High-adhesion scratch-resistant wear-resistant polyurethane transparent coating material

A polyurethane coating, high adhesion technology, applied in the field of coatings, can solve the problems of polyurethane coating adhesion and anti-scratch and friction resistance at the same time, to improve the use effect and protection effect, good anti-scratch and wear resistance, particle size small diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

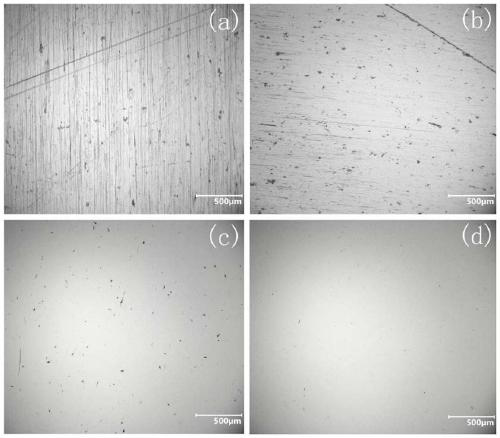

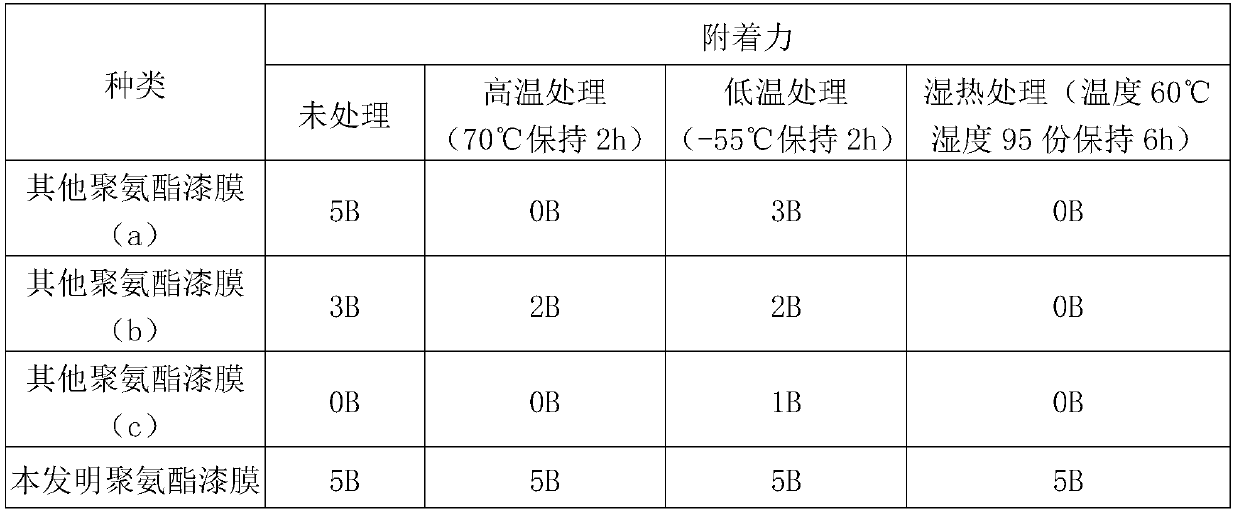

Image

Examples

Embodiment 1

[0041] A scratch-resistant and wear-resistant polyurethane transparent coating with high adhesion proposed by the present invention, its raw materials include by weight: 26.57 parts of polyoxytetramethylene glycol (PTMG, molecular weight 650), 1,2,4- 2.08 parts of butanetriol, 0.11 parts of stannous octoate, 1.77 parts of bisphenol A epoxy resin, 0.02 parts of polyether-modified polydimethylsiloxane, 0.22 parts of polyether-modified polyorganosiloxane, nano-titanium dioxide 0.44 parts (particle size is 20nm), 53.14 parts of N,N dimethylformamide, 15.63 parts of isophorone diisocyanate. The soft segment content of the finally obtained polyurethane is 40%.

[0042] The preparation method of the anti-scratch wear-resistant polyurethane transparent coating of above-mentioned high adhesion comprises:

[0043] Step 1: Weigh polypolyols, chain extenders, catalysts, adhesion promoters, leveling agents, wetting agents, sunscreens and solvents according to the above weight fractions, a...

Embodiment 2

[0046] The present invention proposes a high-adhesion anti-scratch and wear-resistant polyurethane transparent coating, and its raw materials include: 27.57 parts of polyoxypropylene glycol (PPG molecular weight 1000), 3.02 parts of 1,2,4-butanetriol by weight percentage , 0.11 parts of dibutyltin dilaurate, 1.70 parts of bisphenol A epoxy resin, 0.02 parts of polyether-modified polydimethylsiloxane, 0.21 parts of polyether-modified polyorganosiloxane, and 0.42 parts of nano-titanium dioxide (Particle size is 20nm), 55.13 parts of N,N dimethylformamide, 11.82 parts of hexamethylene diisocyanate (HDI). The soft segment content of the finally obtained polyurethane was 35%.

Embodiment 3

[0048] The present invention proposes a high-adhesion anti-scratch and wear-resistant polyurethane transparent coating, and its raw materials include: polycarbonate polyol (PCDL, molecular weight 1000) 25.49 parts, 1,2,4-butanetriol 3.01 parts by weight 0.12 parts of triethylamine, 1.85 parts of bisphenol-A epoxy resin, 0.02 parts of polyether-modified polydimethylsiloxane, 0.23 parts of polyether-modified polyorganosiloxane, 0.46 parts of nano-titanium dioxide (grain diameter of 20nm), N,N dimethylformamide 50.97 parts, 4,4'-dicyclohexylmethane diisocyanate (HMDI) 17.84 parts. The soft segment content of the finally obtained polyurethane was 45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com