Novel and environmentally-friendly type wholly-TPU sports flooring and preparation method thereof

An environmentally friendly, material technology, applied in chemical instruments and methods, layered products, construction, etc., can solve problems such as poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

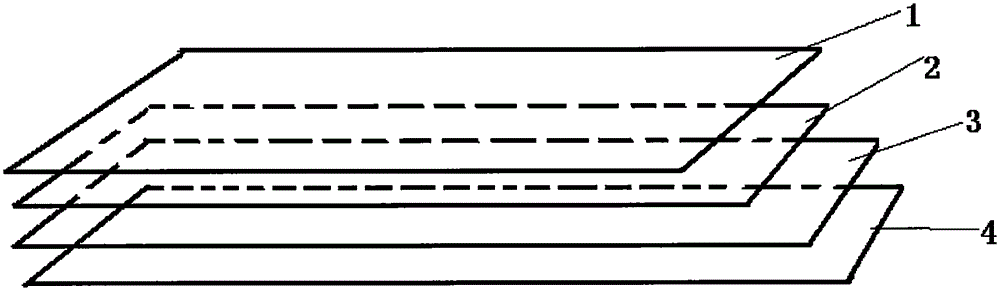

[0021] A new type of environmentally friendly sports floor made of TPU material, including a TPU environmentally friendly wear-resistant layer 1, next to the TPU environmentally friendly wear-resistant layer 1 is a glass fiber layer 2, and next to the glass fiber layer 2 is a TPU elastic buffer layer 3 , next to the TPU elastic buffer layer is the sucker-type shading waterproof layer 4, the thickness of the TPU environmental protection wear-resistant layer 1 is greater than the thickness of the sucker-type shading waterproof layer 4, and the TPU elastic buffer layer 3 The thickness is 8 times of the thickness of the TPU environmental wear-resistant layer 1. The sports floor is detachably installed in the sports field by using Velcro, and its preparation method is as follows, respectively preparing a TPU environmental protection wear-resistant layer, a glass fiber layer, an elastic buffer layer, and a sucker-type shading waterproof layer; wherein the The preparation process of ...

Embodiment 2

[0023] A new type of environment-friendly all-TPU material sports floor, including a TPU environment-friendly wear-resistant layer 1, next to the TPU environment-friendly wear-resistant layer 1 is a fine copper wire layer or a random fiber layer 2, and the thin copper wire layer or random fiber layer 2 Layer 2 is next to the TPU elastic buffer layer 3, and next to the TPU elastic buffer layer is the suction cup type shading waterproof layer 4, and the thickness of the TPU environmental protection wear-resistant layer 1 is greater than the suction cup type shading waterproof layer 4 The thickness of the TPU elastic buffer layer 3 is 6 times of the thickness of the TPU environmental wear-resistant layer 1. The sports floor is detachably installed in the sports field by using Velcro, and its preparation method is as follows, respectively preparing a TPU environmental protection wear-resistant layer, a glass fiber layer, an elastic buffer layer, and a sucker-type shading waterproof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com