Preparation method of building bricks

A technology for construction and preparation steps, which is applied in the field of preparation of construction bricks, which can solve the problems of large resource consumption, hollowing, fracture and collapse of the plaster layer, and achieve the effects of improving mechanical strength, compact internal structure and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

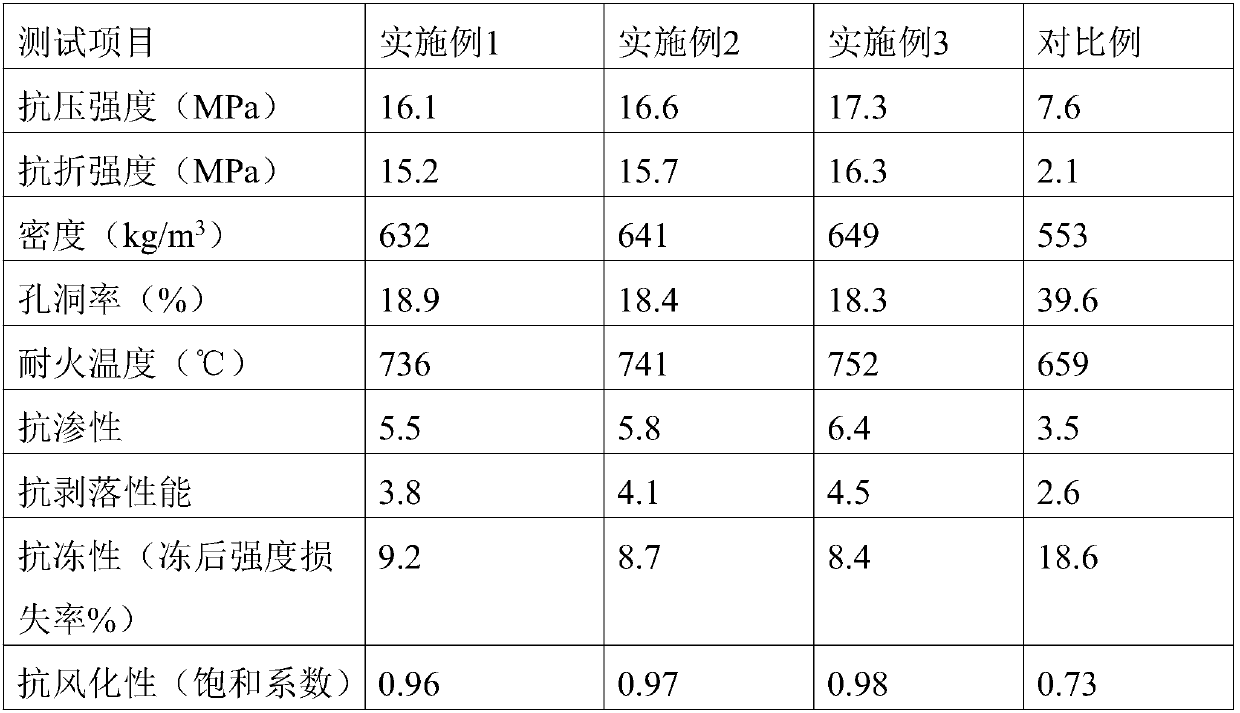

Examples

Embodiment 1

[0023] In parts by weight, weigh 60 parts of concentrated sulfuric acid with a mass fraction of 80%, 1 part of sodium nitrate powder and 3 parts of graphite powder into a three-necked flask, place the three-necked flask in a water bath with a water bath temperature of 0°C and stir Stir at a speed of 310r / min for 10min. After stirring and mixing, add 6 parts of potassium permanganate powder and continue stirring for 10min. Then raise the temperature of the water bath to 36°C and react at a constant temperature for 30min to obtain a dark brown liquid; add the above black Brown liquid with 210% deionized water, raise the temperature of the water bath to 88°C, and react at a constant temperature for 16 minutes to obtain a mixed solution, add 20% of the mass of the mixed solution to the mixed solution and add hydrogen peroxide with a mass fraction of 21%, and keep the temperature of the water bath at a constant temperature for 20 minutes. , to obtain a suspension, filter while it is...

Embodiment 2

[0025]In parts by weight, weigh 65 parts of concentrated sulfuric acid with a mass fraction of 84%, 1.5 parts of sodium nitrate powder and 3.5 parts of graphite powder and put them into a three-necked flask. Stir at a speed of 330r / min for 11min. After stirring and mixing, add 7 parts of potassium permanganate powder and continue stirring for 11min. Then raise the temperature of the water bath to 38°C and react at a constant temperature for 34min to obtain a dark brown liquid; add the above black Brown liquid with 225% deionized water, raise the temperature of the water bath to 89°C, and react at a constant temperature for 17 minutes to obtain a mixed solution, add 24% of the mixed solution to the mixed solution and add hydrogen peroxide with a mass fraction of 23%, and keep the temperature of the water bath at a constant temperature for 22 minutes , to obtain a suspension, filtered while it was hot to obtain a filter residue, washed the filter residue 3 times with dilute hydro...

Embodiment 3

[0027] In parts by weight, weigh 70 parts of concentrated sulfuric acid with a mass fraction of 88%, 2 parts of sodium nitrate powder and 4 parts of graphite powder into a three-necked flask, place the three-necked flask in a water bath with a water bath temperature of 4°C and stir Stir at a speed of 350r / min for 13min, after stirring and mixing, add 8 parts of potassium permanganate powder and continue stirring for 13min, then increase the temperature of the water bath to 40°C, and react at a constant temperature for 38min to obtain a dark brown liquid; add the above black Brown liquid with 240% deionized water, raise the temperature of the water bath to 90°C, and react at a constant temperature for 18 minutes to obtain a mixed solution, add 28% of the mixed solution to the mixed solution and add hydrogen peroxide with a mass fraction of 25%, and keep the temperature of the water bath at a constant temperature for 24 minutes , to obtain a suspension, filter while it is hot to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com