New type pre-twisted armored wire protection bar

A guard wire and pre-twisted technology, which is applied in the direction of conductors, insulated cables, power cables, etc., can solve the problems of affecting normal wire transmission, inestimable economic losses, short circuit and high current impact, etc., to protect safety and improve the overall tie force , The effect of protecting against external damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

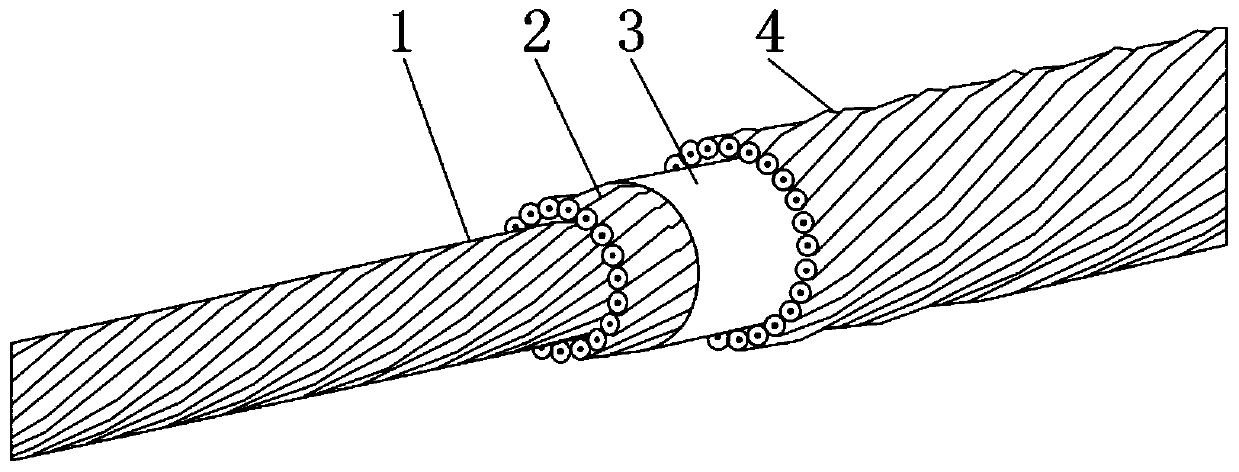

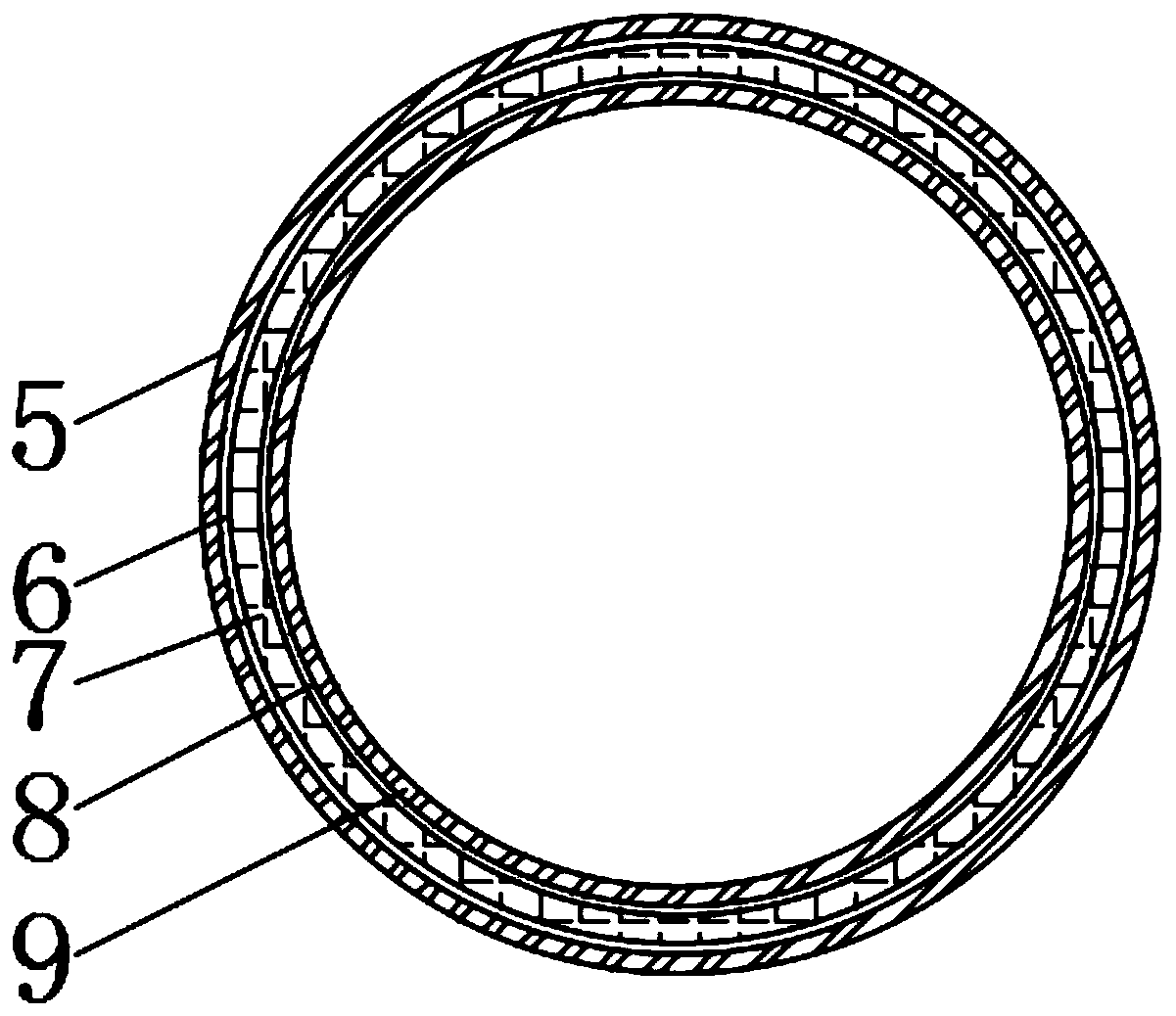

[0022] Embodiment one: refer to Figure 1-3 , a new type of pre-twisted armored protective wire, including a core 1, the core 1 refers to the wire body that plays a conductive role, the outer surface of the core 1 is twisted and wrapped with an inner twisted wire 2, and the inner twisted The wire 2 is a common structure in this field, so I won’t go into too much detail here, and the outer surface of the inner twisted wire 2 is wrapped with a conductive and heat-insulating composite layer 3, and the conductive and heat-insulating composite layer 3 includes an outer carbon fiber layer 5, a ceramic fiber layer 7 and The inner carbon fiber layer 9, and the outer carbon fiber layer 5 is compositely bonded and pressed by the outer silica gel bonding layer 6 and the ceramic fiber layer 7, and the inner carbon fiber layer 9 is compositely bonded and pressed by the inner silica gel bonding layer 8 and the ceramic fiber layer 7, and the outer carbon fiber layer 5 and the inner carbon fi...

Embodiment 2

[0023] Embodiment two: refer to figure 1 , the outer surface of the conductive and heat-insulating composite layer 3 is twisted and wrapped with an outer twisted wire 4, which belongs to a common structure in the field. The outer twisted wire 4 is twisted by aluminum alloy round wires, and the number of aluminum alloy strands and the number of twisted turns are visible Depends on the size of the diameter.

Embodiment 3

[0024] Embodiment three: refer to figure 1 , conductive sand is laid between the inner twisted wire 2 and the wire core 1, and the inner twisted wire 2 is twisted from aluminum alloy round wires, the conductive sand increases the friction between the wire core 1 and the inner twisted wire 2, preventing Relative slippage occurs between the wire core 1 and the inner skeins 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com