Novel textile technology

A process and new technology, applied in the field of new textile technology, can solve the problems of personal injury, poor hand feel, easy to break the silk thread, etc., and achieve the effect of improving the grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

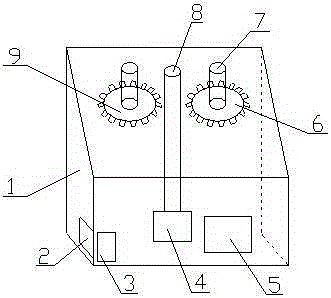

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with examples.

[0018] The invention discloses a textile frame, comprising a novel textile process, characterized in that it comprises the following steps:

[0019] (1) The strands made of pure cotton strands and cotton yarns plus conductive filaments are twisted by twisting equipment using a section warping machine, and are arranged into warp beams according to 2 strands plus conductive filaments per inch, and the looms are used to Weaving;

[0020] (2) Add soft water to the water steamer, the soft water has a bath ratio of 1:15, and the temperature is 50-80°C; add detergent to the water steamer at a rate of 4-8 grams per liter of water, and the water temperature is 60-80°C , steamed for 8 hours;

[0021] (3) Dehydration and drying, using a dryer to dry the washed textile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com