High-strength modified PC material

A high-strength, modified technology, applied in the field of PC materials, can solve the problems of inability to meet high-strength and scratch resistance, improve wear and scratch resistance, good impact resistance and heat resistance, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

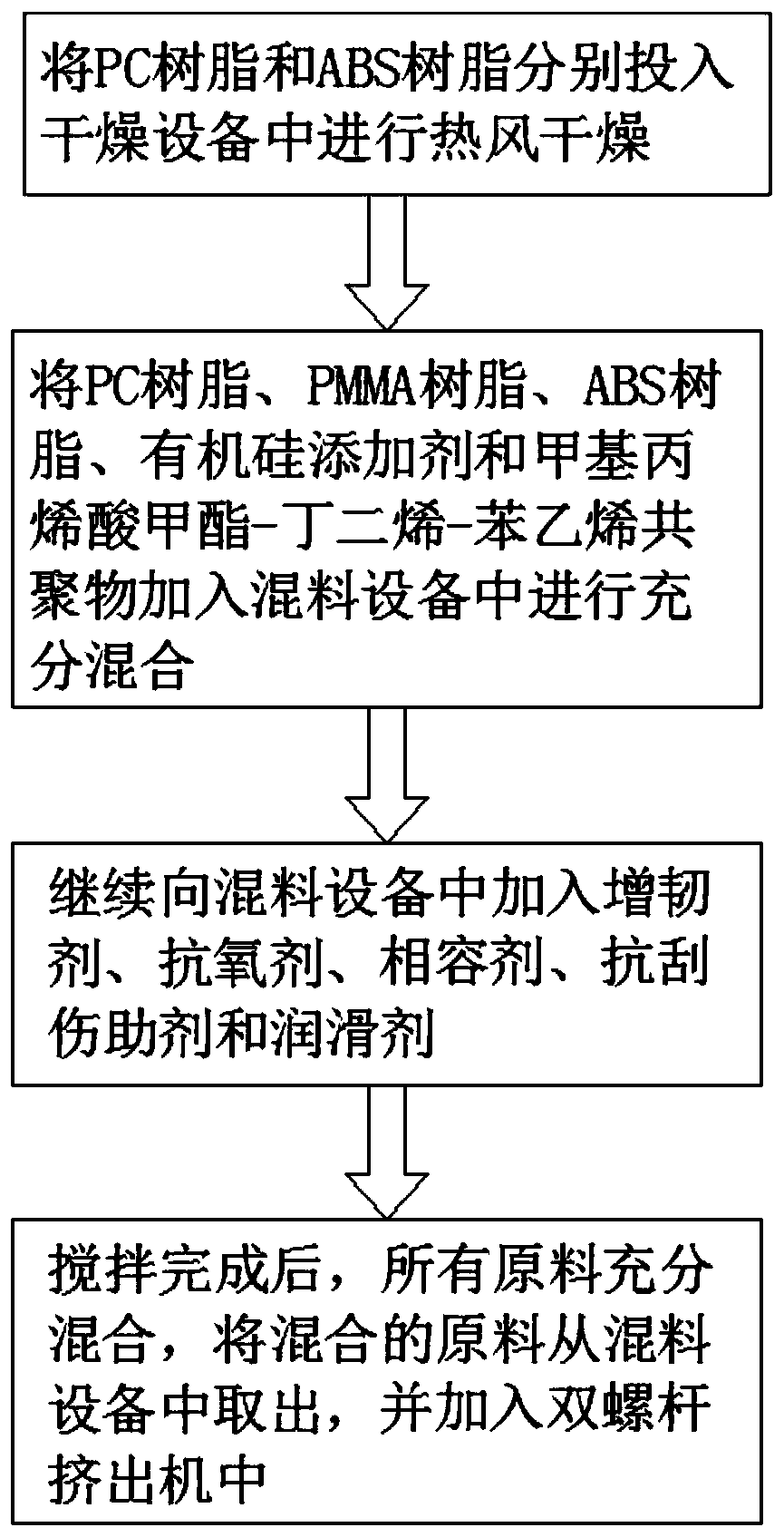

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0025] A high-strength modified PC material, the raw materials of which are calculated by weight, including 60-80 parts of PC resin, the melt index of PC resin is 2-4g / min; 4-8 parts of PMMA resin, and 5-10 parts of ABS resin , 0.5-2 parts of silicone additive, 2-4 parts of methyl methacrylate-butadiene-styrene copolymer, 2-4 parts of toughening agent, the toughening agent is methacrylate-acrylate copolymer, Among them, the mass fraction of methacrylate is 42%, and the mass fraction of acrylate is 58%; both PMMA resin and ABS resin have good impact resistance and heat resistance, which greatly improves the strength of PC materials; , The toughening agent is a methacr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com