Method for preparing Cr2AlC by molten salt process

A molten salt method and powder technology, which is applied in the field of non-oxygen ceramic powder preparation, can solve irrelevant Cr2AlC powder research reports and other problems, and achieve the effect of simple and easy preparation process, environmental protection and good powder activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

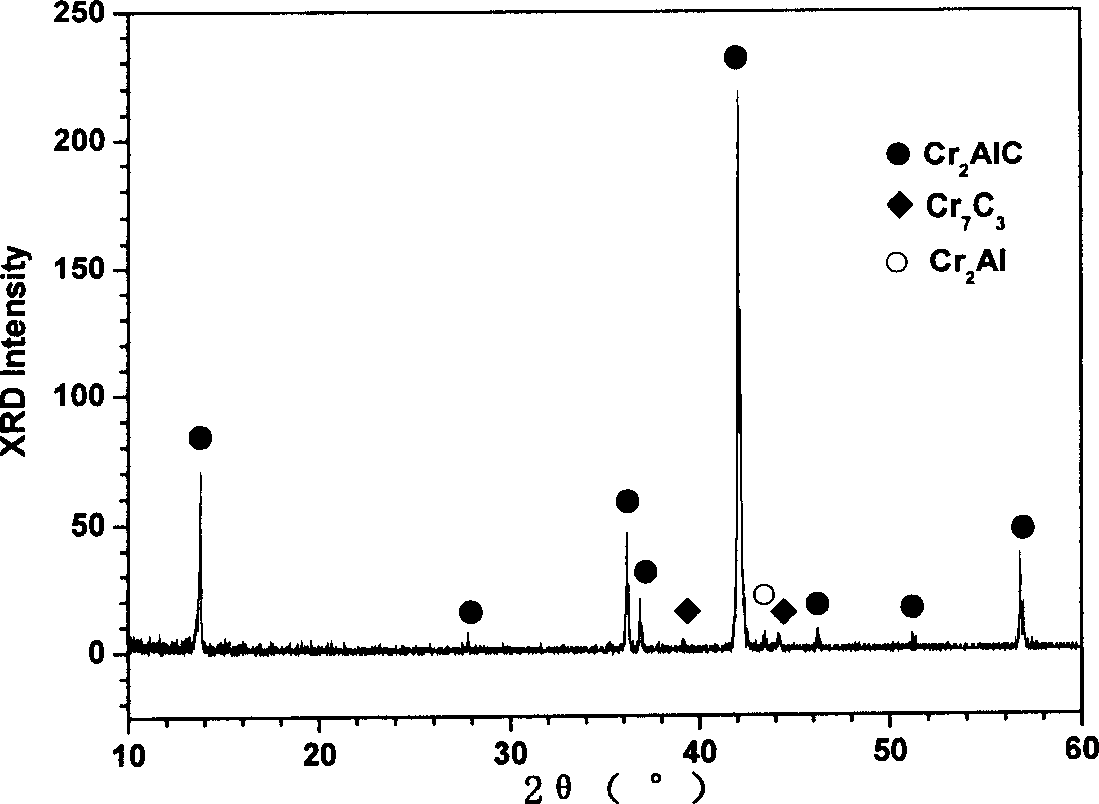

Embodiment 1

[0023] Chromium powder (5μm, 99.95%), aluminum powder (3μm, 99.95%) and carbon powder (5μm, 99%) are used as raw materials. The powder is in accordance with Cr 2The stoichiometric ratio of AlC and an excess of 10at% of aluminum powder; NaCl and KCl are weighed at a weight ratio of 1:1; the raw materials and salt are mixed at a weight ratio of 1:1, using absolute ethanol as the solvent, Use Si 3 N 4 After ball milling, the obtained slurry is dried to obtain a uniformly mixed powder. Put the mixed raw materials in Al 2 O 3 In the crucible, put the crucible into the graphite furnace, and then pass the flowing Ar as the protective atmosphere, heat up to 900°C at a heating rate of 10°C / min, keep it for 1 hour, and finally cool it down at 5°C / min. After the powder is cooled, take it out, wash with deionized water to remove the salt, until the AgNO3 solution is titrated without precipitation, dry to obtain Cr 2 AlC powder. XRD patterns such as figure 1 As shown, Cr in the powder 2 The w...

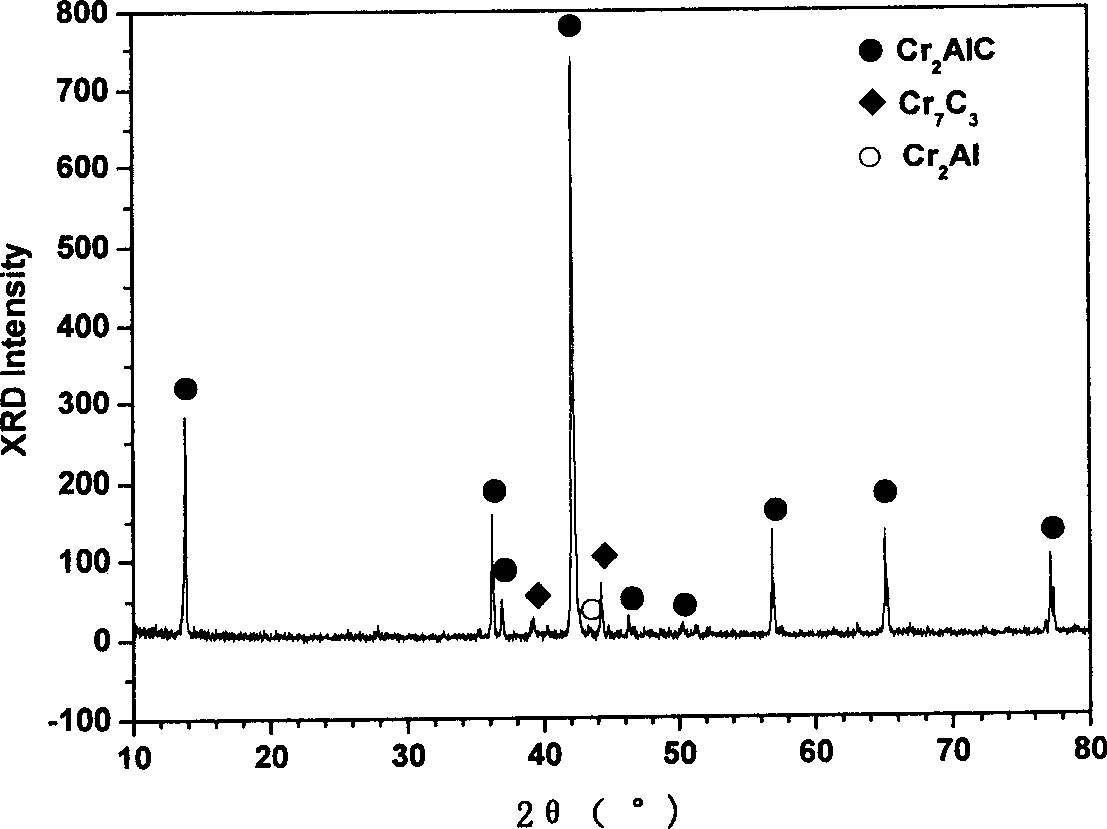

Embodiment 2

[0025] Chromium powder (5μm, 99.95%), aluminum powder (3μm, 99.95%) and carbon powder (5μm, 99%) are used as raw materials. The powder according to Cr 2 The stoichiometric ratio of AlC, and an excess of 5at% of aluminum powder; NaCl and KCl are weighed at a weight ratio of 1:1; the raw materials and salt are mixed at a weight ratio of 1:1, with absolute ethanol as the solvent, Use Al 2 O 3 Or Si 3 N 4 After ball milling, the obtained slurry is dried to obtain a uniformly mixed powder. Put the mixed raw materials in Al 2 O 3 In the crucible, put the crucible in the graphite furnace, then pass the flowing Ar as the protective atmosphere, heat up to 1000°C at a heating rate of 35°C / min, keep it for 3hr, and finally cool it down at 60°C / min. After the powder is cooled, take it out, wash with deionized water to remove the salt, until the AgNO3 solution is titrated without precipitation, dry to obtain Cr 2 AlC powder. XRD patterns such as figure 2 As shown, Cr in the powder 2 The weigh...

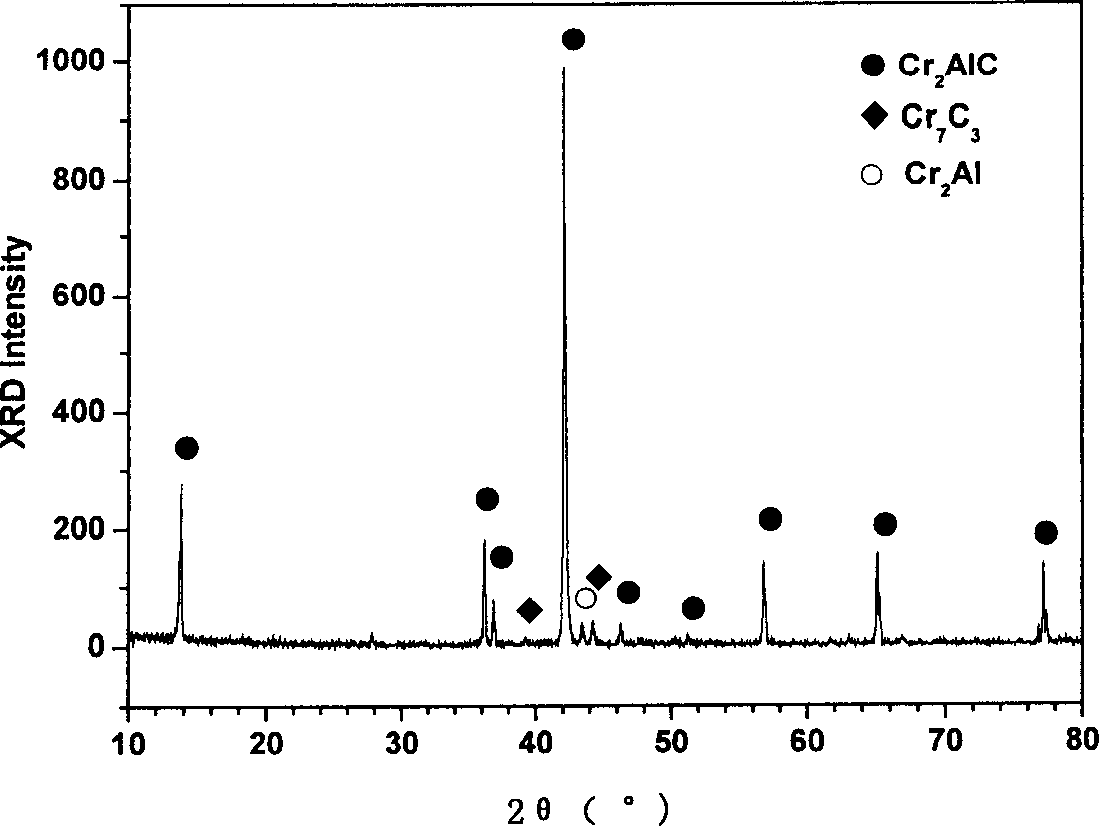

Embodiment 3

[0027] Chromium powder (5μm, 99.95%), aluminum powder (3μm, 99.95%) and carbon powder (5μm, 99%) are used as raw materials. The powder according to Cr 2 The stoichiometric ratio of AlC and an excess of 10at% of aluminum powder; NaCl and KCl are weighed at a weight ratio of 1:1; the raw materials and salt are mixed at a weight ratio of 1:1, using absolute ethanol as the solvent, Use Si 3 N 4 After ball milling, the obtained slurry is dried to obtain a uniformly mixed powder. Put the mixed raw materials in Al 2 O 3 In the crucible, put the crucible into the graphite furnace, and then pass the flowing Ar as the protective atmosphere, heat up to 1000°C at a heating rate of 35°C / min, keep it for 1 hour, and finally cool it at 60°C / min. After the powder is cooled, take it out, wash with deionized water to remove the salt, until the AgNO3 solution is titrated without precipitation, dry to obtain Cr 2 AlC powder. XRD patterns such as image 3 As shown, Cr in the powder 2 The weight percen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com