Self-cleaning coating material for car outer surface

A self-cleaning coating and outer surface technology, applied in coatings, anti-corrosion coatings, conductive coatings, etc., can solve the problems of exhaust, carbon dust and other pollution that cannot exert the desired effect, cannot develop the market, and high construction prices, etc., to achieve reduction The frequency of car washing, the effect of improving environmental protection benefits and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

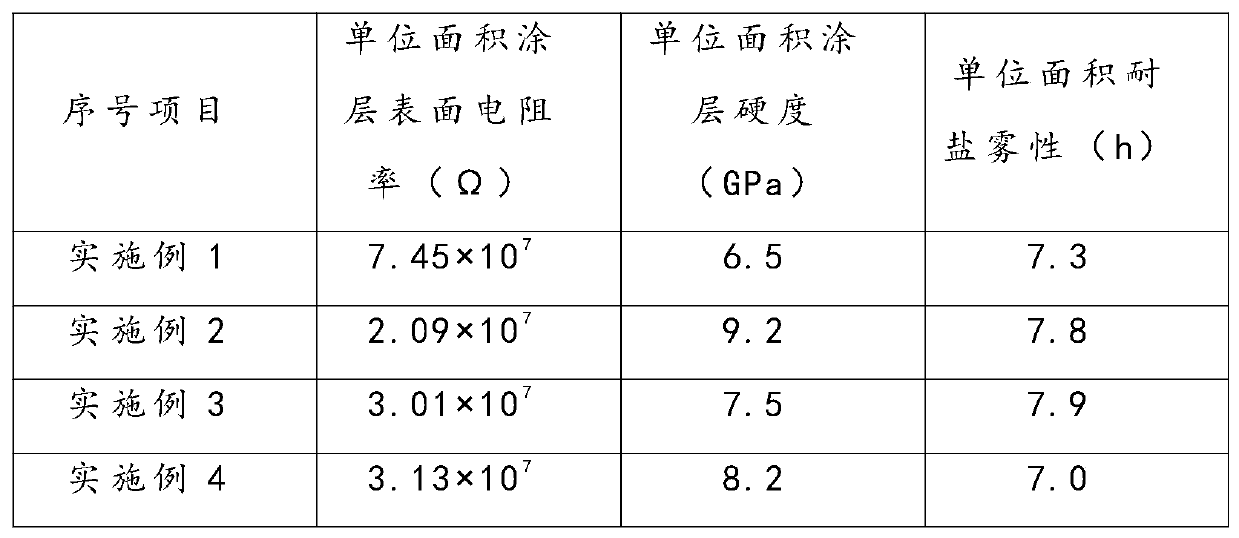

Examples

Embodiment 1

[0015] Embodiment 1: A kind of self-cleaning coating material that is used for the exterior surface of automobile, is made up of the following components by weight: 50 parts of methanol; 21 parts of water; 1 part of tin oxide; 1 part of platinum; 0.5 part of tungsten oxide; 6 parts of silicon oxide. The tin oxide is nano-scale tin oxide particles, the platinum is nano-scale platinum particles, the tungsten oxide is nano-scale tungsten oxide particles, and the silicon dioxide is nano-scale silicon dioxide particles. And the particle diameter of the nano-scale tin oxide particles, nano-scale platinum particles, nano-scale tungsten oxide particles and nano-scale silicon dioxide particles is 30 nm. Nano-tin oxide particles effectively reduce the resistance of the body, thereby reducing the insulation of the body, reducing the static electricity accumulated on the body, and preventing static electricity from absorbing dust, while nano-silica particles have a super-hydrophilic shape...

Embodiment 2

[0021] Embodiment 2: a kind of self-cleaning coating material that is used for the exterior surface of automobile, is made up of the component of following parts by weight: methanol 70 parts; Water 25 parts; Tin oxide 5 parts; Platinum 1.5 parts; Tungsten oxide 1.0 part; 9 parts of silicon oxide.

[0022] The tin oxide is nano-scale tin oxide particles, the platinum is nano-scale platinum particles, the tungsten oxide is nano-scale tungsten oxide particles, and the silicon dioxide is nano-scale silicon dioxide particles. The particle diameters of the nanoscale tin oxide particles, nanoscale platinum particles, nanoscale tungsten oxide particles and nanoscale silicon dioxide particles are all less than 30 nanometers. Nano-tin oxide particles effectively reduce the resistance of the body, thereby reducing the insulation of the body, reducing the static electricity accumulated on the body, and preventing static electricity from absorbing dust, while nano-silica particles have a s...

Embodiment 3

[0028] Embodiment 3: a kind of self-cleaning coating material that is used for the exterior surface of automobile, is made up of the component of following parts by weight: 60 parts of methanol; 23 parts of water; 3 parts of tin oxide; 1.3 parts of platinum; 0.7 part of tungsten oxide; Silicon oxide 8 parts.

[0029] The tin oxide is nano-scale tin oxide particles, the platinum is nano-scale platinum particles, the tungsten oxide is nano-scale tungsten oxide particles, and the silicon dioxide is nano-scale silicon dioxide particles. Nano-tin oxide particles effectively reduce the resistance of the body, thereby reducing the insulation of the body, reducing the static electricity accumulated on the body, and preventing static electricity from absorbing dust, while nano-silica particles have a super-hydrophilic shape, which can form a layer of water molecules and act as an antistatic agent role. Nano-platinum particles have chemical resistance and can resist acid corrosion such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com