PVC high-wear-resistance edge strip and preparation method thereof

An edge banding and high wear-resistant technology, which is applied in the field of PVC high wear-resistant edge banding and its preparation, can solve the problems affecting the economic profit of the factory, the glossiness is difficult to control, and the manufacturing cost increases, so as to optimize the surface effect and customer satisfaction. Experience, easy processing and granulation, and the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

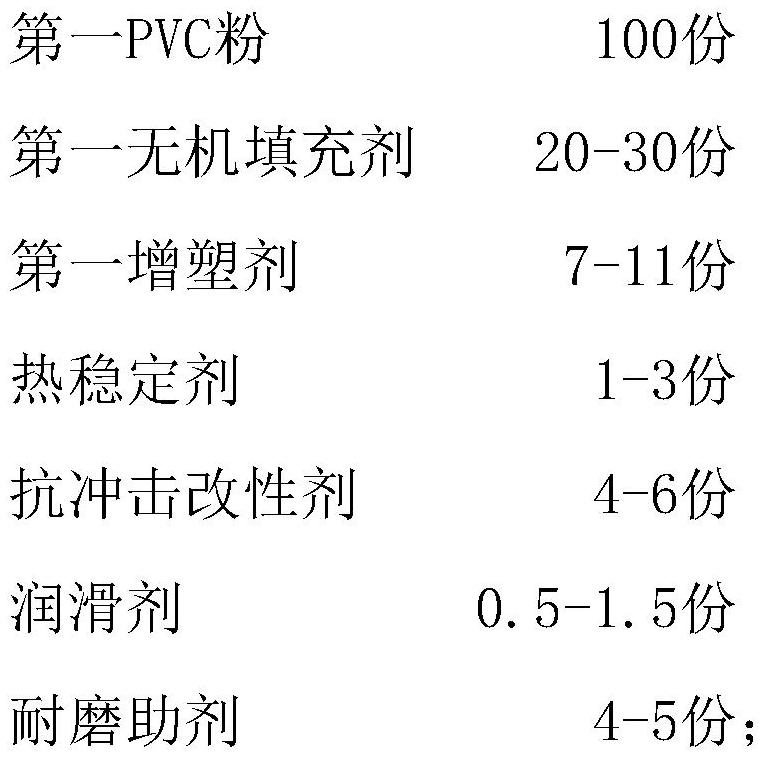

[0032] A PVC high wear-resistant edge banding strip, comprising the following raw materials in parts by weight:

[0033]

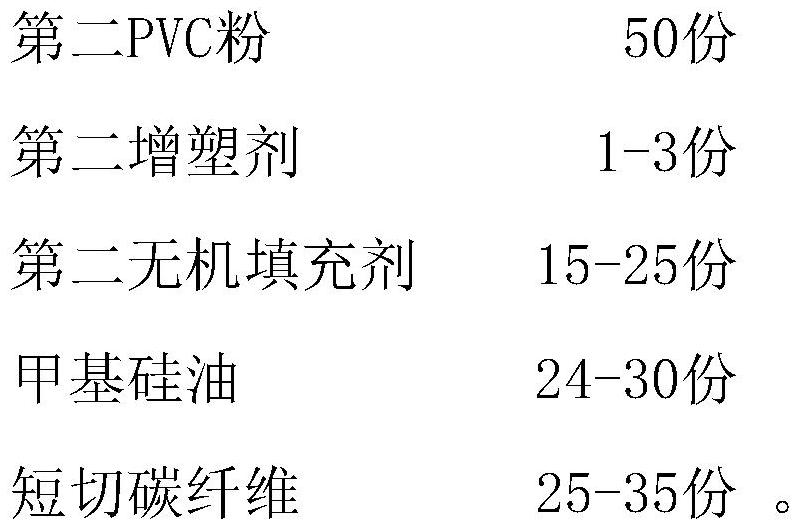

[0034] The wear-resisting additive of every part by weight comprises the raw material of following parts by weight:

[0035]

[0036]

[0037] Wherein, the first PVC powder and the second PVC powder are both SG-1000.

[0038] Wherein, both the first inorganic filler and the second inorganic filler are ground calcium carbonate.

[0039] Wherein, the first plasticizer is composed of dioctyl adipate and methyl chlorostearate in a weight ratio of 5:4, and the second plasticizer is dioctyl adipate.

[0040] Wherein, the heat stabilizer is a calcium-zinc composite heat stabilizer.

[0041] Wherein, the impact modifier is MBS.

[0042] Wherein, the lubricant is composed of synthetic wax and stearic acid in a ratio of 1:1 by weight.

[0043] Wherein, the length of the chopped carbon fiber is 2mm.

[0044] Wherein, the preparation method of the anti-w...

Embodiment 2

[0047]A PVC high wear-resistant edge banding strip, comprising the following raw materials in parts by weight:

[0048]

[0049] The wear-resisting additive of every part by weight comprises the raw material of following parts by weight:

[0050]

[0051] Wherein, the first PVC powder and the second PVC powder are both SG-1000.

[0052] Wherein, the first inorganic filler is heavy calcium carbonate, and the second inorganic filler is light calcium carbonate.

[0053] Wherein, the first plasticizer is composed of dioctyl adipate and methyl chlorostearate in a weight ratio of 1:1, and the second plasticizer is dioctyl adipate.

[0054] Wherein, the heat stabilizer is a calcium-zinc composite heat stabilizer.

[0055] Wherein, the impact modifier is ACR.

[0056] Wherein, the lubricant is synthetic wax.

[0057] Wherein, the length of the chopped carbon fiber is 1mm.

[0058] Wherein, the preparation method of the anti-wear additive includes the following steps: mixing...

Embodiment 3

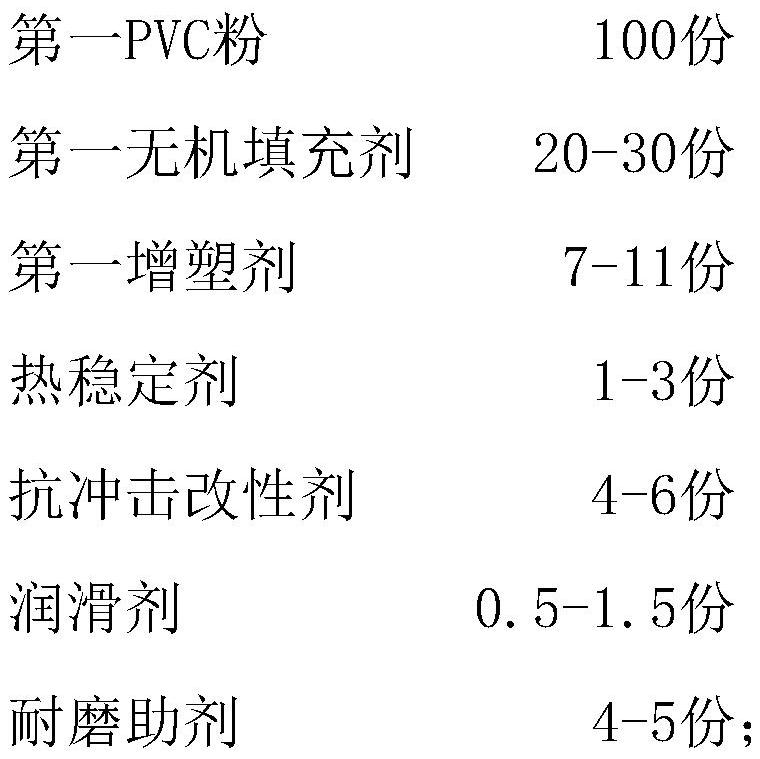

[0061] A PVC high wear-resistant edge banding strip, comprising the following raw materials in parts by weight:

[0062]

[0063]

[0064] The wear-resisting additive of every part by weight comprises the raw material of following parts by weight:

[0065]

[0066] Wherein, the first PVC powder and the second PVC powder are both SG-1000.

[0067] Wherein, the first inorganic filler is carbon black, and the second inorganic filler is heavy calcium carbonate.

[0068] Wherein, the first plasticizer is composed of dioctyl adipate and methyl chlorostearate in a weight ratio of 5:4.5, and the second plasticizer is dioctyl adipate.

[0069] Wherein, the heat stabilizer is a calcium-zinc composite heat stabilizer.

[0070] Wherein, the impact modifier is CPE.

[0071] Wherein, the lubricant is stearic acid.

[0072] Wherein, the length of the chopped carbon fiber is 3mm.

[0073] Wherein, the preparation method of the anti-wear additive includes the following steps: mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com