Electronic product shell and treatment process thereof

A technology for processing technology and electronic products, applied in the direction of layered products, TVs, electrical components, etc., can solve the problems of lack of processing technology, wear resistance, poor adhesion effect, layering, and poor stereoscopic effect, and achieve product quality. Beautiful appearance, long service life, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As mentioned in the background technology, the existing processing technology for the shell of electronic products is to directly form the surface bronzing foil on the surface of the workpiece, partly or on the whole surface. There are many defects such as poor surface adhesion, easy wrinkling and blistering on the surface of bronzing products, poor layering, flatness, gloss and three-dimensional effect, etc.

[0039] Next, the specific technical solution of the present invention will be introduced in detail.

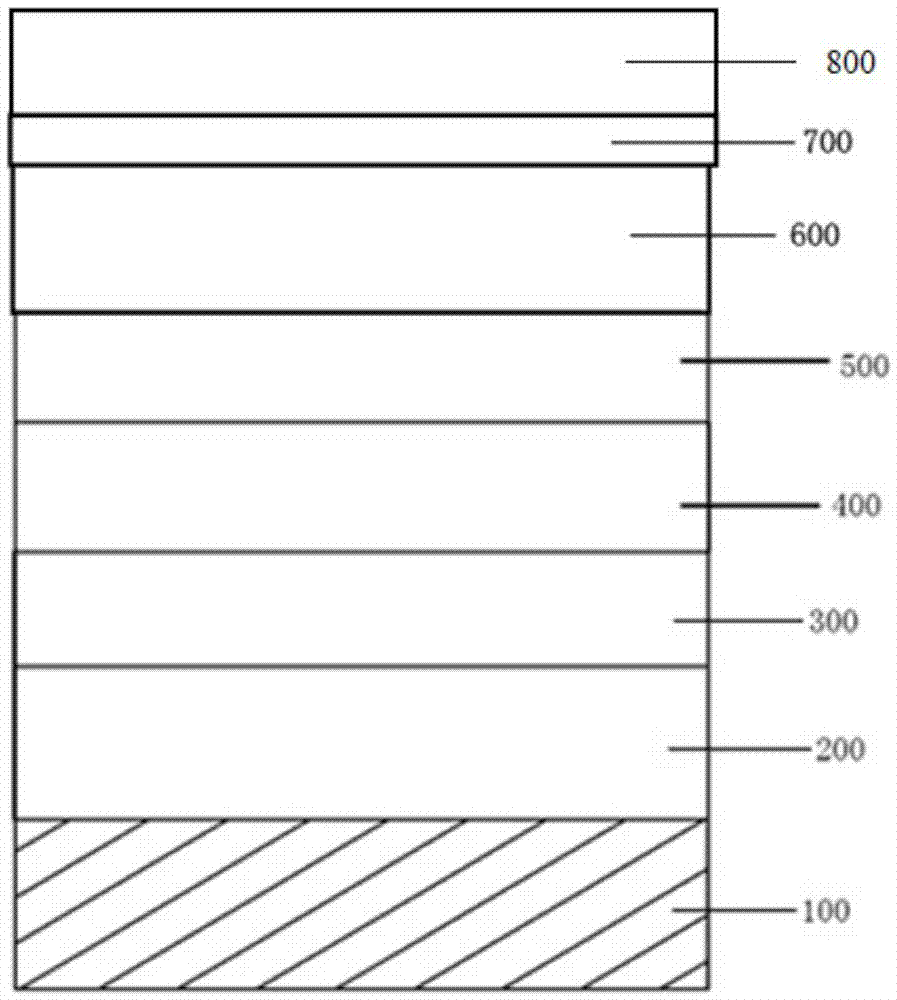

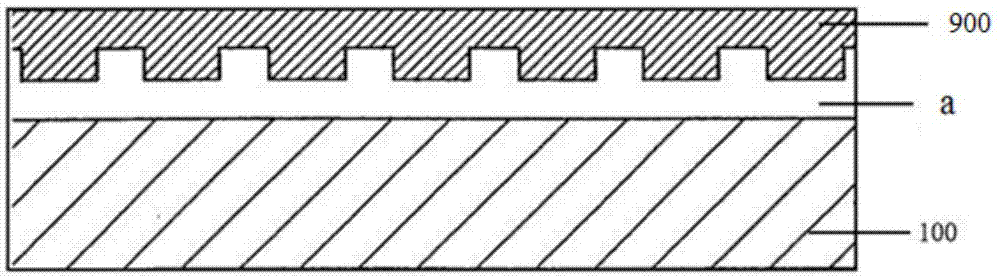

[0040] The shells of electronic products such as computers and mobile phones usually need to undergo a series of process treatments to make them have better wear resistance and scratch resistance, adhesion, flatness, gloss and three-dimensional layering. See figure 1 , is a schematic diagram of the cross-sectional structure of the plate and the multi-layer NIL layer in the present invention, and the specific manufacturing process is as follows:

[0041] 1. Plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com