Technique of fluidized instant calcinations of kaolin in coal series

A technology of coal-based kaolin and calcination process, which is applied in the direction of clay products, aluminum silicate, silicate, etc., can solve the problems of long production process route, difficulty in large-scale equipment, shortening calcination time, etc., to increase the output of a single unit, The effect of reducing energy consumption and shortening the whitening time of calcination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

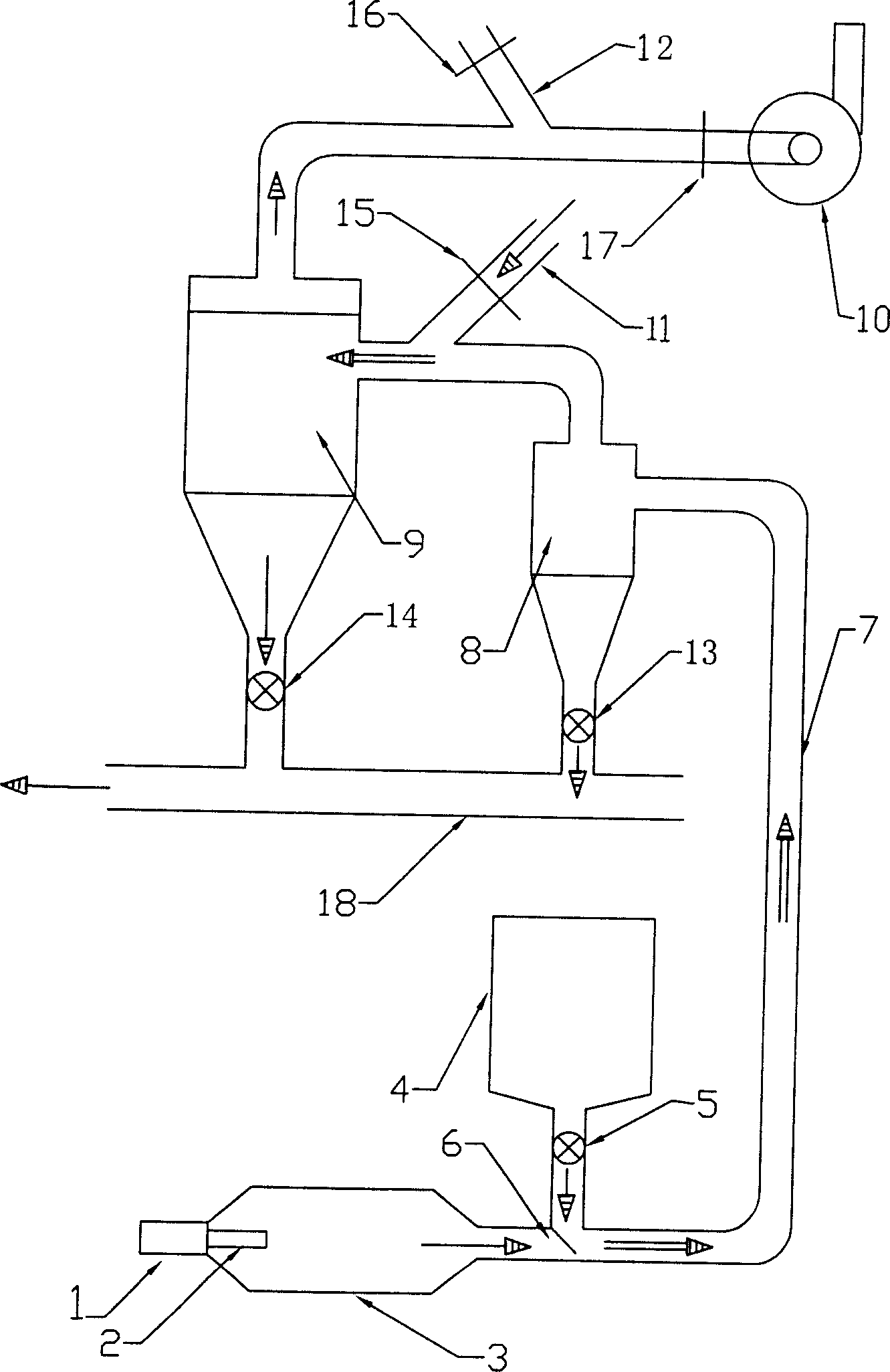

[0037] Such as figure 1 As shown, what the flue gas generation system 3 adopts is an industrially used hot blast stove. First, ignite the nozzle 2 of the burner 1 in the hot blast stove to heat the system. After the temperature at the junction of the calcination pipe 7 and the material spreading device 6 in the fluidized calcination system is stabilized at about 850°C, comprehensively adjust the air inlet of the induced draft fan 10 The damper 17 installed on the top and the butterfly valve 16 on the cold air pipe 12 between the bag filter 9 and the induced draft fan 10 and the butterfly valve 16 on the cold air pipe 11 on the pipeline connecting the cyclone dust collector 8 and the bag filter 9 15, so that the wind speed of the system is about 15m / s, and then open the airlock discharge device 5 on the discharge port of the silo 4 to add the 1250-mesh coal-based kaolin raw powder in the silo 4 and pass the material through the dispersing device 6. After being dispersed, it en...

Embodiment 2

[0039]The calcination temperature in Example 1 is controlled at about 850°C, the wind speed of the system is controlled at about 30m / s, and the rest are the same as in Example 1 to obtain semi-finished products B and finished products B respectively.

Embodiment 3

[0041] The calcination temperature in Example 1 is controlled at about 920°C, the wind speed of the system is controlled at about 40m / s, and the rest are the same as in Example 1 to obtain semi-finished products C and finished products C respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com