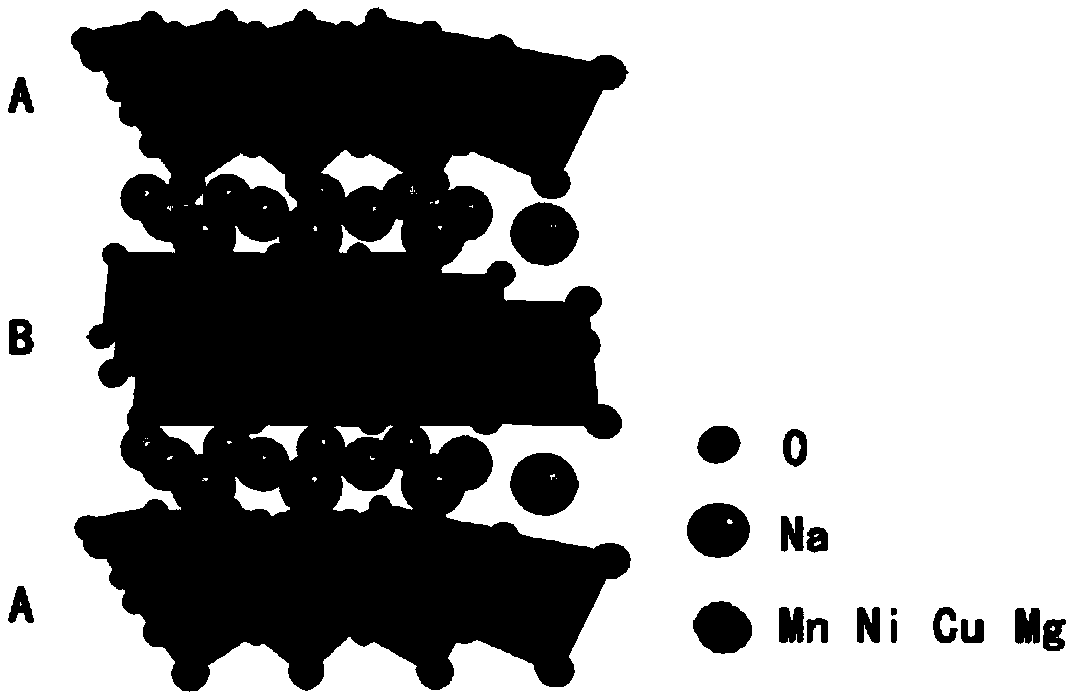

A spherical sodium ion battery positive electrode quaternary material and a preparation method thereof

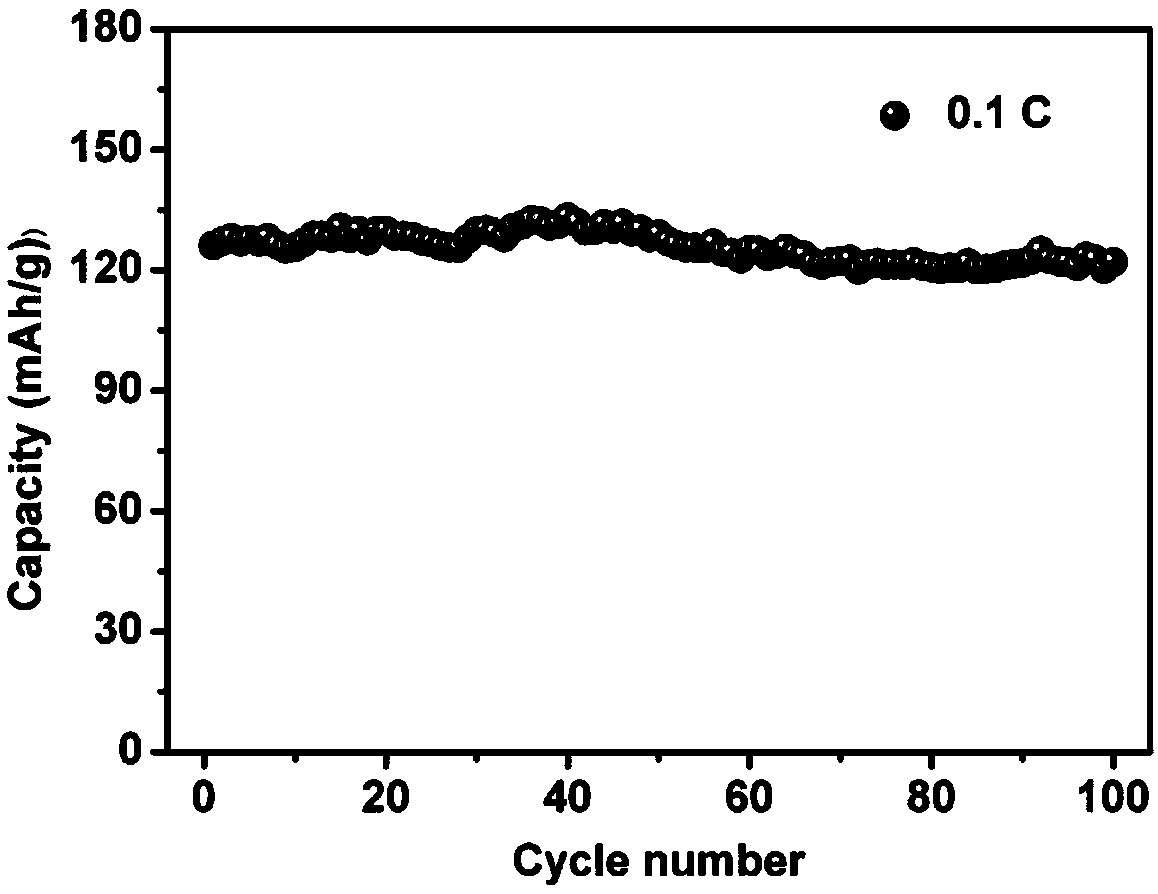

A sodium ion battery and sodium ion technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of discharge average voltage drop, cycle specific capacity drop, short service life, etc., and achieve the suppression of P2-O2 phase transition , improve stability, uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

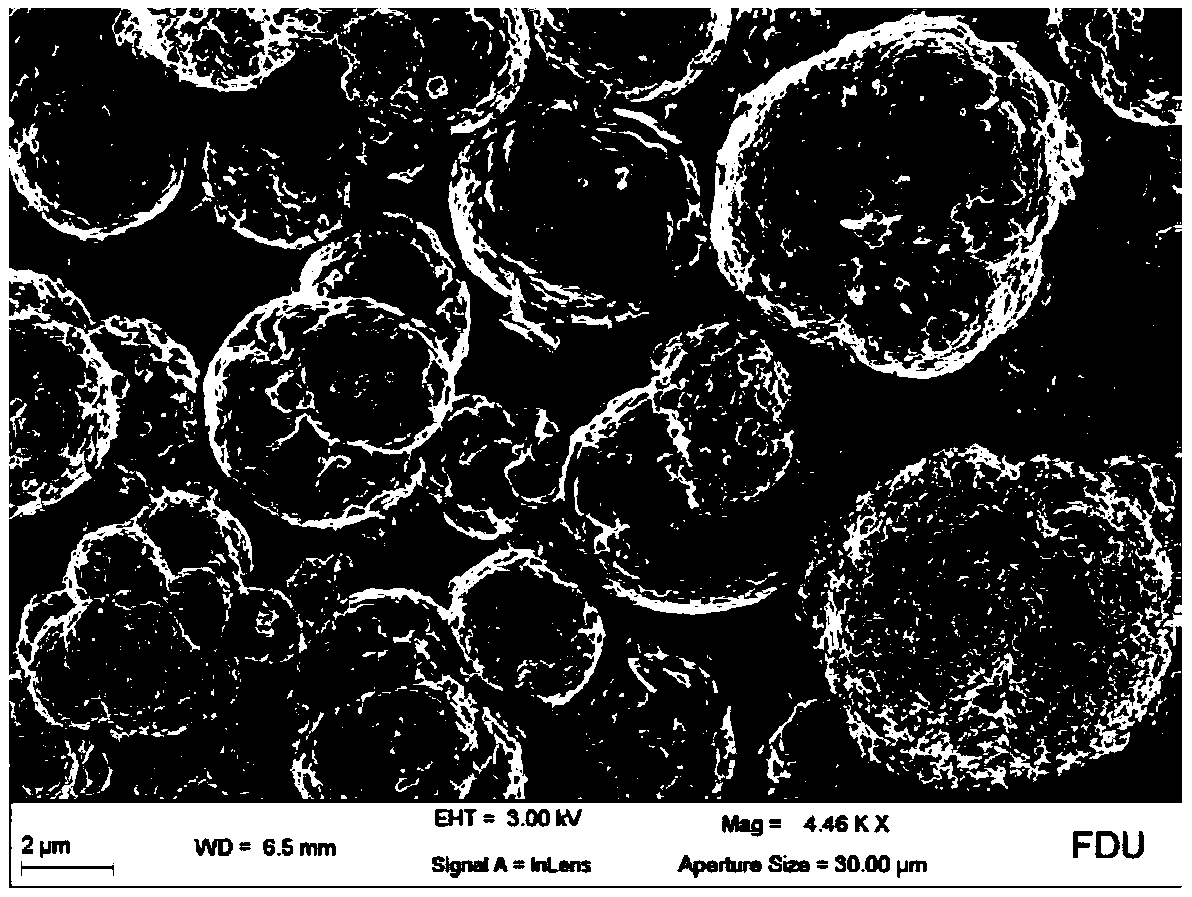

[0033] An embodiment of the present invention provides a method for preparing a positive electrode quaternary material for a spherical sodium ion battery, comprising the following steps:

[0034](1) According to the ratio of Mn:Ni:Cu:Mg=0.6:0.2:0.1:0.1, weigh manganese acetate, nickel acetate, copper acetate and magnesium acetate in total 0.025mol, put them into a 200mL beaker, add 35mL water to prepare a mixed Add 45 mL of ethylene glycol and 0.125 mol of urea to the salt solution, stir at room temperature for 6 hours, then transfer to a high-pressure reactor, and react at 200°C for 15 hours. After the reaction, wash the precipitate obtained three times with deionized water and ethanol , and then placed in an oven at 80°C, dried for 24 hours to obtain a solid powder;

[0035] (2) Add the solid powder to 2 mL of deionized water, then add 0.00875 mol of anhydrous sodium carbonate, stir and disperse at 50°C until the water evaporates, and then put it in an oven to dry at 80°C to...

Embodiment 2

[0046] An embodiment of the present invention provides a method for preparing a positive electrode quaternary material for a spherical sodium ion battery, comprising the following steps:

[0047] (1) According to the ratio of Mn: Ni: Cu: Mg = 0.6: 0.2: 0.05: 0.15, weigh manganese sulfate, nickel sulfate, copper sulfate and magnesium sulfate in total 0.025mol, put them into a 200mL beaker, add 35mL water to prepare a mixed Salt solution, then add 40 mL of ethylene glycol, 0.1 mol of urea, stir at room temperature for 6 hours, transfer to a high-pressure reactor, and react at 180 ° C for 20 hours. After the reaction, the obtained precipitate is washed three times with deionized water and ethanol , and then placed in an oven at 80°C, dried for 24 hours to obtain a solid powder;

[0048] (2) Add the solid powder to 2 mL of deionized water, then add 0.00875 mol of anhydrous sodium carbonate, stir and disperse at 50°C until the water evaporates, and then put it in an oven to dry at ...

Embodiment 3

[0051] An embodiment of the present invention provides a method for preparing a positive electrode quaternary material for a spherical sodium ion battery, comprising the following steps:

[0052] (1) Weigh a total of 0.025mol of manganese nitrate, nickel nitrate, copper nitrate and magnesium nitrate according to the ratio of Mn:Ni:Cu:Mg=0.6:0.2:0.12:0.08, put them into a 200mL beaker, add 35mL of water to prepare a mixed Salt solution, then add 55 mL of ethylene glycol, 0.12 mol of urea, stir at room temperature for 6 hours, transfer to a high-pressure reactor, and react at 150 ° C for 24 hours. After the reaction, the obtained precipitate is washed three times with deionized water and ethanol , and then placed in an oven at 80°C, dried for 24 hours to obtain a solid powder;

[0053] (2) Add the solid powder to 2 mL of deionized water, then add 0.00875 mol of anhydrous sodium carbonate, stir and disperse at 50°C until the water evaporates, and then put it in an oven to dry at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com