Matt UV printing ink and preparation method thereof

A kind of ink and matte technology, applied in the direction of ink, household utensils, applications, etc., can solve the problems of poor matting effect, achieve excellent light absorption effect, improve dispersion effect, and enhance the effect of suspension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

[0041] Weigh 15kgMMA, 0.8kgHD, 8kg isooctane, 0.3kgAIBN, 0.3kgDVB respectively, stir and mix to obtain the oil phase, weigh 0.5kgSDS and 80kg water, stir and mix SDS and water to obtain the water phase, and mix the oil phase Add it into the water phase, stir magnetically for 30 minutes to obtain a microemulsion, disperse at high speed and homogeneously emulsify for 5 minutes to obtain a microemulsion. The miniemulsion was reacted at 65°C under a nitrogen atmosphere at a constant temperature for 2 hours, 10kg of vinyltriethoxysilane was added, and polymerized for 8 hours, 10 hours, and 12 hours respectively to obtain PMMA hollow microspheres with particle sizes of 20, 40, and 60 μm.

[0042] Modifier preparation example

preparation example 4-9

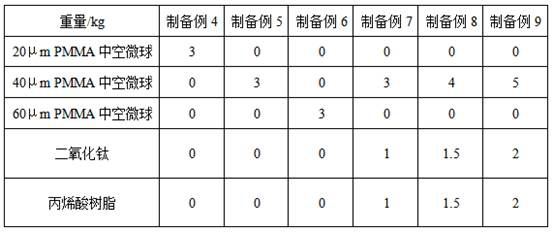

[0044] PMMA hollow microspheres with a particle size of 20-60 μm, silicon dioxide and acrylic resin were weighed, stirred and mixed to prepare Modifiers 1-6. The specific quality is shown in Table 1.

[0045] Table 1 preparation example 4-9 modifier composition

[0046]

[0047] Preparation example of anti-sedimentation dispersant

preparation example 10-13

[0049] Weigh epoxy resin, titanium dioxide and nanocellulose respectively, see Table 2 for the specific quality, first stir and mix titanium dioxide and nanocellulose to obtain an intermediate, then add the intermediate to the epoxy resin in the stirring, and continue stirring for 5 minutes, Ultrasonic treatment for 2 minutes to obtain anti-sedimentation dispersant 1-4.

[0050] Table 2 Preparation Example 10-13 anti-sedimentation dispersant composition

[0051]

[0052] Preparation example of modified polyurethane

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com