Preparation method of solid spherical ITO granulation powder

A granulated powder and spherical technology, which is applied in the field of preparation of solid spherical ITO granulated powder, can solve the problems of difficulty in taking into account, inability to obtain high-quality target materials, complicated preparation method and process flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing solid spherical ITO granulated powder, selecting indium oxide powder with a particle size of 10-500nm and tin oxide powder with a particle size of 10-500nm, and mixing the indium oxide powder and tin oxide powder at a mass ratio of 9:1 Add deionized water to make a slurry with a solid content of 50-80%, and then add a dispersant accounting for 0.1-5% of the total powder mass to it and grind thoroughly. The particle size of the slurry after grinding satisfies D90=0.1-2µm, Then add a binder accounting for 1-10% of the total powder mass to the slurry and mix evenly, then heat the slurry or adjust the pH value of the slurry to control the viscosity of the slurry at 100-1500mPa·s, and finally adjust the slurry Carry out spray drying to ensure that the inlet air temperature is 100~300°C, the outlet air temperature is 60~200°C, and the atomizer frequency is 20~50Hz, that is, the solid spherical ITO granulated powder with a particle size of 20~150µm is obt...

Embodiment 1

[0032] A preparation method of solid spherical ITO granulated powder, the steps are as follows:

[0033] Weigh 9Kg indium oxide powder, 1Kg tin oxide powder, indium oxide powder D50=125nm, tin oxide powder D50=88nm, add 6Kg deionized water to make slurry, then add 0.06Kg polycarboxylic acid dispersant to it, Grind with a sand mill for 2h, the slurry D90=0.6μm. Weigh 0.15Kg of polyvinyl alcohol, add it to the slurry, disperse evenly, heat the slurry to 75°C, and check the viscosity in real time. When the viscosity is 500mPa·s, stop heating. Put the slurry into the spray drying tower for spray drying, the inlet air temperature is 220°C, the outlet air temperature is 90°C, and the atomizer frequency is 35Hz.

[0034] The ITO granulated powder that this embodiment obtains is solid spherical, bulk density 1.91g / cm 3 , after 20MPa dry pressing and 200MPa isostatic pressing to obtain a green body, the relative density of the target obtained by sintering in an oxygen atmosphere is 9...

Embodiment 2

[0036] A preparation method of solid spherical ITO granulated powder, the steps are as follows:

[0037] Weigh 9Kg indium oxide powder, 1Kg tin oxide powder, indium oxide powder D50=50nm, tin oxide powder D50=20nm, add 8Kg deionized water to make slurry, then add 0.1Kg polyacrylamide dispersant to it, use Sand mill grinding 2h, slurry D90=0.3μm. Weigh 0.2Kg of polyethylene glycol, add the slurry, and disperse evenly. Add acetic acid to the slurry, adjust the pH to 5, the viscosity of the slurry is 400mPa·s, stop heating. Put the slurry into the spray drying tower for spray drying, the inlet air temperature is 200°C, the outlet air temperature is 80°C, and the atomizer frequency is 50Hz.

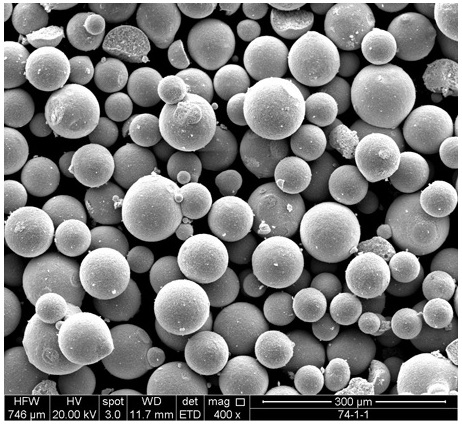

[0038] The ITO granulated powder that this embodiment obtains is solid spherical (as figure 1 shown), bulk density 1.78g / cm 3 , through 20MPa dry pressing and 200MPa isostatic pressing to obtain a green body, and the relative density of the target obtained by sintering in an oxygen atmosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com