Highly-abrasion-resistant anti-scratching modified PC (polycarbonate) material and preparation method thereof

An anti-scratch and high wear-resistant technology, which is applied in the field of high wear-resistant and anti-scratch modified PC materials and its preparation, to achieve the effects of improving mechanical properties, excellent anti-wear effects, and maintaining physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

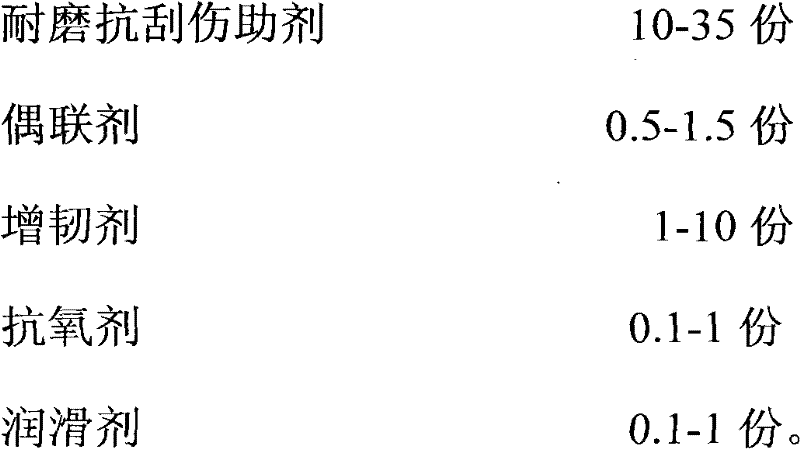

[0030] Highly wear-resistant and anti-scratch modified PC material, which includes the following raw materials:

[0031]

[0032] First dry the polycarbonate and polytetrafluoroethylene in the above formula in a blast drying oven at 100°C for 4 hours, then mix the raw materials weighed according to the above formula in a high-speed mixer for 3 minutes until uniform, and then transfer To the hopper of the twin-screw extruder, the glass fiber is fed into the twin-screw extruder by side feeding, melted at about 260°C, extruded, pelletized, and dried.

[0033] The physical performance of PC material after the modification of table 1 embodiment 1 gained

[0034]

[0035]

Embodiment 2

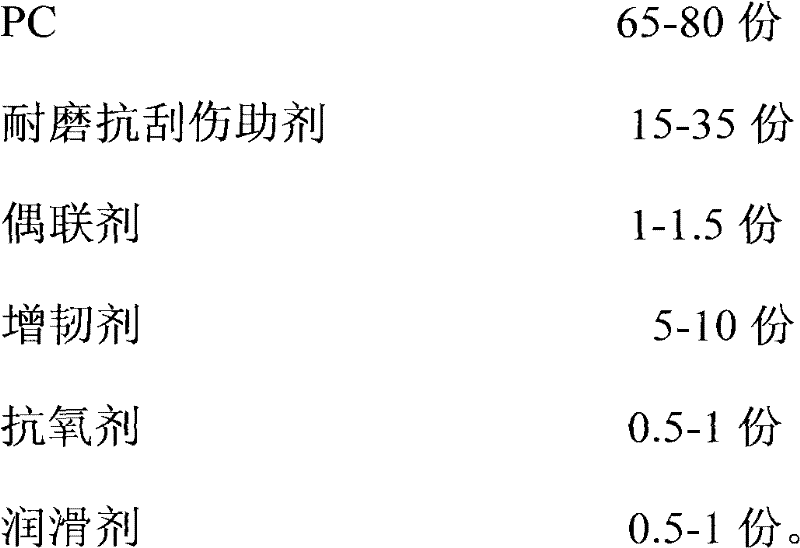

[0037] Highly wear-resistant and anti-scratch modified PC material, which includes the following raw materials:

[0038]

[0039] First dry polycarbonate and carbon fiber in a blast drying oven at 100°C for 4 hours, then mix the raw materials weighed according to the above formula in a high-speed mixer for 5 minutes until uniform, and then transfer to a twin-screw extruder In the hopper, the carbon fiber is fed into the twin-screw extruder by side feeding, melted at about 260°C, extruded, pelletized, and dried.

[0040] The physical performance of PC material after the modification of table 2 embodiment 2 gained

[0041]

Embodiment 3

[0043] Highly wear-resistant and anti-scratch modified PC material, which includes the following raw materials:

[0044]

[0045] First dry polycarbonate and silicon carbide in a blast drying oven at 60°C for 8 hours, then mix the raw materials weighed according to the above formula in a high-speed mixer for 4 minutes until uniform, and then transfer to twin-screw extrusion In the hopper of the machine, melt at about 260°C, extrude, pelletize, and dry.

[0046] The physical properties of PC material after the modification of table 3 embodiment 3 gained

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com