Coloring process for modified polypropylene chemical fiber processing

A chemical fiber and cotton fiber technology, which is applied in the field of coloring technology for cotton fiber processing, can solve the problems of prolonging the production cycle, cumbersome operation steps, and large volume of dyeing machines, so as to improve the uniformity of exhaust dyeing, improve the operation effect, and simplify the operation The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

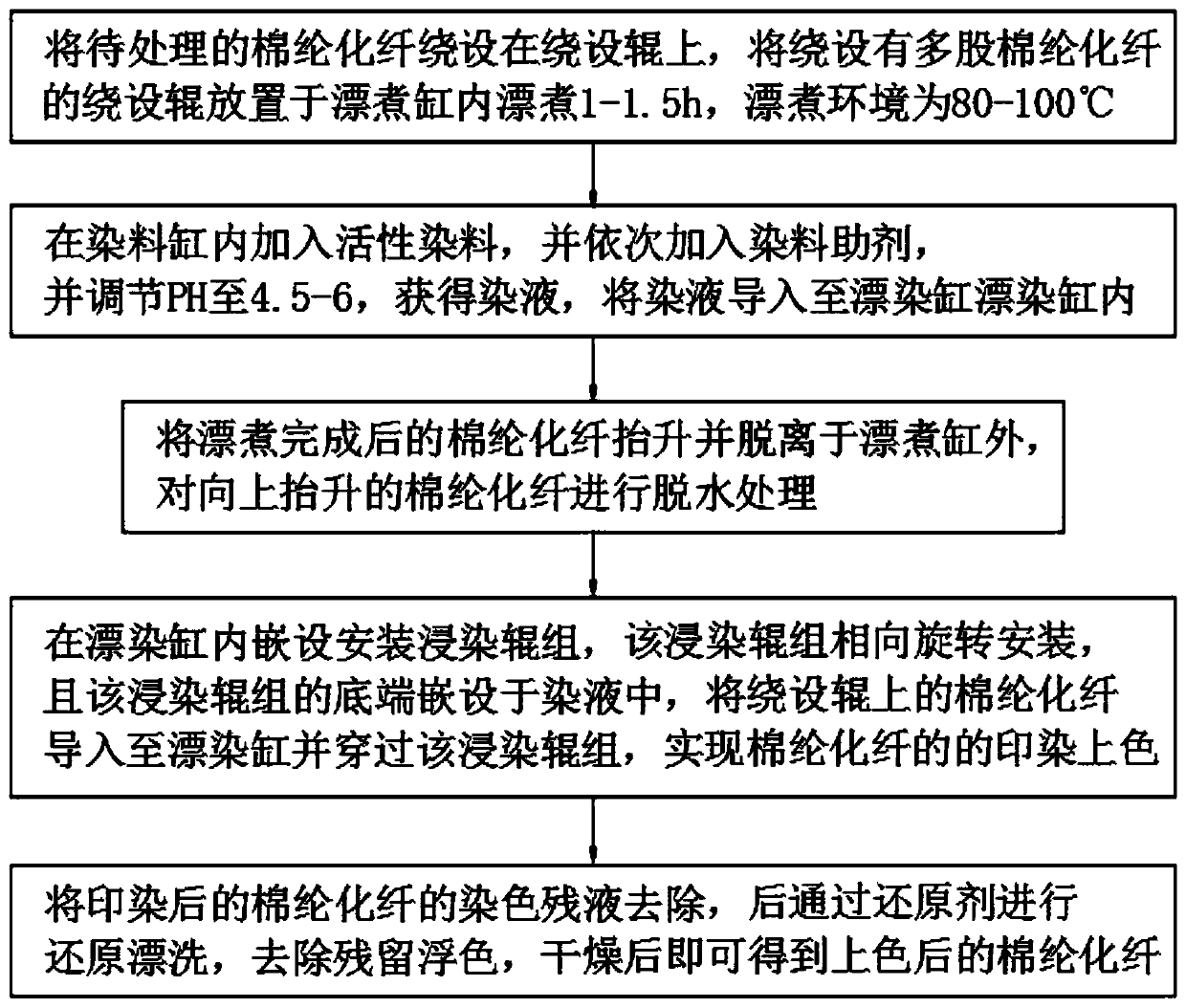

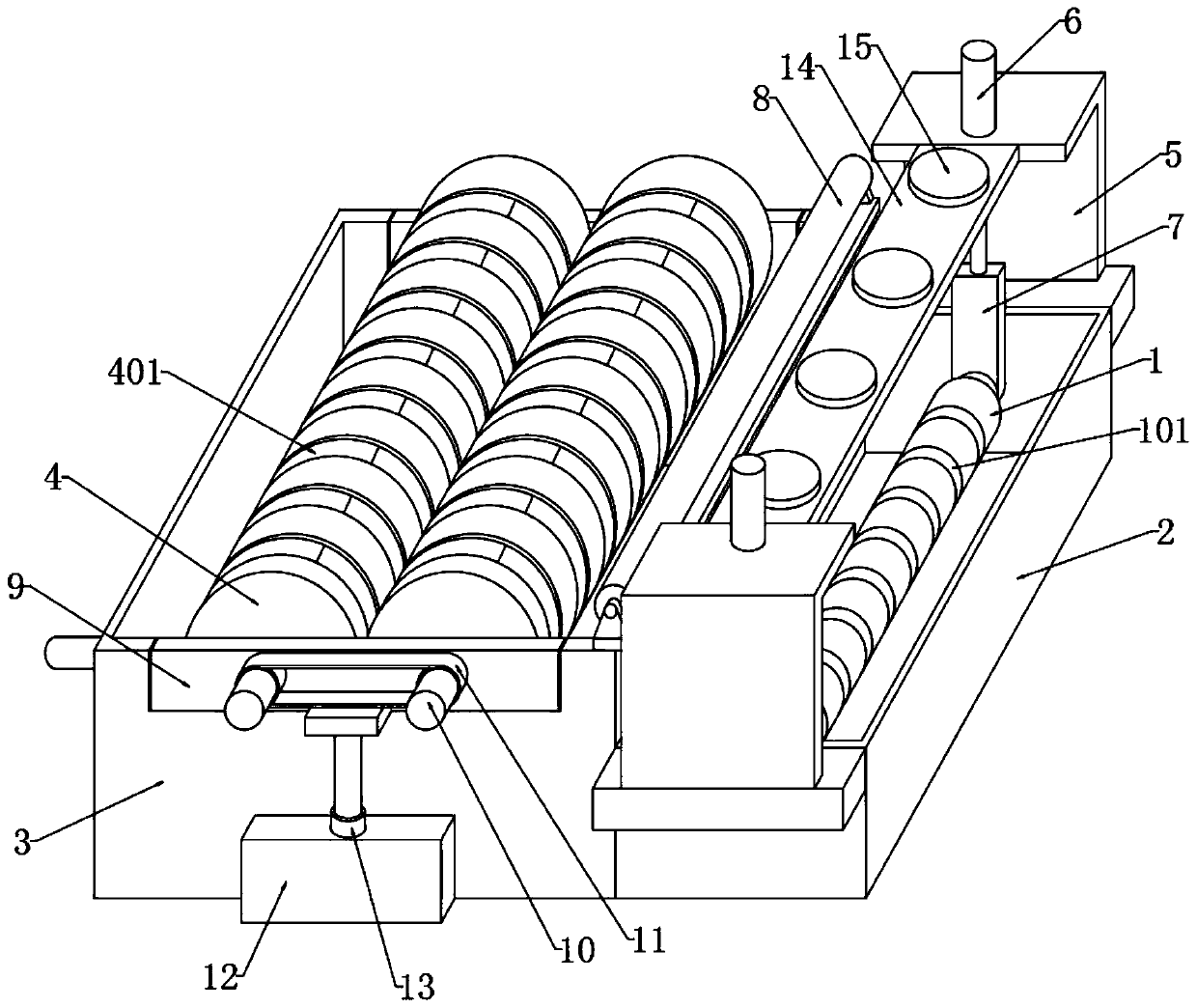

[0042] See figure 1 , A coloring process for cotton fiber processing, including the following steps:

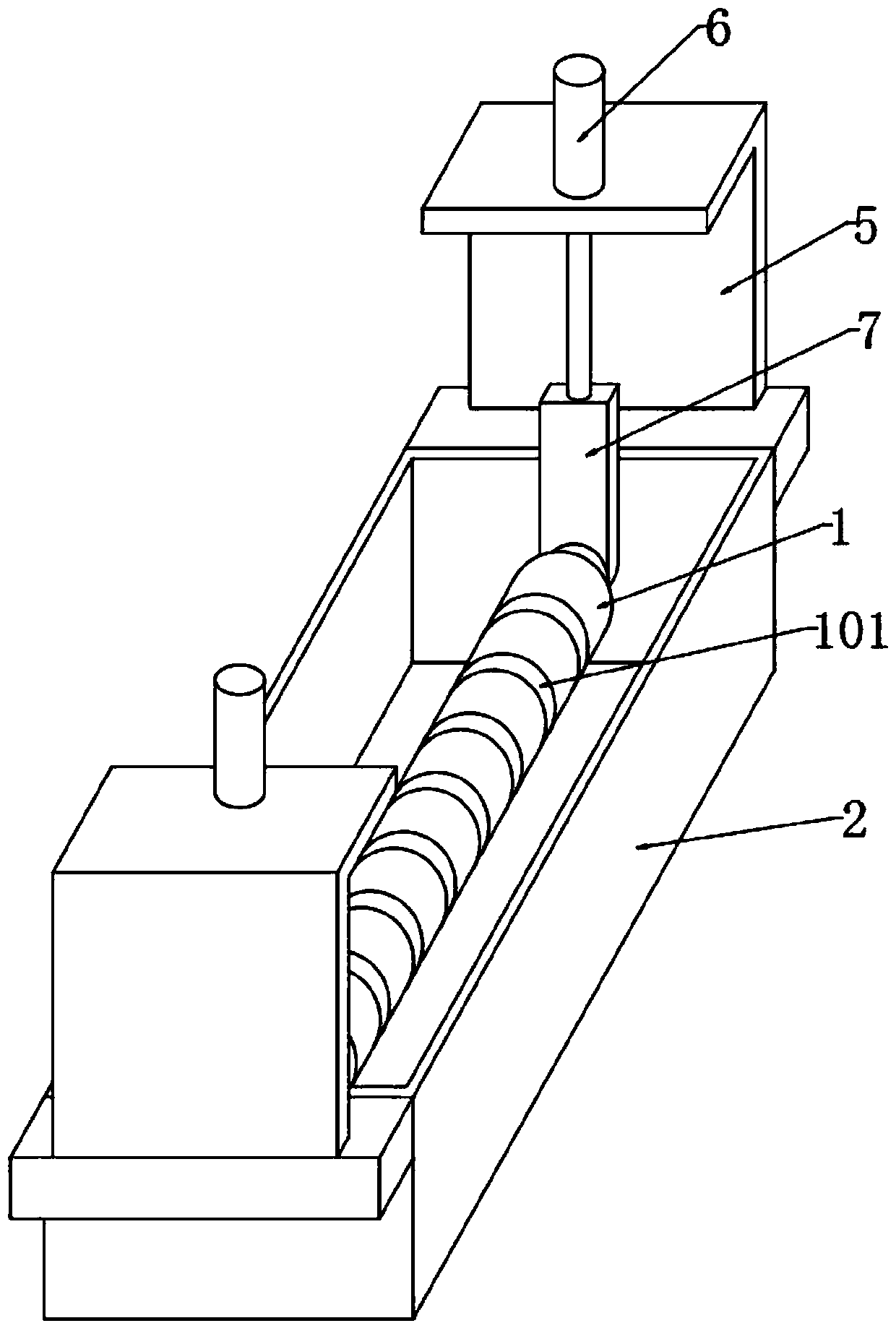

[0043] S1. The cotton chemical fiber to be treated is wound on the winding roller 1, and the winding roller 1 with multiple cotton chemical fibers is placed in the bleaching cylinder 2 for bleaching for 1-1.5h. The bleaching environment is 80-100°C;

[0044] S2. Add reactive dyes in the dye tank, and add dye auxiliaries in turn, adjust the pH to 4.5-6, stir for 0.5-1h, and maintain a high temperature environment of 100-120℃ to obtain the dye liquor, and then introduce the dye liquor to the bleaching Inside the bleaching and dyeing vat 3;

[0045] S3. Lift the cotton chemical fiber after bleaching and boiling in S1 and leave it out of the bleaching cylinder 2, and perform dehydration treatment on the raised cotton chemical fiber;

[0046] S4. A set of impregnating rollers 4 is embedded and installed in the bleaching vat 3, and the set of impregnating rollers 4 is rotatably installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com