Foaming polyolefin anti-static material and preparation method thereof

A foamed polyolefin, anti-static technology, applied in the field of polymer materials, can solve the problems of poor anti-static effect, poor compression characteristics, poor tensile strength, etc., and achieve cost saving, physical performance improvement, and surface resistance reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

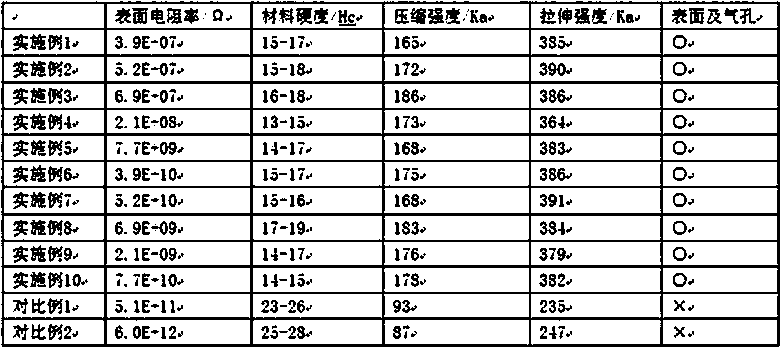

Examples

Embodiment 1

[0026] The preparation method of the above-mentioned foamed polyolefin antistatic material comprises the following steps: (1) immersing the foamed polyolefin base material in an antistatic liquid mixed with water with a mass fraction of 1%, a pH of 7.0, and a temperature of In the solution at 20°C, so that the solution is absorbed and coated on the substrate, the antistatic liquid is a commercially available antistatic liquid; (2) Preliminarily filter and dry until the substrate hangs and does not drip; (3 ) using a group of pressure rollers with a flexible surface to squeeze the preliminarily filtered and dried substrate coated with the antistatic liquid, and the extrusion force is 0.1N, so that the antistatic liquid is inside the substrate and The surface is evenly distributed; (4) corona treatment on the surface of the substrate. The product is obtained.

Embodiment 2

[0028] A method for preparing a foamed polyolefin antistatic material, comprising the following steps: (1) soaking the foamed polyolefin base material in an antistatic solution mixed with water with a mass fraction of 2%, a pH of 7.5, and a temperature of 25 ℃ solution, so that the solution is absorbed and coated on the substrate, and the antistatic solution is a commercially available antistatic solution; (3) a set of pressure rollers with a flexible surface is used to absorb and coat the preliminary filter. The substrate of the antistatic liquid is extruded, and the extrusion force is 3N, so that the antistatic liquid is evenly distributed inside and on the surface of the substrate; (4) Corona treatment is performed on the surface of the substrate. The product is obtained.

Embodiment 3

[0030] The preparation method of the above-mentioned foamed polyolefin antistatic material comprises the following steps: (1) immersing the foamed polyolefin base material in an antistatic liquid mixed with water with a mass fraction of 3%, a pH of 7.3, and a temperature of In the solution at 23°C, so that the solution is absorbed and coated on the substrate, the antistatic liquid is a commercially available antistatic liquid; (2) Preliminarily filter and dry until the substrate hangs and does not drip; (3 ) using a group of pressure rollers with flexible surfaces to squeeze the preliminarily drained base material coated with the antistatic liquid, and the extrusion force is 5N, so that the antistatic liquid is inside and on the surface of the base material Uniform distribution; (4) Corona treatment on the surface of the substrate. The product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com