Method for processing suede ultrafine fiber synthetic leather with high scratch resistance and high wear resistance

A superfine fiber and wear-resistant technology, which is applied in the processing field of suede superfine fiber synthetic leather, can solve the problems of poor suede bass physical properties, insufficient uniformity and density of cells, and high production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

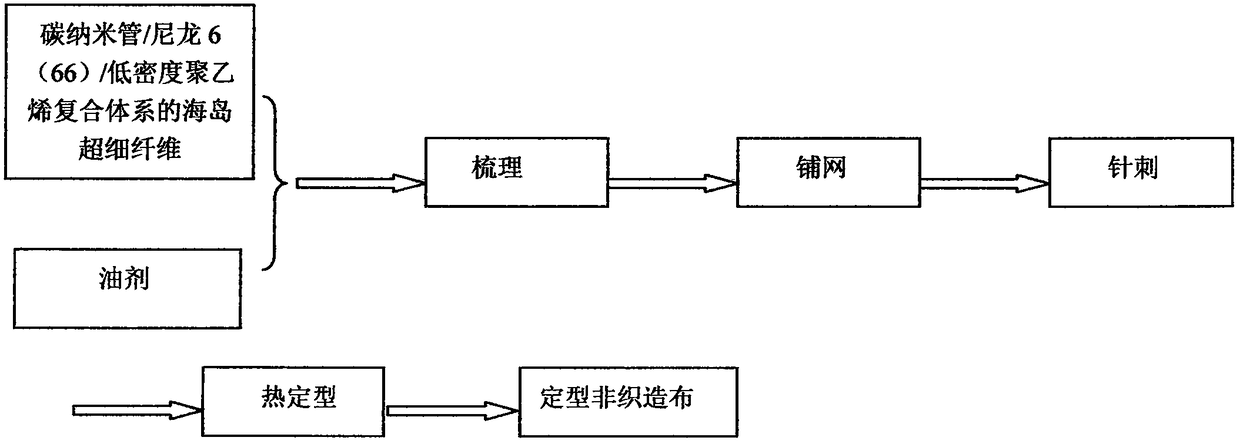

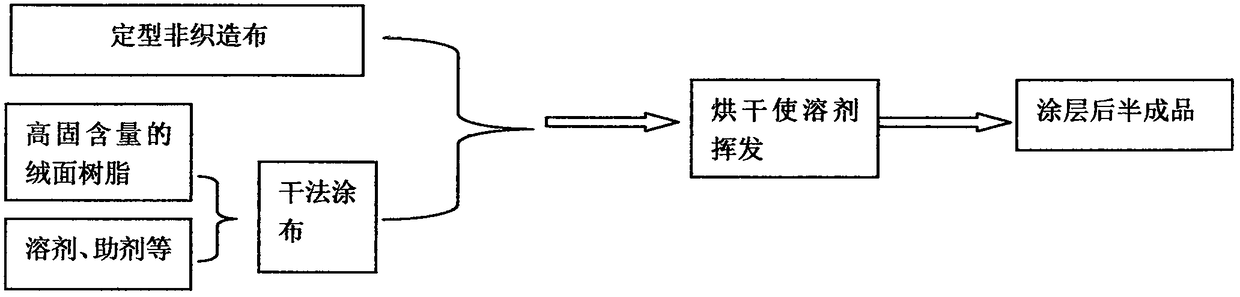

[0025] As a specific implementation example, a method for processing suede superfine fiber synthetic leather with higher scratch resistance and wear resistance is realized through the following steps:

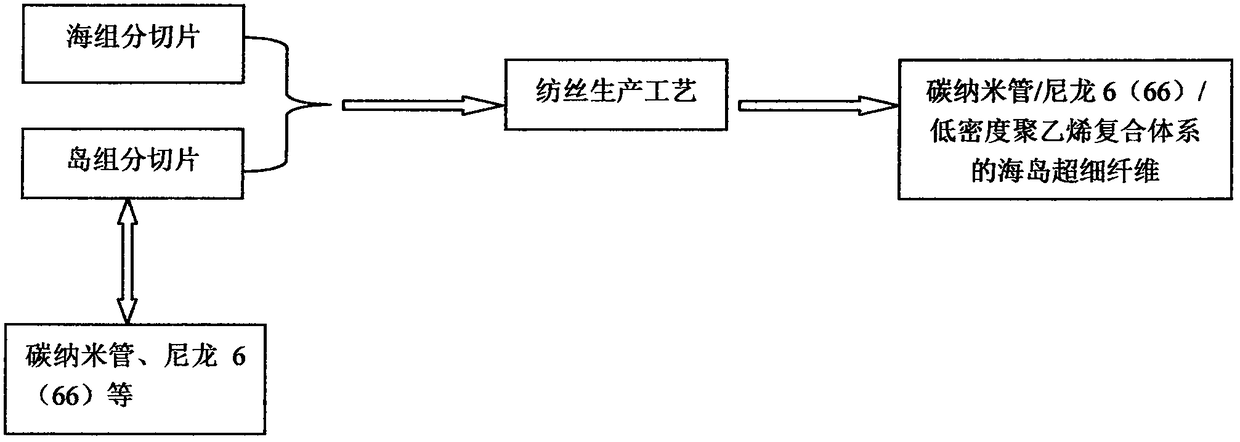

[0026] 1) Island microfiber processing

[0027] Firstly, sea-island microfibers are produced by spinning sea-island component slices and island component slices according to a weight ratio of 1:1. The sea-component slices are polyethylene slices, and the island component slices are polyamide slices. The spinning production process includes spinning by mixed melt spinning or compound spinning, and the primary filaments are cooled and formed under the condition of a special air-conditioned ring blowing; in order to optimize the spinnability and physical properties of the filaments, the filaments are processed. Oil, and use the drafting effect of the drafting roller to improve the consistency of the polymer molecules inside the filament. At this time, the internal structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com