Antistatic interior wall coating and preparation method thereof

An interior wall coating and antistatic technology, applied in the direction of conductive coatings, coatings, etc., can solve the problems of unsatisfactory, complex coating process, high cost, etc., achieve good electrical properties, improve mechanical properties, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

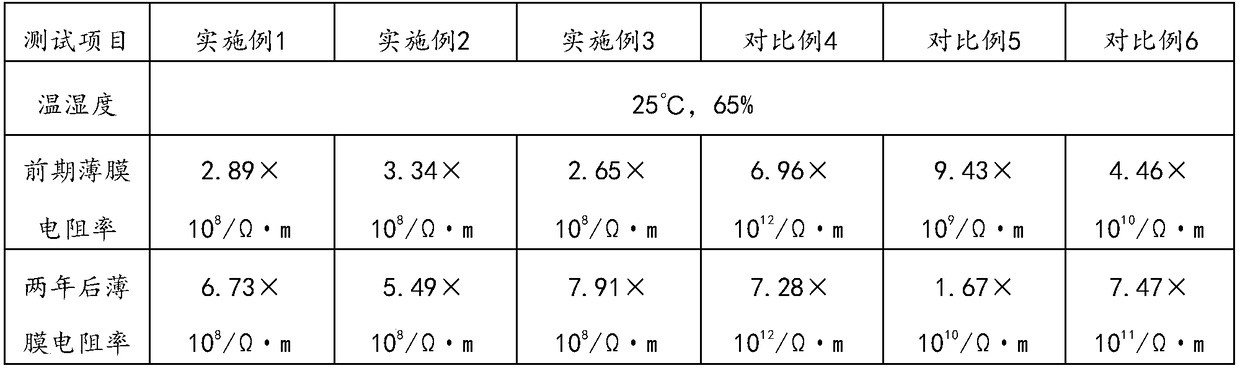

Examples

Embodiment 1

[0044] According to the formula weight ratio, mix 20.0 parts of water and 0.2 parts of cellulose in a container, stir at a speed of 800r / min until the cellulose is completely dissolved, and form a mixed solution; add 5 parts of ethylene glycol, 0.4 1 part of sodium dodecylbenzenesulfonate, 0.1 part of wetting agent and 0.2 part of defoamer are stirred evenly; add 4.5 parts of carbon nanotubes and 25 parts of composite titanium dioxide, and disperse at a speed of 1500 r / min until the fineness is less than 60 μm; Reduce the rotation speed, add 55.0 parts of water-based acrylic polyaniline, and slowly add 0.8 parts of antistatic ionic liquid after dispersing evenly; finally add 0.2 parts of preservatives, 0.2 parts of antifungal agents, and 0.1 parts of thickeners in sequence, and discharge after dispersing evenly , That is, antistatic interior wall paint.

Embodiment 2

[0046] According to the formula weight ratio, mix 20 parts of water and 0.3 parts of cellulose in a container, stir at a speed of 800r / min until the cellulose is completely dissolved, and form a mixed solution; add 4.5 parts of ethylene glycol, 0.4 parts of 1 part of sodium dodecylbenzene sulfonate, 0.2 part of stearyl alcohol, 0.1 part of wetting agent and 0.2 part of defoamer and stirred evenly; add 6 parts of carbon nanotubes and 20 parts of composite titanium dioxide, and disperse at 1500r / min to The fineness is less than 60μm; reduce the speed, add 50.0 parts of water-based acrylic polyaniline, and slowly add 0.6 parts of antistatic ionic liquid after dispersing evenly; finally add 0.5 parts of preservatives, 0.5 parts of antifungal agents, and 0.3 parts of thickeners in sequence, After uniform dispersion, the material is discharged, and the antistatic interior wall paint is obtained.

Embodiment 3

[0048] According to the formula weight ratio, mix 25 parts of water and 0.4 parts of cellulose in a container, stir at a speed of 800r / min until the cellulose is completely dissolved, and form a mixed solution; add 3.5 parts of ethylene glycol, 0.2 1 part of sodium dodecylbenzene sulfonate, 0.4 part of stearyl alcohol, 0.2 part of wetting agent and 0.3 part of defoamer and stirred evenly; add 5 parts of carbon nanotubes and 10 parts of composite titanium dioxide, and disperse at 1500r / min to The fineness is less than 60μm; reduce the speed, add 45.0 parts of water-based acrylic polyaniline, and slowly add 0.4 parts of antistatic ionic liquid after dispersing evenly; finally add 0.8 parts of preservatives, 0.8 parts of antifungal agents, and 0.4 parts of thickeners in sequence, After uniform dispersion, the material is discharged, and the antistatic interior wall paint is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com