Multifunctional finishing additive

An additive and multifunctional technology, applied in fiber treatment, textiles and papermaking, fiber types, etc., can solve the problems of increased volatile substances, environmental impact, etc., and achieve the effect of increasing antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

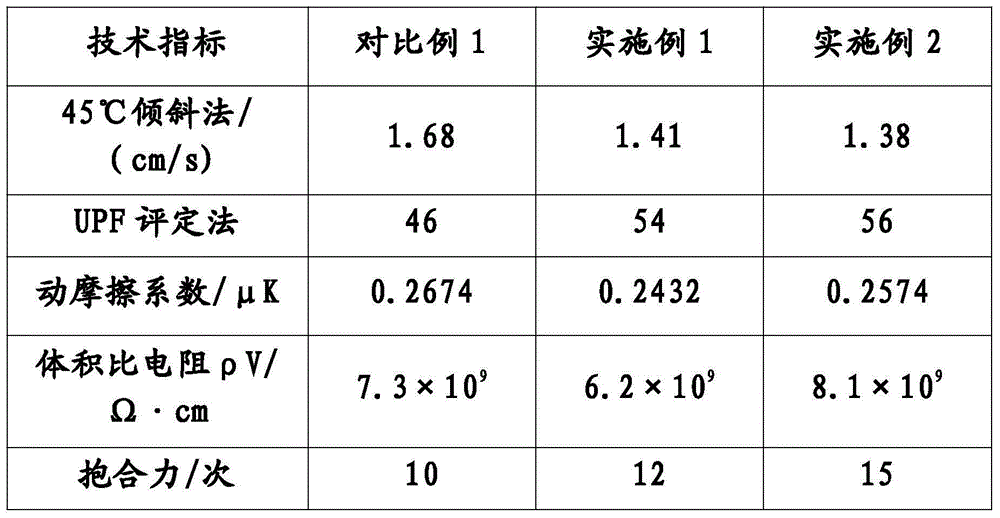

Examples

Embodiment 1

[0016] This embodiment relates to a kind of multi-functional finishing additive, each component according to weight part number is:

[0017] Dibromonitroethanol 6,

[0018] Tetrahydroxymethylphosphonium chloride 3,

[0019] Phosphite 5,

[0020] Benzotriazole 3,

[0021] 2,4-Dihydroxybenzophenone 3,

[0022] 10# mineral oil 30,

[0023] Polyoxyethylene laurate 2.

[0024] The preparation method of this multifunctional additive is:

[0025] Step 1: Take 30 parts of mineral oil, heat to a certain temperature, take 6 parts of dibromonitroethanol, 5 parts of phosphite, and 3 parts of 2,4-dihydroxybenzophenone, mix them in a constant temperature shaking pot, Keep the shaking speed at 100-200 rpm for 20 minutes, disperse it in mineral oil, and prepare oil agent A.

[0026] Step 2: Add 3 parts of tetrahydroxymethyl phosphorus chloride and 2 parts of polyoxyethylene laurate to oil agent A, heat, control the stirring speed, stir for 30 minutes, and then add 3 parts of benzotriaz...

Embodiment 2

[0028] This embodiment relates to a multifunctional finishing additive. The preparation method refers to Example 1, and the components are composed of:

[0029] Dibromonitroethanol 7,

[0030] bronopol 5,

[0031] Tetrahydroxymethylphosphonium chloride 4,

[0032] Benzotriazole 4,

[0033] 2,4-Dihydroxybenzophenone 3,

[0034] 10# mineral oil 25,

[0035] Polyoxyethylene laurate 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com