Environment-friendly PVC material for textilene dinner pad and preparation method of environment-friendly PVC material

A PVC material and Teslin technology, which is applied in the field of PVC materials for environmentally friendly Teslin placemats and its preparation, can solve the problems of non-abrasion-resistant PVC coating layer and strong smell of Teslin placemats, so as to improve wear resistance and scratch resistance. The effect of high stability, low VOC value and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

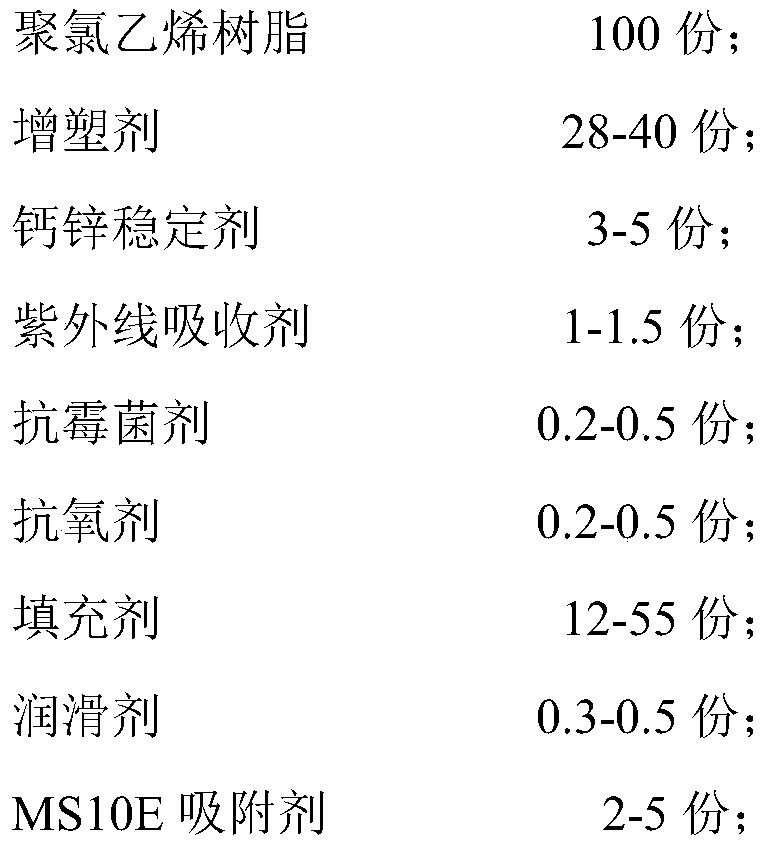

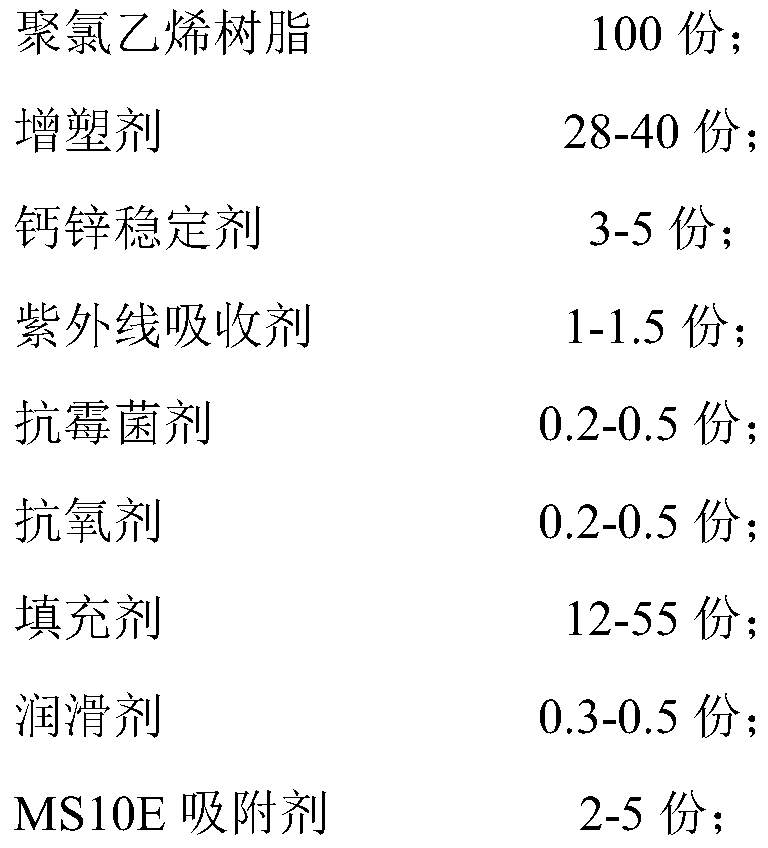

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the PVC material of environment-friendly Teslin placemat of the present invention, it comprises the steps:

[0035] (1) Add the weighed MS10E adsorbent into the plasticizer, mix evenly, and add high-speed mixed in a mixer;

[0036] (2) When the temperature rises to 80-90°C, add the weighed filler, continue mixing, the temperature rises to 110-120°C, put it into a two-stage extruder, and extrude to granulate.

[0037] Among them, the parameters of the two-stage extruder are as follows: twin-screw temperature 100-140 ° C, single-screw temperature 110-150 ° C, feeding speed 18 ± 2, twin-screw main machine speed 30 ± 5, single-screw main machine speed 25 ± 5, cutting The speed of the granulator is 24±5, and the material temperature is 165-170°C.

[0038] The preparation method of the PVC material for the environment-friendly Teslin table mat of the present invention adopts a domestic double-stage extrusion production line for production, and has ...

Embodiment 1

[0040] Embodiment 1 provides a kind of PVC material for environment-friendly Teslin placemat, and it comprises the component of following parts by weight:

[0041] 100 parts of polyvinyl chloride resin; 30 parts of DOTP; 4 parts of epoxy soybean oil; 4 parts of calcium zinc stabilizer; 0.5 parts of UV-531; 0.5 parts of UV-P; 45 parts of calcium; 4 parts of transparent powder; 0.5 parts of lubricant stearic acid; 3 parts of MS10E adsorbent.

[0042] The preparation method of the PVC material of environment-friendly Teslin placemat of the present invention, it comprises the steps:

[0043] (1) Add the weighed MS10E adsorbent into the plasticizer, mix evenly, and add high-speed mixed in a mixer;

[0044] (2) When the temperature rises to 80-90°C, add the weighed filler, continue mixing, the temperature rises to 110-120°C, put it into a two-stage extruder, and extrude to granulate.

[0045] Among them, the parameters of the two-stage extruder are as follows: twin-screw temperat...

Embodiment 2

[0046] Embodiment 2 provides a PVC material for environment-friendly Teslin placemats, which includes the following components in parts by weight: the formula components are basically the same as those in Example 1, except that: 5 parts of transparent powder; 5 parts of MS10E adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com