Multifunctional synthetic leather

A synthetic leather, multi-functional technology, applied in the field of artificial leather, can solve the problem of low functionality of synthetic leather, and achieve the effects of enhancing mechanical properties and air permeability, improving wear resistance and scratch resistance, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

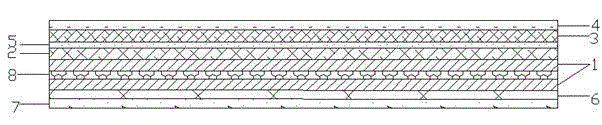

[0019] Such as figure 1 Shown, a kind of multifunctional synthetic leather of the present invention comprises base cloth layer 1, the wet method PU layer 2 that is formed on base cloth layer 1 and the dry method PU layer 3 that is bonded on wet method PU layer 2, dry method The upper surface of the PU layer 3 is formed with a sound-absorbing resin film layer 4, and a mite-removing interlayer 5 is arranged between the wet-process PU layer 2 and the dry-process PU layer 3. The mite-removing interlayer 5 is a non-woven fabric made of antibacterial and mite-removing fibers. Cloth, the non-woven fabric is bonded between the wet-process PU layer 2 and the dry-process PU layer 3.

[0020] Preferably, as a possible embodiment, the bottom of base cloth layer 1 is coated with wet-process nano-silica modified polyurethane layer 6, and the bottom of wet-process nano-silica modified polyurethane layer 6 is coated with wet-process anion powder Modified polyurethane layer 7.

[0021] Prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com