Patents

Literature

55results about How to "Increase wear resistance and scratch resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

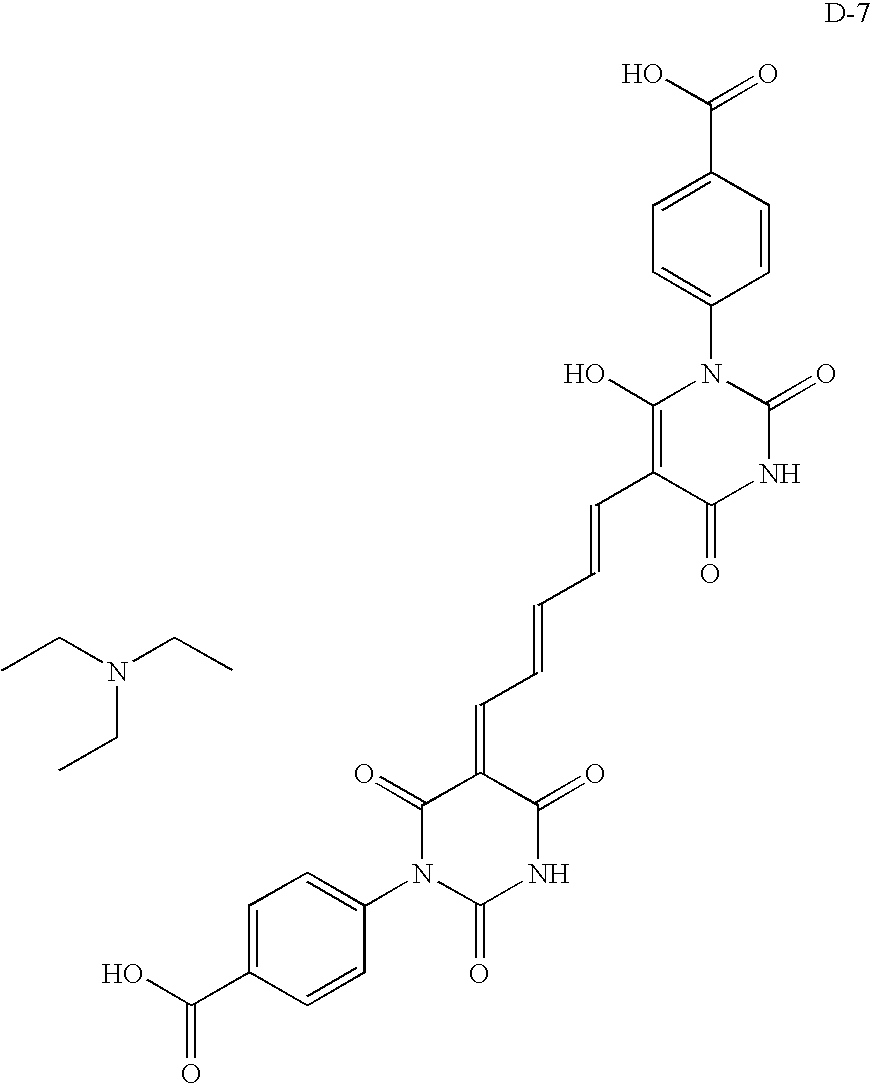

Scratch-resistant optical film having organic particles with highly uniform particle size

ActiveUS20080311351A1Avoid impairmentIncrease brightnessPrismsDiffusing elementsAcrylateParticle-size distribution

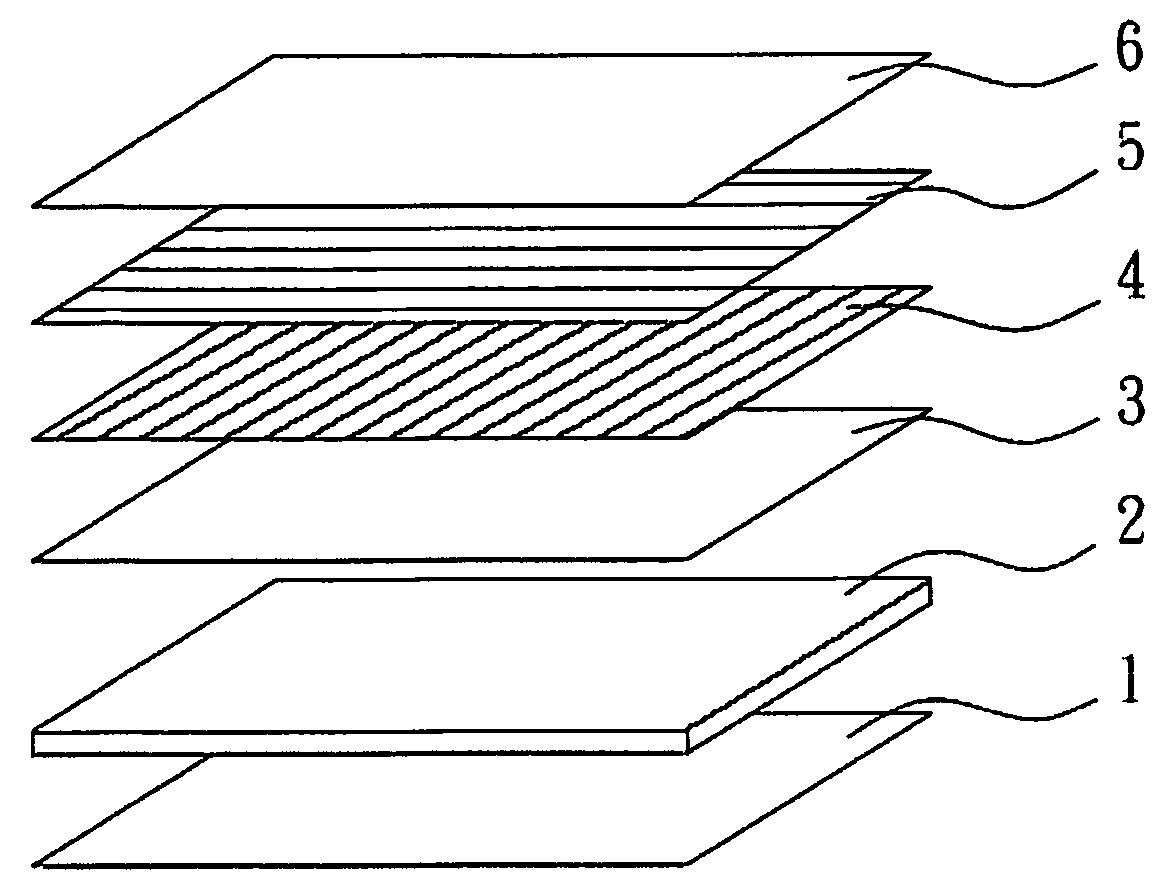

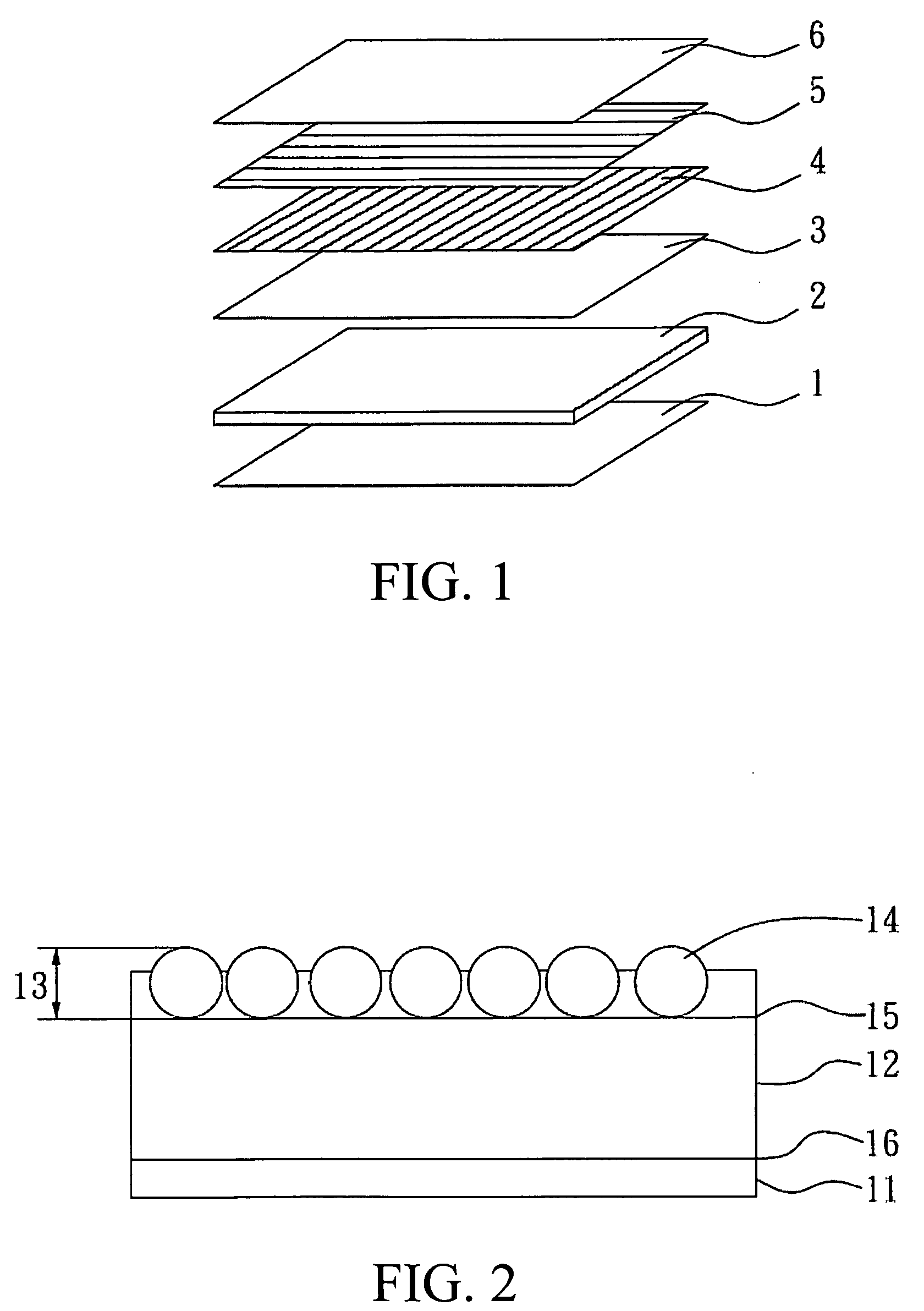

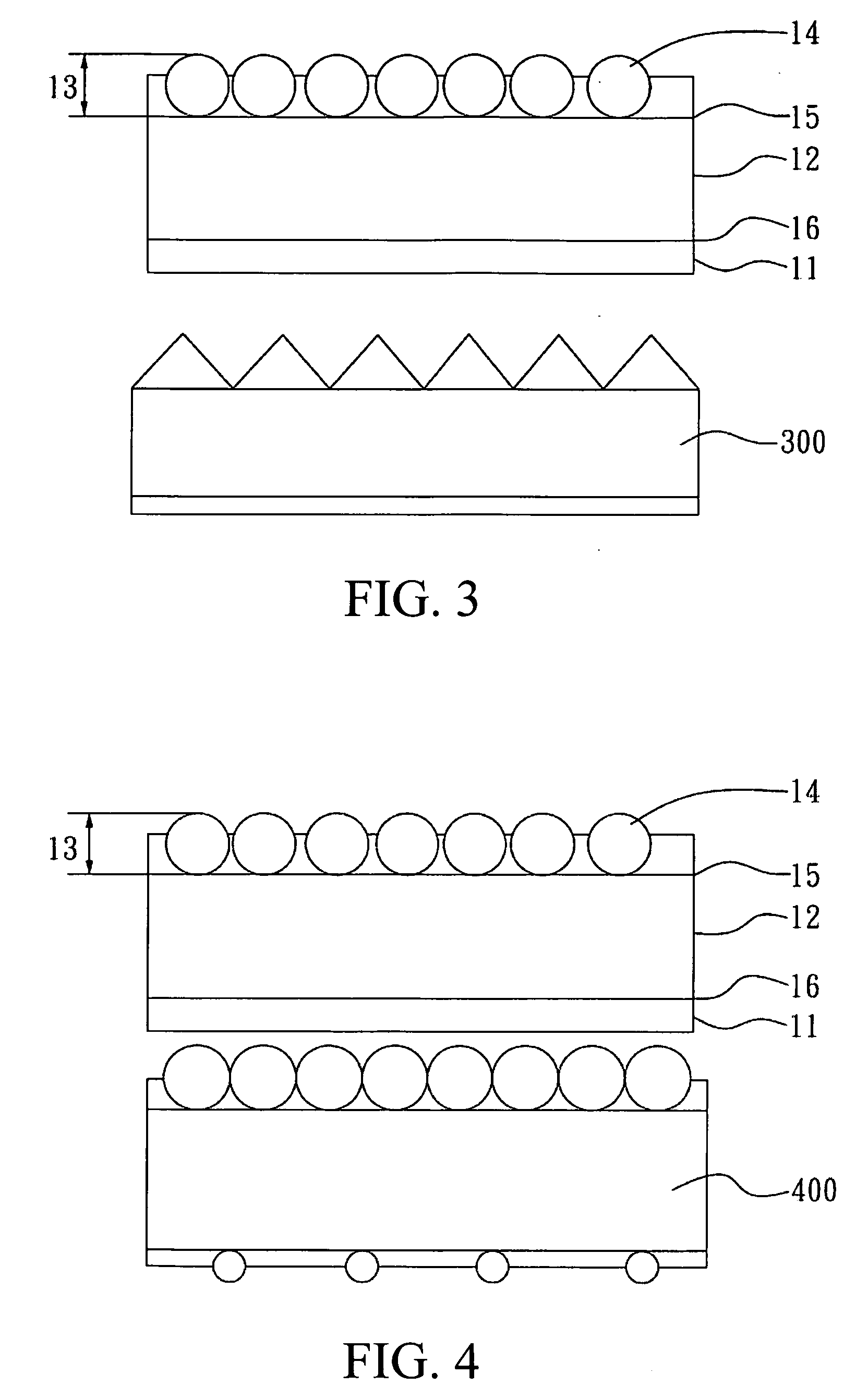

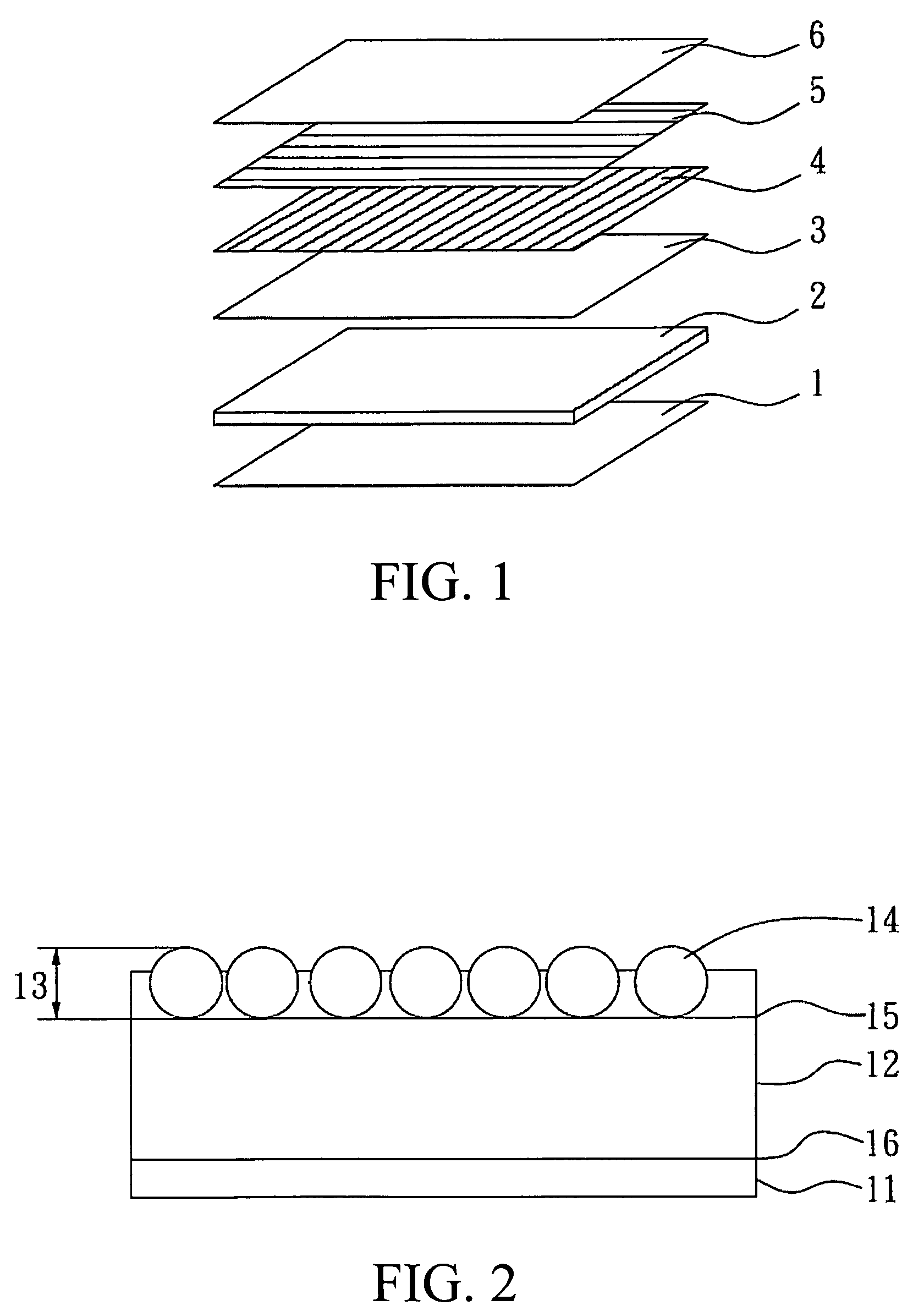

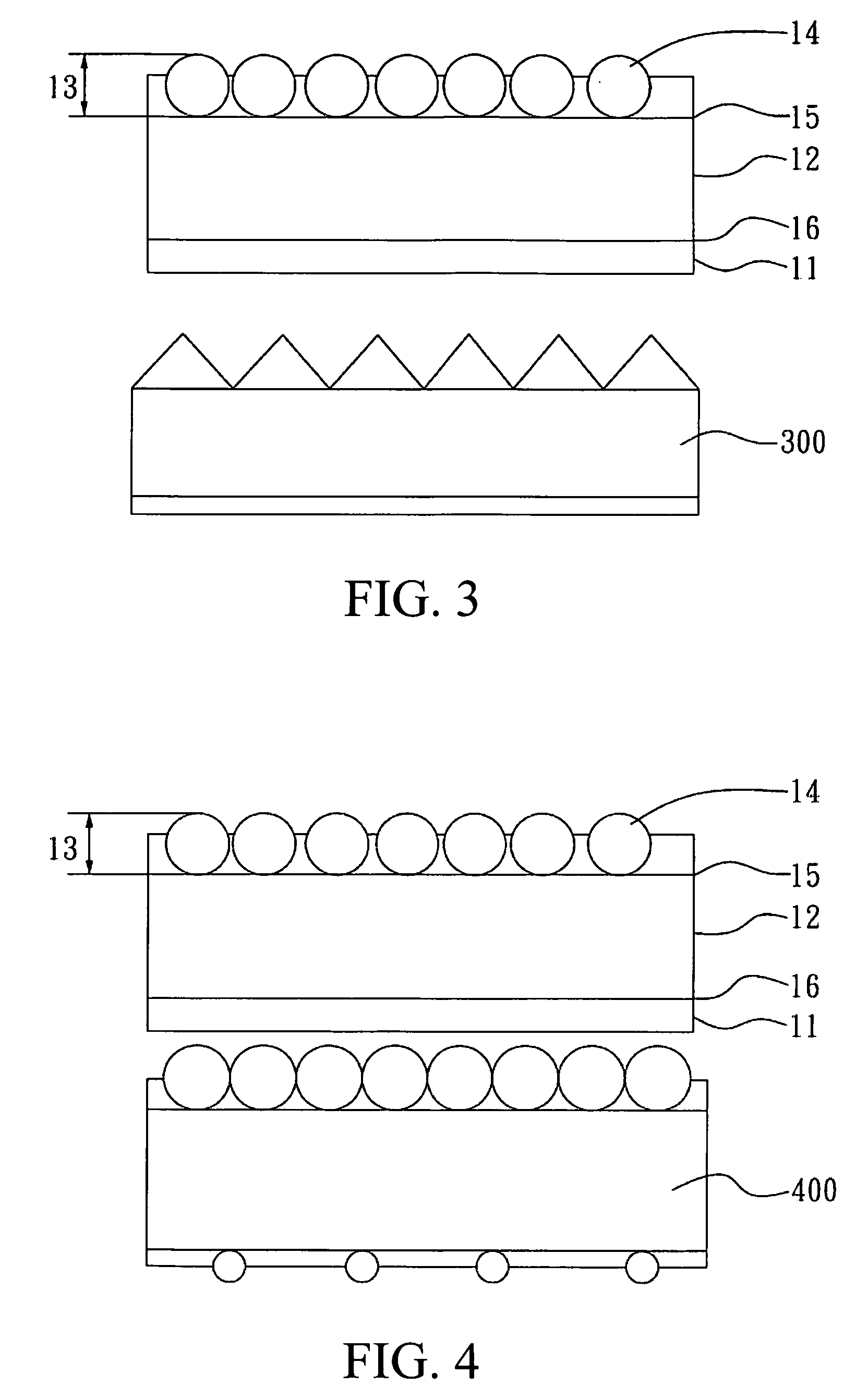

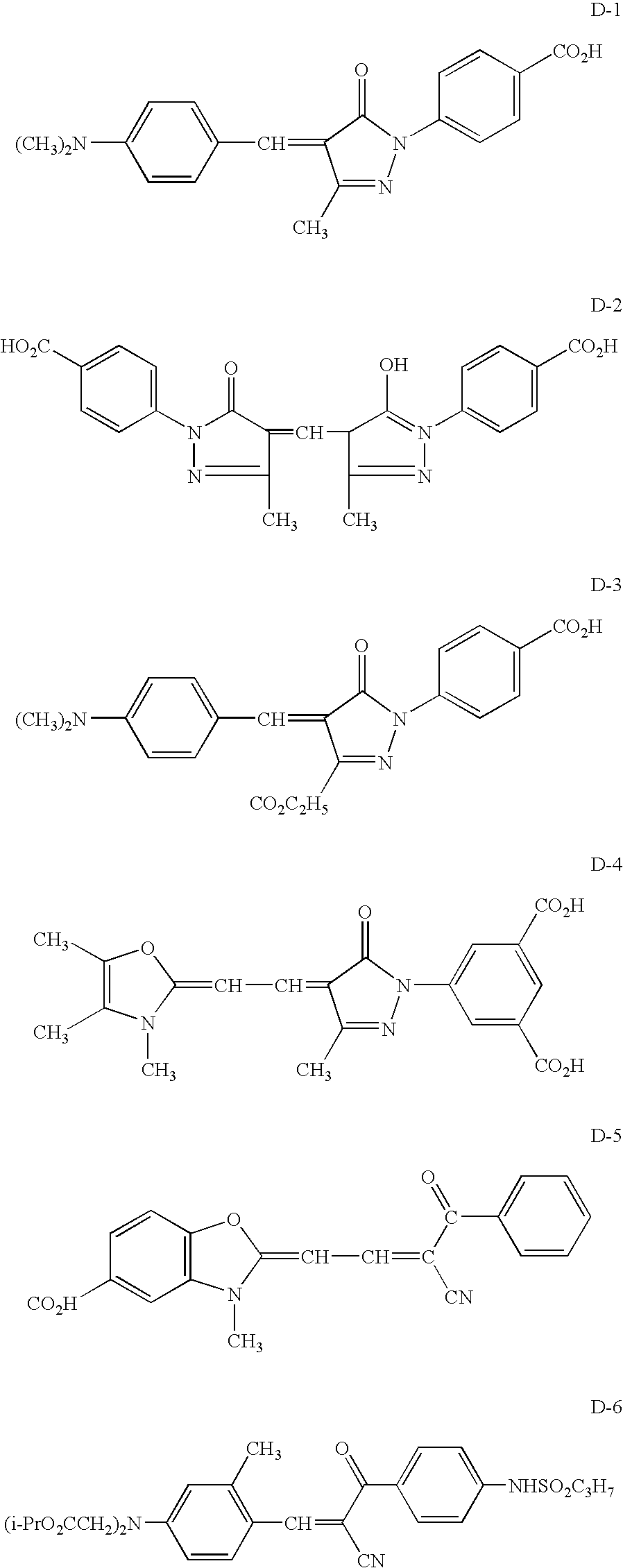

The subject invention relates to a scratch-resistant optical film, which comprises:(a) a transparent substrate having a first surface and a second surface;(b) a diffusion layer on the first surface of the substrate, which has a convex-concave structure and is comprised of a first hard coat layer comprising organic particles;(c) a scratch-resistant layer on the second surface of the substrate, which is comprised of a second hard coat layer;wherein the organic particles in the first hard coat layer are formed from a polyacrylate resin which comprises at least one multi-functional acrylate monomer as polymerization units, said multi-functional acrylate monomer being in an amount from 30 to 70 wt % based on the total weight of the monomer used, and wherein the organic particles have a single mean particle size and have a particle size distribution in the range within about ±5% of the mean particle size.

Owner:ETERNAL MATERIALS CO LTD

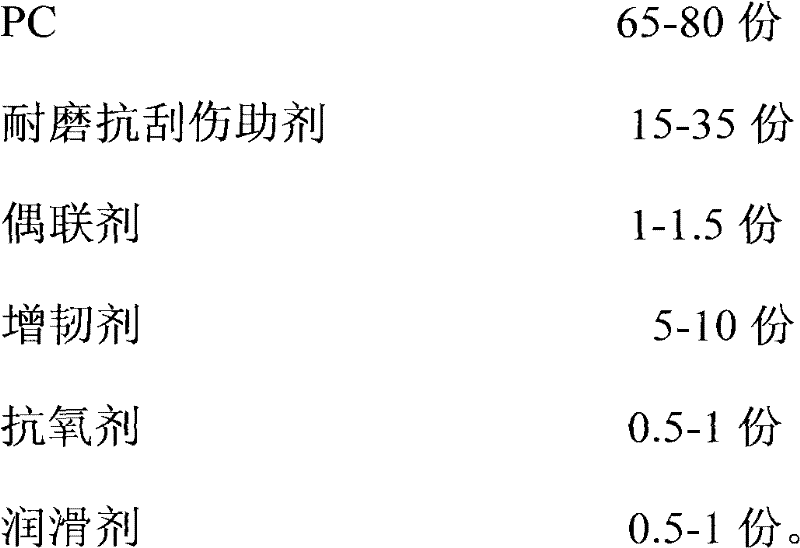

Highly-abrasion-resistant anti-scratching modified PC (polycarbonate) material and preparation method thereof

InactiveCN102391634AIncrease wear resistance and scratch resistanceAvoid oxidative degradationPolymer scienceAntioxidant

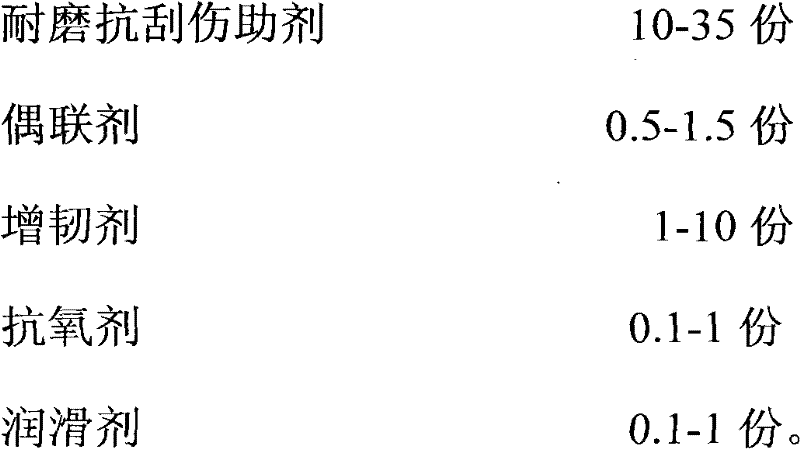

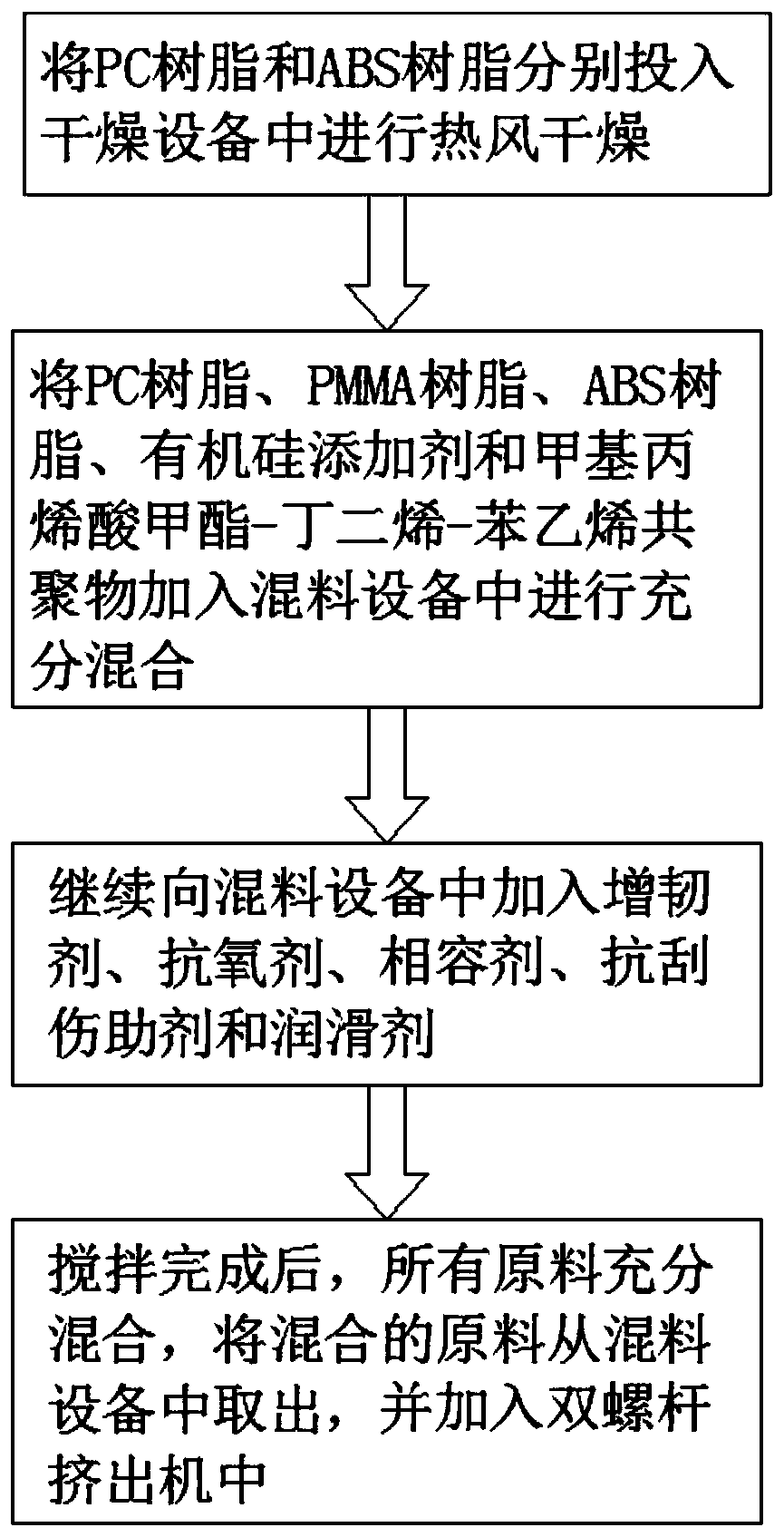

The invention relates to the field of high polymer materials and particularly relates to a highly-abrasion-resistant anti-scratching modified PC (polycarbonate) material and a preparation method thereof. The high-abrasion-resistant anti-scratching modified PC material comprises the following raw materials in parts by weight: 65-90 parts of PC, 10-35 parts of abrasion-resistant anti-scratching auxiliary agent, 0.5-1.5 parts of coupling agent, 1-10 parts of toughening agent, 0.1-1 part of antioxidant and 0.1-1 part of lubricating agent. According to the invention, PC is used as a substrate material, and composite systems such as the abrasion-resistant anti-scratching auxiliary agent, the lubricating agent, other auxiliary agents and the like are added, so that the abrasion-resistant anti-scratching property of the material is improved; the abrasion-resistant anti-scratching modified PC material is prepared by adopting high-temperature smelting, mixing and extruding modes in a twin-screw extruder, thus the hardness and abrasion-resistant anti-scratching effect of PC are improved; and modified PC has the advantages of high rigidity, high toughness, high flowability, high heat resistance, bright surface and the like.

Owner:GUANGDONG JANUS SMART GRP CO LTD

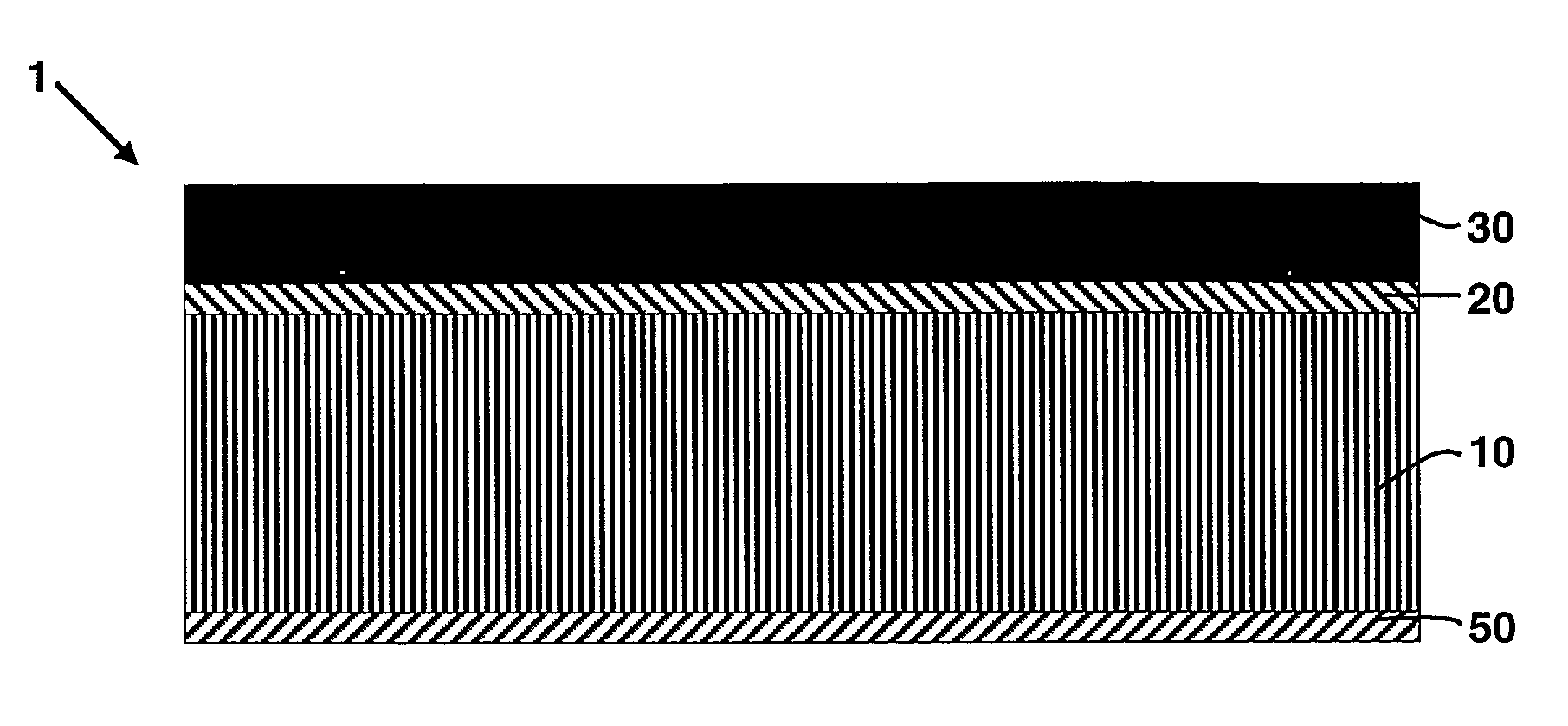

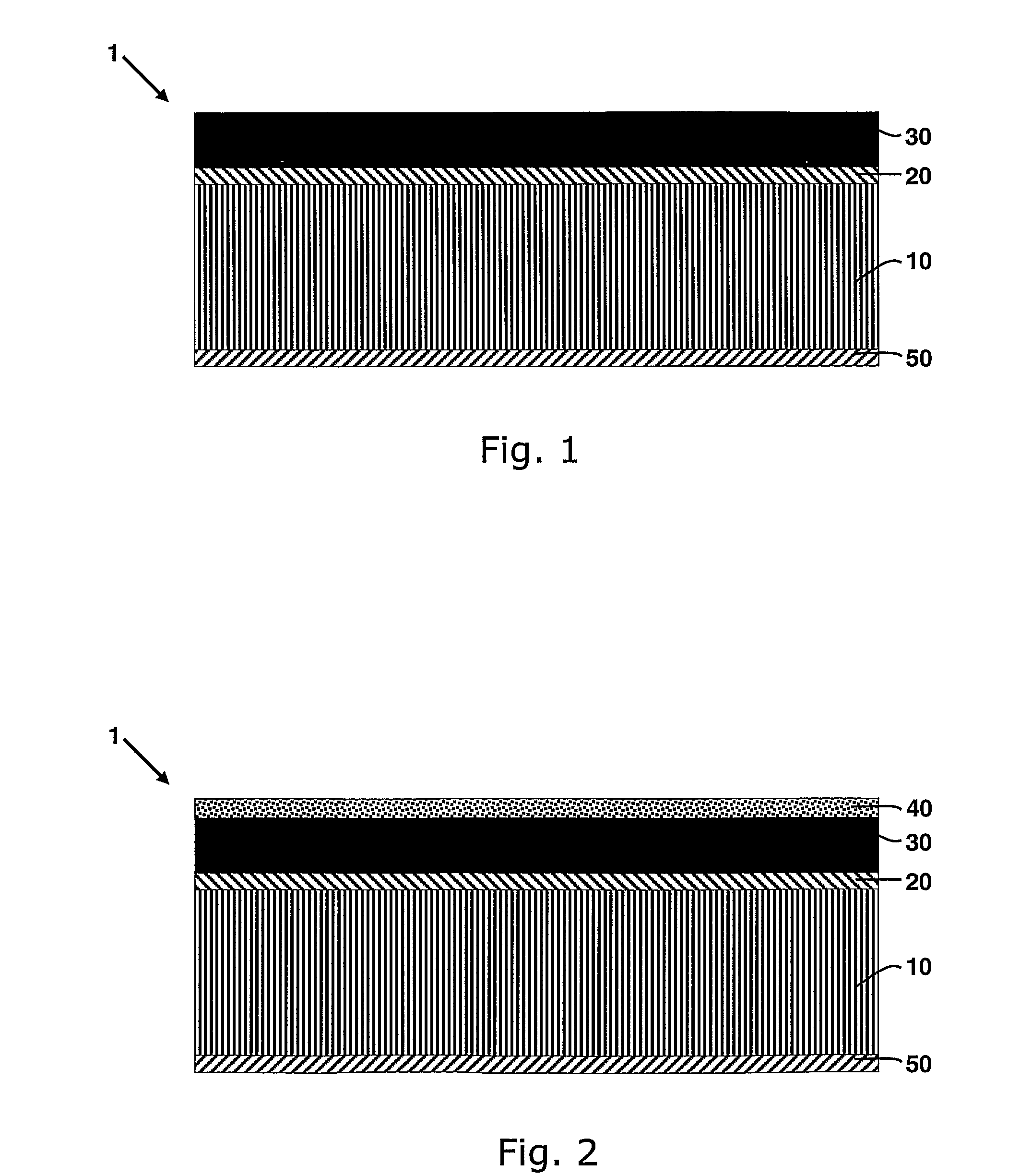

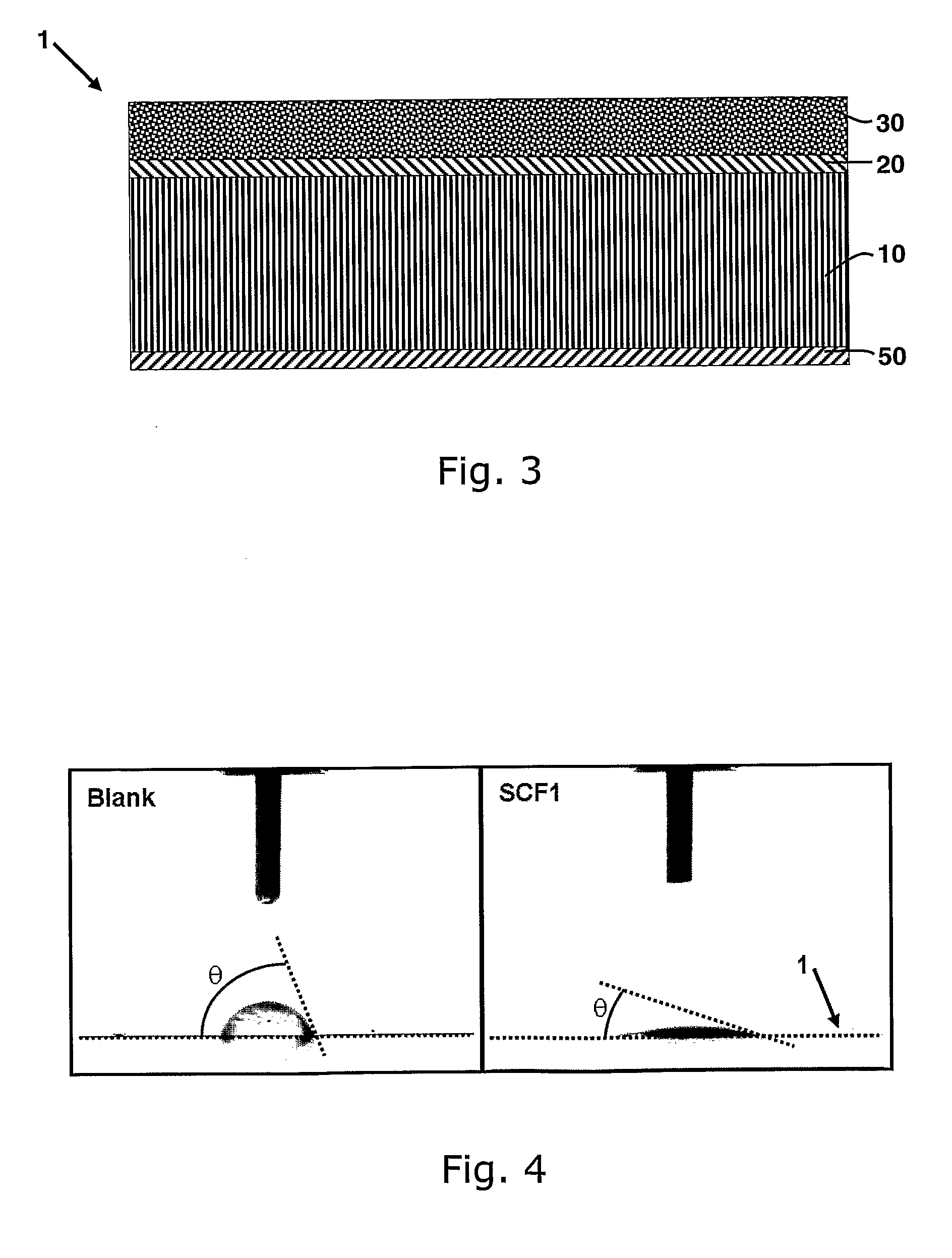

Photocatalytic boards or panels and a method of manufacturing thereof

InactiveUS20100297434A1Improve washing effectCleaner lookCovering/liningsSynthetic resin layered productsNanoparticleEngineering

A board or panel, having an upper surface, comprising a base and at least one layer overlaying said base, wherein at least one of said overlaying layers comprises first nanoparticles embedded in the layer such that the upper surface shows hydrophilic characteristics. Also described are methods for manufacturing such a panel or board, and compositions for use in such methods.

Owner:VAELINGE PHOTOCATALYTIC AB

Scratch resistant precoating film

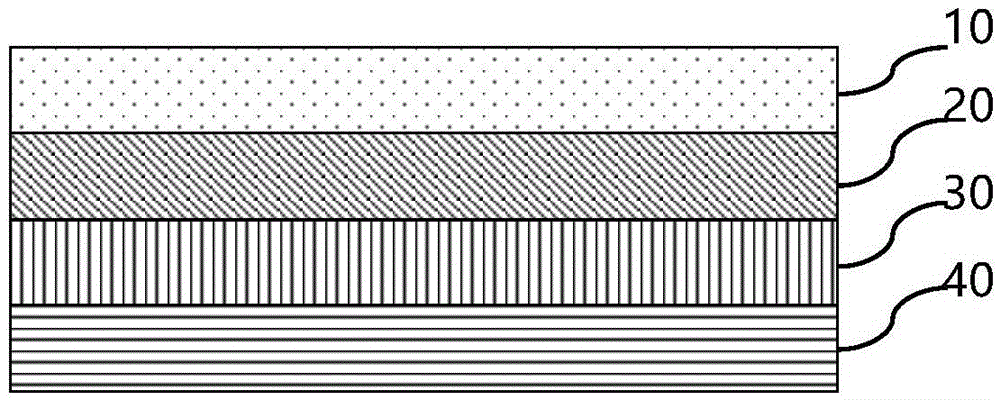

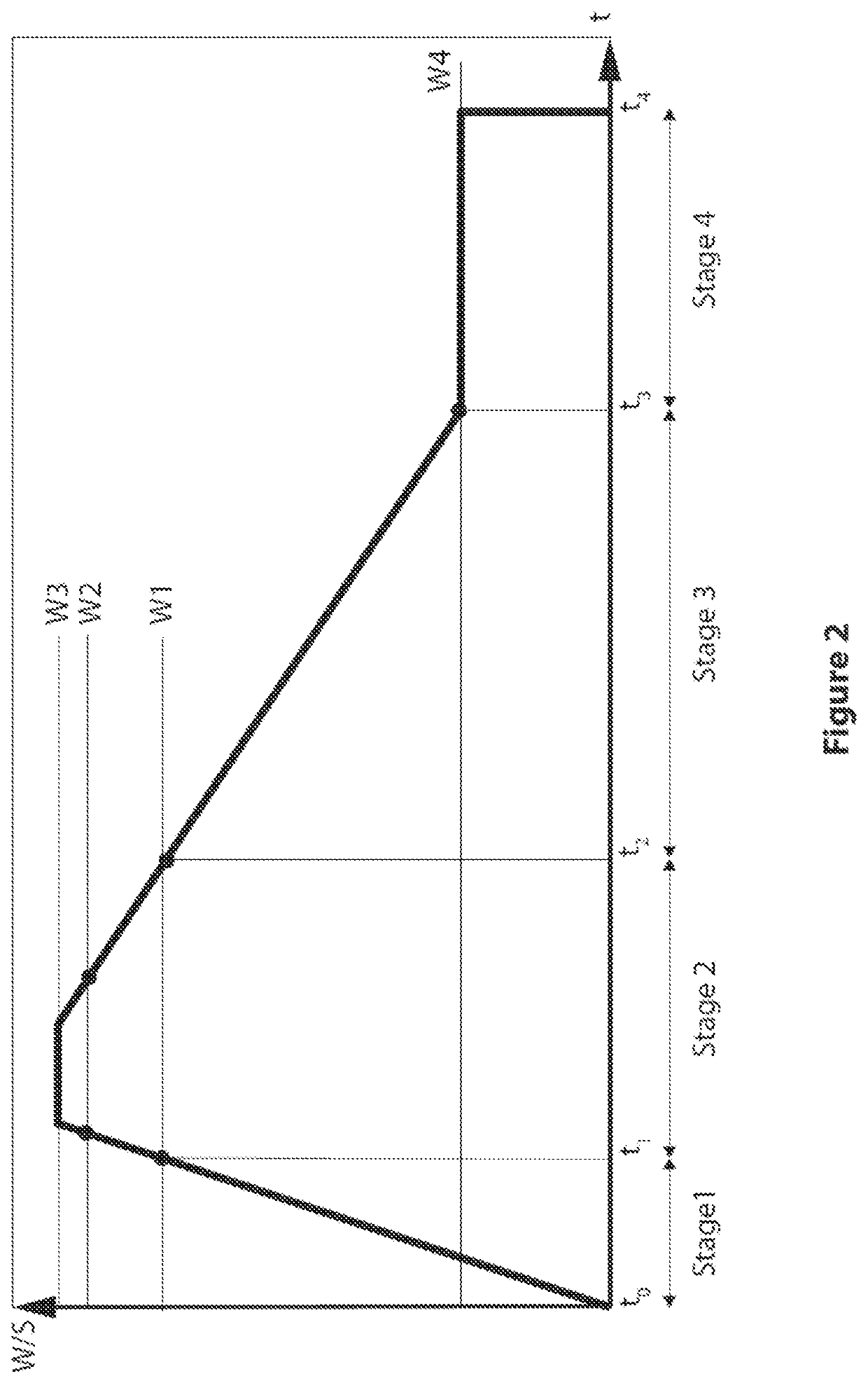

ActiveCN105482728ASimple processingEnergy savingFilm/foil adhesivesPolyurea/polyurethane coatingsFunctional TreatmentPolymer thin films

The invention provides a scratch resistant precoating film. The scratch resistant precoating film sequentially comprises a scratch resistant substrate layer, a color layer, a hot melt adhesive layer and a treatment layer from outside to inside, and the scratch resistant substrate layer is formed through coating the upper surface of a polymer film with a modified aqueous scratch-resistant coating liquid in an online coating mode. The aqueous scratch-resistant coating layer is coated in an online coating mode, so the polymer film functional treatment technology is simplified, energy is saved, and the product yield is improved.

Owner:张家港保税区康得菲尔实业有限公司

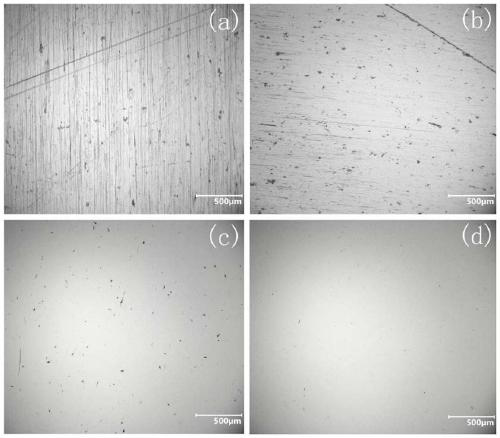

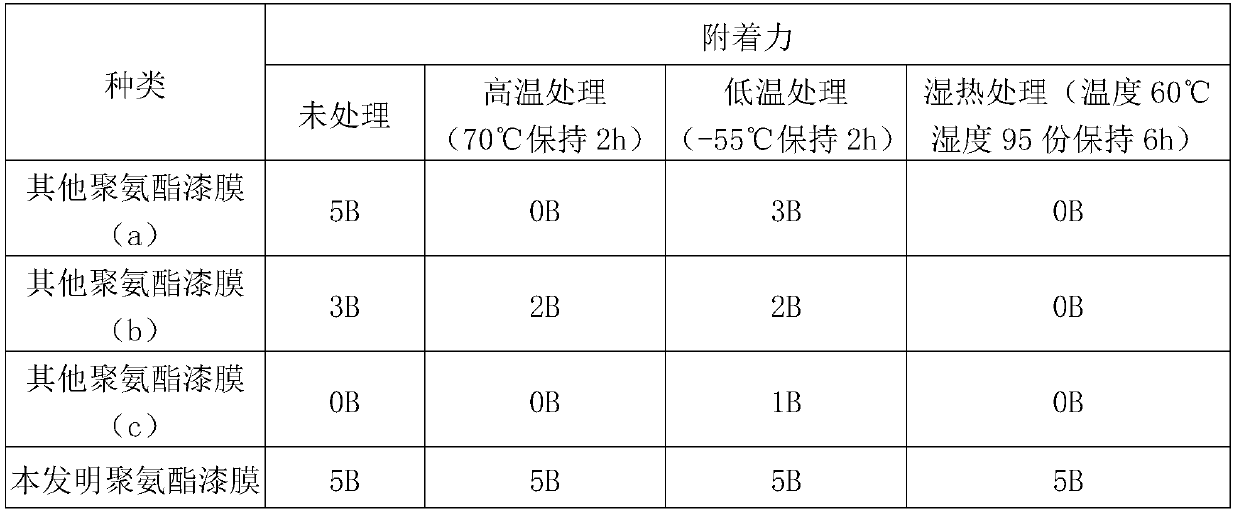

High-adhesion scratch-resistant wear-resistant polyurethane transparent coating material

ActiveCN111303754AImprove aging resistanceSmall particle sizeFireproof paintsPolyurea/polyurethane coatingsPolymer scienceSunscreen agents

The invention provides a high-adhesion scratch-resistant wear-resistant polyurethane transparent coating material, and relates to the technical field of coating materials. In the transparent coating material, the content of polyurethane soft segments ranges from 35% to 45%, and the polyurethane coating material is a two-component coating material and comprises a coating material agent A and a coating material agent B, wherein the coating material agent A comprises polyol, a chain extender, a catalyst, an adhesion promoter, a solvent, a leveling agent, a wetting agent and a sun-screening agent,and the coating material agent B is aliphatic diisocyanate. According to the invention, the polyurethane paint film has excellent mechanical properties and good resilience, and can significantly enhance the wear resistance and the scratch resistance of the polyurethane paint film, and after the paint film is scratched, scratches can be automatically repaired as before in a short time, so that theuse effect and protection effect of the product are improved, and good scratch resistance and wear resistance of the product are realized.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

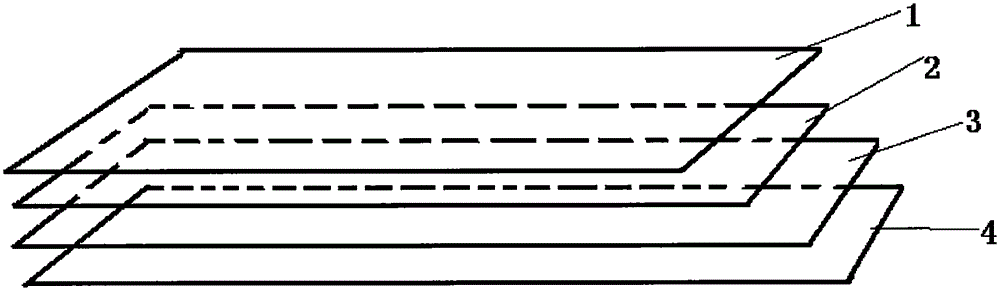

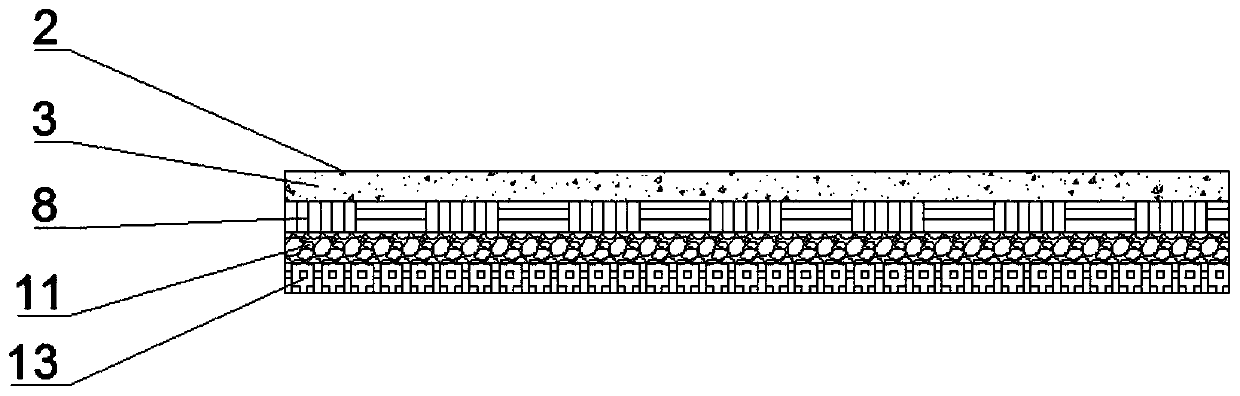

Novel and environmentally-friendly type wholly-TPU sports flooring and preparation method thereof

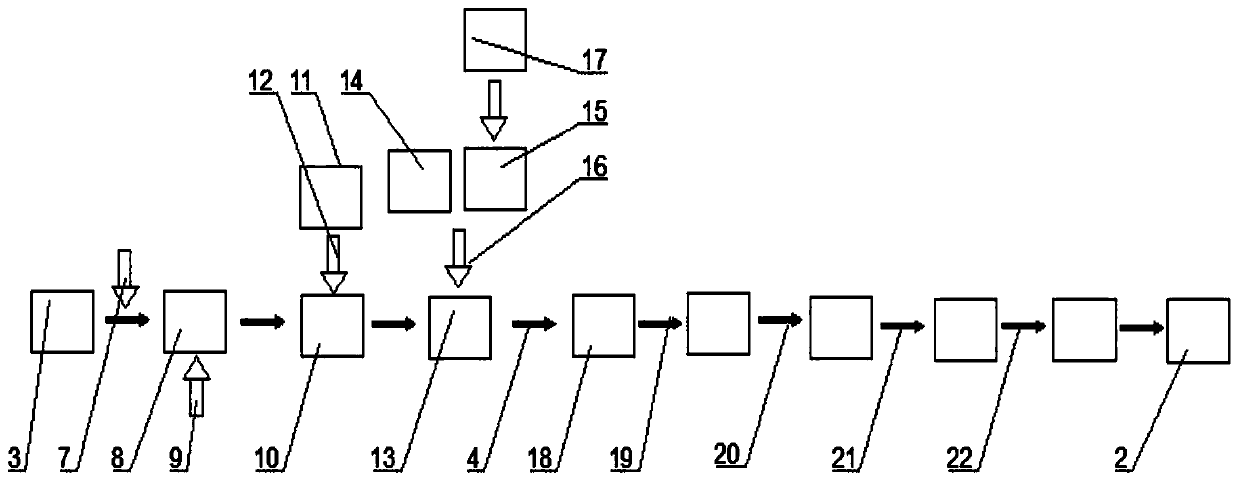

InactiveCN105275187AOvercome the technical problem of poor miscibilityIncrease wear resistance and scratch resistanceSynthetic resin layered productsGlass/slag layered productsGlass fiberCopper wire

The invention relates to a novel and environmentally-friendly type wholly-TPU sports flooring, which comprises a TPU environmentally-friendly and wear-resistant layer, a reinforcing layer closely adjacent to the TPU environmentally-friendly and wear-resistant layer, a TPU elastic buffer layer closely adjacent to the reinforcing layer, and an osculum type shading waterproof layer closely adjacent to the TPU elastic buffer layer. The reinforcing layer is in the form of a glass fiber layer, a fine copper wire layer, or a disorderly fiber layer. The tensile strength of the glass fiber layer is 5200-5500 MPa. The tensile strength of the fine copper wire layer or the disorderly fiber layer is 450-500 MPa. The novel and environmentally-friendly type wholly-TPU sports flooring is highly resistant to abrasion, resistant to scratching, highly flexible, easy to recover, environmentally-friendly, and gentle in hand feeling.

Owner:LONGHAI AOYI SPORTS GOODS CO LTD

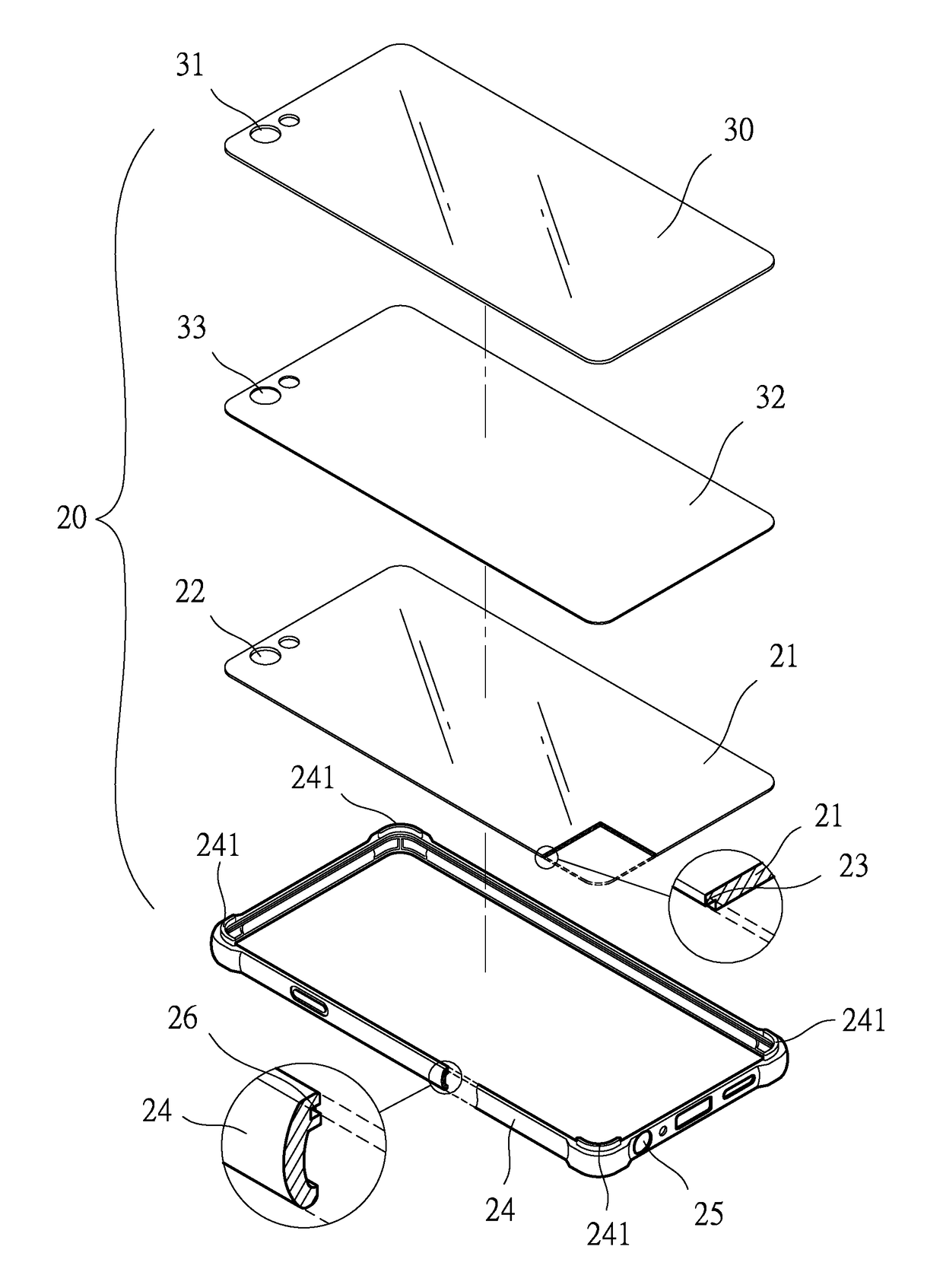

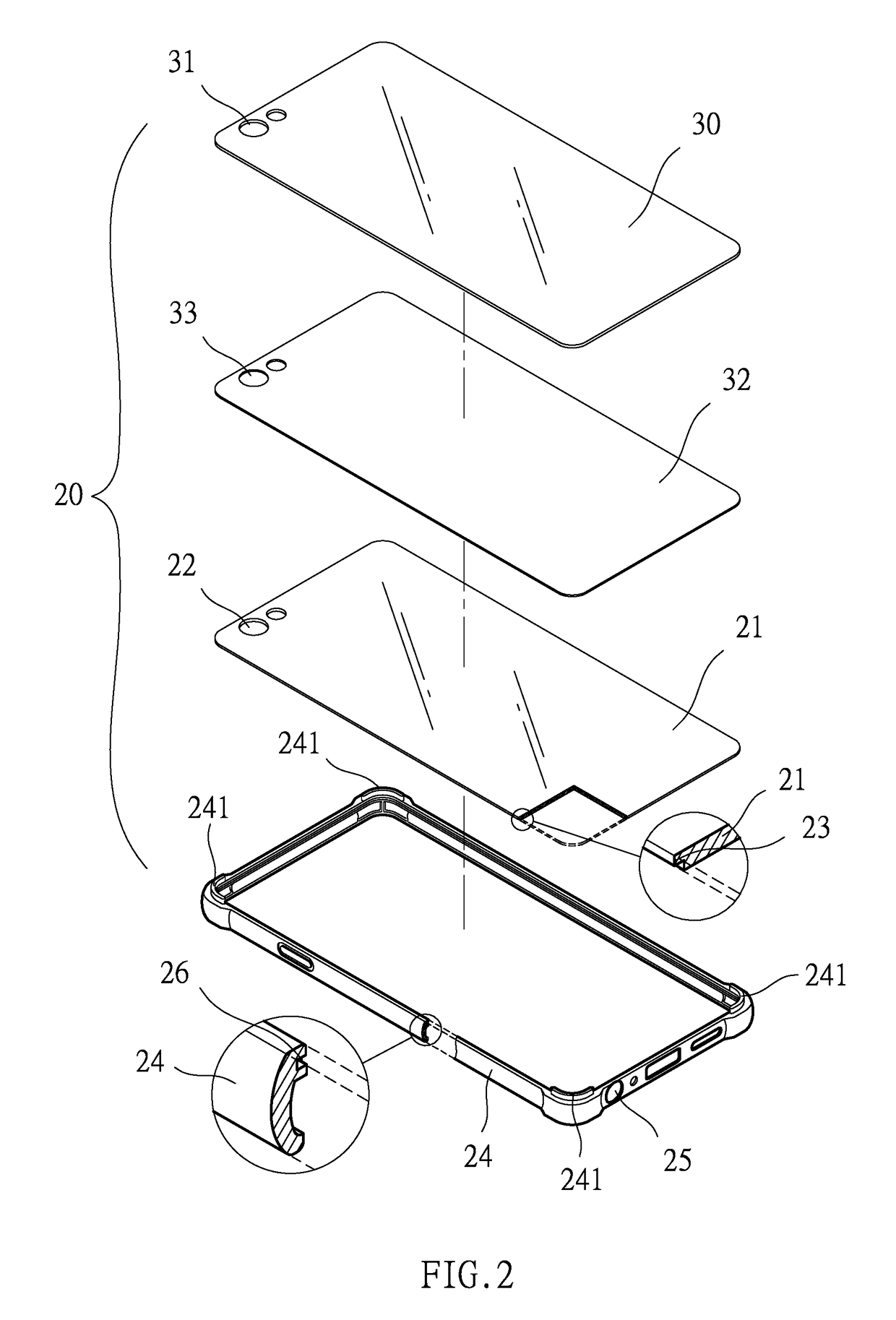

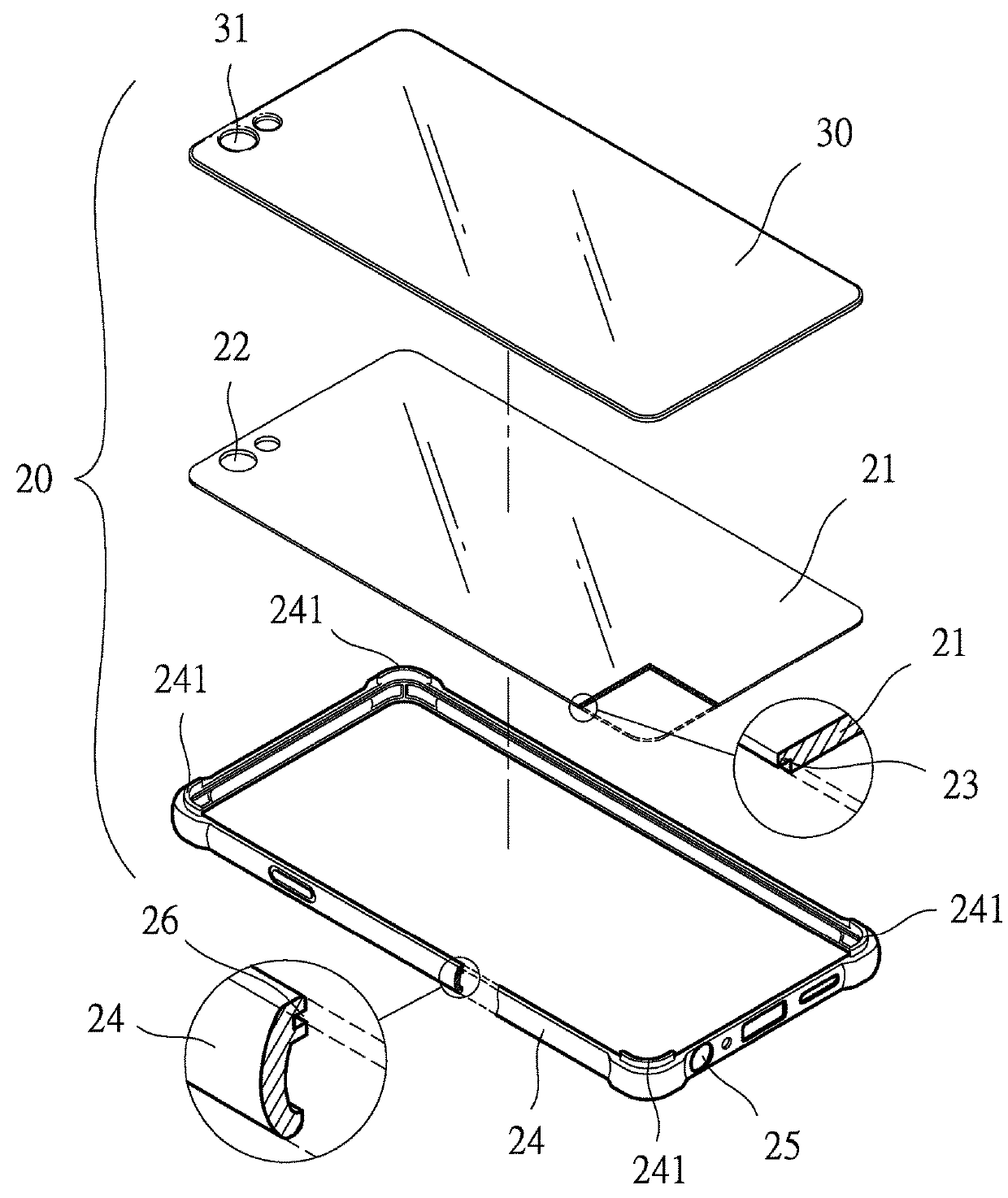

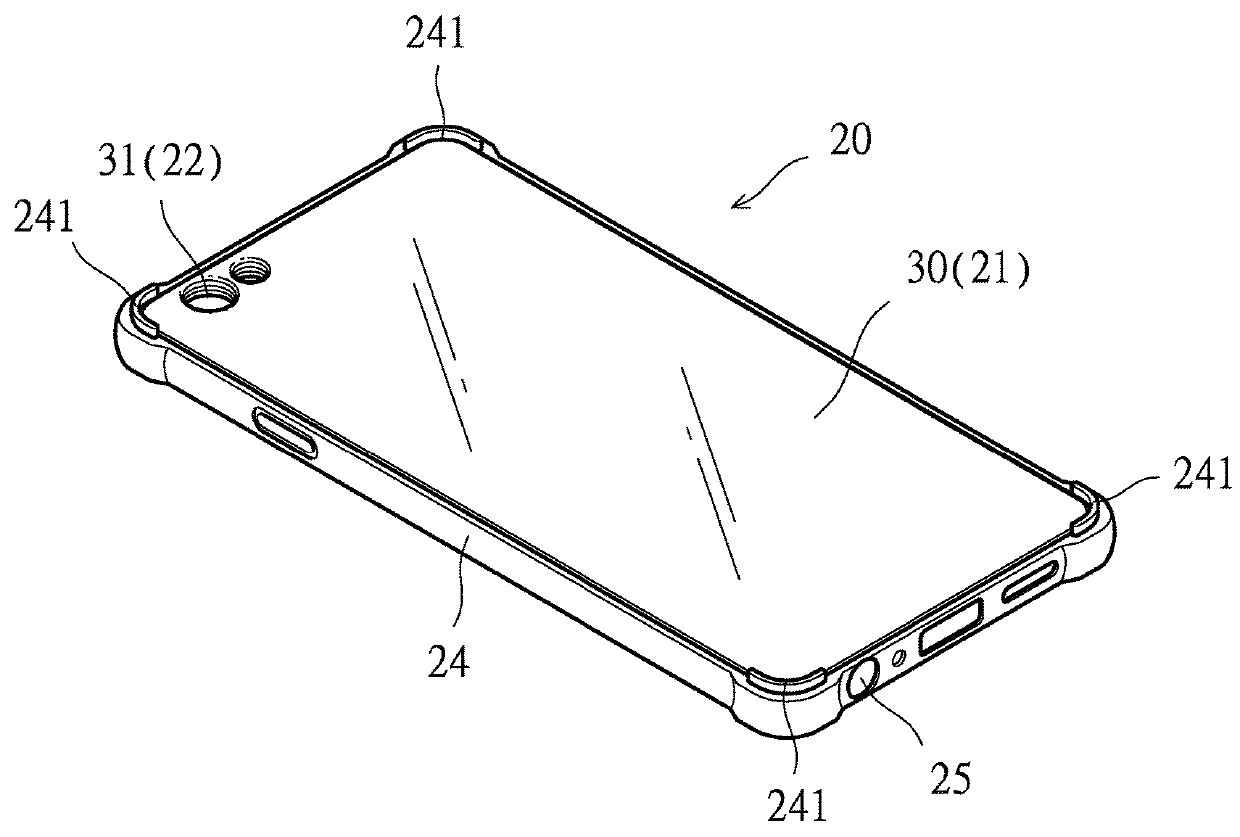

Protective Case for Portable Electronic Device

InactiveUS20180289122A1Increase wear resistance and scratch resistanceQuality improvementLuggageOther accessoriesEngineeringProtection KIT

A protective case for a portable electronic device includes a hard bottom plate, having at least one hole and a flange around a periphery thereof; a soft frame, connected to the bottom plate and having at least one through hole; an inner peripheral edge of the frame being provided with an engaging groove, the flange being engaged in the engaging groove, the frame cooperating with the bottom plate to form an accommodation space for receiving the portable electronic device, a face of the bottom plate, opposite to the accommodation space, cooperating with the frame to form an accommodation trough; a glass substrate, corresponding in shape to the accommodation trough; and a plastic film, disposed between the bottom plate and the glass substrate, the glass substrate and the plastic film being bonded together and disposed in the accommodation trough. Thereby, the glass substrate may increase the scratch resistance of the back of the protective case and may be provided with a color, a pattern or a character to enhance the quality of the protective case.

Owner:LIN CHIA HAO

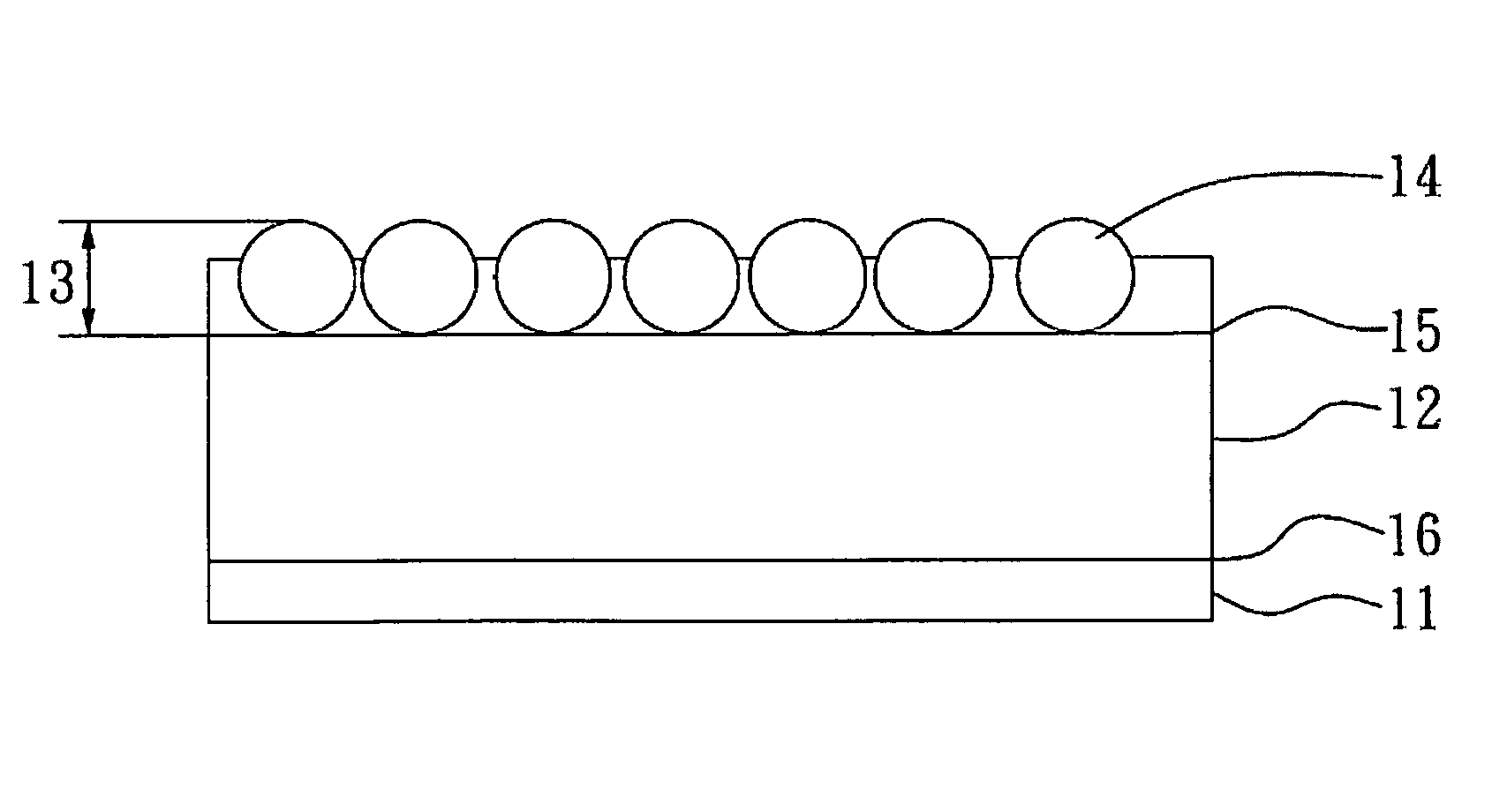

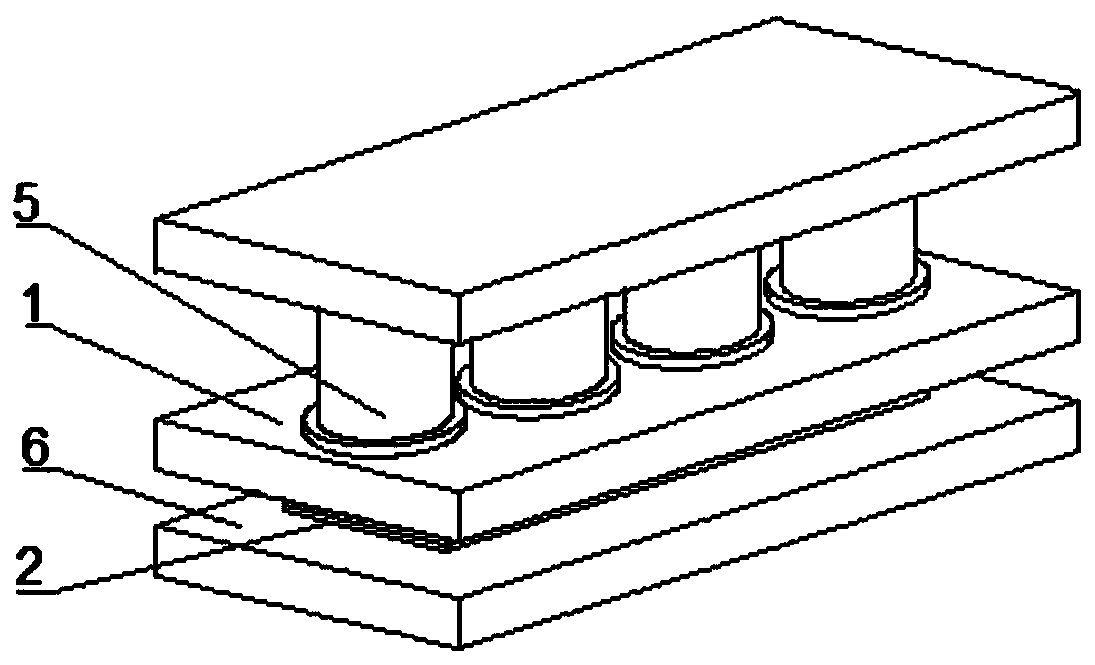

PVC composite floor board

InactiveCN106499152AIncrease wear resistance and scratch resistanceWear-resistantLamination ancillary operationsLayered product treatmentHot-melt adhesiveAluminium oxide

The invention relates to a PVC composite floor board. The board comprises a PVC base material and a decoration board hot-pressed with aluminum oxide on the surface. A method of producing the board is also provided, and comprises the steps of laminating the PVC base material and the decoration board hot-pressed with aluminum oxide on the surface through hot melt adhesive. The board has the advantages of being good in anti-friction properties, having prominently enhanced anti-indentation property, and being especially good in compression stability.

Owner:肖文辉

Preparation method for corrosion-resistant and flame retardant crude wood

InactiveCN103817755AImprove stabilityImprove water and corrosion resistanceWood treatment detailsPressure impregnationVacuum pressurePreservative

The invention belongs to the field of decorative materials, and discloses a preparation method for corrosion-resistant and flame retardant crude wood. The method is characterized by comprising the flowing steps: firstly, preparing a fire-retardant preservative; secondly, performing vacuum pressure dipping processing on wood, so as to ensure that the wood absorbs the fire-retardant preservative; thirdly, drying the wood subjected to dipping processing through a gradual warming gradient drying method till the water content of the wood is 8 to 12 percent. The crude wood is subjected to corrosion resistant and flame retardant processing, the stability is enhanced, the wood has low possibility of deformation and cracking, and simultaneously the wood has capacities of flame retardance, mould resistance and corrosion prevention; the waterproof and corrosion-resistant performance, the wear-resisting and scratch-resistant performance, and the chemical resistance of the crude wood are improved; glossiness is high and the durability of the crude wood is improved.

Owner:YIXING LION KING TIMBER IND

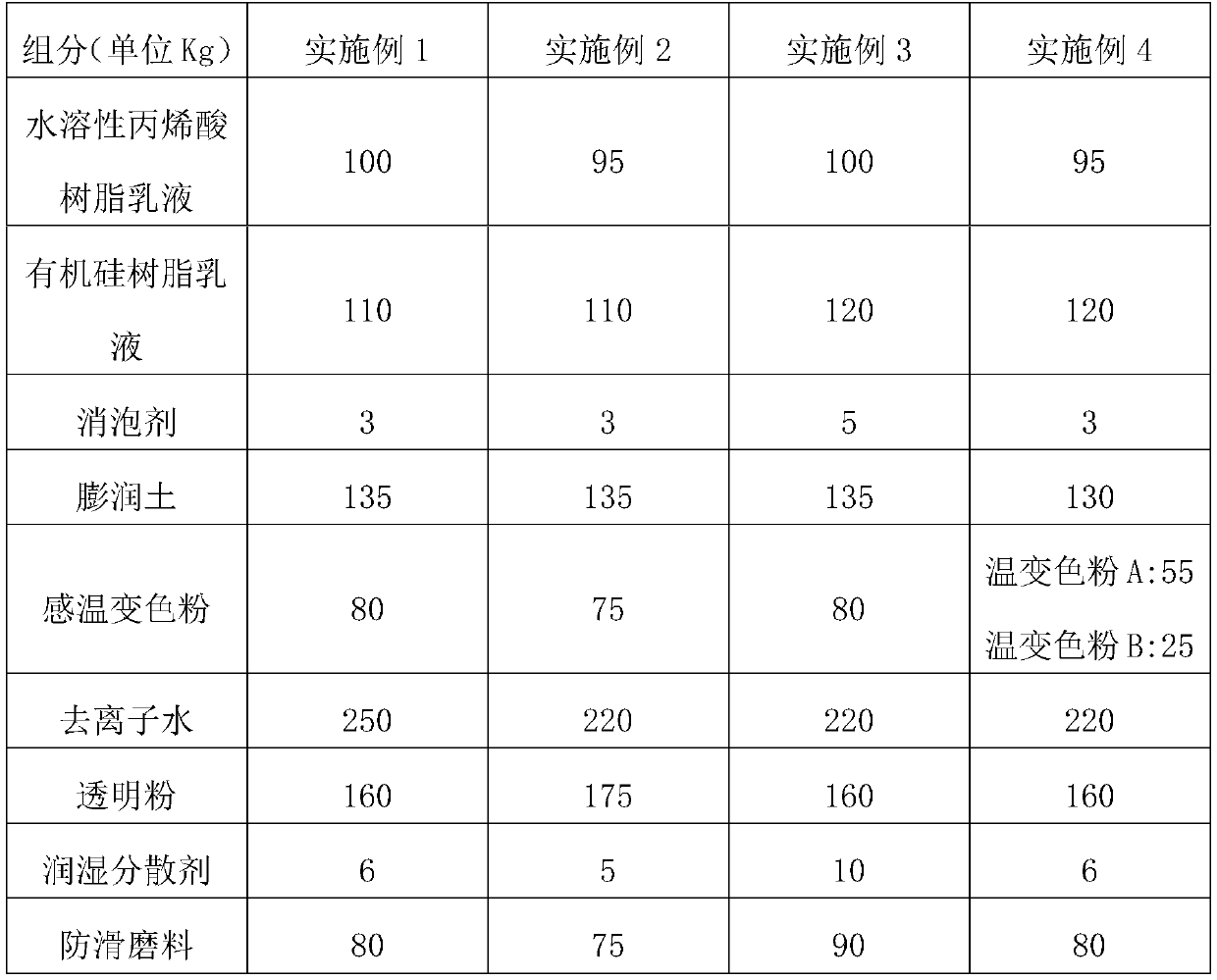

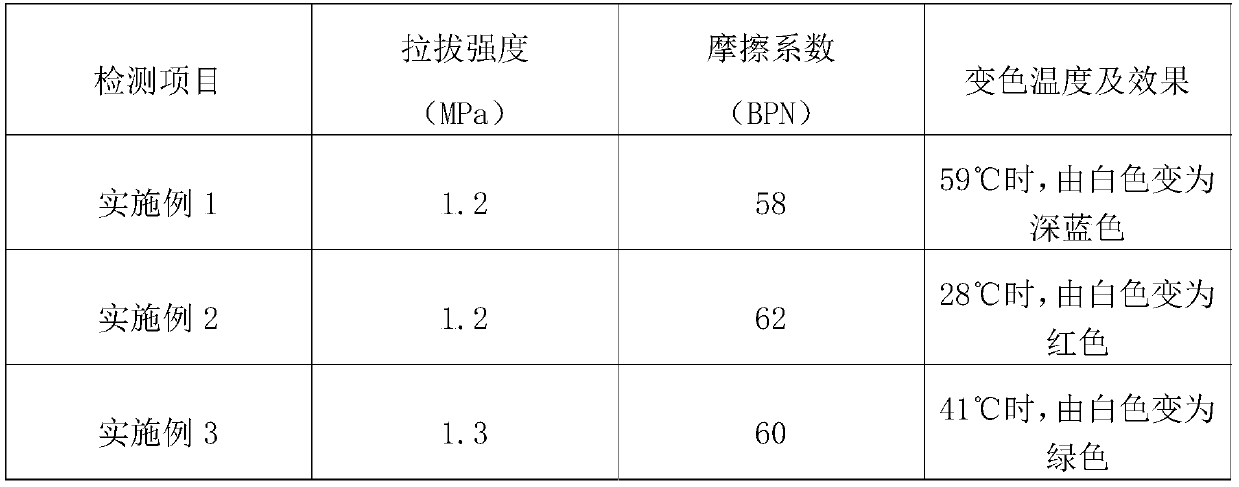

Reversible thermochromic pavement coating and preparation method thereof

InactiveCN110330831ARich in colorPlay a high temperature warning effectThermosensitive paintsEmulsionAcrylic resin

The invention relates to the technical field of road traffic, and particularly discloses a reversible thermochromic pavement coating and a preparation method thereof. The reversible thermochromic pavement coating comprises, by mass, 95-100 parts of a water-soluble acrylic resin emulsion, 110-120 parts of a silicone resin emulsion, 3-5 parts of an antifoaming agent, 120-135 parts of bentonite, 75-80 parts of a thermochromic powder and 220-250 parts of deionized water. The reversible thermochromic pavement coating can alert the temperature.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Outer shell and preparation method thereof

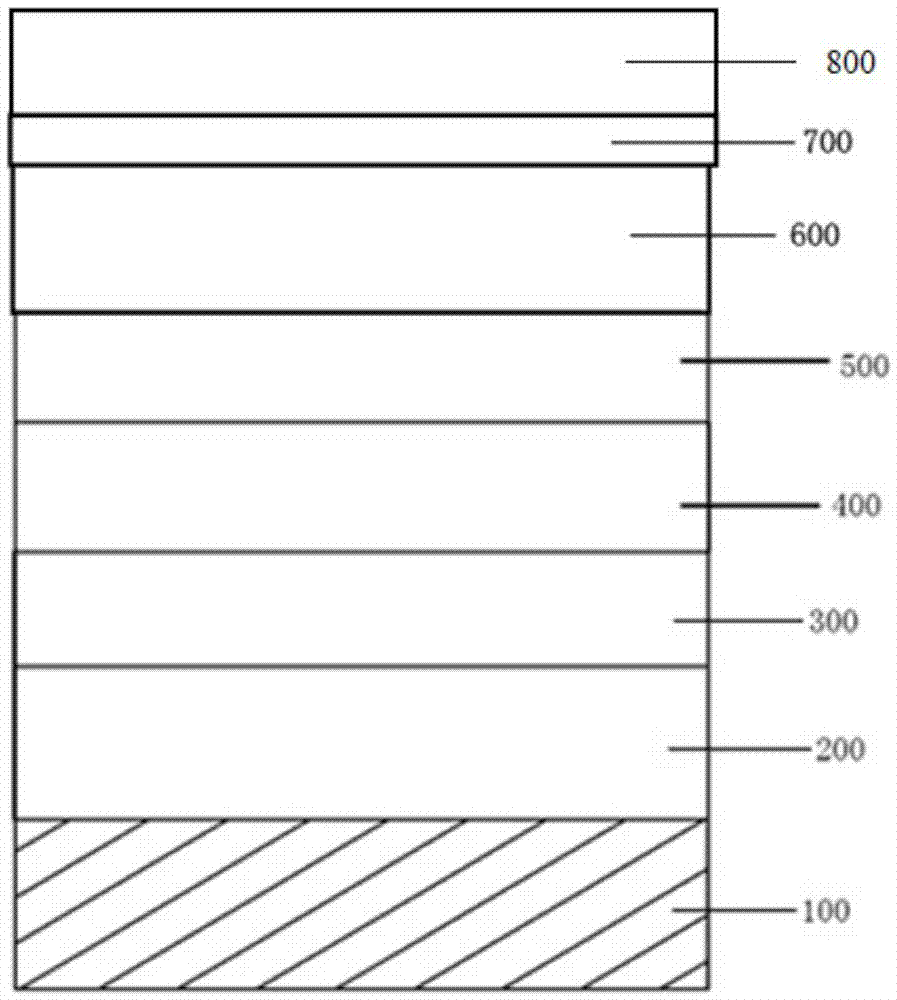

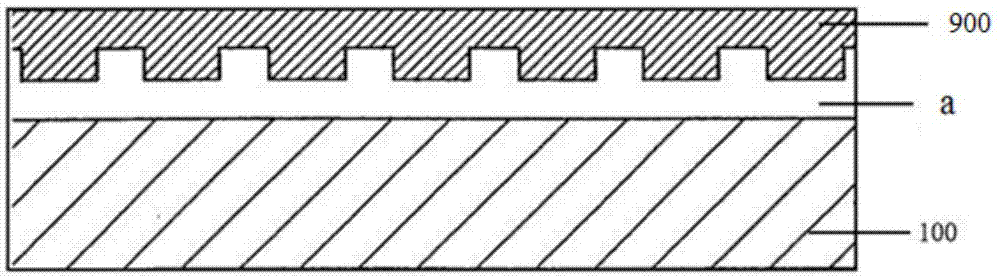

ActiveCN106817859AProtect HighlightsIncrease wear resistance and scratch resistanceSpecial ornamental structuresElectrical apparatus casings/cabinets/drawersPolymer sciencePolymer

The invention discloses an outer shell, which is characterized by comprising a shell body, a first polymer, a second polymer and a gold foil layer, wherein the shell body comprises a first surface and a second surface arranged opposite to the first surface; the first polymer is located on the first surface of the shell body, and one side, away from the shell body, of the first polymer is provided with a graphic structure or a textured structure, thereby forming a first structural layer; the second polymer is formed on the side, away from the shell body, of the first polymer; and the gold foil layer is positioned between the first polymer and the second polymer. According to the outer shell and the preparation method thereof, the surface of a product produces different texture effects, the stereo feeling and layering feeling are strong, the surface effect is rich and beautiful, the glossiness and flatness of the product surface are good, and the service life of the product is long.

Owner:SHINE OPTOELECTRONICS KUNSHAN CO LTD +1

High-strength modified PC material

The invention relates to the technical field of PC materials, and particularly relates to a high-strength modified PC material. Raw materials of the material are calculated by weight and comprise 60-80 parts of PC resin, 4-8 parts of PMMA resin, 5-10 parts of ABS resin, 0.5-2 parts of an organosilicon additive, 2-4 parts of a methyl methacrylate-butadiene-styrene copolymer, 2-4 parts of a flexibilizer, 4-5 parts of an antioxidant, 3-6 parts of a flame retardant, 0.5-2 parts of a compatilizer, 2-4 parts of an anti-scratch auxiliary agent and 0.4-1 part of a lubricant. The high-strength modifiedPC material provided by the invention has good toughness, flame retardancy, wear resistance and scratch resistance, meets the application conditions of the PC material, and has greatly improved performance than a PC material.

Owner:宁波速派电器有限公司

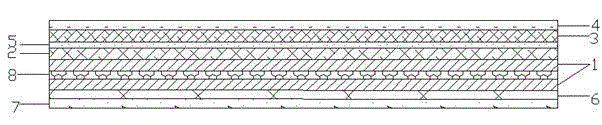

High-definition rainbow-free scratch-proof PC material protective film and preparation method thereof

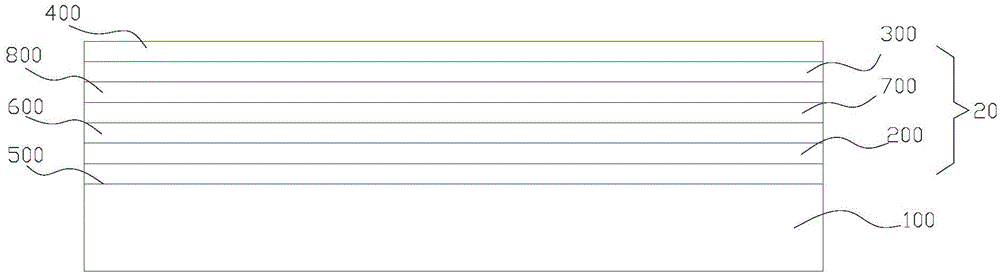

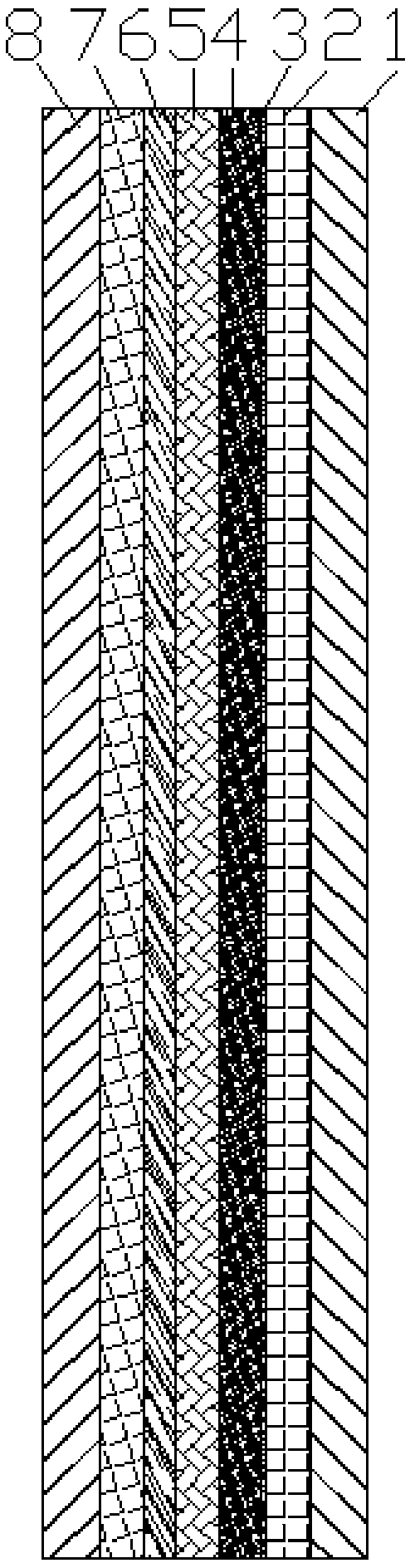

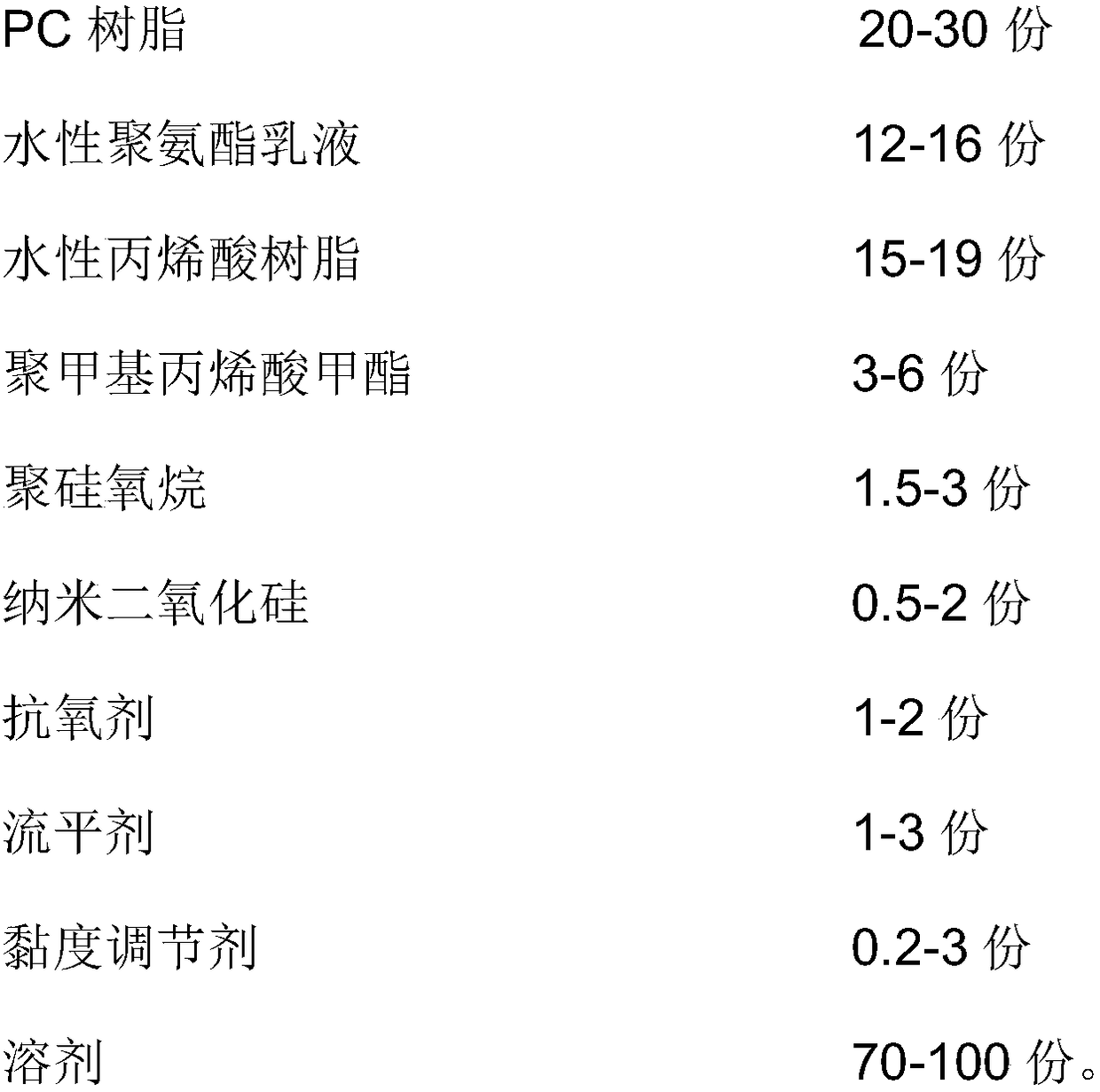

ActiveCN109130349AUniform layer distributionReduce reflectionLamination ancillary operationsSynthetic resin layered productsTectorial membraneRainbow

The invention discloses a high-definition rainbow-free scratch-proof PC material protective film. The film sequentially includes an upper protective layer, an upper glue layer, an antireflective layer, a scratch-proof layer, a PC film layer, a lower glue layer, a release glue layer and a release layer from the outside to the inside. The scratch-proof layer is formed by coating a scratch-proof coating agent. The scratch-proof coating agent includes the following raw materials, by weight, 20-30 parts of PC resin, 12-16 parts of water-borne polyurethane, 15-19 parts of waterborne acrylic resin, 3-6 parts of polymethyl methacrylate, 1.5-3 parts of polysiloxane, 0.5-2 parts of nano silicon dioxide, 1-2 parts of antioxidant, 1-3 parts of leveling agent, 0.2-3 parts of viscosity regulator and 70-100 parts of solvent. According to the defects that the PC has no scratch resistance, high transparency and uneven thickness and rainbows easily occur, the two problems are solved through even coatingand film coating, and the application value of the PC protective film is improved.

Owner:浙江欣麟新材料技术有限公司

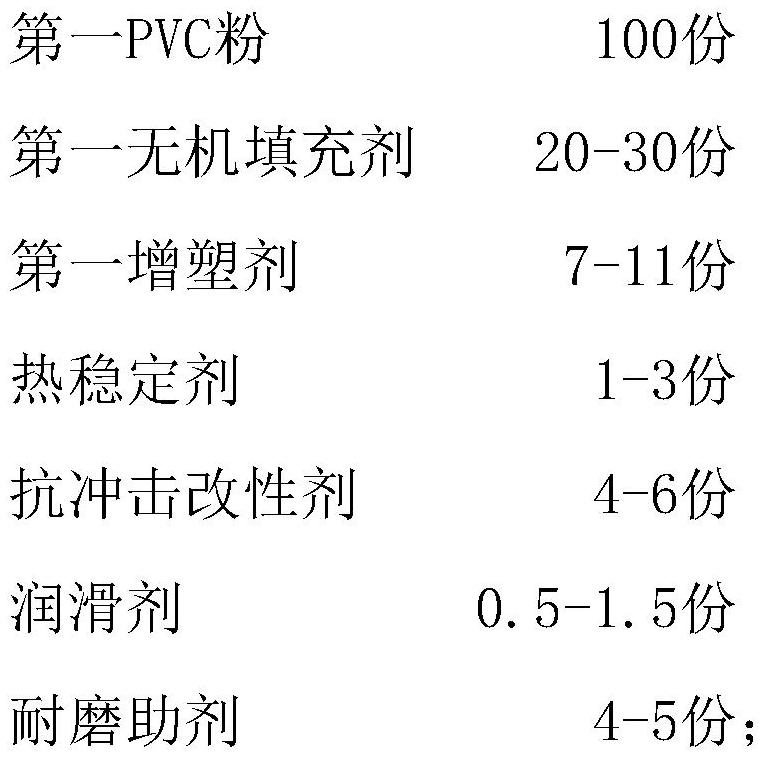

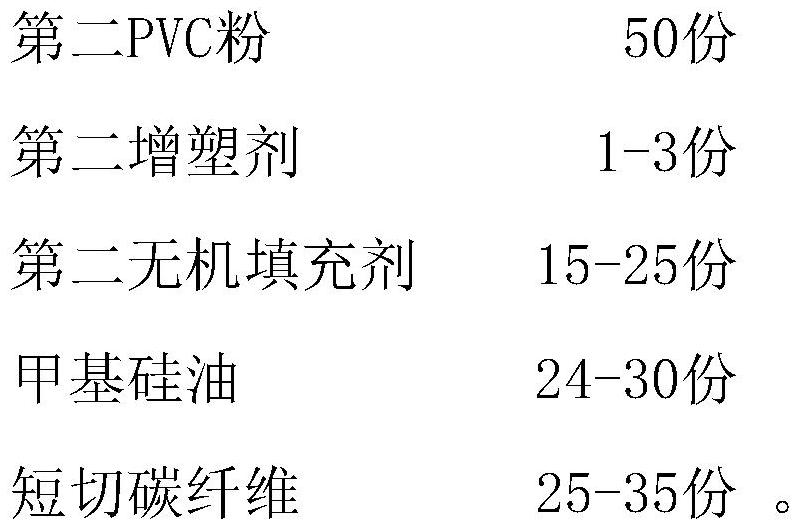

PVC high-wear-resistance edge strip and preparation method thereof

The invention relates to the technical field of PVC edge sealing strips, in particular to a PVC high-wear-resistance edge sealing strip and a preparation method thereof. The PVC high-wear-resistance edge sealing strip comprises PVC, a filler, a plasticizer, a heat stabilizer, an impact modifier, a lubricant and a wear-resistant additive, and the wear-resistant additive comprises PVC, a plasticizer, a filler, methyl silicone oil and chopped carbon fibers. According to the invention, the compatibility of the chopped carbon fiber and the PVC material is greatly improved through the methyl silicone oil, and the wear-resistant auxiliary master batch is prepared and added into a formula system for secondary blending dispersion so that the precipitation phenomenon caused by poor dispersion and compatibility is avoided. Meanwhile, the scratch resistance and the wear resistance of the product can be obviously improved so that the phenomenon of surface scratches caused by poor wear resistance ofthe product in the turnover process is avoided, and the surface effect of the product and the customer experience are optimized.

Owner:SINOWOLF PLASTIC DEKOR

Technology for processing rainbow multi-color film sheet

InactiveCN107933055AEmission reductionGorgeous appearanceSynthetic resin layered productsLaminationRainbowAging resistance

The invention relates to the field of chemical engineering, in particular to a technology for processing a rainbow multi-color film sheet. The process comprises the following steps: 1, mixing and drying TPU (thermoplastic polyurethane) raw materials; 2, adding the TPU raw materials in the step 1 into casting equipment to make a cast film, wherein screw extrusion temperatures in the casting equipment are as follows: the temperature of a first feeding section is set as 170-185 DEG C; the temperature of a second compression section is set as 180-205 DEG C; the temperature of a third discharging section is set as 185-200 DEG C; the temperature of a die head is set as 180-195 DEG C; 3, bonding the cast film in the step 2 and the upper and lower surfaces of a rainbow film; 4, cooling and rolling. The invention aims to provide a processing technology for processing the rainbow multi-color film sheet capable of realizing direct online lamination and improving the production efficiency. The rainbow multi-color film sheet prepared by the technology has excellent wear resistance, scratch resistance, low-temperature resistance and aging resistance, the experience effect of a user is increased,and economic benefits are increased.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD +1

Water-based chameleon solvent-resistant elastic coating

ActiveCN109836988AImprove scratch resistanceHigh elongationPolyurea/polyurethane coatingsWater basedEnvironmental resistance

The invention provides a water-based chameleon solvent-resistant elastic coating, which comprises the following ingredients (by weight): 10-15 parts of deionized water, 40-60 parts of waterborne resin, 6-10 parts of chameleon pigment, 8-10 parts of a water-based curing agent, 2.5-5 parts of water-based matting powder, 0.3-0.5 part of a dispersant, 0.3-0.5 part of a wetting agent, 0.8-1.2 parts ofa leveling agent, 3-4 parts of a coalescing agent, 1-2 parts of a hand feeling agent, 1-2 parts of water-based wax, 0.1-0.3 part of an antifoaming agent, 0.1-0.3 part of a pH regulator, 0.2-0.4 part of a thickening agent, 2-3 parts of propylene glycol methyl ether acetate, and 1-3 parts of DB7650 special modified polyurethane. The coating is safe and environmentally-friendly, and has good solventresistance, film fullness, scratch resistance and wear resistance. In addition, hand feeling and application property are also greatly enhanced.

Owner:湖北双键精细化工有限公司

Scratch-resistant optical film having organic particles with highly uniform particle size

ActiveUS8110278B2Avoid impairmentIncrease brightnessPrismsDiffusing elementsDiffusion layerParticle-size distribution

The subject invention relates to a scratch-resistant optical film, which comprises:(a) a transparent substrate having a first surface and a second surface;(b) a diffusion layer on the first surface of the substrate, which has a convex-concave structure and is comprised of a first hard coat layer comprising organic particles;(c) a scratch-resistant layer on the second surface of the substrate, which is comprised of a second hard coat layer;wherein the organic particles in the first hard coat layer are formed from a polyacrylate resin which comprises at least one multi-functional acrylate monomer as polymerization units, said multi-functional acrylate monomer being in an amount from 30 to 70 wt % based on the total weight of the monomer used, and wherein the organic particles have a single mean particle size and have a particle size distribution in the range within about ±5% of the mean particle size.

Owner:ETERNAL MATERIALS CO LTD

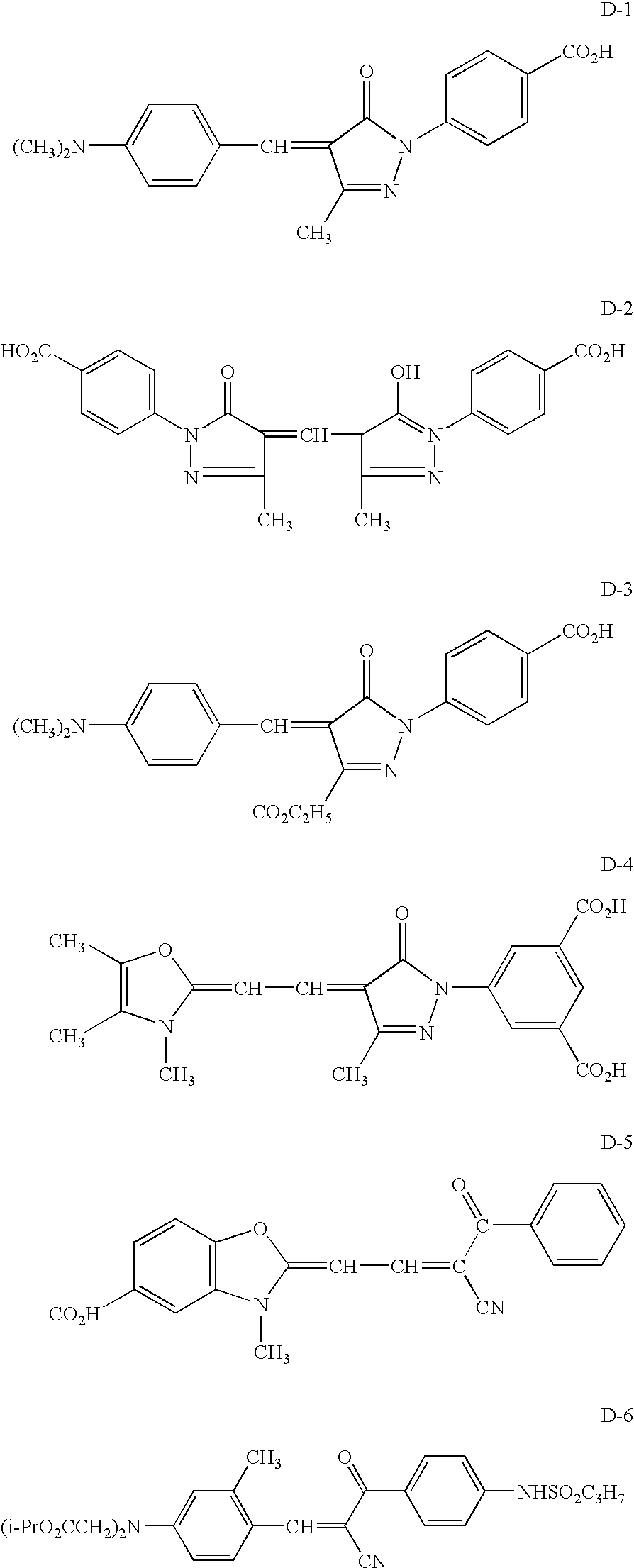

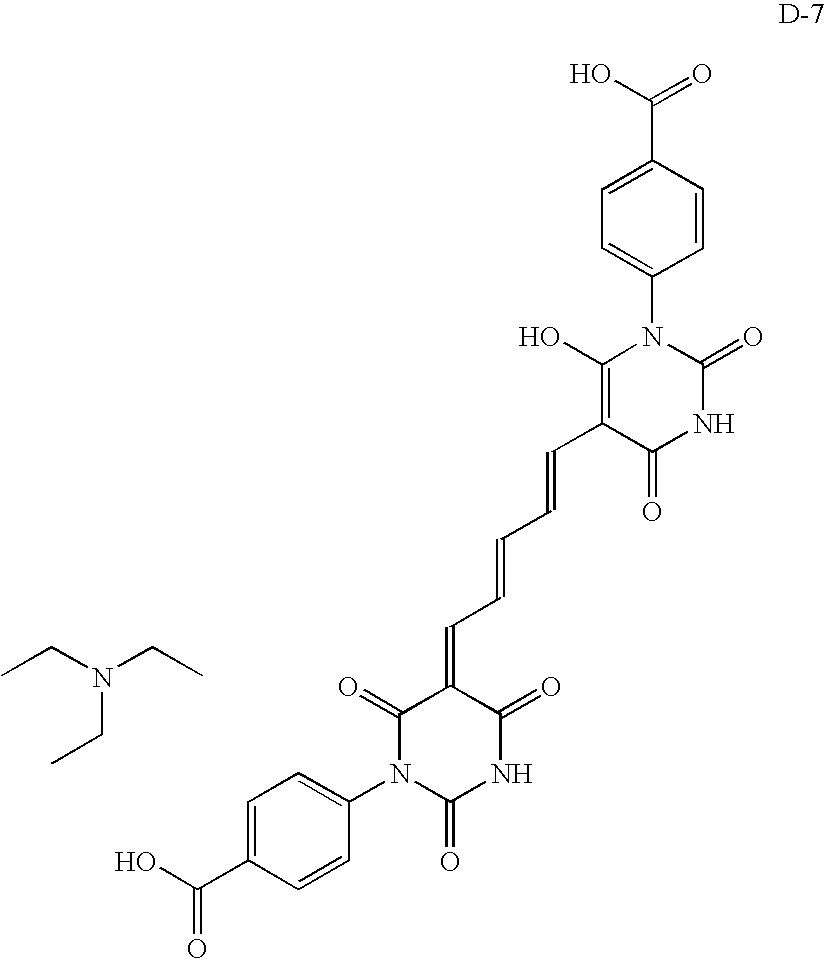

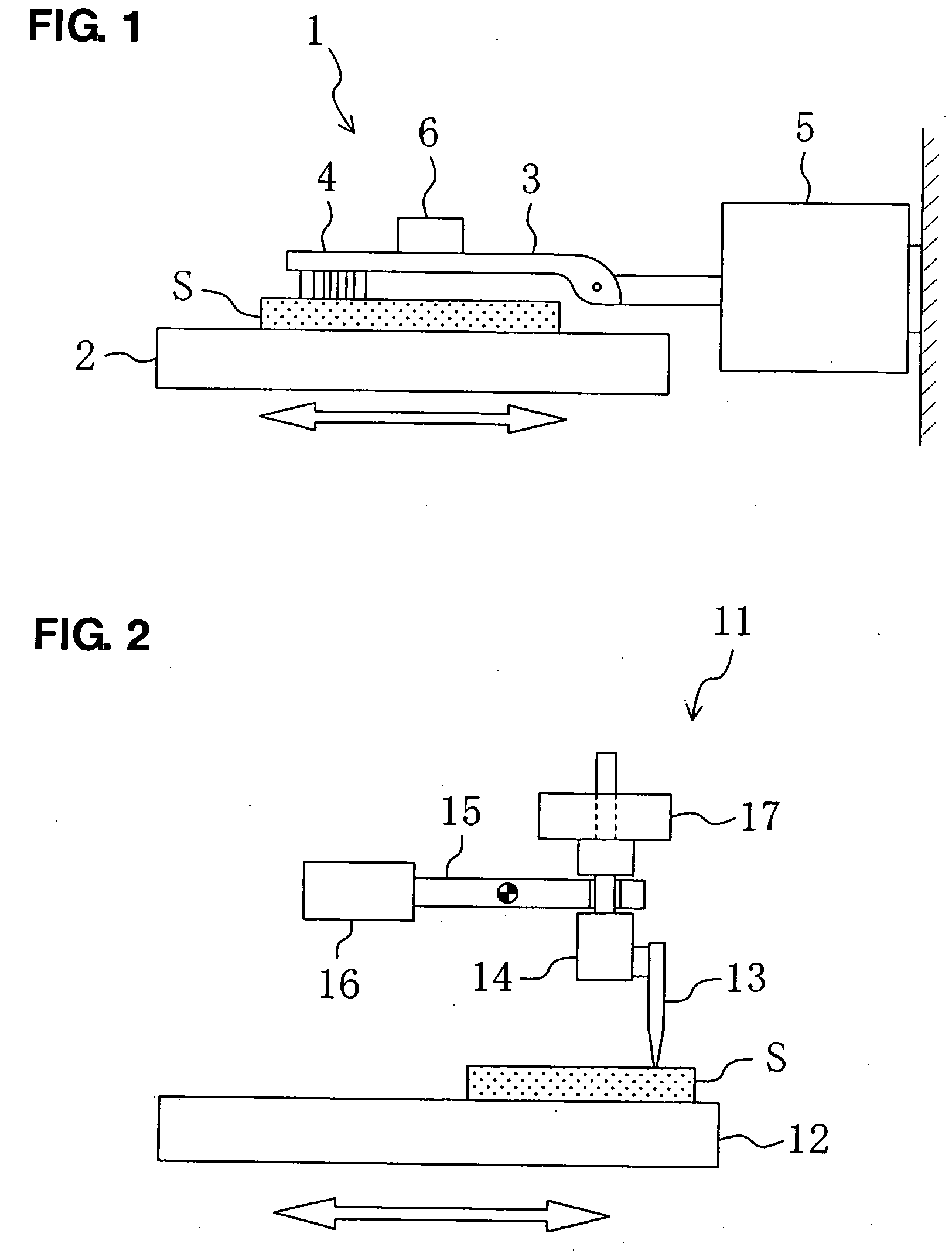

Highly lubricated imaging element with elastomeric matte

InactiveUS6913874B2Good workmanshipIncrease wear resistance and scratch resistanceRadiation applicationsMulticolor photographic processingElastomerMicrometer

A photographic imaging element is disclosed comprising a support having on a front side thereof a silver halide imaging layer and an outermost protective overcoat layer comprising a film-forming binder, and on the backside thereof an outermost protective backcoat layer comprising a film-forming binder; the protective overcoat and backcoat layers each comprising a lubricant present in an amount of at least 5 mg / m2 and permanent matting agent having a Tg of at least 40° C. and an average particle size of from about 0.5 to about 3 micrometers in an amount of at least 1 mg / m2; and at least one of the protective overcoat layer or the protective backcoat layer further comprising crosslinked elastomeric polymer matte particles, wherein the crosslinked elastomeric polymer matte particles have a Tg of 20° C. or less, an average particle size of at least 90% of or greater than that of the permanent matting agent particles having a Tg of at least 40° C. in the protective layer in which the crosslinked elastomeric matte is included, and are present in the protective overcoat layer or protective backcoat layer in an amount which is (i) at least 1 mg / m2 and (ii) less than the total level of permanent matting agent particles having a Tg of at least 40° C. in the protective overcoat and backcoat layers combined. Imaging elements comprising highly lubricated protective outermost layers in accordance with the invention advantageously provide increased scratch and wear resistance, while the presence of relatively low Tg crosslinked elastomeric matte particles in combination with higher Tg permanent matte particles has been found to increase the coefficient of friction of the layer in which they are included to provide good manufacturability of the imaging element while also maintaining wear and other desired film performance properties.

Owner:EASTMAN KODAK CO

Scratch-resistant functional pre-coated film with and preparation process thereof

InactiveCN108503876ASimple processIncrease wear resistance and scratch resistanceCoatingsPolymer scienceWear resistant

The invention discloses a scratch-resistant functional pre-coated film. The pre-coated film comprises a UV scratch-resistant resin coating, a film layer, a hot melt adhesive layer and a treatment layer arranged in sequence; the UV scratch-resistant resin coating is formed by coating the upper surface of a polymer film layer with a modified waterborne scratch-resistant coating liquid in an online coating way. Due to the adoption of the online coating way, the coating of a waterborne scratch-resistant coating is realized, the treatment process of polymer film functionalization is simplified, theenergy is saved, the finished product rate of the product can be increased, and the wear-resistant and scratch-resistant capacities of the surface treatment layer are improved.

Owner:重庆中膜复合材料有限公司

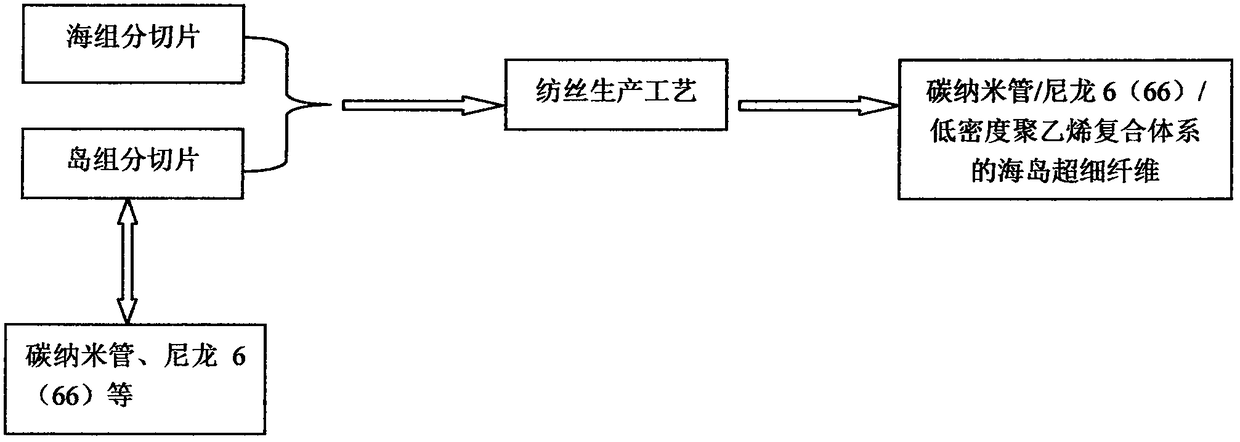

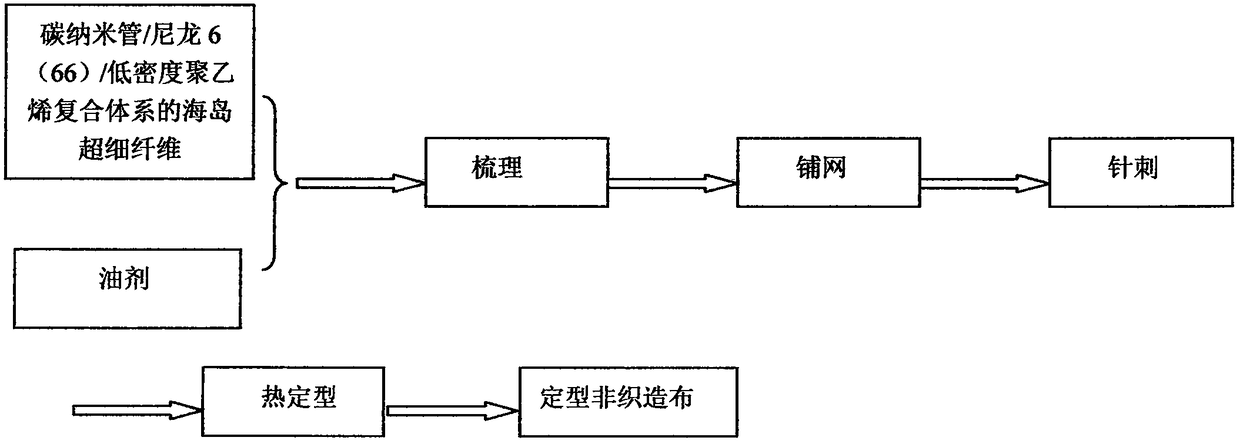

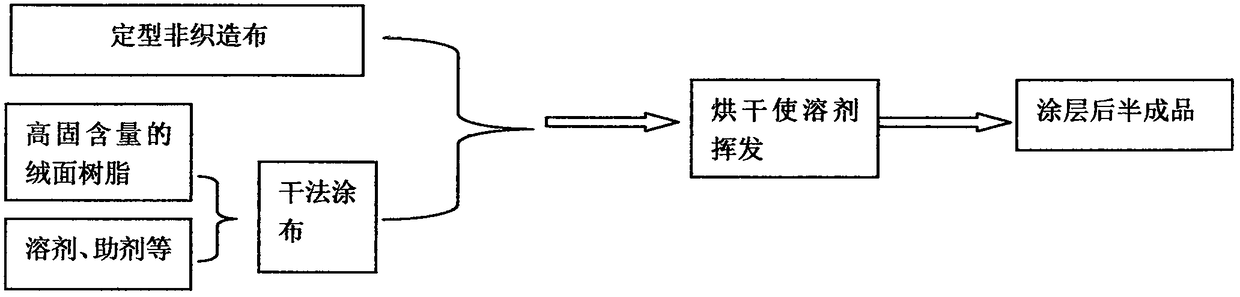

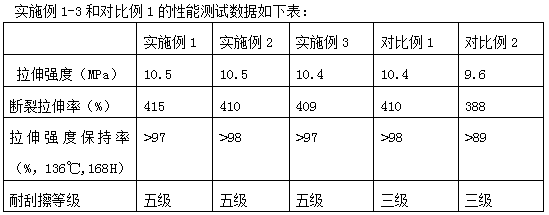

Method for processing suede ultrafine fiber synthetic leather with high scratch resistance and high wear resistance

PendingCN108951177AIncrease wear resistance and scratch resistanceReduce manufacturing costConjugated synthetic polymer artificial filamentsLow-density polyethyleneHigh resistance

The invention relates to a method for processing suede microfiber synthetic leather with high scratch resistance and high resistance. The method comprises the following steps: adding single-walled carbon nanotubes or multi-walled carbon nanotubes to nylon 6 (66) and polyethylene spinning solution, performing a solution blending process to prepare carbon nanotube / nylon 6 (66) / low density polyethylene composite system ultrafine fibers, coating the surface layer of an ultrafine fiber nonwoven fabric with a high-solid suede resin coating layer by a dry coating process, carrying out solvent volatilization to form dense and uniform resin cells in the surface layer of the nonwoven fabric, and performing impregnation, reduction and after-finishing processes to finally form the compact and uniformsuede ultrafine fiber synthetic leather with a low production cost and high physical properties.

Owner:ANAN CHINA

Halogen-free, anti-scratch, anti-abrasion and fireproof electric wire insulation material

InactiveCN107556688AImprove mechanical propertiesEasy to processPlastic/resin/waxes insulatorsPolypropyleneElectric cables

The invention relates to an insulation material of an electric wire or an electric cable. A halogen-free, anti-scratch, anti-abrasion and fireproof electric wire insulation material is prepared from the following components in percentage by mass: 15 to 25 percent of hydrogenated SEBS (Styrene-Ethylene-Butadiene-Styrene Block Copolymer), 5 to 15 percent of mineral oil, 5 to 15 percent of polypropylene, 5 to 15 percent of metallocene polyethylene, 5 to 10 percent of EPDM (Ethylene-Propylene-Diene Monomer) rubber, 15 to 25 percent of polyphenyl ether, 5 to 15 percent of diethyl aluminum phosphinate, 5 to 15 percent of melamine cyanurate, 1.5 to 2.0 percent of an anti-scratch agent, 0.1 to 0.3 percent of an anti-aging agent and 0.5 to 1.5 percent of a lubricating agent. According to the halogen-free, anti-scratch, anti-abrasion and fireproof electric wire insulation material disclosed by the invention, ceramic microbeads or grafted maleic anhydride is added as the anti-scratch agent, so that the scratch resistance and the abrasion resistance of the halogen-free, anti-scratch, anti-abrasion and fireproof electric wire insulation material are remarkably increased.

Owner:惠州市元塑高分子材料有限公司

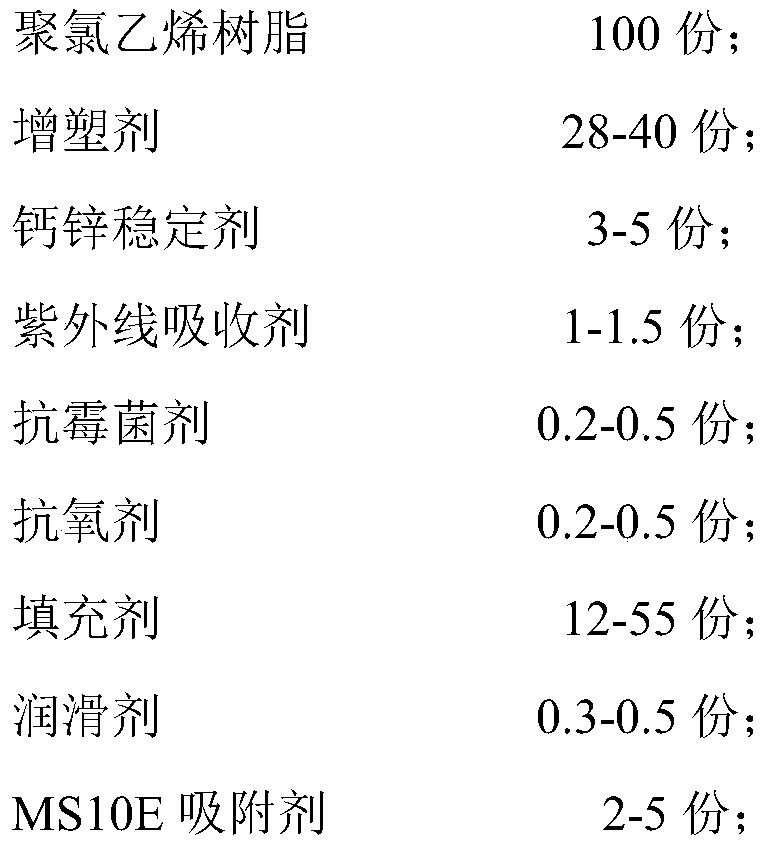

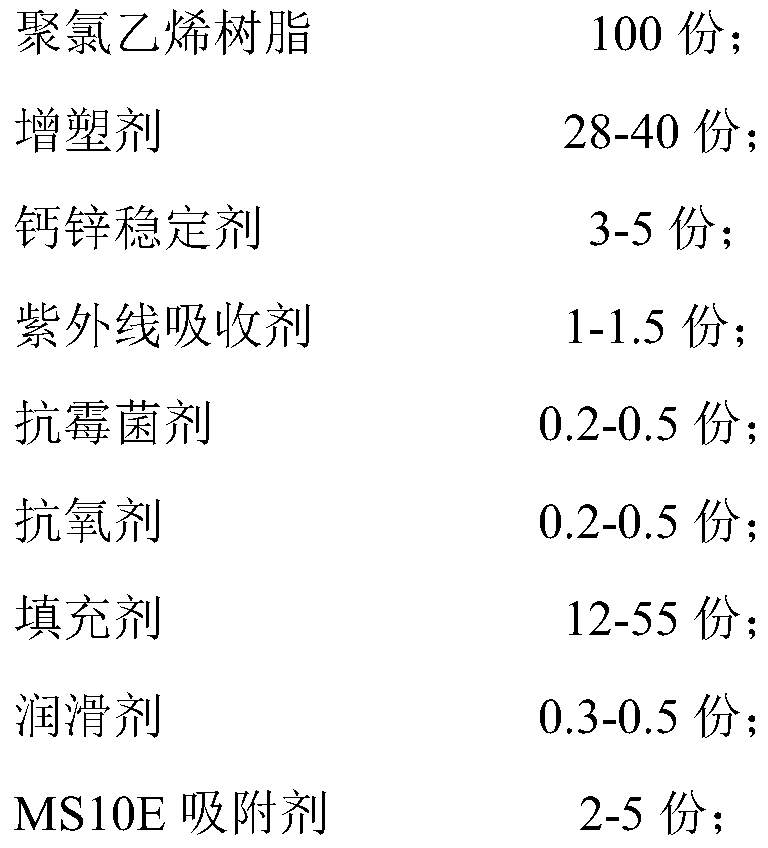

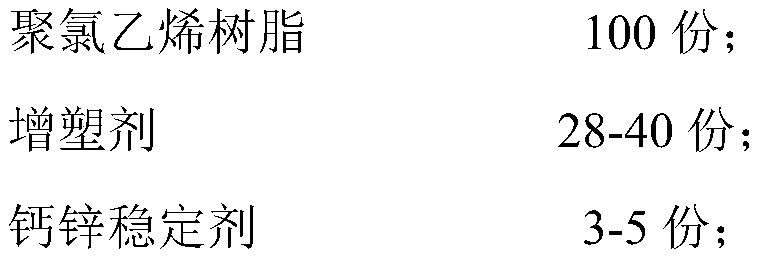

Environment-friendly PVC material for textilene dinner pad and preparation method of environment-friendly PVC material

PendingCN110437562AIncrease wear resistance and scratch resistanceSmall smellAntioxidantPolyvinyl chloride

The invention discloses an environment-friendly PVC material for a textilene dinner pad. The environment-friendly PVC material for the textilene dinner pad comprises the following components in partsby weight: 100 parts of polyvinyl chloride resin, 28-40 parts of a plasticizer, 3-5 parts of a calcium zinc stabilizer, 1-1.5 parts of an ultraviolet absorber, 0.2-0.5 part of an antimycotic agent, 0.2-0.5 part of an antioxidant, 12-55 parts of a filler, 0.3-0.5 part of a lubricant and 2-5 parts of an MS10E adsorbent, wherein the filler comprises transparent powder and calcium carbonate, the transparent powder is aluminosilicate crystals, and the MS10E adsorbent is a magnesium silicate adsorbent. According to the environment-friendly PVC material for the textilene dinner pad, a proper amount of the transparent powder is added into the polyvinyl chloride resin, so that the wear resistance and scratch resistance of a PVC coating layer are improved, meanwhile, the MS10E adsorbent is added, the odor of a product is reduced, and the VOC value is low; and meanwhile, a preparation process is simple, the yield is high, and the environment-friendly PVC material for the textilene dinner pad is simple and easy to obtain.

Owner:ANHUI CHUZHO DEWEI NEW MATERIAL

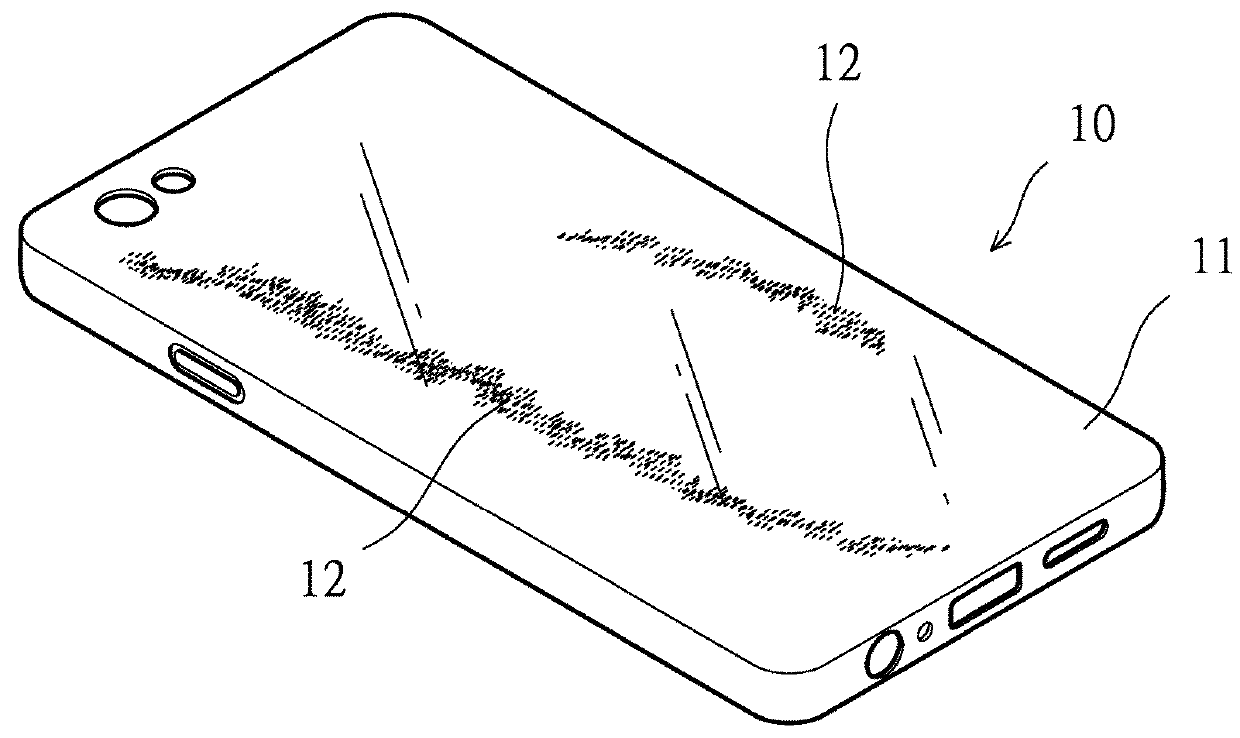

Protective Case for Portable Electronic Device

InactiveUS20180271263A1Increase wear resistance and scratch resistanceQuality improvementTravelling carriersHoldersEngineeringFlange

A protective case for a portable electronic device includes a bottom plate, a frame, and a glass substrate. The bottom plate has at least one hole and a flange around a periphery thereof. The frame is connected to the bottom plate. The frame has at least one through hole. An inner peripheral edge of the frame is provided with an engaging groove. The flange is engaged in the engaging groove. The frame cooperates with the bottom plate to form an accommodation space for accommodating a portable electronic device. A side of the bottom plate, opposite to the accommodation space, cooperates with the frame to form an accommodation trough. The glass substrate corresponds in shape to the accommodation trough. An adhesive layer is provided between the bottom plate and the glass substrate. The glass substrate is adhesively disposed in the accommodation trough.

Owner:LIN CHIA HAO

Implant with ceramic coating, method of forming an implant, and method of applying a ceramic coating

PendingUS20210338889A1Improve adhesionDistinctive advantageTissue regenerationCoatingsElectrolytic agentCeramic coating

An implant comprises a metal body having a ceramic coating comprising monoclinic and orthorhombic phases of zirconium oxide ZrO2 and at least one multi-metal phosphate from the group comprising l-IV metal phosphates. A method of forming an implant is provided. A method of applying a ceramic coating to a metal body comprises the step of electrochemical oxidation of at least a portion of the surface of a metal body in aqueous electrolyte; in which the electrolyte contains at least two elements from a group consisting of zirconium, titanium, magnesium, phosphorus, calcium, fluoride, potassium, sodium, strontium, sulphur, argentum, zinc, copper, silicon, gallium; in which electrochemical oxidation is conducted in a plasma discharge (PEO) mode for at least one interval of time, and non-discharge modes for at least two intervals of time.

Owner:CAMBRIDGE NANOCERAMIX LTD

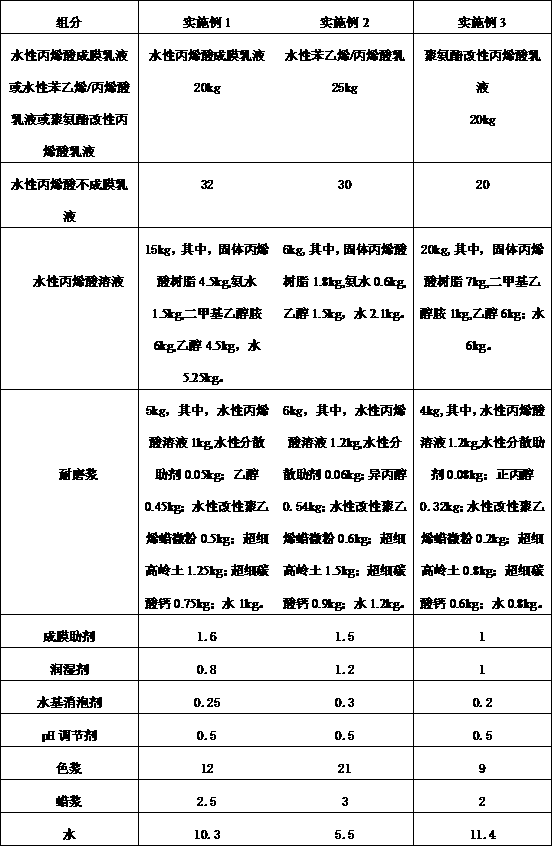

Overprint varnish-free high wear resistance aluminum foil lined paper water-based ink and preparation method thereof

This invention relates to the field of inks, and discloses an overprint varnish-free high wear resistance aluminum foil lined paper water-based ink. The overprint varnish-free high wear resistance aluminum foil lined paper water-based ink comprises 20-25 wt% of an aqueous acrylic film-forming emulsion or an aqueous styrene / acrylic emulsion or a polyurethane modified acrylic emulsion, 20-35 wt% ofan aqueous acrylic non-film forming emulsion, 2-25 wt% of an aqueous acrylic solution, 0.2-2 wt% of a wetting agent, 0.1-0.5 wt% of a defoamer, 0.4-0.6 wt% of a pH adjuster, 10-25 wt% of a color paste, 4-10 wt% of a wax paste, 4-10 wt% of a wear-resistant slurry, 5-15 wt% of water and 0.1-2 wt% of a film forming aid, wherein the wear-resistant slurry comprises 20-30 wt% of an aqueous acrylic solution, 20-25 wt% of water, 5-10 wt% of a water-modified modified polyethylene wax micro-powder, 1-2 wt% of an aqueous dispersion aid, 8-9 wt% of a cosolvent, 20-25 wt% of ultrafine kaolin and 10-15 wt%of ultrafine calcium carbonate. The ink has the adhesion of prime coating, also has the heatproof, waterproof, anti-slip, wear-resistant and scratch-resistant properties of a varnish, is convenient touse, and can simplify aluminum foil pre-coating, monochrome printing and three-time overprint varnish printing into one-time inking printing, so two printing processes are saved, and energy saving and environmental protection are achieved.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

Multifunctional synthetic leather

The invention relates to the technical field of artificial leather, and especially relates to multifunctional synthetic leather. An employed technical scheme is as follows: the multifunctional synthetic leather comprises a base cloth layer, a wet method PU layer which is formed on the base cloth layer and a dry method PU layer which is bonded on the wet method PU layer; a resin film layer for damping is formed on the upper surface of the dry method PU layer; a mite eliminating interlayer is arranged between the wet method PU layer and the dry method PU layer, the mite eliminating interlayer is a piece of non-woven fabric which is prepared from anti-microbial and mite eliminating fibers, and the non-woven fabric is bonded between the wet method PU layer and the dry method PU layer. The synthetic leather has the advantages of reasonable structure, good function, and good practicality; the synthetic leather is suitable for promotion and usage.

Owner:仲林

Highly lubricated imaging element with elastomeric matte

InactiveUS20050084810A1Improve scratch resistanceImprove wear resistanceRadiation applicationsMulticolor photographic processingElastomerMedicine

A photographic imaging element is disclosed comprising a support having on a front side thereof a silver halide imaging layer and an outermost protective overcoat layer comprising a film-forming binder, and on the backside thereof an outermost protective backcoat layer comprising a film-forming binder; the protective overcoat and backcoat layers each comprising a lubricant present in an amount of at least 5 mg / m2 and permanent matting agent having a Tg of at least 40° C. and an average particle size of from about 0.5 to about 3 micrometers in an amount of at least 1 mg / m2; and at least one of the protective overcoat layer or the protective backcoat layer further comprising crosslinked elastomeric polymer matte particles, wherein the crosslinked elastomeric polymer matte particles have a Tg of 20° C. or less, an average particle size of at least 90% of or greater than that of the permanent matting agent particles having a Tg of at least 40° C. in the protective layer in which the crosslinked elastomeric matte is included, and are present in the protective overcoat layer or protective backcoat layer in an amount which is (i) at least 1 mg / m2 and (ii) less than the total level of permanent matting agent particles having a Tg of at least 40° C. in the protective overcoat and backcoat layers combined. Imaging elements comprising highly lubricated protective outermost layers in accordance with the invention advantageously provide increased scratch and wear resistance, while the presence of relatively low Tg crosslinked elastomeric matte particles in combination with higher Tg permanent matte particles has been found to increase the coefficient of friction of the layer in which they are included to provide good manufacturability of the imaging element while also maintaining wear and other desired film performance properties.

Owner:EASTMAN KODAK CO

Electronic product shell and treatment process thereof

InactiveCN106976299APlay a protective effectImprove wear resistanceTelevision system detailsLamination ancillary operationsProduction lineMaterials science

An electronic product casing and its treatment process, which combines the bronzing foil process with the process of coating transparent solution, printing, dyeing, coating microstructure layer, embossing and other processes to form a multi-layer structure layer, that is, the first bonding layer, printing layer, dyed layer, second adhesive layer, bronzing foil layer, third contact layer and microstructure layer. While ensuring the partial or entire surface of the product presents a high-gloss surface of different colors, it can also improve the wear resistance and scratch resistance of the product surface. At the same time, different molds are used for embossing to produce different texture effects on the product surface, three-dimensional Strong feeling and layering, rich and beautiful surface effects, good surface gloss and flatness, and long service life.

Owner:瑞宏精密电子(太仓)有限公司

Solid wood paint-free composite single board

InactiveCN109719809AImprove penetrating adhesionHigh glossPlywood pressesVeneer pressesHydraulic cylinderSolid wood

The invention relates to the technical field of composite boards, in particular to a solid wood paint-free composite single board. A pressing-fit machine lower pressing plate, a composite single board, regenerated veneer and a pressing-fit part are included. The outer surface of the upper side of the pressing-fit machine lower pressing plate is fixedly connected with a hydraulic cylinder. A pressing-fit tabletop is arranged on the lower side of the pressing-fit machine lower pressing plate. The regenerated veneer is combined with fiber paper after being subjected to the step of water supplementing, the fiber paper is treated through a melamine glue immersing step, and after being combined with the regenerated veneer, the fiber paper is combined with a thin wood slice. Various valuable woodis selected as a solid wood veneer layer of the third layer, the valuable wood is planed and cut into the thin wood slice with 20-30 filaments, and in the actual effect, the surface solid wood pipe hole texture and grain quality and the abundant color and luster presentation are improved. In the fourth-layer paint glue film technology, during machining, through adding of aluminum oxide in resin,the capability of abrasion and scratching resisting can be improved, and practicability is improved. Integral practicability is high, and the usage effect is better compared with a traditional manner.

Owner:临沂大瑞木业有限公司

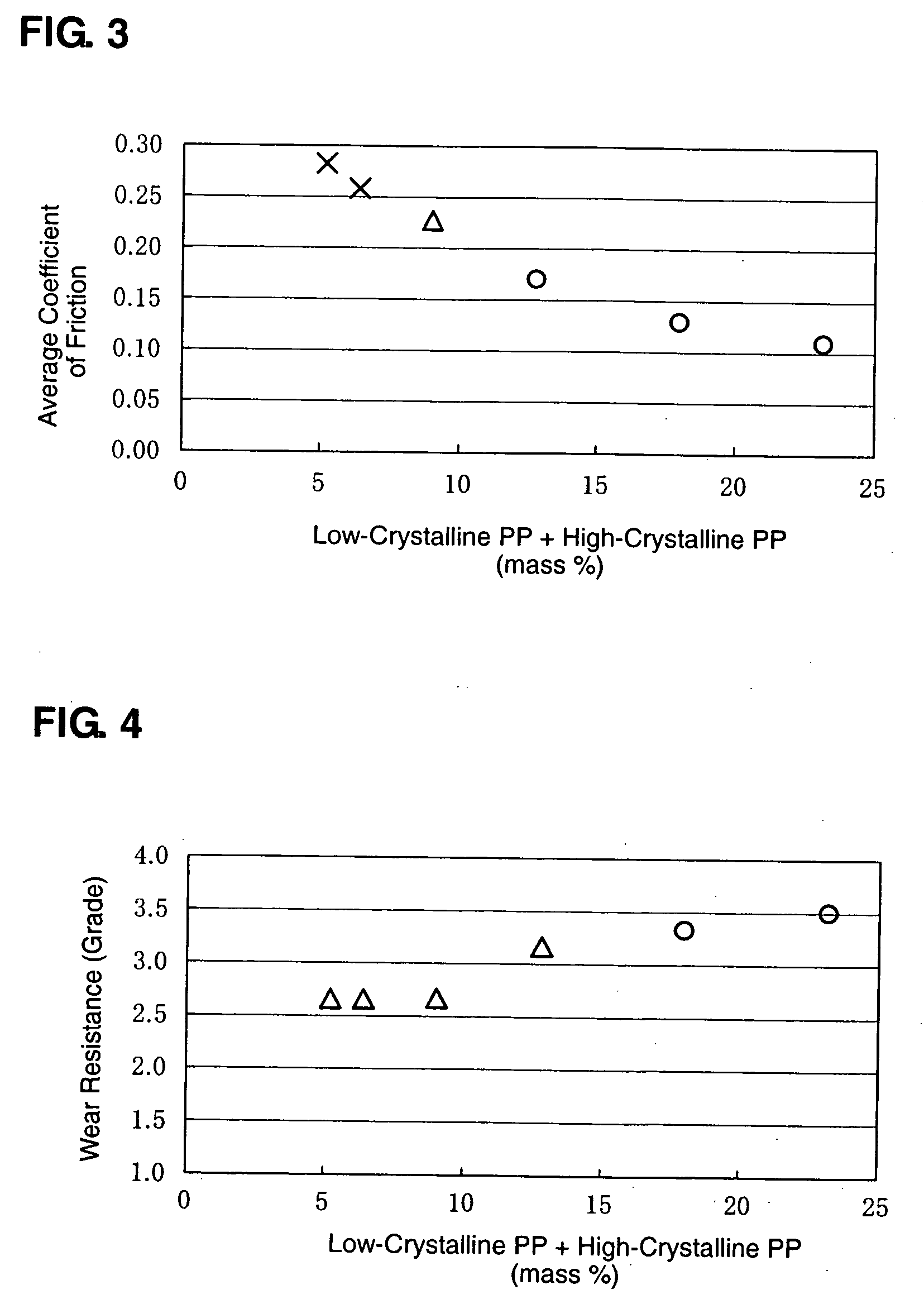

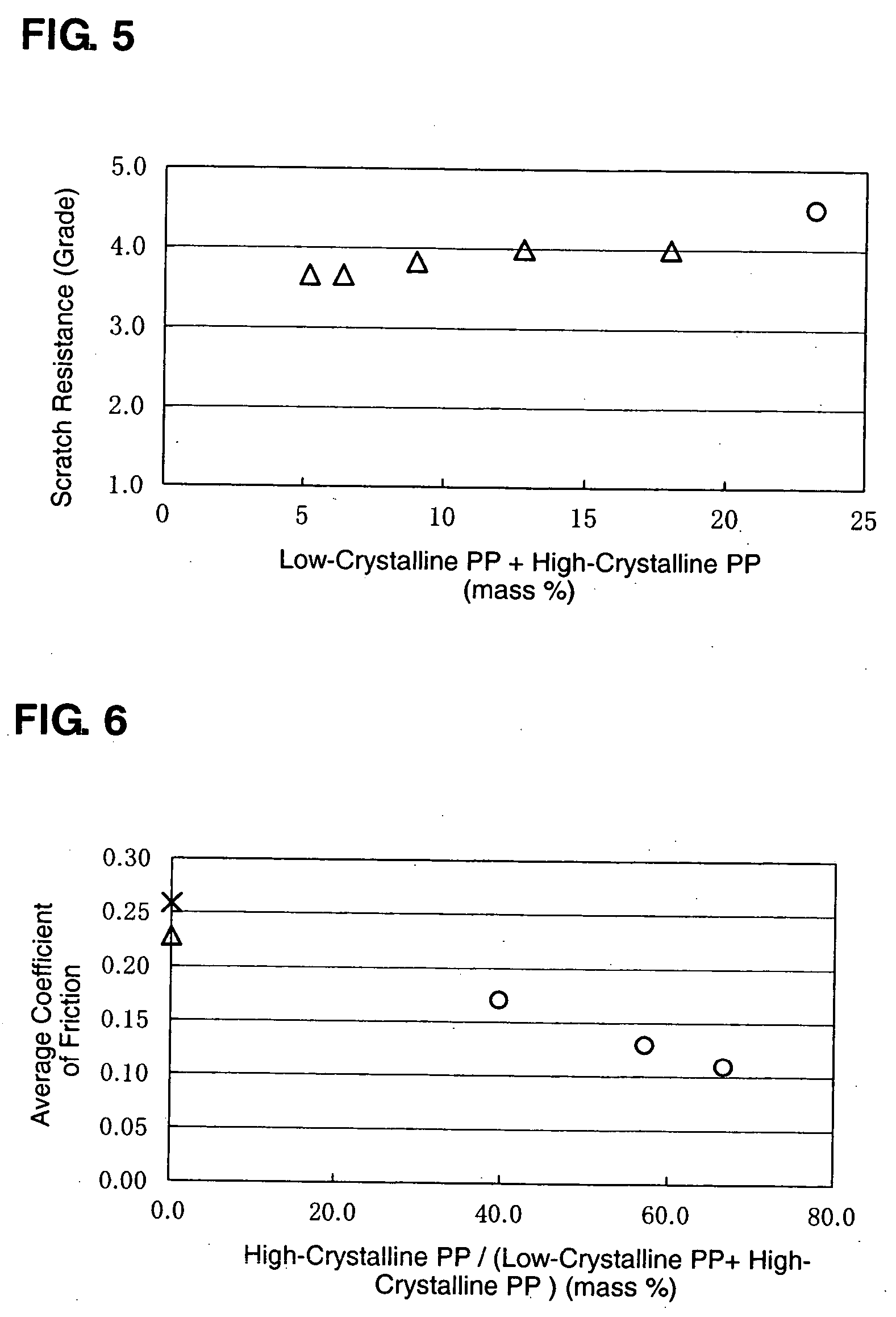

Thermoplastic elastomer composition for operating member and molded member obtained by molding the same

A thermoplastic elastomer composition for an operating member, comprising high-crystalline polypropylene having crystallinity of 95% or more, low-crystalline polypropylene having crystallinity of less than 95%, poly(1-butene), partial-cross-linked olefin family rubber having SP value of 7.5 or more and 8.5 or less, and non-cross-linked olefin family rubber having SP value of 7.5 or more and 8.5 or less. Accordingly, there can be provided the thermoplastic elastomer composition for an operating member and the molded member obtained by molding the same, which can provide the better tactic quality and improve the wear resistance and scratch resistance.

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com