Thermo-thickening polymer based on graft modification of polyether and preparation method thereof

A graft modification and polymer technology, applied in the field of water-soluble polymers, can solve the problems of difficulty in meeting the actual application requirements of industrialization, increased application costs, harsh preparation conditions, etc. Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

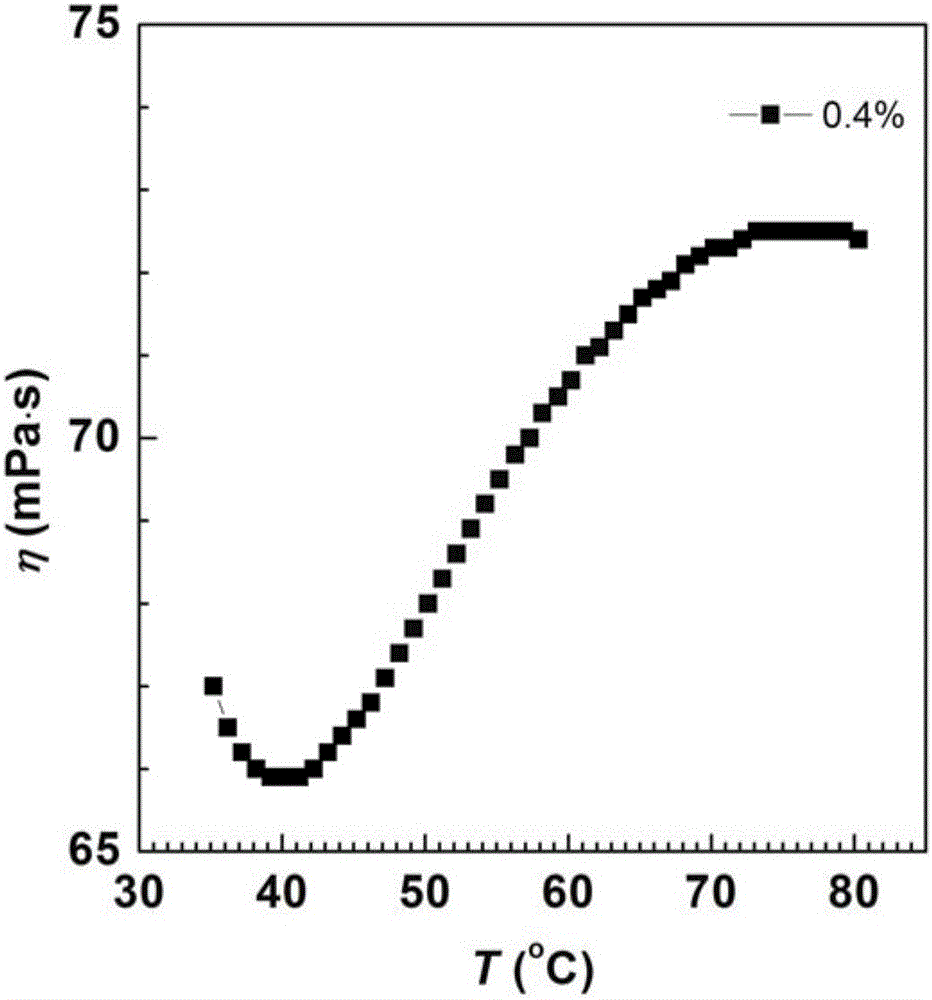

Embodiment 1

[0033] (1) 4g hexadecyl polyvinylpyrrolidone is dissolved with 100g n-dodecane to form the first solution; 16g of acrylic acid is dissolved in 30% sodium hydroxide solution and adjusted to be neutral, then add 20g of F127, Form the second solution, the amount of lye can be adjusted to a neutral hydrophilic monomer solution with the acidic hydrophilic monomer and the polyether can be completely dissolved; the first solution and the second solution are added to a 500mL four-necked flask and mixed. Form a mixed reaction system of aqueous phase and organic phase;

[0034] (2) Continuously feed N into the flask 2 After removing the oxygen, add the initiator 0.001g 2,2'-azobis(2,4-dimethylvaleronitrile) (V52) and 0.003g lauroyl peroxide (LPO) into the water phase and mix with the organic phase under stirring The reaction system was then reacted at 70°C for 4 hours under nitrogen protection and stirring. After the reaction was completed, it was naturally cooled to room temperature t...

Embodiment 2

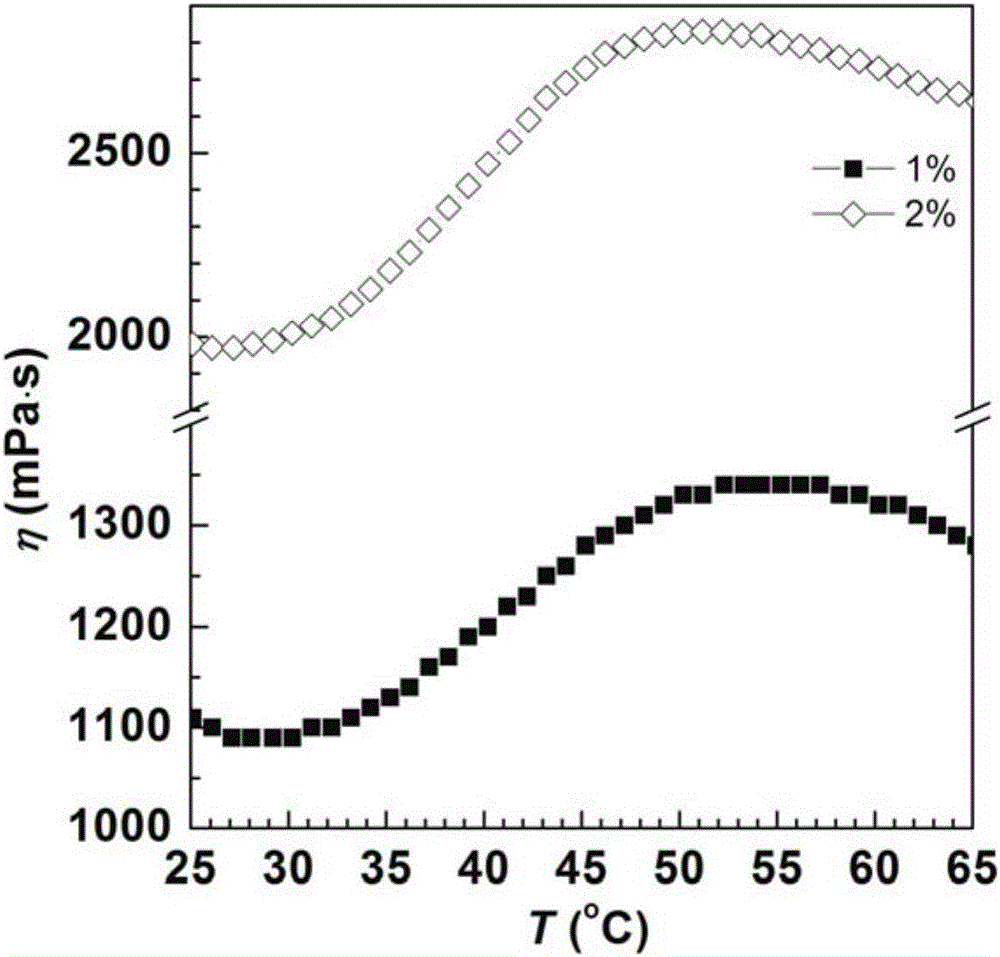

[0036](1) 4g hexadecyl polyvinylpyrrolidone is dissolved in 100g n-dodecane to form the first solution, 12g of acrylic acid is dissolved in 30% sodium hydroxide solution and adjusted to be neutral, then add 20g of F127, 4g of acrylamide to form the second solution. The amount of lye can be adjusted to a neutral hydrophilic monomer solution and the polyether can be completely dissolved. Add the first solution and the second solution to 500mL four ports Mix in the flask to form a mixed reaction system of water phase and organic phase;

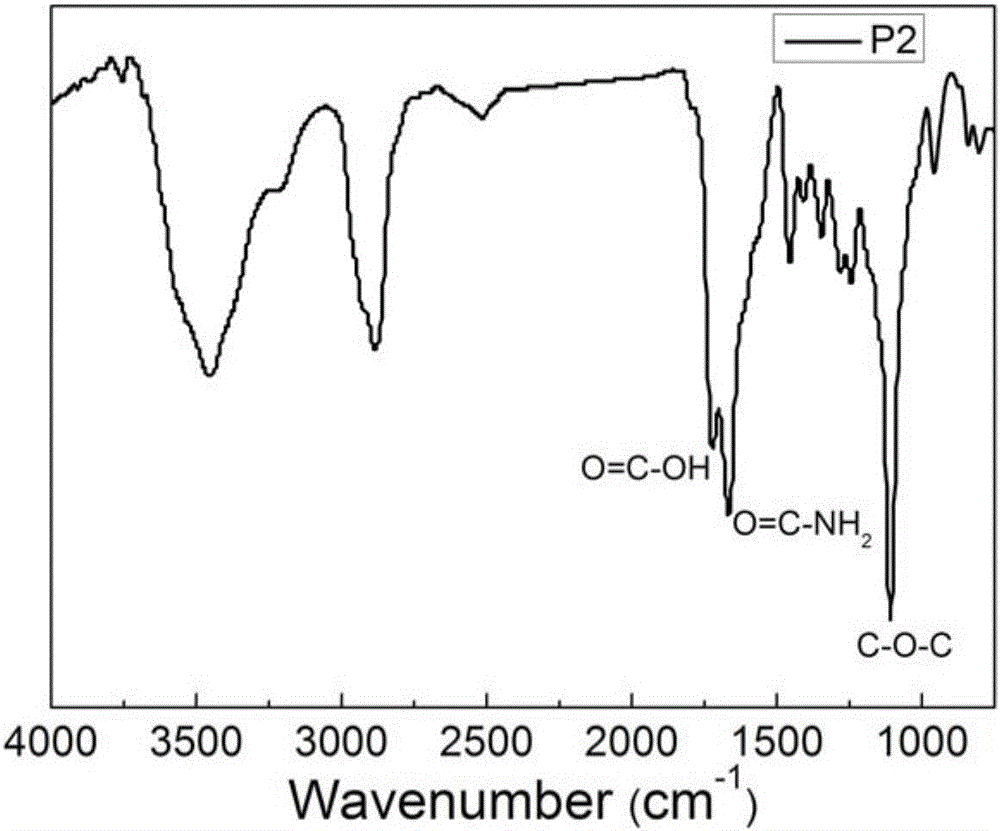

[0037] (2) Continuously feed N into the flask 2 After removing the oxygen, add the initiator 0.001g V52 and 0.003g LPO into the mixed reaction system of the water phase and the organic phase under stirring, then react at 70°C for 4 hours under the protection of nitrogen and stirring, and naturally cool to the room after the reaction to obtain the reaction liquid. The resulting reaction solution was filtered, the white solid product was collected...

Embodiment 3

[0039] (1) 4g hexadecyl polyvinylpyrrolidone is dissolved in 100g n-dodecane to form the first solution, 8g of acrylic acid is dissolved in 30% sodium hydroxide solution and adjusted to neutrality, then add 20g of F127, 8g of acrylamide to form the second solution. The amount of lye can be adjusted to a neutral hydrophilic monomer solution and the polyether can be completely dissolved. Add the first solution and the second solution to 500mL four ports Mix in the flask to form a mixed reaction system of water phase and organic phase;

[0040] (2) Continuously feed N into the flask 2 After removing the oxygen, add the initiator 0.001g V52 and 0.003g LPO into the mixed reaction system of the water phase and the organic phase under stirring, then react at 70°C for 4 hours under the protection of nitrogen and stirring, and naturally cool to the room after the reaction to obtain the reaction liquid. The obtained reaction solution was filtered, and the white solid product was collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com