A kind of preparation method and application of organosilicon antistatic agent

An antistatic agent and organosilicon technology, which is applied in the field of preparation of organosilicon antistatic agents, can solve problems such as unstable quality and scrapped products, and achieve the effects of stable product quality, low cost, and good hydrophilic and hygroscopic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the organosilicon antistatic agent described in the present embodiment comprises the steps:

[0034] (1) H 2 PtCl 6 ·6H 2 O is dissolved in an organic solvent, fully stirred at 25-27 ° C, placed in an ultrasonic oscillator for 20 minutes, and left to stand for use; the organic solvent is selected from at least one of white isopropanol, toluene, and tetrahydrofuran, and the The mass fraction of chloroplatinic acid solution is 0.5-1.0%.

[0035] As an embodiment of the present invention, in this embodiment, weigh H 2 PtCl 6 ·6H 2 O 1.3g was dissolved in 130mL isopropanol, fully stirred at 26°C, placed in an ultrasonic oscillator for 20min, and left to stand to obtain a chloroplatinic acid isopropanol solution with a mass fraction of 1.0%.

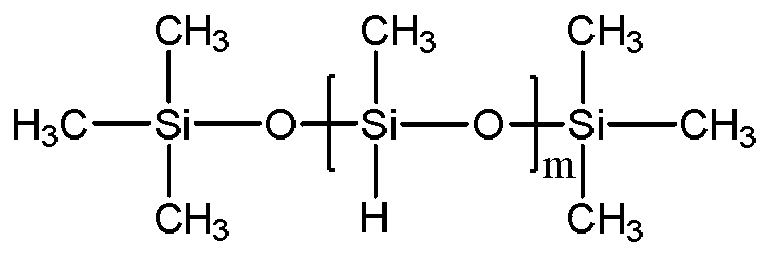

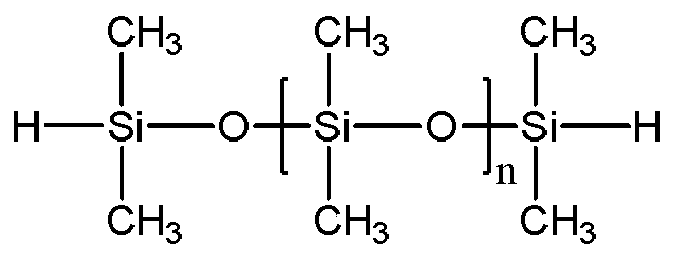

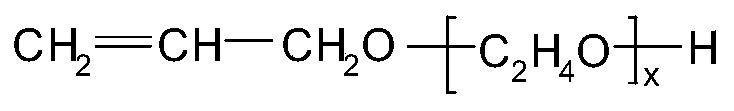

[0036] (2) Add low-hydrogen silicone oil and allyl alcohol polyoxyethylene ether into the reaction kettle equipped with a reflux device according to the mass ratio of 1: (0.5-5), heat the reaction system...

Embodiment 2

[0048] The preparation method of the organosilicon antistatic agent described in the present embodiment comprises the steps:

[0049] (1) Weigh H 2 PtCl 6 ·6H 2 O 1.3g was dissolved in 250mL isopropanol, fully stirred at 25°C, placed in an ultrasonic oscillator for 20min, and left to stand to obtain a chloroplatinic acid isopropanol solution with a mass fraction of 0.5%.

[0050] (2) Weigh 200.0kg of side-chain hydrogen-containing silicone oil with a molecular weight of 4000, weigh 500.0kg of allyl alcohol polyoxyethylene ether with a molecular weight of 10000, add it to a reaction kettle equipped with a reflux device, start stirring, and heat the reaction system , when the temperature rises to 60°C, add 167mL of the isopropanol solution of chloroplatinic acid configured in step (1); continue to heat up, and when the temperature rises to 85°C, add the remaining 83mL of the isopropanol solution of chloroplatinic acid, add Process control reaction temperature does not exceed ...

Embodiment 3

[0054] The preparation method of the organosilicon antistatic agent described in the present embodiment comprises the steps:

[0055] (1) Weigh H 2 PtCl 6 ·6H 2 25.3 g of O was dissolved in 3000 mL of toluene, fully stirred at 27 ° C, placed in an ultrasonic oscillator for 20 min, and left to stand to obtain a chloroplatinic acid toluene solution with a mass fraction of 0.76%.

[0056] (2) Weigh 1000.0kg of side chain hydrogen-containing silicone oil with a molecular weight of 8000, weigh 500.0kg of allyl alcohol polyoxyethylene ether with a molecular weight of 4000, add it to the reaction kettle equipped with a reflux device, start stirring, and heat the reaction system , when the temperature rises to 60°C, add 2000mL of the chloroplatinic acid toluene solution configured in step (1); continue to heat up, and when the temperature rises to 85°C, add the remaining 1000mL of the chloroplatinic acid toluene solution, and add the process to control the reaction temperature Do n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com