PVC (Poly Vinyl Chloride) thermal contraction printing film

A printing film and heat-shrinking technology, applied in the field of PVC heat-shrinkable printing film, can solve the problems of lower ink printing quality, and the anti-static function of PVC heat-shrinkable printing film has not been effectively solved, so as to delay controllable effect and reduce defects effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

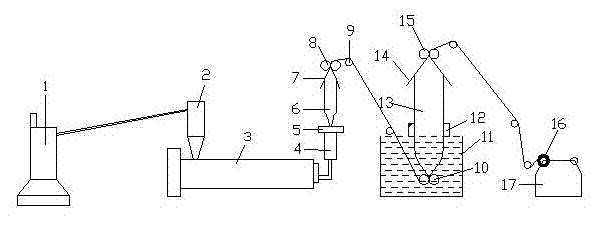

Image

Examples

Embodiment 1

[0024] Example 1: Formula: 100 parts by weight of suspension method loose type (SG-5 type) PVC resin, 2.0 parts by weight of methyl tin mercaptide 181, 4.5 parts by weight of dioctyl phthalate (DOP), processing aid acrylic acid Ester copolymer (ACR-201) 1.5 parts by weight, impact modifier methacrylic acid-butadiene-styrene copolymer (MBS BTA-717) 3.2 parts by weight, internal lubricant diglyceryl ether monooleate (G-16) 0.9 parts by weight, external lubricant oxidized polyethylene wax (AC316A) 0.3 parts by weight, antistatic agent (SN) 0.8 parts by weight of isopropyl triisostearate titanate coupling treatment.

[0025] Antistatic agent coupling treatment: Add 2000g antistatic agent SN (stearamidopropyldimethyl-β-hydroxyethylammonium nitrate) and 24g isopropyl triisostearate titanate to a 5L high-speed Mix at high speed in a mixer with a rotation speed of 2960rpm. When the temperature of high-speed mixing rises to 110-120°C, discharge and cool to room temperature to obtain a ...

Embodiment 2

[0030] Embodiment 2: formula: 100 parts by weight of SG-7 type PVC resin, 2.5 parts by weight of methyl tin 191, 5.0 parts by weight of dioctyl terephthalate (DOTP), processing aid acrylate copolymer (ACR K- 120ND) 2.0 parts by weight, 4.0 parts by weight of impact modifier methacrylic acid-butadiene-styrene copolymer (MBS B521), 1.2 parts by weight of dicarboxylic acid ester (G60) of internal lubricant saturated fatty alcohol, 0.6 parts by weight of complex ester (G78) for external lubricant, 1.2 parts by weight of antistatic agent SP coupled with isopropyl triisostearate titanate.

[0031] Antistatic agent coupling treatment: Add 2000g antistatic agent SP (stearamidopropyl dimethyl-β-hydroxyethyl ammonium dihydrogen phosphate) and 20g isopropyl triisostearate titanate to Mix at medium speed in a 5L high-speed mixer with a rotation speed of 2960rpm. When the temperature rises to 110~120°C, release and cool to room temperature for later use.

[0032] Add 2400g antistatic agen...

Embodiment 3

[0035] Embodiment 3: formula: 100 parts by weight of SG-5 type PVC resin, 1.8 parts by weight of isooctyl dimercaptoacetate di-n-octyltin (DOTTG), 3.0 parts by weight of epoxy soybean oil (ESBO), processing aid acrylate copolymerization (ACR K-125) 1.8 parts by weight, impact modifier methacrylic acid-butadiene-styrene copolymer (MBS B22) 2.8 parts by weight, internal lubricant monoglyceride stearate (GMS) 0.8 parts by weight 0.3 parts by weight of the external lubricant oxidized polyethylene wax, and 1.0 parts by weight of the antistatic agent Atmos150 treated with isopropyl triisostearate titanate coupling.

[0036] Antistatic agent coupling treatment: Add 2000g Atmos150 (mono-diglycerides of palmitic acid and stearic acid) and 22g isopropyl triisostearate titanate to a 5L high-speed mixer and mix at a high speed at 2960rpm , when the temperature rises to 110~120°C, release and cool to room temperature for later use.

[0037] Add 1600g Atmos150 (mono-diglycerides of palmiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com