Method for producing methyl methacrylate by methyl acetate and formaldehyde

A technology of methyl methacrylate and methyl acetate, which is applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of organic compounds, etc., can solve the problem of low yield of methyl methacrylate, easy deactivation of catalysts, difficult Regeneration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

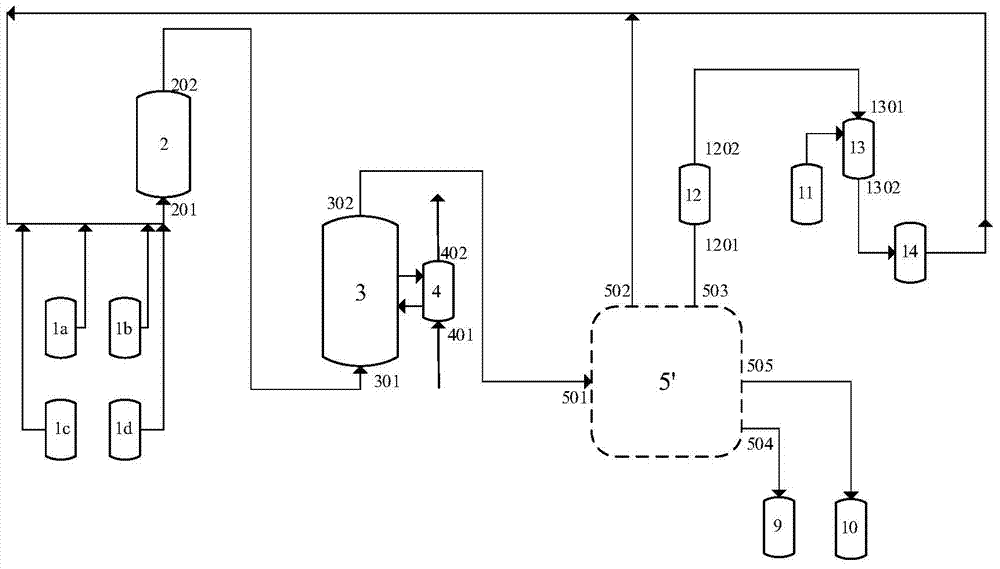

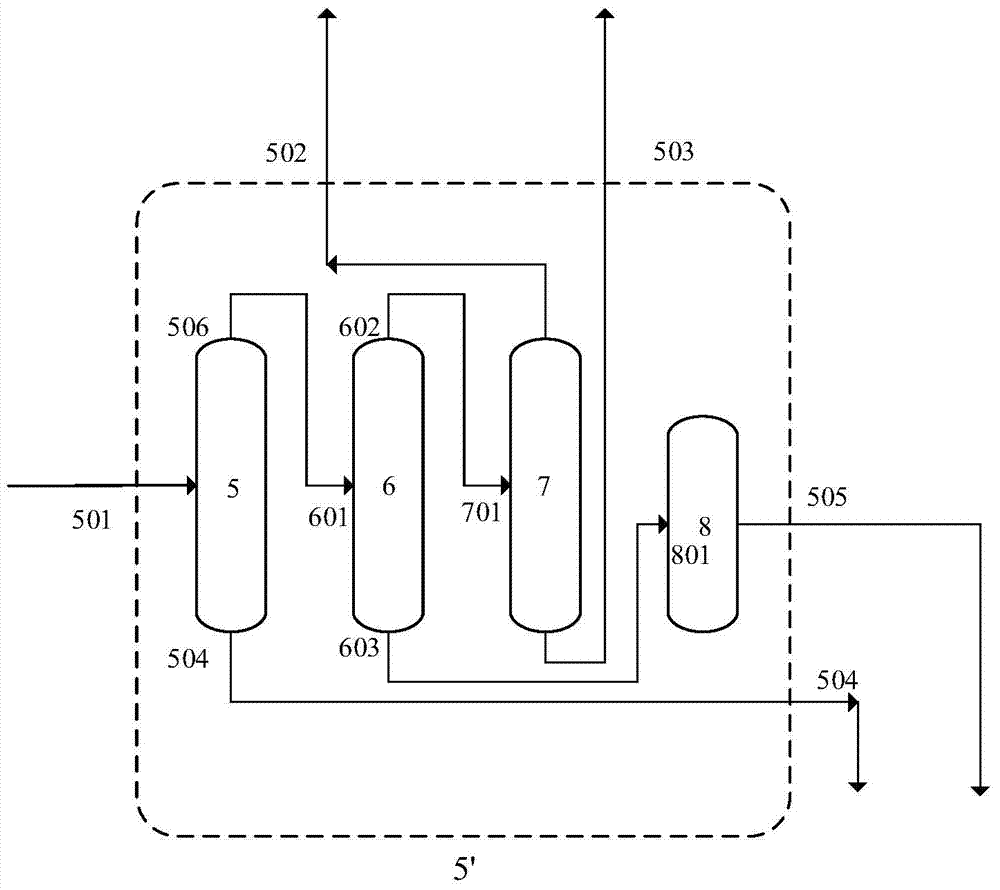

[0079] The catalyst used in the fluidized bed is cesium and antimony supported by silica, wherein the cesium content is 15 wt%, and the antimony content is 10 wt%; the catalyst used in the fixed bed is platinum and ruthenium supported by aluminum oxide. The temperature of the raw material preheater is 280°C, the operating temperature of the fluidized bed reactor is 380°C, the molar ratio of methyl acetate:methyl propionate:formaldehyde:methanol is 2:1:1.5:2, and the fluidizing gas is nitrogen. Airspeed is 5h -1 , the pressure is 0.1MPa; the temperature of the catalyst regenerator is 450°C, and air is used as the regeneration gas for charcoal regeneration, and the space velocity is 20h -1 , the pressure is 0.1MPa; the residence time of the catalyst in the fluidized bed reactor is 4 hours, the amount of carbon deposit when the catalyst enters the regenerator is 6%, and the regeneration time is 1 hour; the temperature of the intermediate product preheater is 180°C, The operating...

Embodiment 2

[0082] The catalyst used in the fluidized bed is cesium and antimony supported by silica, wherein the cesium content is 15 wt%, and the antimony content is 10 wt%; the catalyst used in the fixed bed is platinum and ruthenium supported by aluminum oxide. The temperature of the raw material preheater is 280°C, the operating temperature of the fluidized bed reactor is 380°C, the molar ratio of methyl acetate: formaldehyde: methanol is 1:1:2, the fluidizing gas is nitrogen, and the space velocity is 5h -1 , the pressure is 0.1MPa; the temperature of the catalyst regenerator is 450°C, and air is used as the regeneration gas for charcoal regeneration, and the space velocity is 20h -1 , the pressure is 0.1MPa; the residence time of the catalyst in the fluidized bed reactor is 4 hours, the amount of carbon deposit when the catalyst enters the regenerator is 6%, and the regeneration time is 1 hour; the temperature of the intermediate product preheater is 180°C, The operating temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com