Halogen-free, anti-scratch, anti-abrasion and fireproof electric wire insulation material

A technology for fireproof wires and insulating materials, applied in organic insulators, plastic/resin/wax insulators, etc., can solve the problems of poor wear resistance and scratch resistance of insulating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

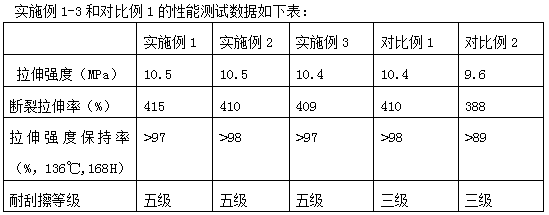

Examples

Embodiment 1

[0012] A halogen-free, scratch-resistant, wear-resistant, fire-resistant wire insulation material, composed of the following components in mass percentage: SEBS 20%; mineral oil 10%; polypropylene 10%; metallocene polyethylene 10%; EPDM 7% rubber; 20% polyphenylene ether; 10% aluminum diethylphosphinate; 10% melamine cyanurate; 1.8% ceramic microbeads; 0.2% anti-aging agent; 1% lubricant.

Embodiment 2

[0014] A halogen-free, scratch-resistant, wear-resistant, fire-resistant wire insulation material, composed of the following components in mass percentage: SEBS 15%; mineral oil 7.9%; polypropylene 15%; metallocene polyethylene 15%; EPDM Rubber 10%; polyphenylene ether 15%; aluminum diethylphosphinate 15%; melamine cyanurate 5%; ceramic microbeads 1.5%; anti-aging agent 1010 0.1%; lubricant 0.5%.

Embodiment 3

[0016] SEBS 25%; mineral oil 11.2%; polypropylene 5%; metallocene polyethylene 5%; EPDM rubber 5%; polyphenylene ether 25%; aluminum diethylphosphinate 5%; melamine cyanurate 15% ; Ceramic microbeads 2.0%; Anti-aging agent 0.3%; Lubricant 1.5%.

[0017] The preparation methods of the above examples are well known in the art and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com