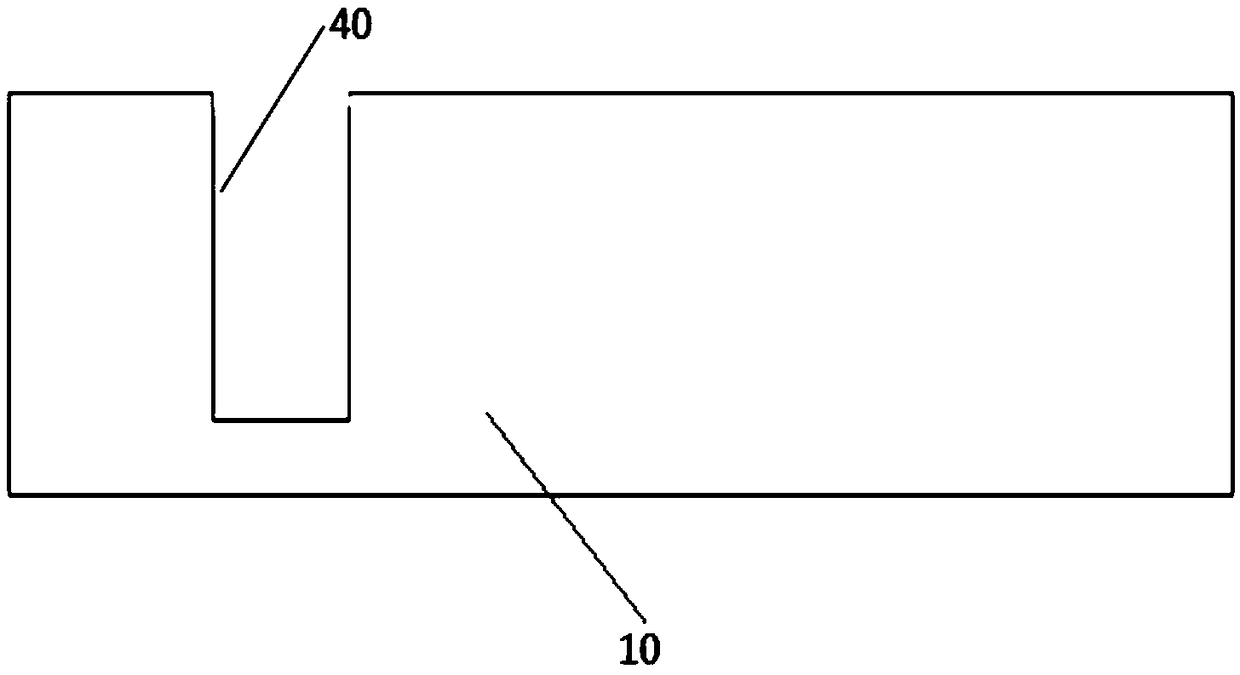

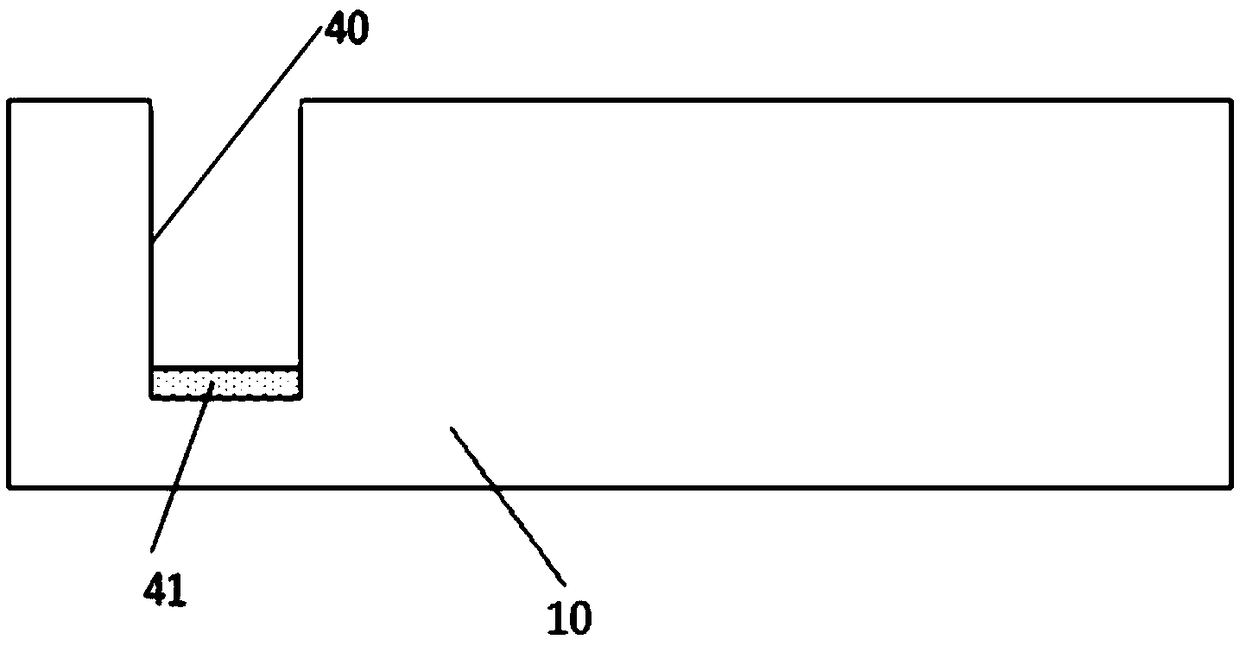

[0013] see figure 1 , the semiconductor device 1 includes a substrate 10, a trench 40 formed on the substrate 10, a compensation layer 41 of the first conductivity type formed at the bottom of the trench 40, a first oxide layer formed on the compensation layer 41 42. The wiring layer 43 formed on the first oxide layer 42, at least one first implantation region 44 of the second conductivity type and at least one second implantation region of the first conductivity type formed on the sidewall of the trench 40 region 45, the first electrode 50 and the second electrode 60, the first injection region 44 and the second injection region 45 are spaced apart, the top of the sidewall of the trench 40 is the second injection region 45, the The first electrode 50 is electrically connected to the first injection region 44 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com