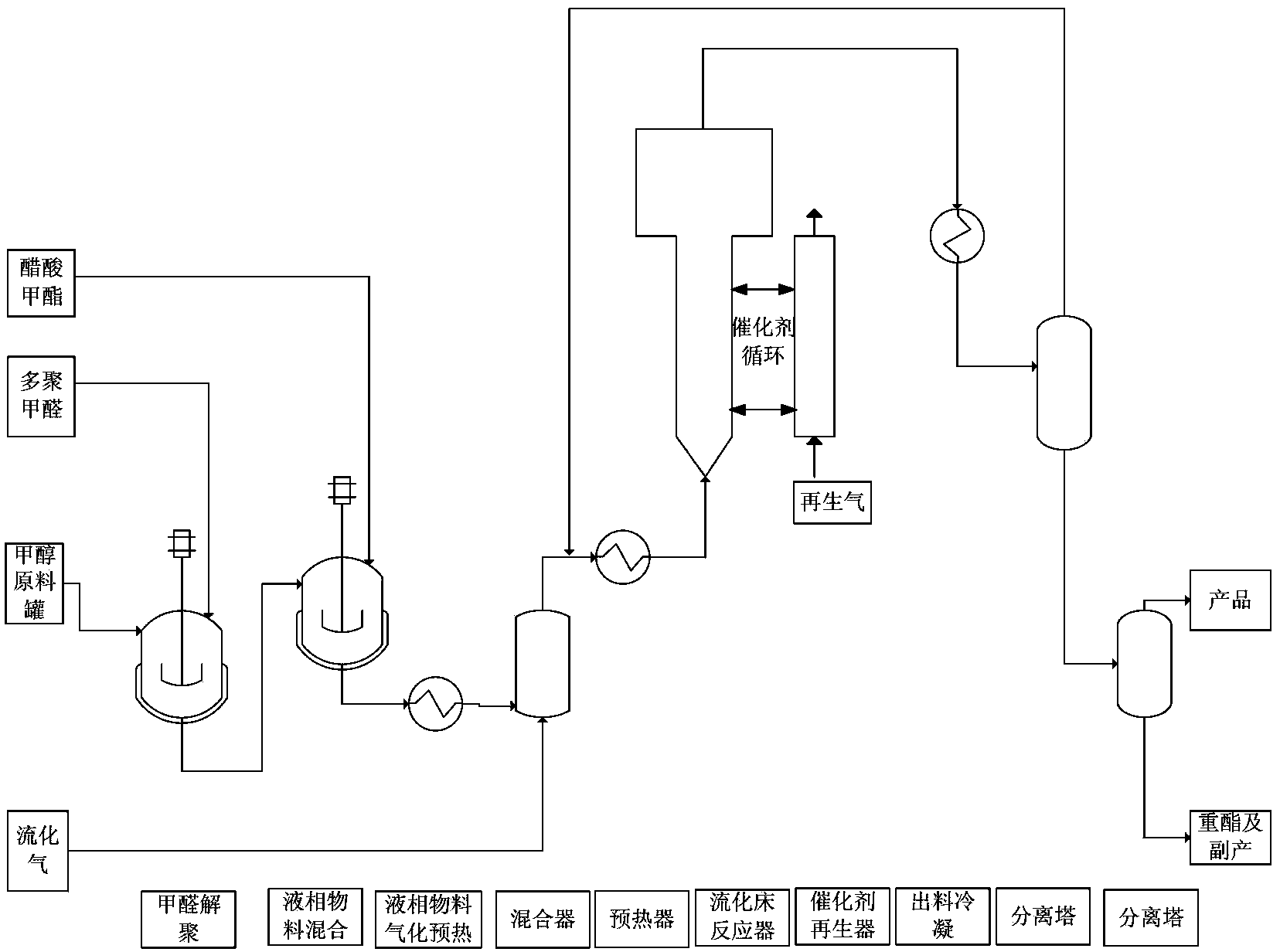

Synthesis method for methyl acrylate from methyl acetate and formaldehyde

A technology of methyl acrylate and methyl acetate, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of fast catalyst deactivation, short life, and cannot solve the problem of rapid deactivation of catalyst, etc. Achieve the effect of achieving continuity, solving short lifespan and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

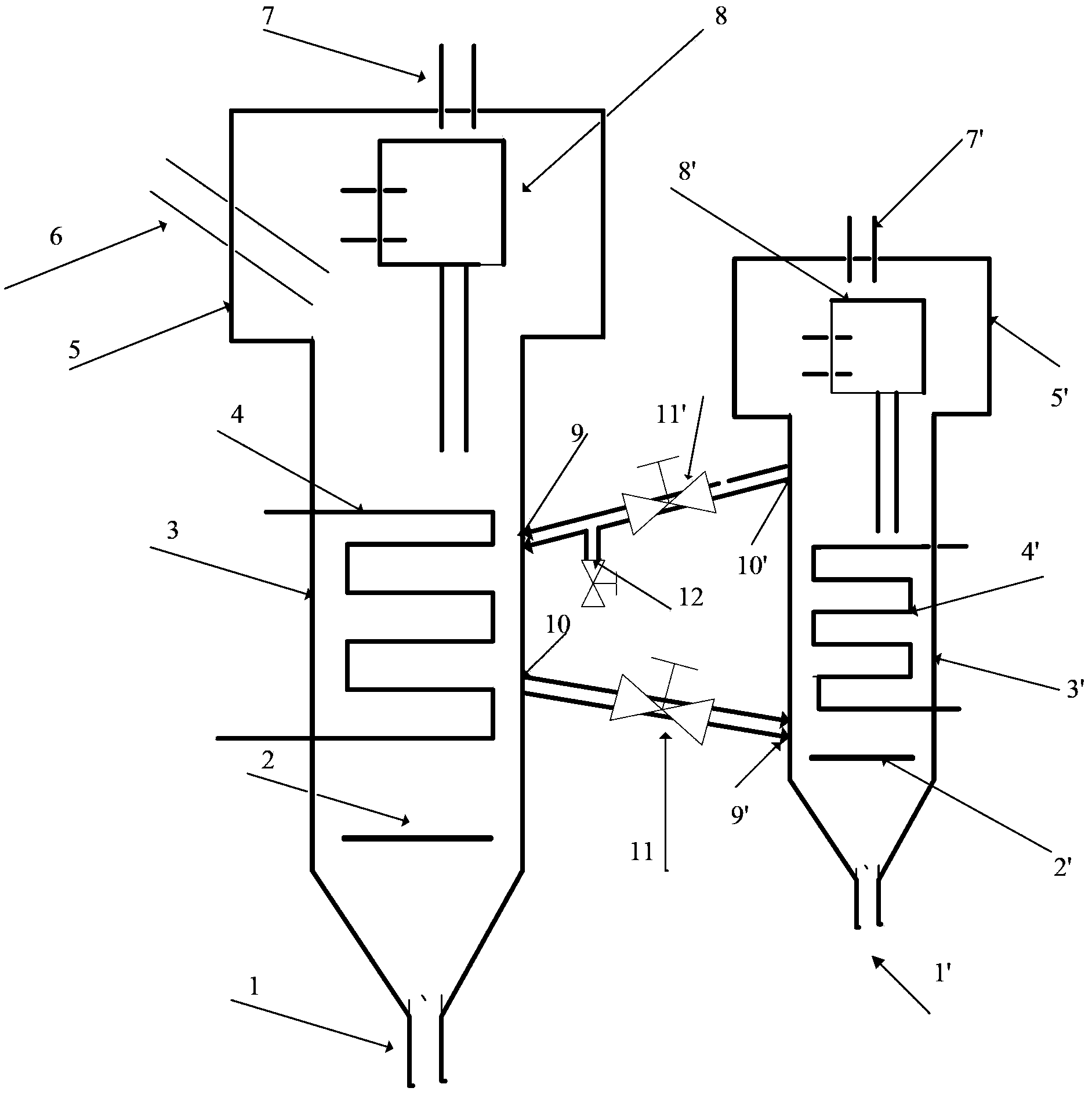

Embodiment 1

[0033] Embodiment 1: The catalyst is Cs-Zr salt or its oxide supported on silica, the content of Cs is 10%, the content of Zr is 1%, and the particle size of the silica carrier is 150-250 microns. The temperature of the mixing preheater is 300°C, the reaction temperature is 330°C, the molar ratio of methyl acetate: formaldehyde: methanol is 1:1:1.5, the fluidizing gas is nitrogen, and its space velocity is 5h -1 , the pressure is 0.05MPa; the temperature of the catalyst regenerator is 420°C, and nitrogen with an oxygen content of 1% is used as the regeneration gas for charcoal regeneration, and the space velocity is 30h -1 , the pressure is 0.1MPa; the residence time of the catalyst in the fluidized bed reactor is 4 hours, the carbon content of the catalyst when it enters the regenerator is 4wt%, the regeneration time is 4 hours, and the carbon content after regeneration is 0.1%; The molar conversion of methyl ester was 14.5%, and the molar selectivity of methyl acrylate was 9...

Embodiment 2

[0034] Embodiment two: the catalyst is Cs-Zr-Mg salt or its oxide supported by silica, the Cs content is 13%, the Zr content is 0.5%, the Mg content is 0.5%, and the particle diameter of the silica carrier is 150- 250 microns. The temperature of the mixing preheater is 330°C, the reaction temperature is 340°C, the molar ratio of methyl acetate: formaldehyde: methanol is 1:1:1.5, the fluidizing gas is nitrogen, and its space velocity is 10h -1 , the pressure is 0.05MPa; the temperature of the catalyst regenerator is 450°C, and nitrogen with an oxygen content of 1% is used as the regeneration gas for charcoal regeneration, and the space velocity is 30h -1 , the pressure is 0.1MPa; the residence time of the catalyst in the fluidized bed reactor is 10 hours, the carbon content of the catalyst when it enters the regenerator is 5wt%, the regeneration time is 4 hours, and the carbon content after regeneration is 0.1%; The molar conversion of methyl ester was 18%, and the molar selec...

Embodiment 3

[0035] Embodiment 3: The catalyst is Cs-Zr salt or its oxide supported by silica, the Cs content is 15%, the Zr content is 0.5%, and the particle size of the silica carrier is 75-150 microns. The temperature of the mixing preheater is 260°C, the reaction temperature is 360°C, the molar ratio of methyl acetate: formaldehyde: methanol is 0.5:1:1.5, the fluidizing gas is nitrogen, and its space velocity is 6h -1 , the pressure is 0.05MPa; the temperature of the catalyst regenerator is 450°C, and nitrogen with an oxygen content of 1% is used as the regeneration gas for charcoal regeneration, and the space velocity is 30h -1 , the pressure is 0.1MPa; the residence time of the catalyst in the fluidized bed reactor is 8 hours, the carbon content of the catalyst when it enters the regenerator is 4.8wt%, the regeneration time is 4 hours, and the carbon content after regeneration is 0.1%; The molar conversion of methyl acetate is 28%, and the molar selectivity of methyl acrylate is 93%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com