High flame-retardant epoxy resin heavy anticorrosive paint

An epoxy resin and heavy-duty anti-corrosion technology, which is applied in the field of coatings, can solve problems such as unsatisfactory anti-corrosion performance, brittle anti-corrosion coatings, poor impact resistance, and poor flame retardancy, so as to improve the ability of anti-fouling and sterilization , Improve construction performance, improve shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

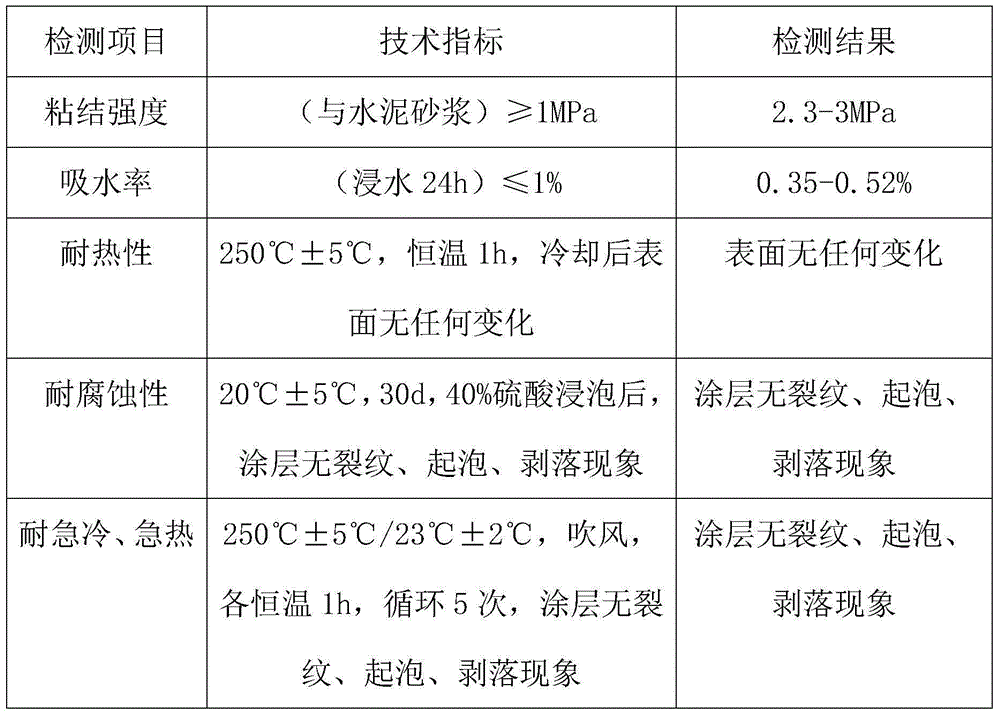

Image

Examples

Embodiment 1

[0023] A kind of high flame-retardant epoxy resin heavy-duty anticorrosion coating proposed by the present invention, its raw material comprises the following components by weight: 40 parts of epoxy resin, 20 parts of polyurethane, 7 parts of silicone resin, 9 parts of carboxy-terminated nitrile liquid rubber , 10 parts of triethylamine, 9 parts of zinc borate, 10 parts of nano-calcium carbonate, 8 parts of modified nano-titanium dioxide, 15 parts of polyaniline modified glass flakes, 6.8 parts of graphite, 6 parts of dipropanol ketone, 9 parts of propylene glycol butyl ether , 18 parts of propylene glycol methyl ether acetate, 12 parts of xylene, 3.8 parts of methyl nonyl ketone, 7 parts of gluconic acid, 38 parts of water, 1.3 parts of leveling agent, 1 part of defoamer, 1.8 parts of hydroxymethyl cellulose share.

Embodiment 2

[0025] A kind of high flame-retardant epoxy resin heavy-duty anticorrosion coating proposed by the present invention, its raw material comprises the following components by weight: 45 parts of epoxy resin, 15 parts of polyurethane, 8 parts of silicone resin, 7 parts of carboxy-terminated nitrile liquid rubber , 12 parts of triethylamine, 8 parts of zinc borate, 12 parts of nano-calcium carbonate, 7 parts of modified nano-titanium dioxide, 17 parts of polyaniline modified glass flakes, 6 parts of graphite, 7 parts of dipropanol ketone, 7 parts of propylene glycol butyl ether , 20 parts of propylene glycol methyl ether acetate, 10 parts of xylene, 4.3 parts of methyl nonyl ketone, 5 parts of gluconic acid, 43 parts of water, 0.9 parts of leveling agent, 1.5 parts of defoamer, 1.3 parts of hydroxymethyl cellulose share;

[0026] Wherein, the modifying agent of the modified nano-titanium dioxide is a combination of silane coupling agent KH550, silane coupling agent KH560, silane c...

Embodiment 3

[0029] A kind of high flame-retardant epoxy resin heavy-duty anticorrosion coating that the present invention proposes, its raw material comprises the following components by weight: 20 parts of bisphenol A type epoxy resin, 10 parts of bisphenol F type epoxy resin, 25 parts of polyurethane, 3 parts of silicone resin, 10 parts of carboxy-terminated nitrile liquid rubber, 8 parts of triethylamine, 10 parts of zinc borate, 5 parts of nano calcium carbonate, 10 parts of modified nano titanium dioxide, 8 parts of polyaniline modified glass flakes, 8 parts of graphite Parts, 3 parts of dipropanol ketone, 10 parts of propylene glycol butyl ether, 15 parts of propylene glycol methyl ether acetate, 15 parts of xylene, 3 parts of methyl nonyl ketone, 8 parts of gluconic acid, 30 parts of water, 1.5 parts of leveling agent part, 0.8 part of defoamer, 2 parts of hydroxymethyl cellulose;

[0030] Wherein, the modifying agent of the modified nano-titanium dioxide is a combination of silane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com