Breathable antistatic foam material and preparation method thereof

A foam material, anti-static technology, applied in the direction of organic chemistry, etc., can solve the problems of explosion, easy combustion, dust collection and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

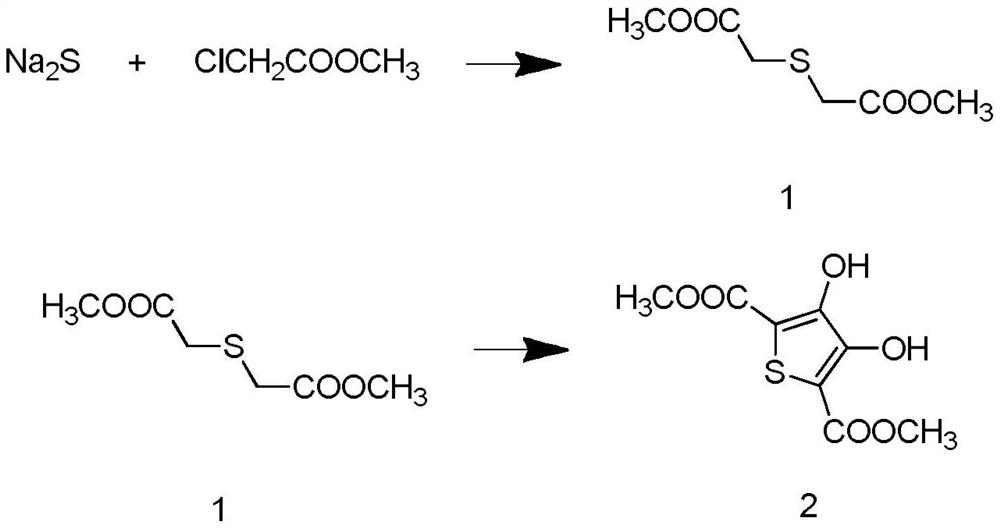

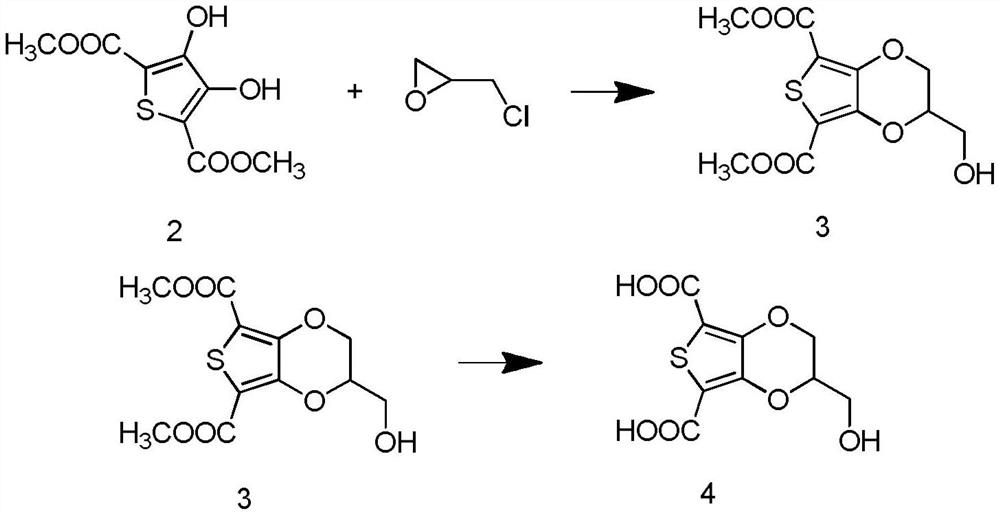

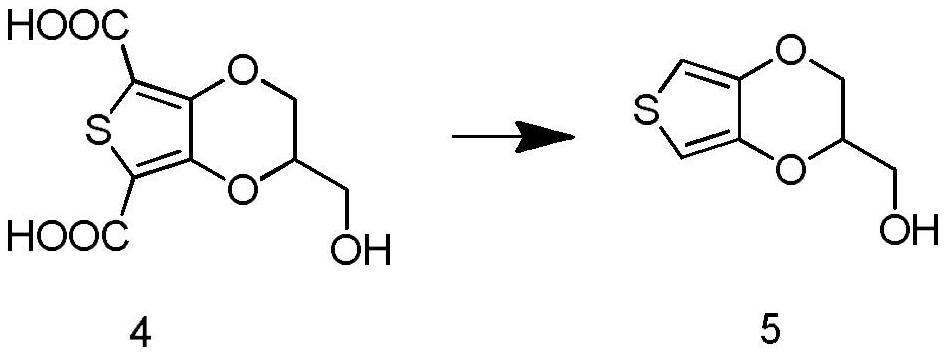

Method used

Image

Examples

Embodiment 1

[0040] A breathable and antistatic foam material, comprising the following raw materials in parts by weight: 100 parts of low-density polyethylene, 10 parts of glyceryl monostearate, 3 parts of talcum powder, 3 parts of antistatic agent, 1 part of flame-retardant particles, magnesium carbonate 3 parts, 1 part of carbon black;

[0041] Step S1: Add low-density polyethylene, glyceryl monostearate, talcum powder, antistatic agent, flame-retardant particles, and carbon black into the internal mixer, and carry out internal mixing at a temperature of 130°C for 15 minutes to produce got the mixture;

[0042] Step S2: Put the mixture and magnesium carbonate prepared in step S1 at a temperature of 100°C, continue banburying for 10 minutes, put them into the mold, and keep them warm for 10 minutes at a temperature of 180°C and a pressure of 1.5 MPa , to make a preform;

[0043] Step S3: adding the preform into a foaming mold, and foaming for 10 minutes at a temperature of 80° C. to ob...

Embodiment 2

[0052] A breathable and antistatic foam material, comprising the following raw materials in parts by weight: 105 parts of low-density polyethylene, 12 parts of glyceryl monostearate, 4 parts of talcum powder, 4 parts of antistatic agent, 2 parts of flame-retardant particles, magnesium carbonate 4 parts, 2 parts of carbon black;

[0053] Step S1: Add low-density polyethylene, glyceryl monostearate, talcum powder, antistatic agent, flame-retardant particles, and carbon black into the internal mixer, and carry out internal mixing at a temperature of 130°C for 20 minutes to produce got the mixture;

[0054] Step S2: Put the mixed material and magnesium carbonate prepared in step S1 at a temperature of 100° C., continue banburying for 15 minutes, then put them into a mold, and keep them warm for 10 minutes at a temperature of 180° C. and a pressure of 2 MPa. make preforms;

[0055] Step S3: adding the preform into a foaming mold, and foaming for 10 minutes at a temperature of 100...

Embodiment 3

[0064] A breathable and antistatic foam material, comprising the following raw materials in parts by weight: 115 parts of low-density polyethylene, 14 parts of glyceryl monostearate, 6 parts of talcum powder, 4 parts of antistatic agent, 2 parts of flame-retardant particles, magnesium carbonate 4 parts, 2 parts of carbon black;

[0065] Step S1: Add low-density polyethylene, glyceryl monostearate, talcum powder, antistatic agent, flame-retardant particles, and carbon black into the internal mixer, and carry out internal mixing at a temperature of 150°C for 15 minutes to produce got the mixture;

[0066] Step S2: Put the mixture and magnesium carbonate prepared in step S1 at a temperature of 110°C, continue banburying for 10 minutes, put them into the mold, and keep them warm for 15 minutes at a temperature of 190°C and a pressure of 1.5 MPa , to make a preform;

[0067] Step S3: adding the preform into a foaming mold, and foaming for 15 minutes at a temperature of 80° C. to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com