Die assembly for double-stage differential pressure type capillary rheometers

A capillary rheometer and die technology, applied in the field of rheometer, can solve the problems of low experimental efficiency and low test pressure, and achieve the effect of improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

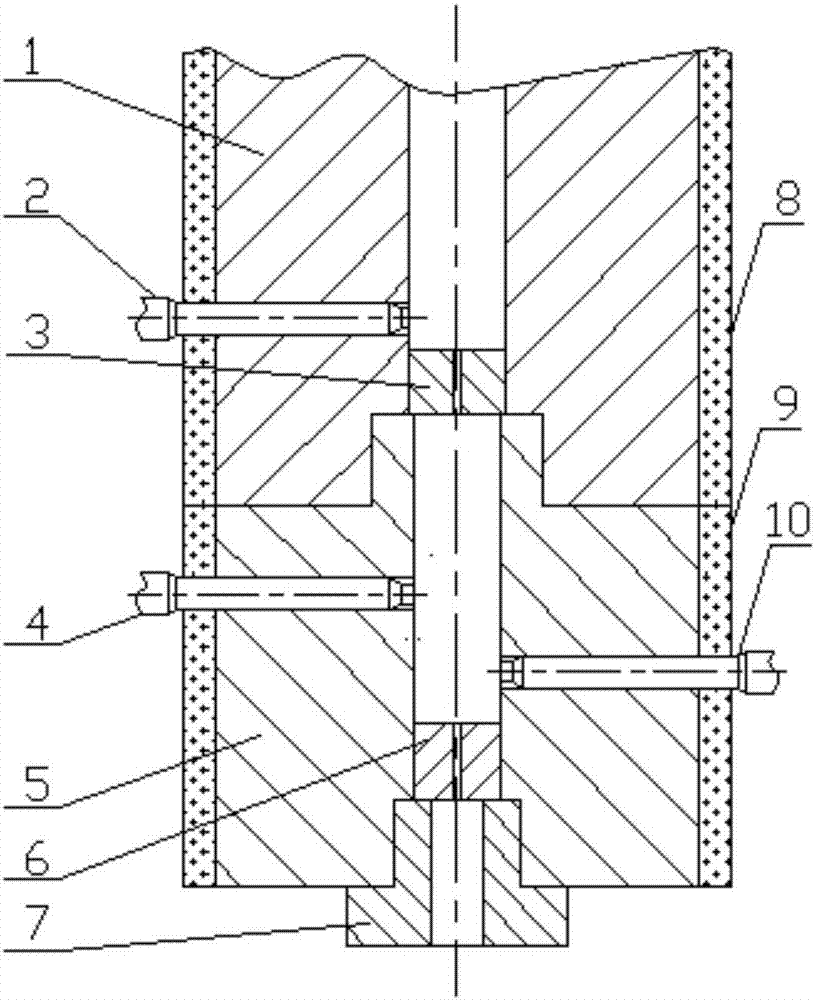

[0032] Such as figure 1 As shown, a die assembly of a two-stage partial pressure capillary rheometer.

[0033] The die assembly includes a first barrel 1 and a second barrel A5, the first barrel 1 is on the top, the second barrel A5 is on the bottom, and the outer wall of the first barrel 1 and the outer wall of the second barrel A5 are respectively provided with The first heating jacket 8 and the second heating jacket 9; the first barrel 1 and the second barrel A5 are connected through a threaded structure; the end of the first barrel 1 is provided with an internal thread groove, and the groove is connected to the inner surface of the first barrel. The cavity is concentric, and the diameter of the groove is greater than the diameter of the inner cavity; the top of the second barrel A5 is provided with an external thread boss, the boss is concentric with the inner cavity of the second barrel, and the boss is concentric with the inner thread groove of the first barrel. Coopera...

Embodiment 2

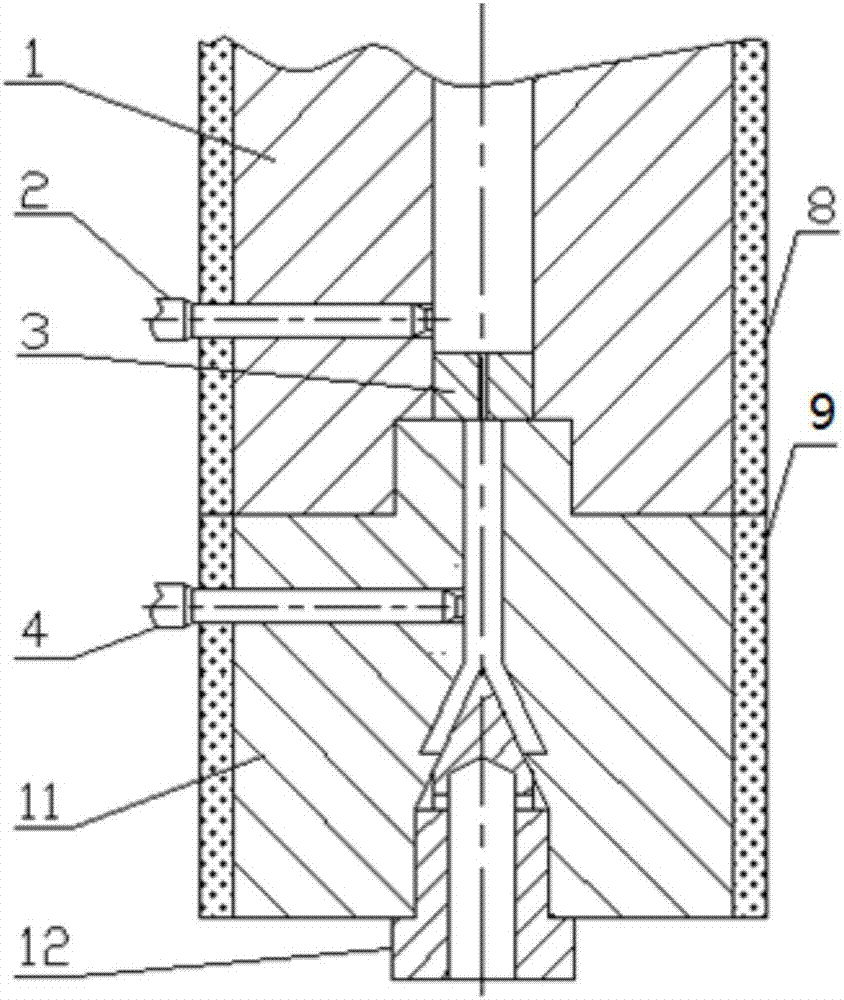

[0040] Such as figure 2 As shown, a die assembly of a two-stage partial pressure capillary rheometer.

[0041] The die assembly includes a first barrel 1 and a second barrel B11, the first barrel 1 is on the top, the second barrel B11 is on the bottom, and the outer wall of the first barrel 1 and the outer wall of the second barrel B11 are respectively provided with The first heating jacket 8 and the second heating jacket 9; the first barrel 1 and the second barrel B11 are connected through a threaded structure; the end of the first barrel 1 is provided with an internal thread groove, and the groove is connected to the inner surface of the first barrel. The cavity is concentric, and the diameter of the groove is larger than the diameter of the inner cavity; the top of the second barrel B11 is provided with an external thread boss, the boss is concentric with the inner cavity of the second barrel, and the boss is concentric with the inner thread groove of the first barrel Coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com