Patents

Literature

51 results about "Formaldehyde synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The commercially available formalin has 10 to 12% methanol with a few impurities like aluminum and copper. Almost 21 million tonnes of formaldehyde is produced annually all around the world. Synthesis of Formaldehyde. Formaldehyde is produced by catalytic oxidation of methanol.

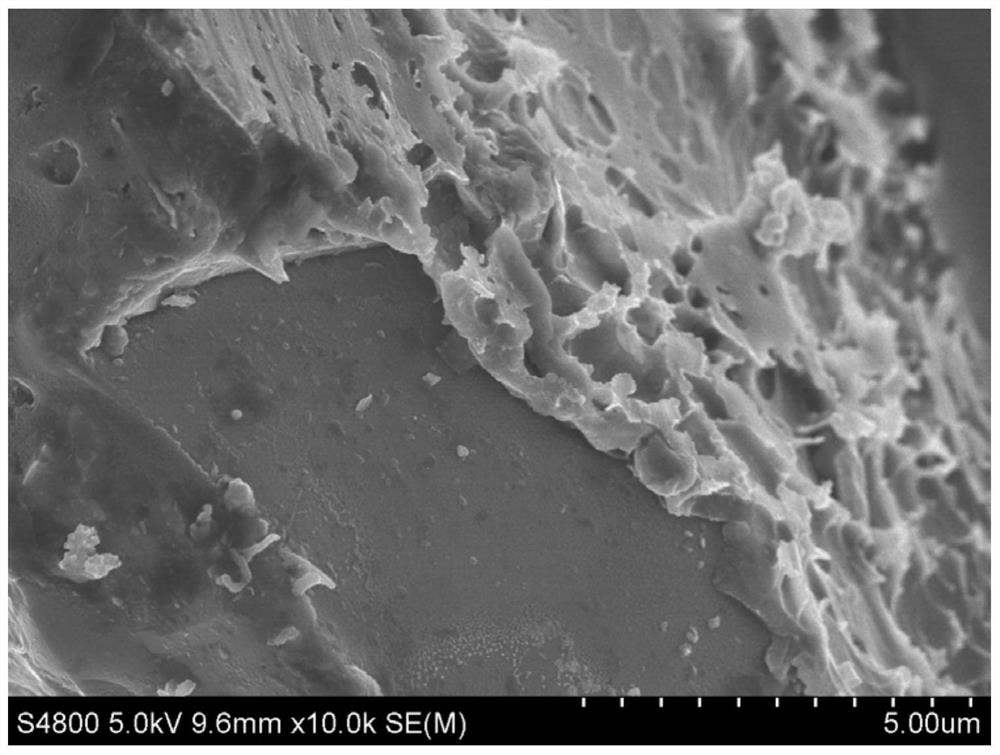

Method for modifying melamine foam

The invention relates to a method for modifying melamine foam, which comprises the following steps of: adding an emulsifier, a foaming agent, a curing agent and other aids into a base material, namely melamine formaldehyde resin synthesized by melamine and formaldehyde in a low molar ratio, adding melamine and one or more hydramine compounds, and uniformly emulsifying; heating and foaming at certain temperature for a certain period of time through microwaves in a microwave oven; and curing at high temperature, and processing and forming. In the process of foaming through the microwaves, the melamine or the melamine formaldehyde resin and the hydramine compounds can generate a compound capable of improving the performance of foam at high temperature under the action of the microwaves, and the foam is modified at the same time, so that the aim of improving the performance of the melamine foam is fulfilled.

Owner:SICHUAN NEW ENERGY POWER CO LTD

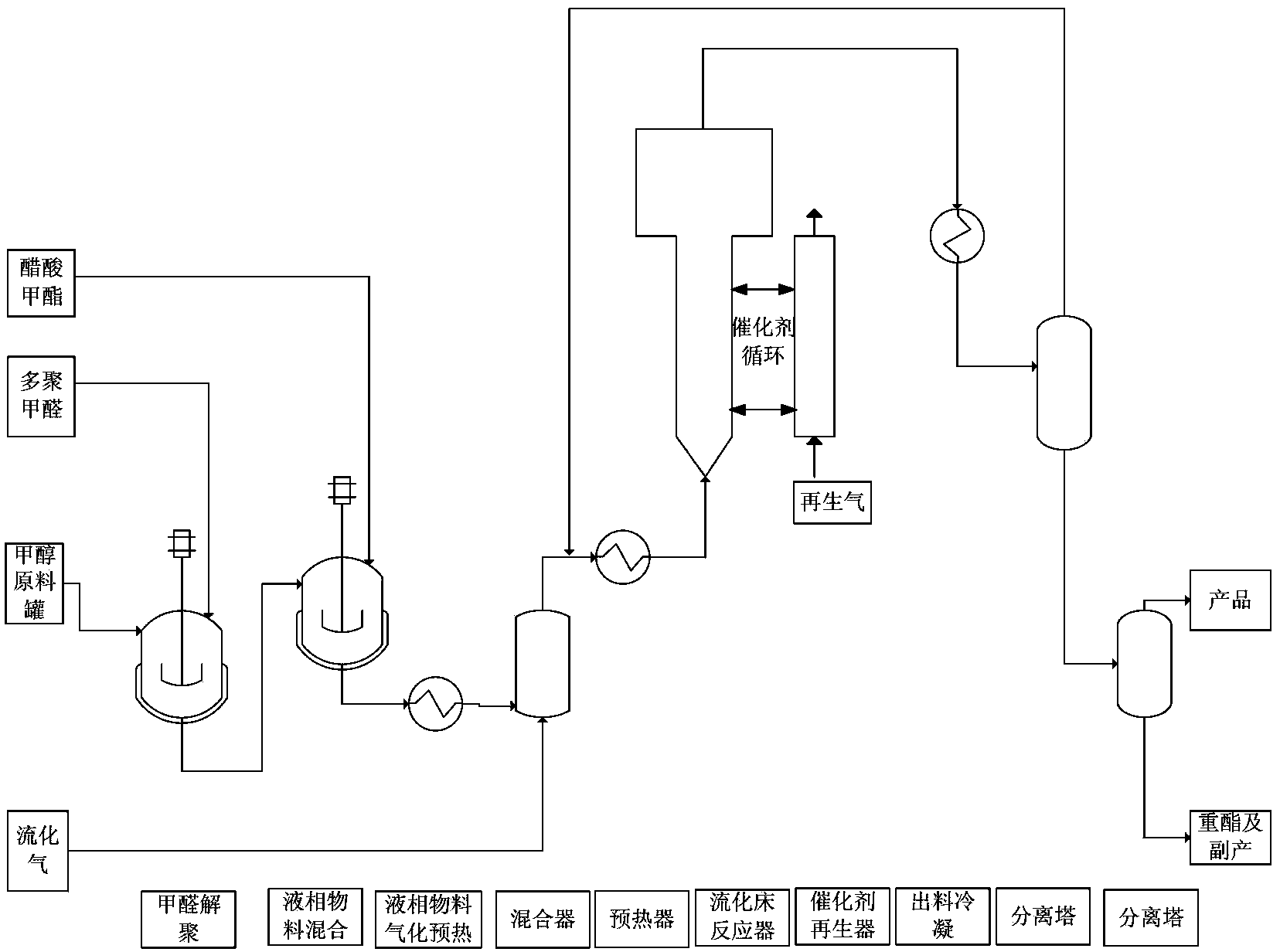

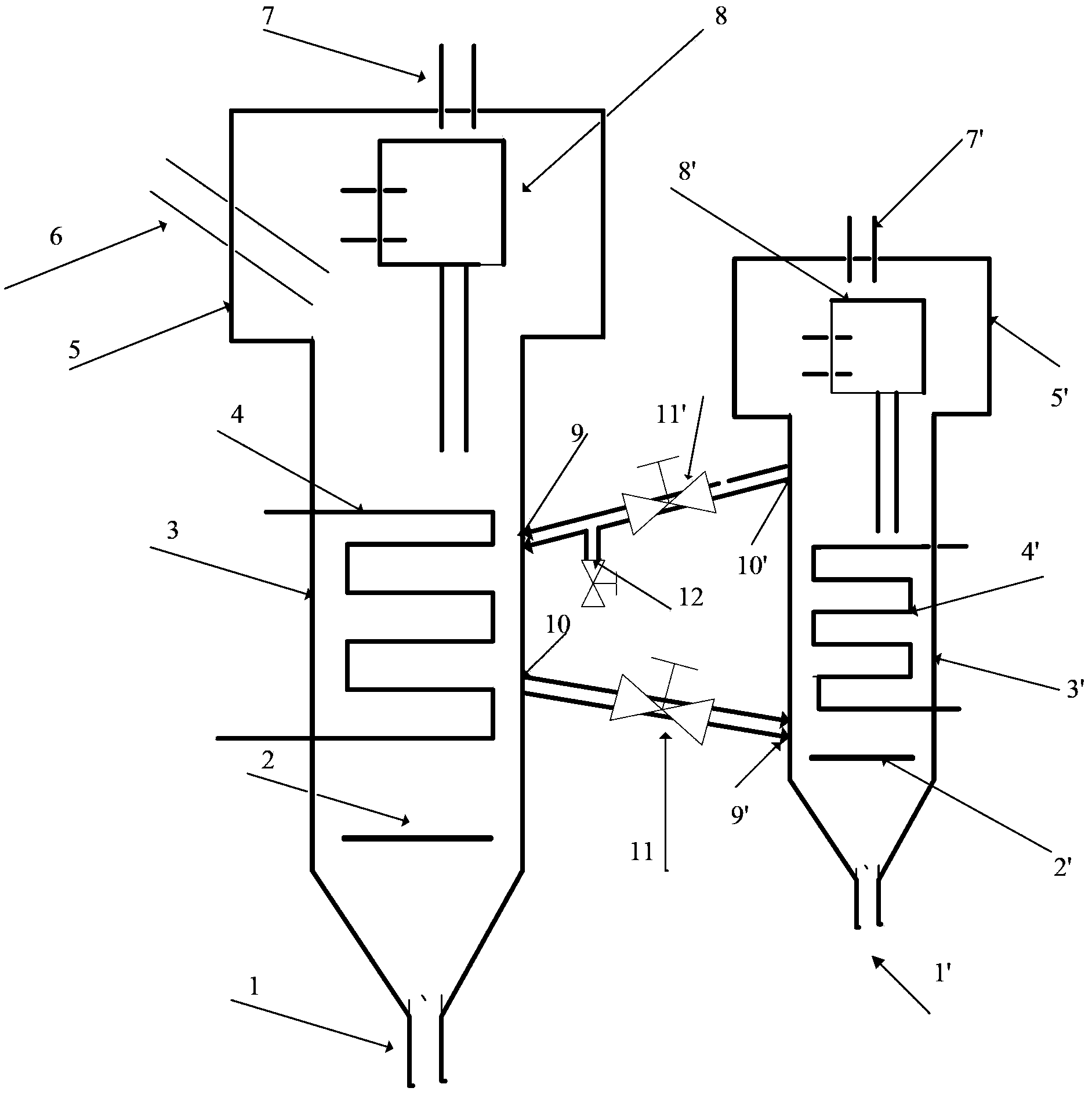

Synthesis method for methyl acrylate from methyl acetate and formaldehyde

InactiveCN103435483AReduce self-aggregationEasy to solveOrganic compound preparationCarboxylic acid esters preparationFormaldehyde synthesisFluidized bed

The invention relates to a synthesis method for methyl acrylate from methyl acetate and formaldehyde. According to the method, a catalyst is regenerated in a catalyst regenerator, the problem of rapid inactivation of the catalyst is overcome through coupling of a fluidized bed reactor and the catalyst regenerator, and continuous production is realized.

Owner:旭阳化学技术研究院有限公司

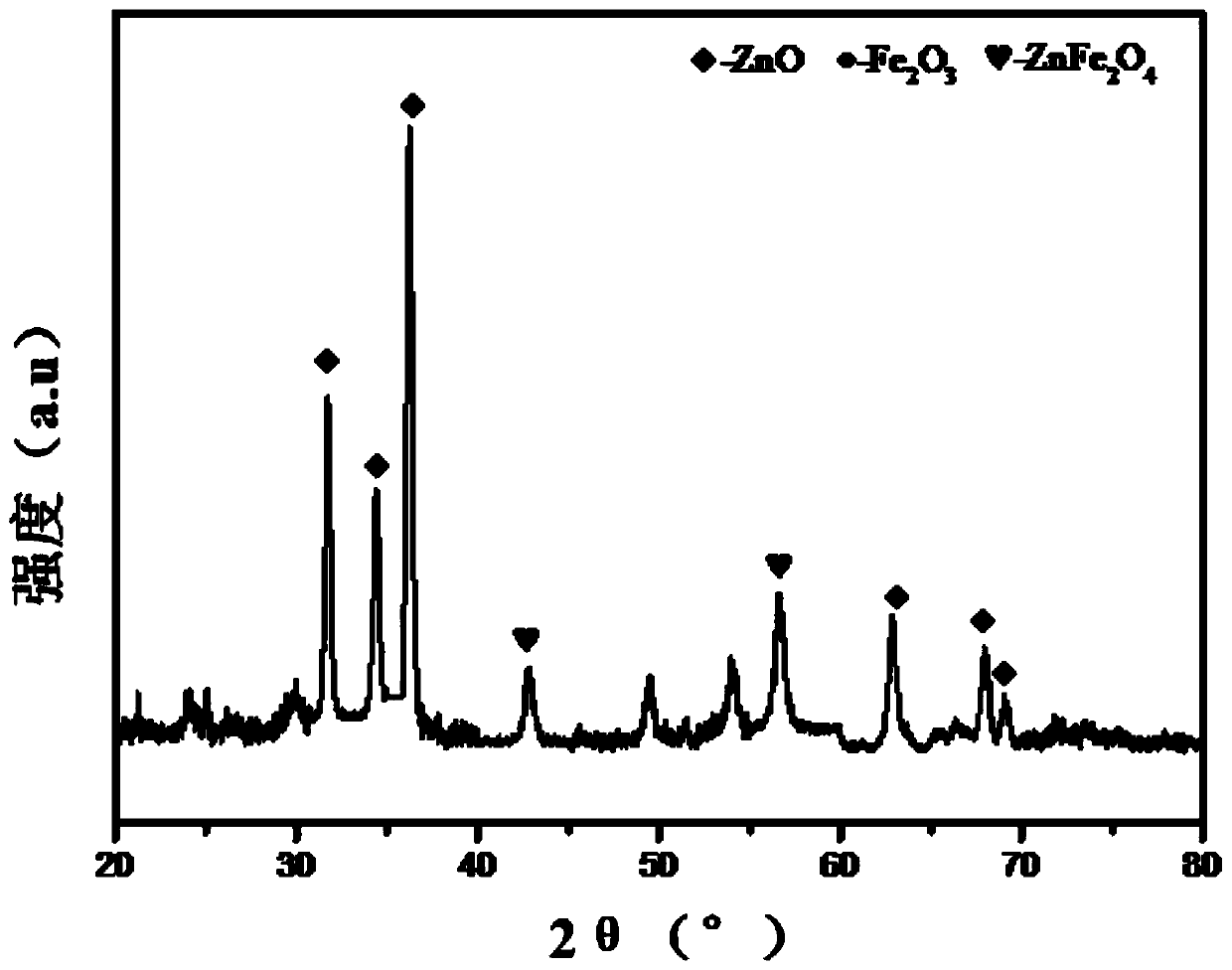

Iron-molybdenum catalyst for formaldehyde synthesis through methanol oxidation as well as preparation method and application

ActiveCN106693981ALow firing temperatureReduce manufacturing costOrganic compound preparationHeterogenous catalyst chemical elementsFormaldehyde synthesisOxide

The invention discloses an iron-molybdenum catalyst for formaldehyde synthesis through methanol oxidation. The iron-molybdenum catalyst consists of an active metal oxide, an assistant metal oxide and a binder metal oxide, wherein the molar ratio of Mo to Fe to V to assistant metal to binder metal is 1:(0.33-0.67):(0.001-0.1):(0.001-0.1):(0.01-0.5). The iron-molybdenum catalyst has the advantages of low cost, long service life and low calcination temperature and reaction temperature.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

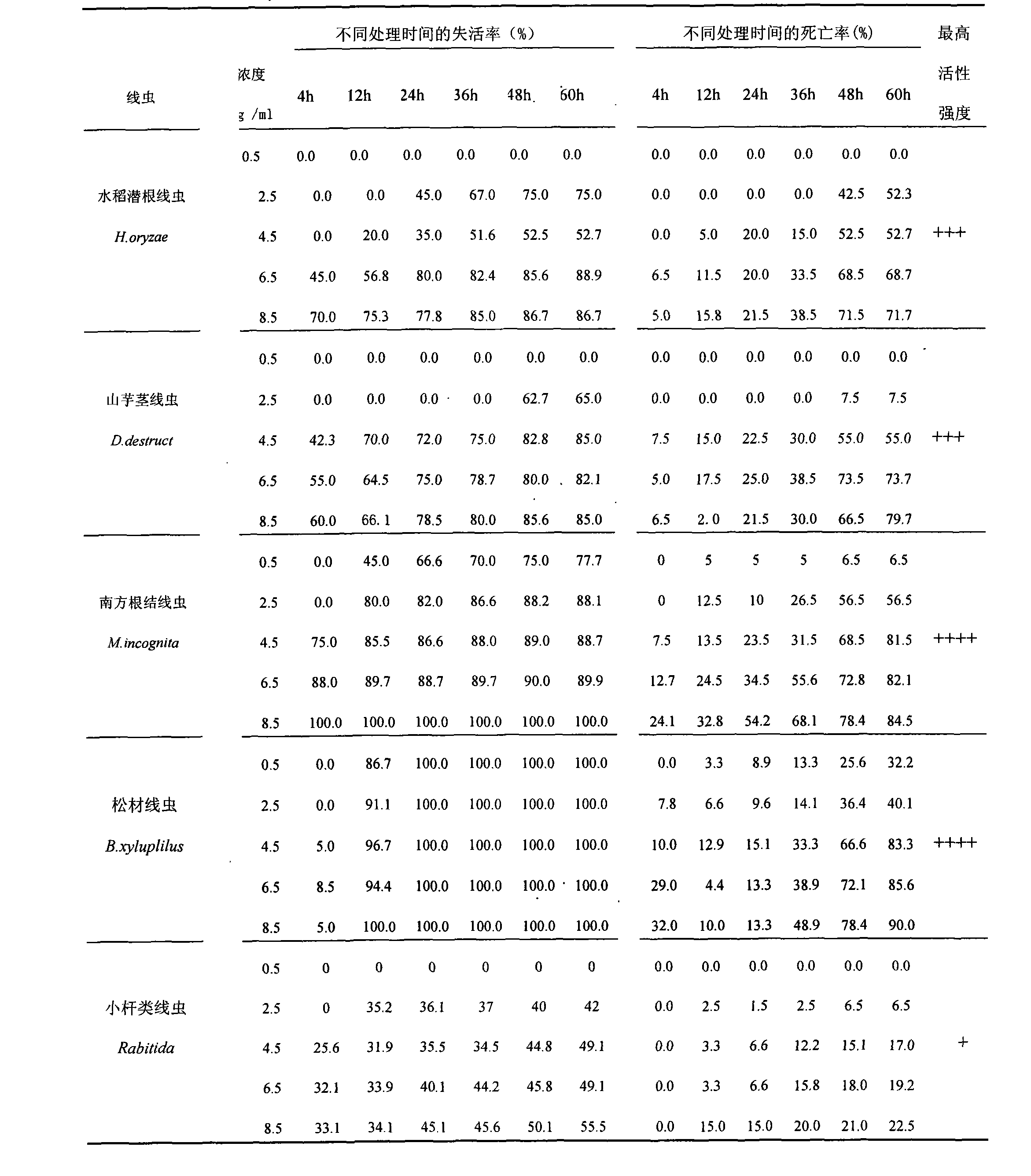

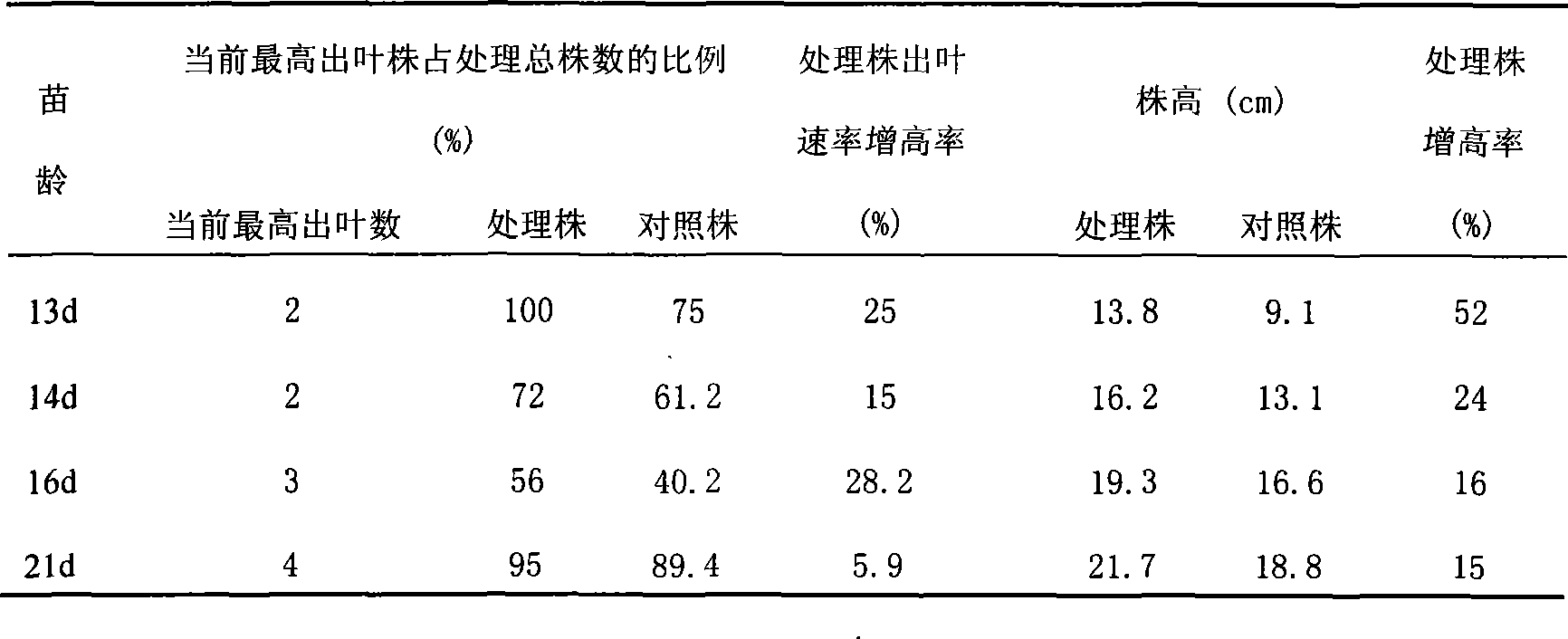

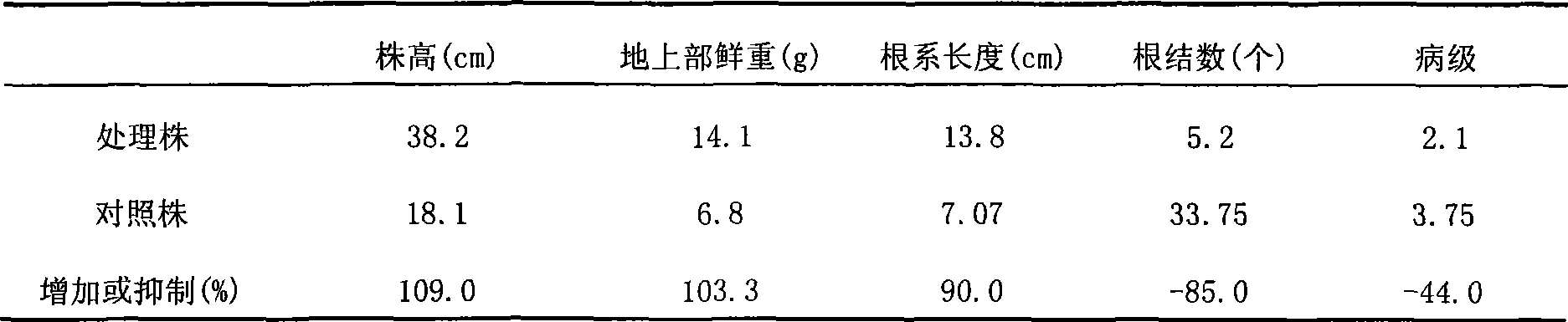

Tea saponin granular formulation for killing nematode and preparation method thereof

The invention relates to a tea saponin nematocide granule and a method for preparing the same, which belongs to the field of plant source biological pesticides. The invention aims to provide the tea saponin nematocide granule which has low toxicity and high efficiency, no residue and low cost, is advantageous for the ecological balance of the plant rhizosphere soil microflora and is selective to a target nematode and can promote the growth of a host, and the method for preparing the same. The tea saponin nematocide granule comprises the following raw material components in portion by weight: 40 to 50 portions of tea saponin, 10 to 20 portions of auxiliary agent, and 30 to 50 portions of stuffing, wherein the auxiliary agent is one or more than two of tween-80, waste liquor of sulfite pulp, lignin and derivative sulfonate, naphthalene and alkyl naphthalene formaldehyde synthesis sulfonate, and alkyl sulfonate; and the stuffing is one or more than two of red brick, clay, cake, slag kaolin, diatomite and white carbon black. Test results show that the tea saponin nematocide granule not only has actively for killing nematodes and selectivity to the target nematode, but also is advantageous for the ecological balance of the plant rhizosphere soil microflora and can promote the growth of the host.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Method for synthesizing and preparing 2-vinyl pyridine

InactiveCN102863375AReduce energy consumptionImprove securityOrganic chemistry2-VinylpyridineGas phase

The invention relates to a method for synthesizing and preparing 2-vinyl pyridine by synthesizing 2-methyl pyridine and formaldehyde, which comprises the following steps of: adding the raw materials 2-methyl pyridine and formaldehyde (36%) into a high pressure reactor according to the weight ratio of 1: 0.03, stirring and heating for reaction to obtain 2-hydroxyethyl pyridine solution; slowly adding the obtained 2-hydroxyethyl pyridine solution into a dehydration kettle filled with sodium hydroxide (50%) solution through a measuring tank (1 ton) to obtain the crude product 2-vinyl pyridine; and sending the obtained crude product 2-vinyl pyridine into a washing kettle through a pipeline, adding sodium hydroxide (95%) solution into the washing kettle, and carrying out cut fraction on the crude product 2-vinyl pyridine which is separated by washing to obtain the 2-vinyl pyridine with the gas phase chromatography test content of more than 98.5%. The method adopts novel catalyst, so that the unit comprehensive energy consumption is reduced by 20%; the production process is automatically controlled, the product purity is greatly improved, and the product content reaches up to more than 98.5%; and the whole process route is clean and environment-friendly.

Owner:沙文茜

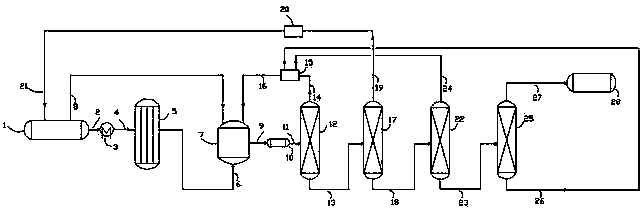

Process for synthesis of polyoxymethylene dimethyl ether from methyl

ActiveCN104230684AHigh yieldHigh selectivityEther separation/purificationOrganic compound preparationPolymer sciencePtru catalyst

The invention relates to a process for the synthesis of polyoxymethylene dimethyl ether from methyl, solves the problems of low cost and high yield in the synthesis of polyoxymethylene dimethyl ether. The process for the synthesis of polyoxymethylene dimethyl ether from methyl is divided into a reaction zone and a separation zone; the reaction zones includes a methanol storage tank, a preheater, a fixed bed reactor and a bubbling reactor; the process is the reaction zone is as below: methanol by is preheated, vaporized, mixed with air and sent into the fixed bed reactor, the methanol is subjected to catalytic oxidation under the action of a formaldehyde synthesis catalyst to generate formaldehyde; the formaldehyde enters into the bubbling reactor and reacts with methanol and a recycled mixture under the catalysis of a solid acid catalyst to form polyoxymethylene dimethyl ether. The separation zone includes an anion exchange resin bed, a rectification module and a product storage tank; and the process steps in separation zone are as below: the material discharged from the bubbling reactor passes through the anion exchange resin to remove acid and enters into the distillation separation module, trimer and tetramer of polyoxymethylene dimethyl ether enter into the product storage tank, and other components are recycled to the reactor. The technical scheme can be used in polyoxymethylene dimethyl ether production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Iron-molybdenum method formaldehyde synthesis catalyst, and preparation method thereof

ActiveCN105457648AImprove thermal stabilityExtended service lifeOrganic compound preparationCarbonyl compound preparationFormaldehyde synthesisReaction speed

The invention relates to an iron-molybdenum method formaldehyde synthesis catalyst, and a preparation method thereof. According to the invention, an auxiliary agent which is a nickel oxide is added into an iron-molybdenum two-component catalyst system; a co-precipitation reaction speed is controlled, such that the obtained catalyst has a wide pore size distribution, while the proportion of mesopores is relatively large; and macropores are artificially produced, such that the catalyst is prepared. During a catalytic reaction process, the prepared catalyst is beneficial for heat and mass transfer, and assists in improving formaldehyde and methanol conversion rate. The catalyst has good thermal stability and a long service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of super heavy oil refined oil-soluble efficient electro-desalting demulsifying agent

ActiveCN103865070AReduce manufacturing costIncrease profitDewatering/demulsification with chemical meansEpoxyFormaldehyde synthesis

The invention discloses a preparation method of a super heavy oil refined oil-soluble efficient electro-desalting demulsifying agent, which comprises the steps of synthesizing phenol amine resin; performing condensation reaction of the phenol amine resin with epoxy propane and ethylene oxide sequentially to obtain block polyether; synthesizing thermoplastic phenolic resin by use of phenol, hydrochloric acid and formaldehyde; finally, performing a phenolic resin graft modification reaction between the obtained thermoplastic phenolic resin and the block polyether to obtain a product of super heavy oil refined oil-soluble efficient electro-desalting demulsifying agent. By adopting the preparation method disclosed by the invention, the oil-soluble efficient electro-desalting demulsifying agent can be efficiently prepared, the production cost is reduced, and the utilization rate of raw materials is improved; the demulsifying agent produced by the method can remarkably increase the desalting and dehydration speed of super heavy oil, saves the limited time and can effectively compensate for the shortcomings of a super heavy oil treatment process of a processing device.

Owner:克拉玛依市天明化工有限责任公司

Method for synthesizing polyvinyl acetal acid safety adhesive

The invention relates to a method which uses non-toxic, tasteless and non-volatile glyoxylate to replace formaldehyde for composing polyvinyl acetal acid safe adhesive. The acetalation degree can be controlled in 20 to 40 percent by adjusting the usage mol ratio of polyvinyl alcohol to glyoxylate is 1 to 0.1-0.2. The polyvinyl acetal acid adhesive can self dry and film under normal temperature, the adhesive film does not dissolve in water after drying, and the adhesive is applicable for conglutinating paper products, building materials and fibers.

Owner:TIANJIN VOCATIONAL INST

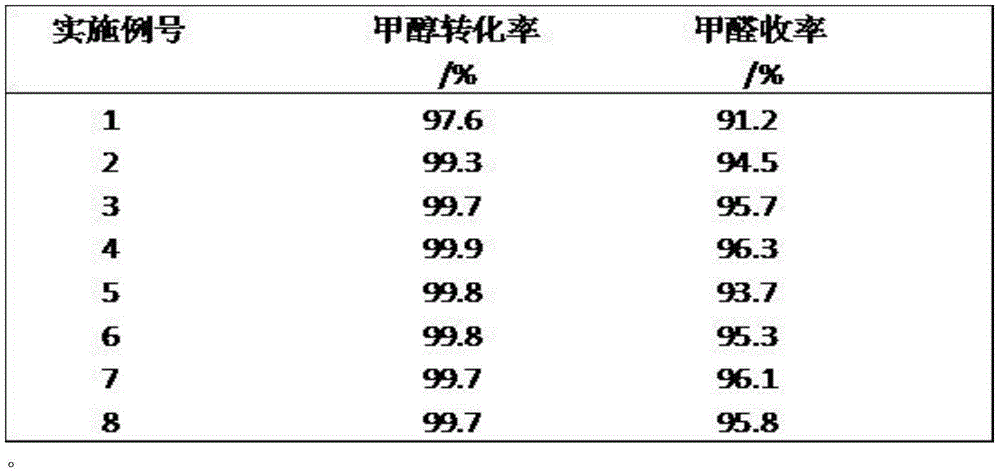

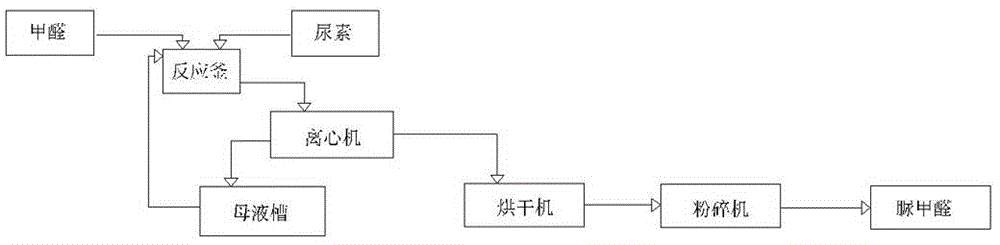

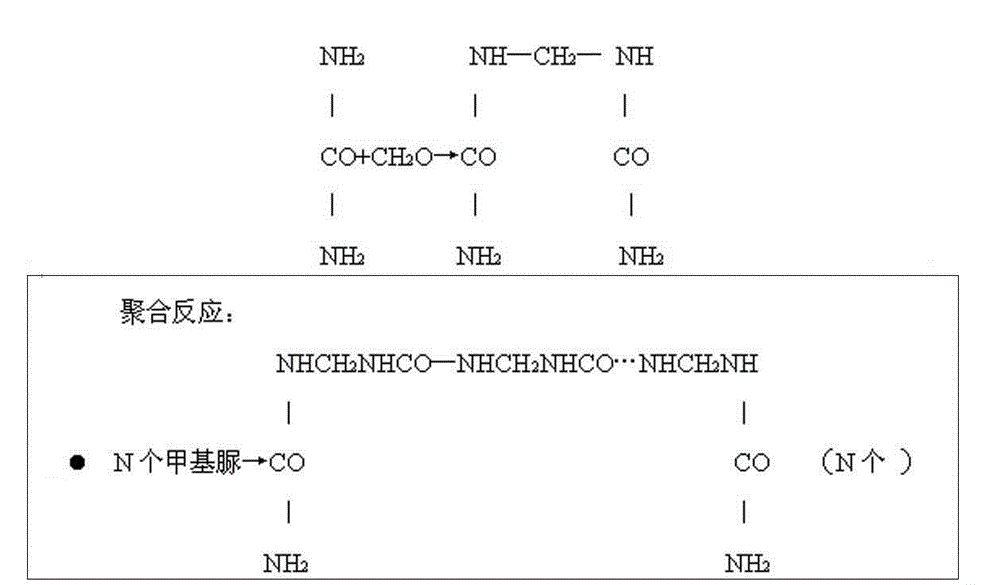

Urea formaldehyde (UF) sustained-release fertilizers and production process thereof

InactiveCN104609998ARaw materials are easy to obtainReduce releaseAgriculture gas emission reductionUrea compound fertilisersFormaldehyde synthesisAgricultural science

The invention provides sustained and controlled release fertilizers which are urea formaldehyde (UF) sustained-release fertilizers. The fertilizers are chemical type sustained-release fertilizers synthesized from urea and formaldehyde. According to a production process of the fertilizers, through the control over the reaction conditions such as raw material ratio, pH value, temperature and reaction time, sustained-release fertilizers with different effect periods can be produced. That is to say, fast-acting, medium-acting and long-acting sustained-release fertilizers can be produced. Therefore, fertilizer deficiency during a seedling stage is prevented, plant growth is vigorous, fertilizer shortage in a late stage is prevented, and yield improvement can be realized. Through the regulation upon the production process, various products with fertilizer effects of 50-60 days, 90-120 days and more than one year can be produced; and fertilizer utilization rate can be improved by more than 1 time. The fertilizers can be widely applied in agriculture, forestry, urban greening, and engineering greening. The fertilizers can be used independently, can be used with other fertilizers, and can be prepared into various compound fertilizers. The production process is simple and feasible, and has the advantages of low investment, fast effect, sufficient raw materials, and vast market.

Owner:LIAONING LYUYUAN BIOLOGICAL FERTILIZER

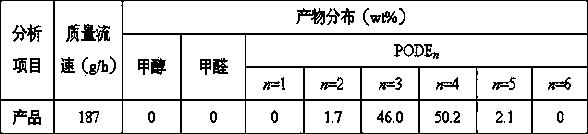

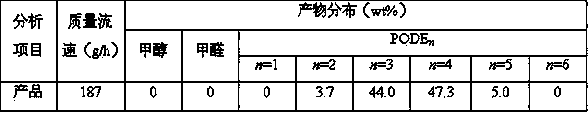

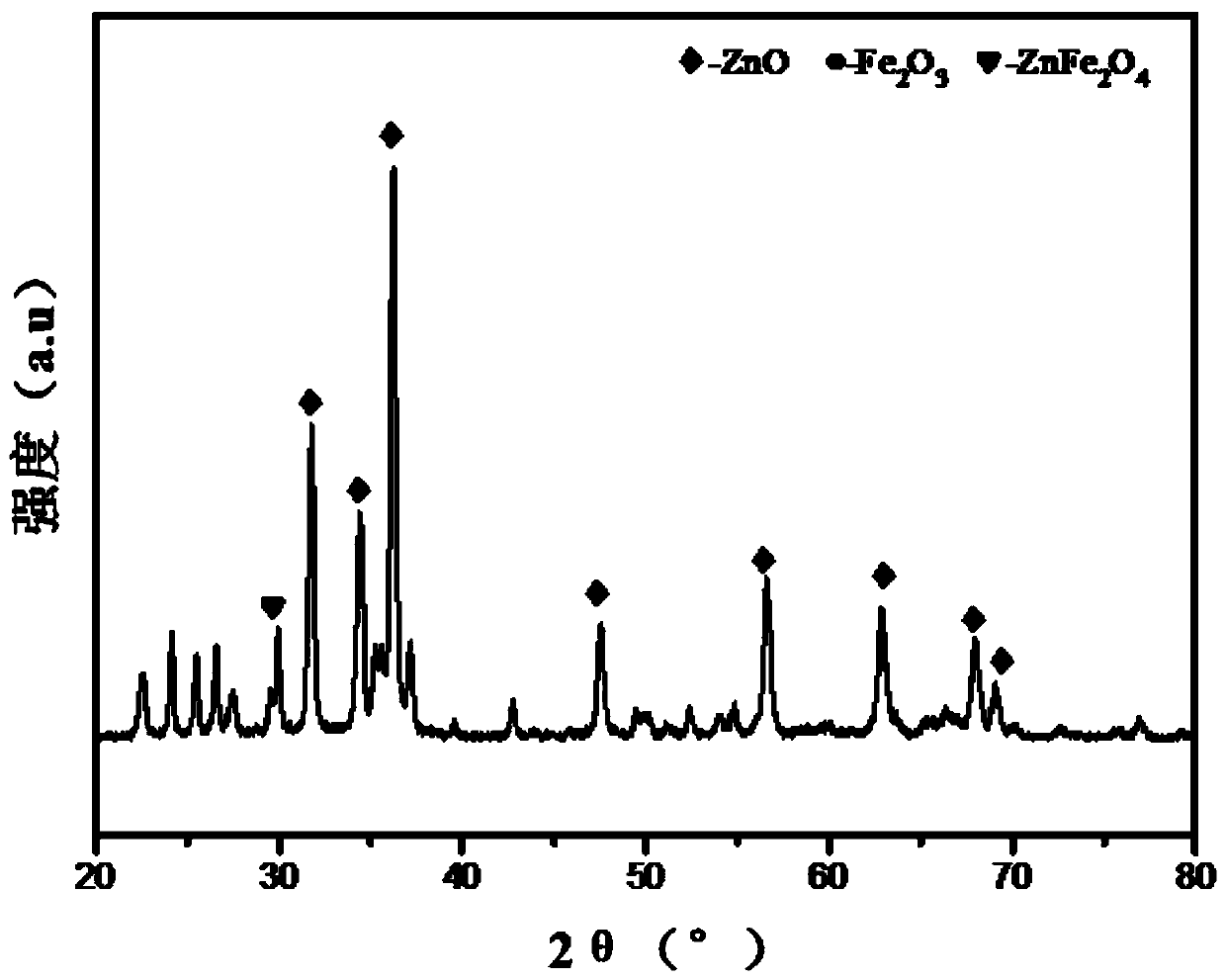

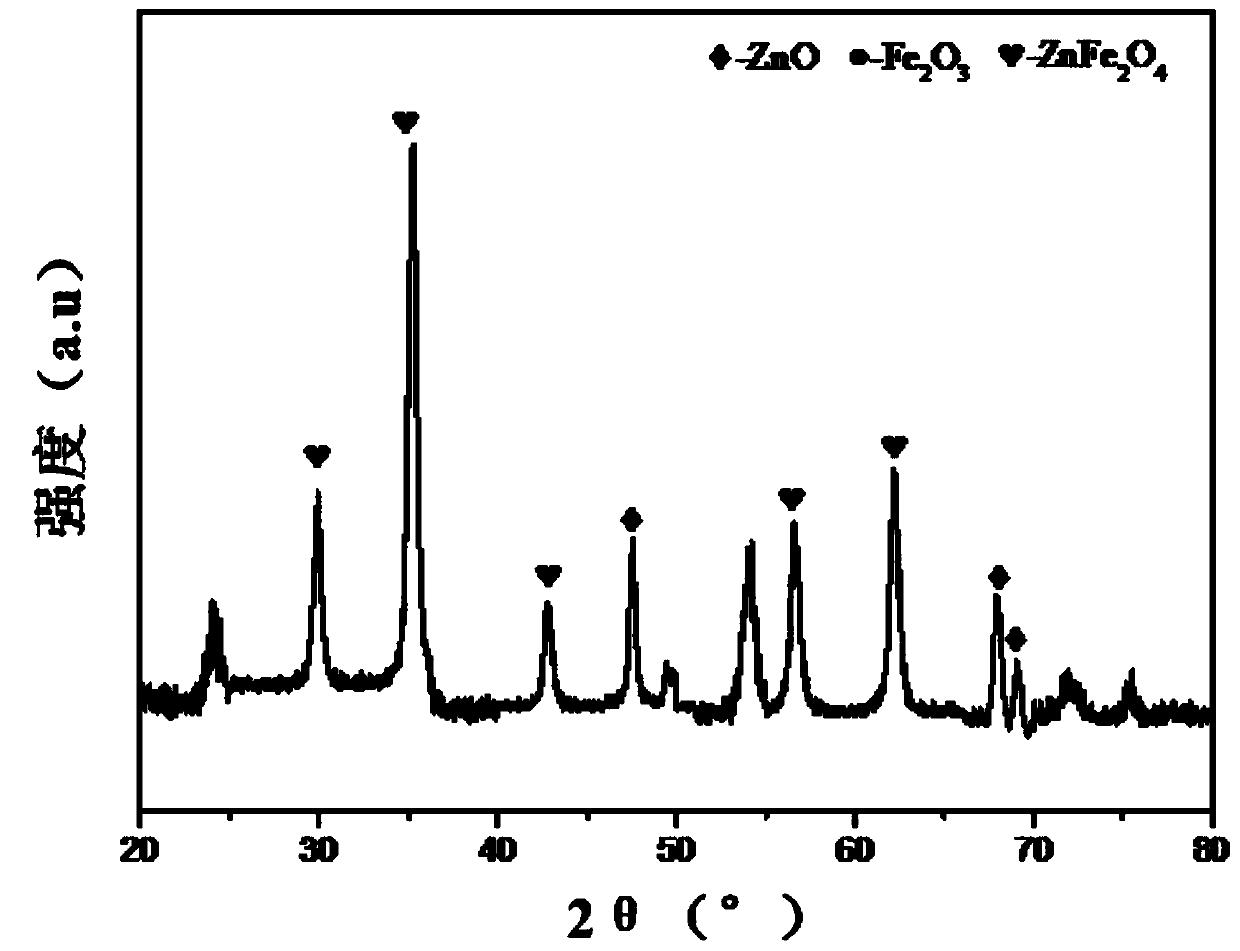

Sulfation binary metallic oxide solid acid catalyst and preparation method and application thereof

InactiveCN110102318AImprove stabilityHigh catalytic activityPhysical/chemical process catalystsOrganic chemistrySolid acidHigh water content

The invention discloses a sulfation binary metallic oxide solid acid catalyst. The composition components are iron oxide, zinc oxide and sulfation oxide; the sulfation oxide comprises sulfation iron oxide or sulfation zinc oxide. The raw materials used for the sulfation binary metallic oxide solid acid catalyst are simple and easy to obtain, the production cost is low, the preparation process is simple, and the corrosivity to equipment is low; under the condition of high water content, the catalytic activity for polyoxymethylene dimethyl ether synthesis through methyl alcohol and formaldehydeis high, the conversion rate of the reactant methyl alcohol is high, the selectivity for the product PODE 3-5 is high, and the stability of the catalyst is high; under the optimal reaction condition,the conversion rate of methyl alcohol in a reaction raw material is 54.96%, and the selectivity for the PODE 3-5 is 28.18%.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of nanometer solid super base catalyst applied to synthesis of acrylic acid by utilizing acetic acid and formaldehyde

InactiveCN103230789AReduce riskEasy to makeCatalyst carriersOrganic compound preparationWater bathsDistillation

The invention discloses a preparation method of a nanometer solid super base catalyst applied to the synthesis of acrylic acid by utilizing acetic acid and formaldehyde. The preparation method comprises the following steps of preparing monodisperse spherical nanometer silicon oxide grains by taking silylating reagent as a raw material and ammonia water as a catalyst and reasonably controlling reaction conditions; preparing impregnation liquid by utilizing a certain of CsOH, adding a carrier to impregnate for a while, drying the impregnation liquid by distillation in a water bath manner, drying in a drying oven at a certain temperature, putting a dried mixture in a muffle furnace to roast for a while at the controlled temperature, and obtaining the fresh load-type nanometer solid super base catalyst. The nanometer solid super base catalyst prepared by the method disclosed by the invention contains nanometer SiO2, so that the poison tolerance of the solid super base catalyst is improved and the stability is better; and the preparation method disclosed by the invention has the advantages of simple experimental devices, simple catalyst preparation process, low requirements on preparation devices, high catalyst activity and the like during preparation.

Owner:谦信化工集团有限公司

Acid-base bifunctional catalyst for synthesizing methyl acrylate from methyl acetate and formaldehyde and preparation method of acid-base bifunctional catalyst

PendingCN112774658AEffective number of controlsEffective regulation strengthOrganic compound preparationCarboxylic acid esters preparationFormaldehyde synthesisPtru catalyst

The invention discloses a catalyst for synthesizing methyl acrylate from methyl acetate and formaldehyde and a preparation method of the catalyst. The preparation method mainly comprises the following steps: (1) washing a carrier with water, putting into a drying oven for drying at 120 DEG C, and then roasting in a muffle furnace at 300-500 DEG C for 2-8 hours; and (2) respectively weighing compounds containing active components Al and Cs, preparing into a solution with a certain concentration, fully impregnating the active components for 2-24 hours according to an equivalent-volume impregnation mode, drying at 60-150 DEG C for 4-15 hours, and finally, roasting the components in a muffle furnace at 400-650 DEG C for 2-8 hours to obtain the catalyst. The catalyst provided by the invention is an acid-base bifunctional catalyst, can effectively improve the selectivity and conversion rate of the product, and has high carbon deposition resistance; and the preparation method of the catalyst is simple and easy to implement, and is suitable for large-scale industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

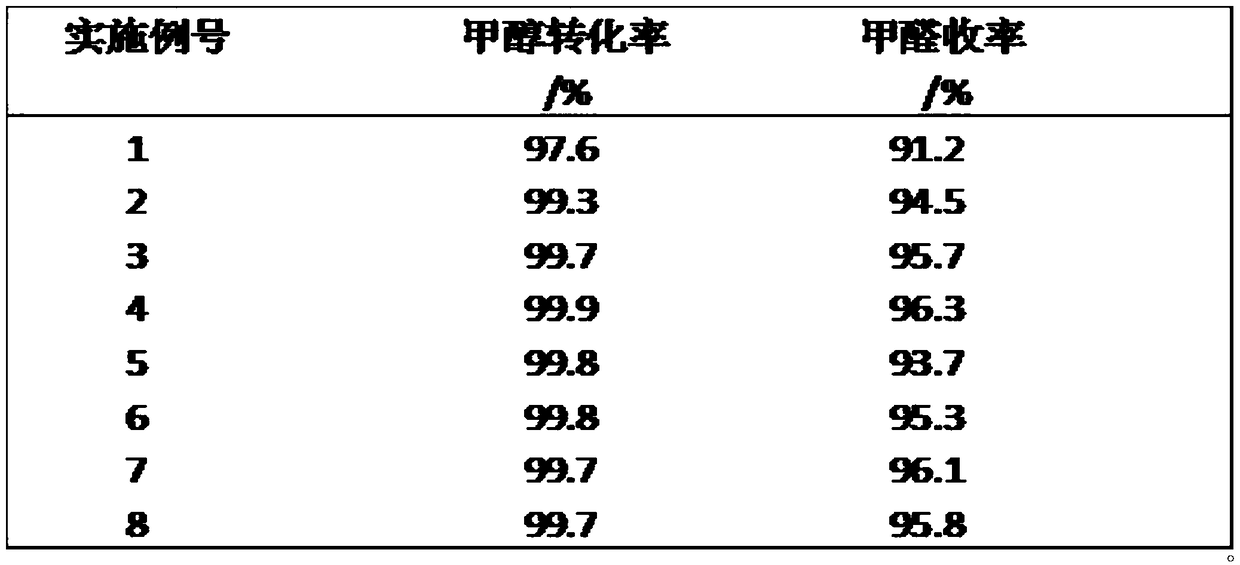

Formaldehyde synthesis catalyst by iron molybdenum method and preparation method thereof

ActiveCN105457648BImprove thermal stabilityExtended service lifeOrganic compound preparationCarbonyl compound preparationFormaldehyde synthesisReaction speed

The invention relates to an iron-molybdenum method formaldehyde synthesis catalyst and a preparation method thereof. The oxide of nickel as an auxiliary agent is added to the iron-molybdenum two-component catalyst system, and by controlling the reaction speed of co-precipitation, the obtained catalyst has a wide pore size distribution, The proportion of mesopores is relatively large, and some macropores are artificially manufactured, and the prepared catalyst is conducive to mass transfer and heat transfer during the catalytic reaction process, and improves the yield of formaldehyde and the conversion rate of methanol. The catalyst has good thermal stability and long service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Formaldehyde synthesis

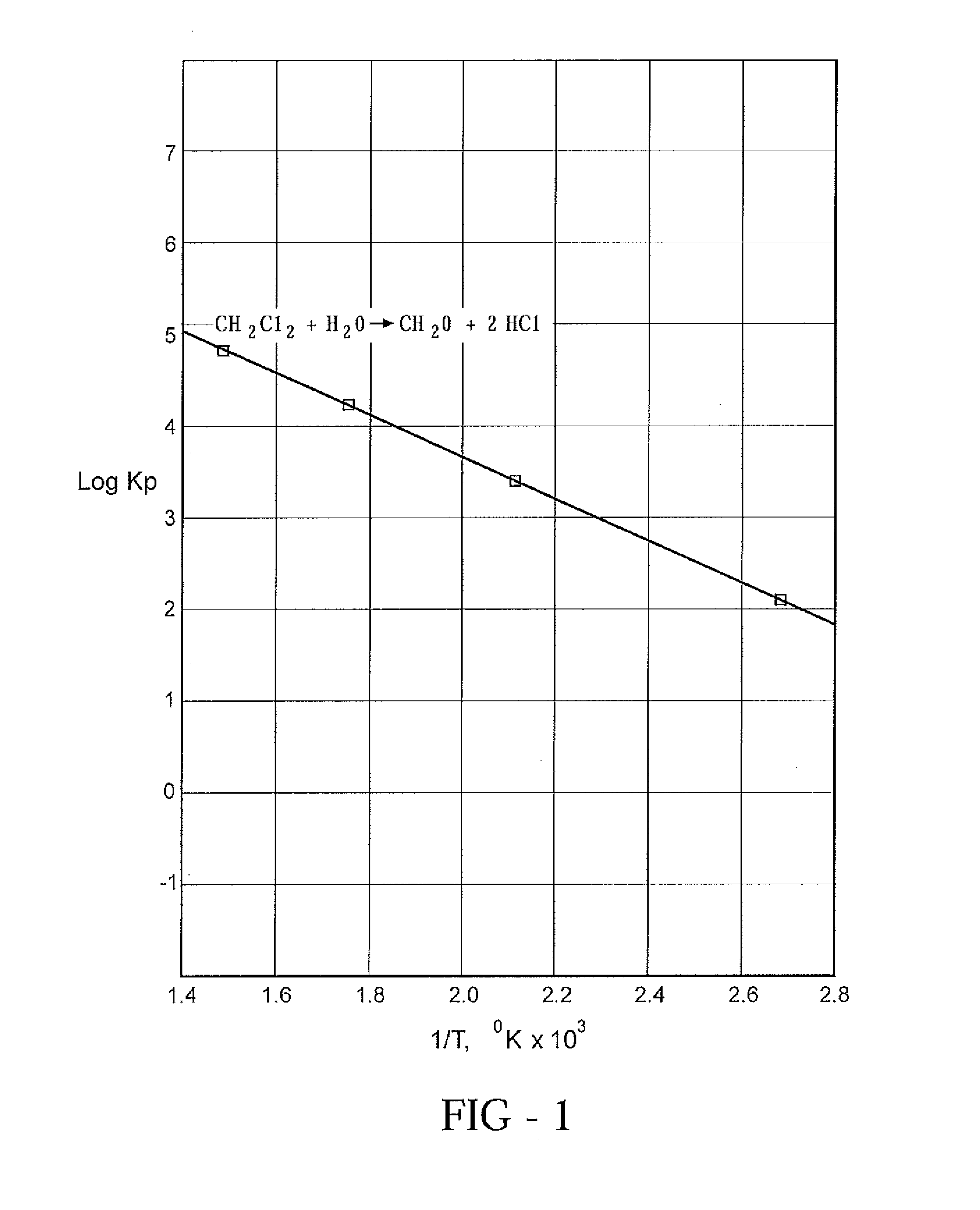

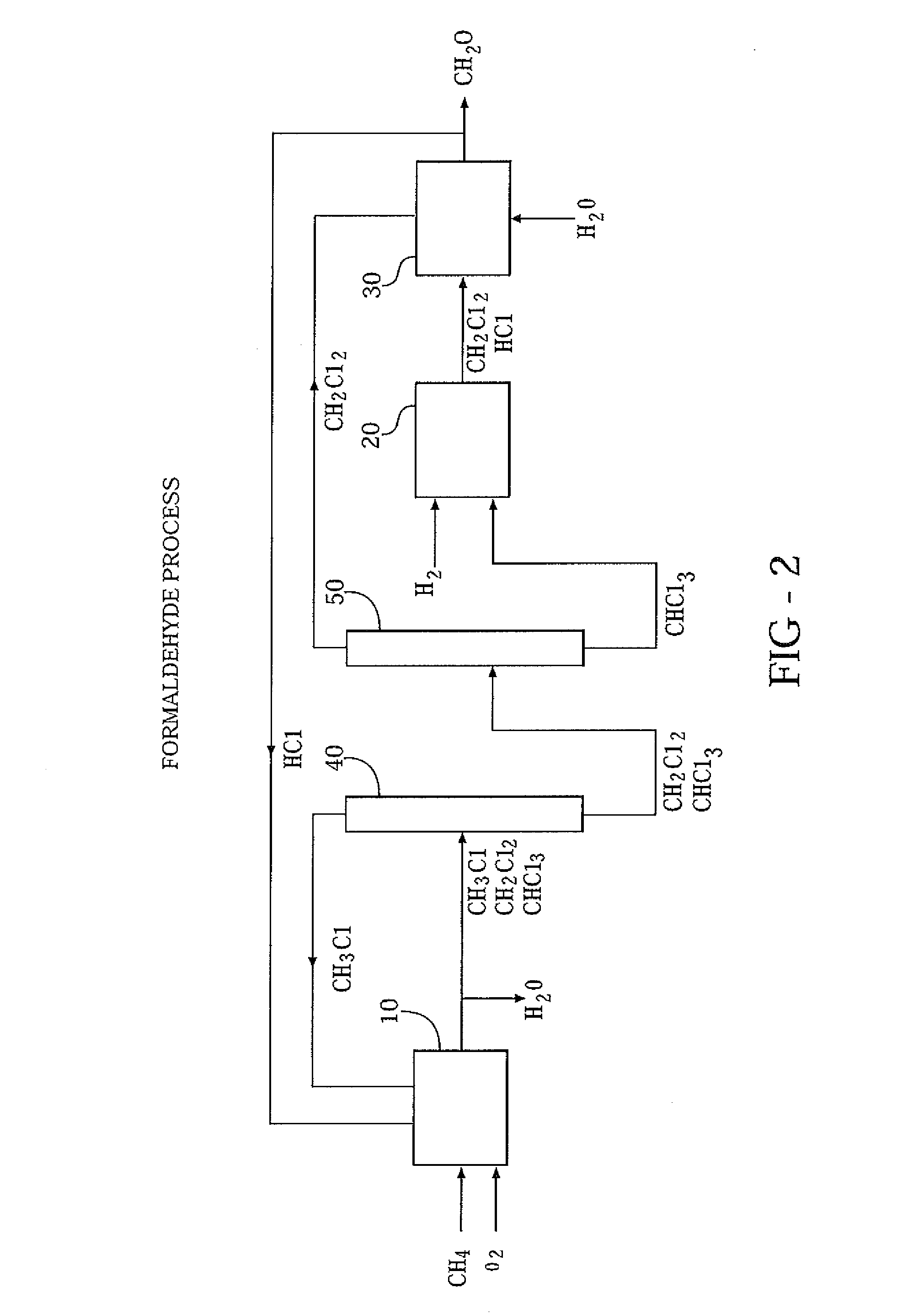

InactiveUS7790933B1Organic compound preparationCarbonyl compound preparation by hydrolysisFormaldehyde synthesisChloride

A process is disclosed for the synthesis of formaldehyde from methane starting with the oxychlorination of methane to produce methylene chloride. Hydrolysis of methylene chloride yields the product formaldehyde. Byproduct chloroform and carbon tetrachloride are recovered and hydrogenated to provide additional methylene chloride.

Owner:JES TECH LLC

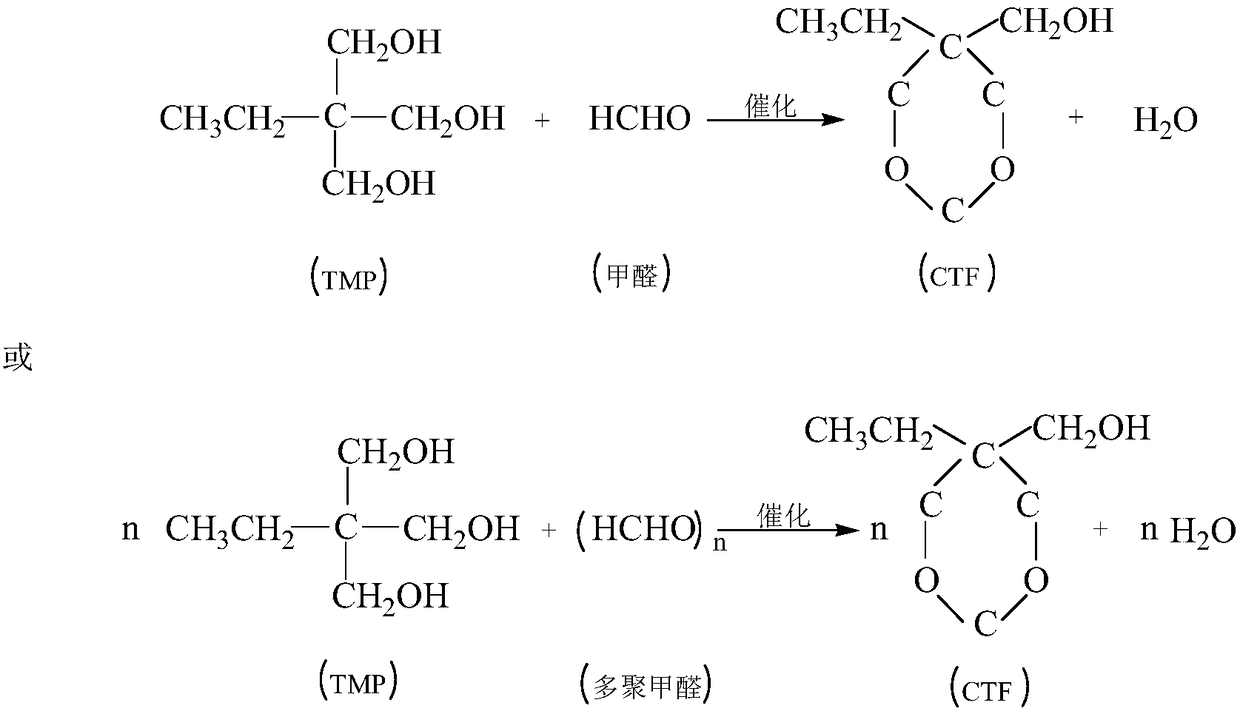

Preparation method of cyclic trimethylolpropane formaldehyde

InactiveCN108383826ASignificant technologySignificant craftsmanshipOrganic chemistryFormaldehyde synthesisFormaldehyde product

The invention relates to a preparation method of cyclic trimethylolpropane formaldehyde (CTF or MCF), mainly aiming at solving the problems in the prior art that synthetic conditions of trimethylolpropane formal are harsh, a process route is complicated, the purity of a product is low and the APHA color number is high. The preparation method comprises the following steps: taking trimethylolpropane(TMP) as a raw material, and mixing TMP, aldehyde, a solvent, a catalyst and an auxiliary agent according to a certain ratio; reacting at 60 to 120 DEG C for 0.1 to 6h; evaporating under low pressure, filtering and rectifying to obtain a cyclic trimethylolpropane formaldehyde product with the quality purity being greater than or equal to 98 percent and the color number APHA being less than or equal to 20. By adopting the preparation method provided by the invention, the problems are solved relatively well; a synthesis technology is simple and conditions are moderate, so that the preparation method can be widely applied to large-scale industrial production.

Owner:天津博奥新材料科技有限公司

A kind of iron-molybdenum catalyst and preparation method and application of methanol oxidation synthesis formaldehyde

ActiveCN106693981BLow firing temperatureReduce manufacturing costOrganic compound preparationHeterogenous catalyst chemical elementsFormaldehyde synthesisPtru catalyst

The invention discloses an iron-molybdenum catalyst for formaldehyde synthesis through methanol oxidation. The iron-molybdenum catalyst consists of an active metal oxide, an assistant metal oxide and a binder metal oxide, wherein the molar ratio of Mo to Fe to V to assistant metal to binder metal is 1:(0.33-0.67):(0.001-0.1):(0.001-0.1):(0.01-0.5). The iron-molybdenum catalyst has the advantages of low cost, long service life and low calcination temperature and reaction temperature.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

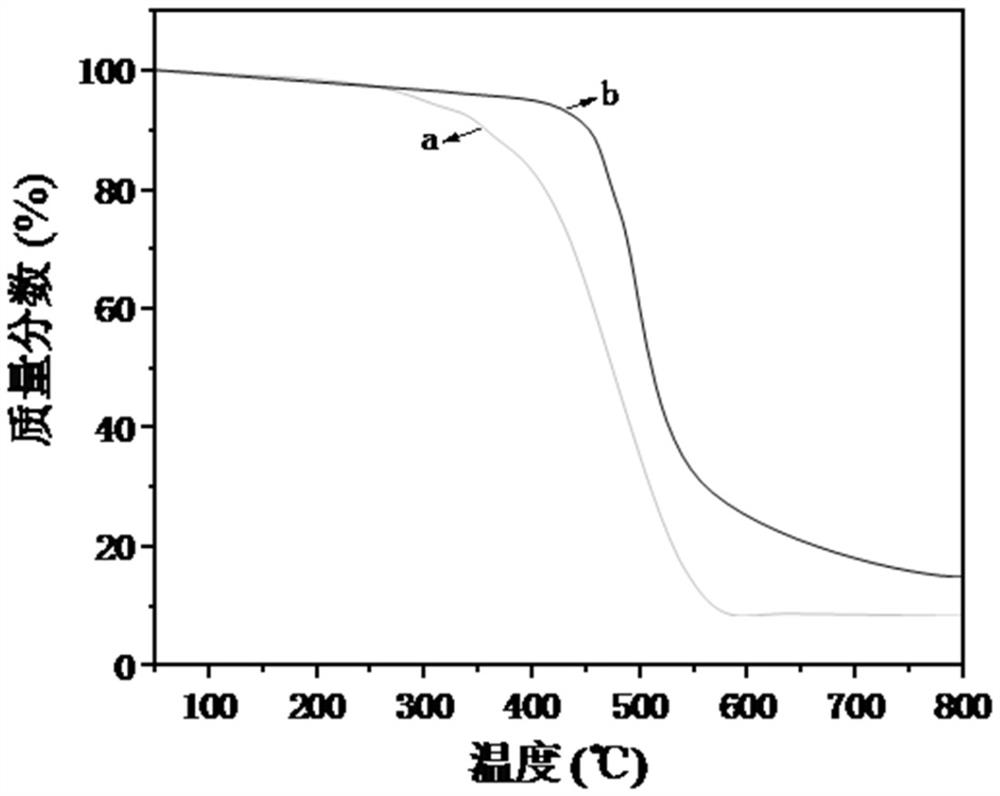

Corrosion-resistant phenolic resin coating and preparation method thereof

ActiveCN114736584ADecreased molecular weight regularityGood dispersionAnti-corrosive paintsEpoxy resin coatingsXylyleneMeth-

The invention provides a corrosion-resistant phenolic resin coating and a preparation method thereof, and the preparation method comprises the following steps: adding corrosion-resistant phenolic resin and epoxy acrylate into xylene, and carrying out high-speed shearing dispersion to prepare a dispersion liquid B; adding pentaerythritol, polyvinyl butyral, talcum powder, glass powder, turpentine and hexamethylenetetramine into the dispersion liquid B, heating, stirring and dispersing, cooling to room temperature, and grinding to obtain the corrosion-resistant phenolic resin coating. Wherein the corrosion-resistant phenolic resin is synthesized from polyacrylic acid, 4-hydroxybenzylamine and formaldehyde. The corrosion-resistant phenolic resin has good thermal stability, and the prepared corrosion-resistant phenolic resin coating has good corrosion resistance, flexibility and impact resistance.

Owner:常熟东南塑料有限公司

Synthesis method of methylal

InactiveCN103664551AImprove conversion rateQuality improvementOrganic chemistryOrganic compound preparationFormaldehyde synthesisWater discharge

The invention relates to a synthesis method of methylal, and belongs to the technical field of chemical product preparation. The synthesis method comprises the specific steps: pumping formaldehyde into a formaldehyde synthesis tower by a formaldehyde feeding pump, mixing with methanol coming from a methanol measuring tank and pumped by a methanol feeding pump, and carrying out a reaction to generate methylal under the action of a catalyst in a reactive rectifying tower; adjusting the feeding ratio and the feeding amount to control the purity and the yield of the product, adjusting the reaction temperature to control the reaction speed and the content of effective substances in waste water, and ensuring to reach waste water discharge requirements; and taking out the product gas from the top of the reactive rectifying tower, and cooling the product by utilizing two condensers connected with each other in series. The method is simple in operation, low in consumption of the raw materials, and high in conversion rate; and the product is qualified and discharged at a time, and has stable quality.

Owner:HUIZHOU LIERAN CHEM

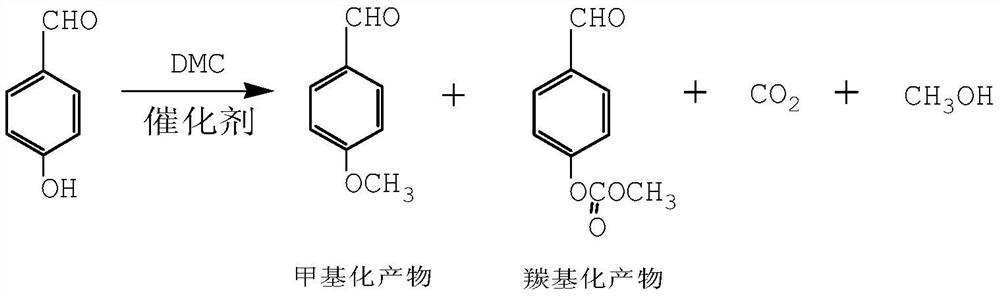

A kind of environment-friendly synthetic method of p-methoxybenzaldehyde

ActiveCN106946674BIncrease profitQuick responseOrganic compound preparationCarbonyl compound preparationPtru catalystActive agent

The invention relates to an environment-friendly synthesis method of p-methoxybenzaldehyde, which uses p-hydroxybenzaldehyde as a raw material, uses polar solvent water as a solvent in the temperature range of 130-180°C, and uses Y-type zeolite, an alkaline substance, as a solvent. Catalyst, and add appropriate surfactant Turkish red oil to make emulsifier etc. under specific conditions, prepare p-methoxybenzaldehyde with environment-friendly dimethyl carbonate (DMC) as methylation raw material, and its yield reaches more than 96% , The purity of the final product reaches more than 99%.

Owner:山东达冠科技有限责任公司

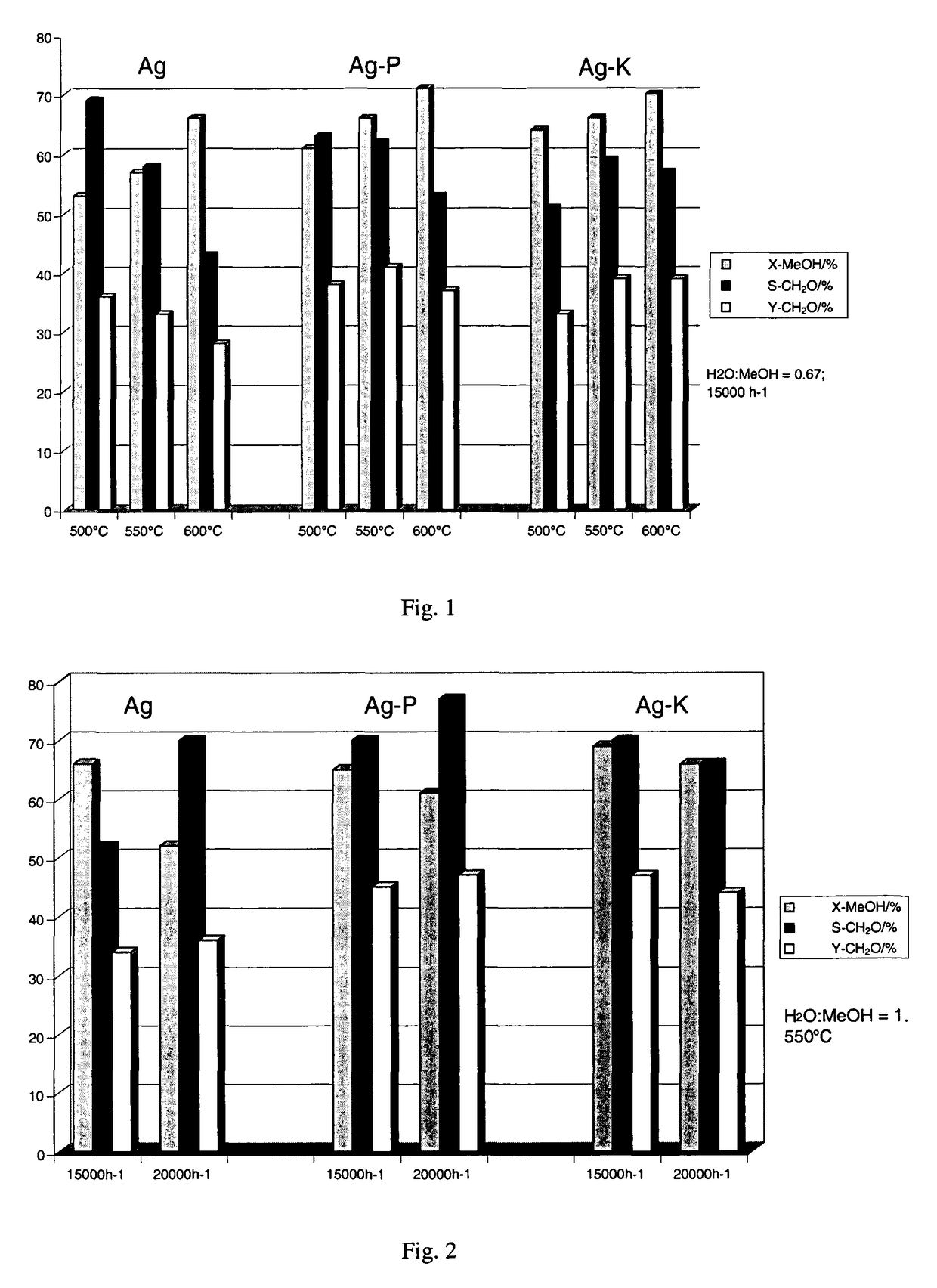

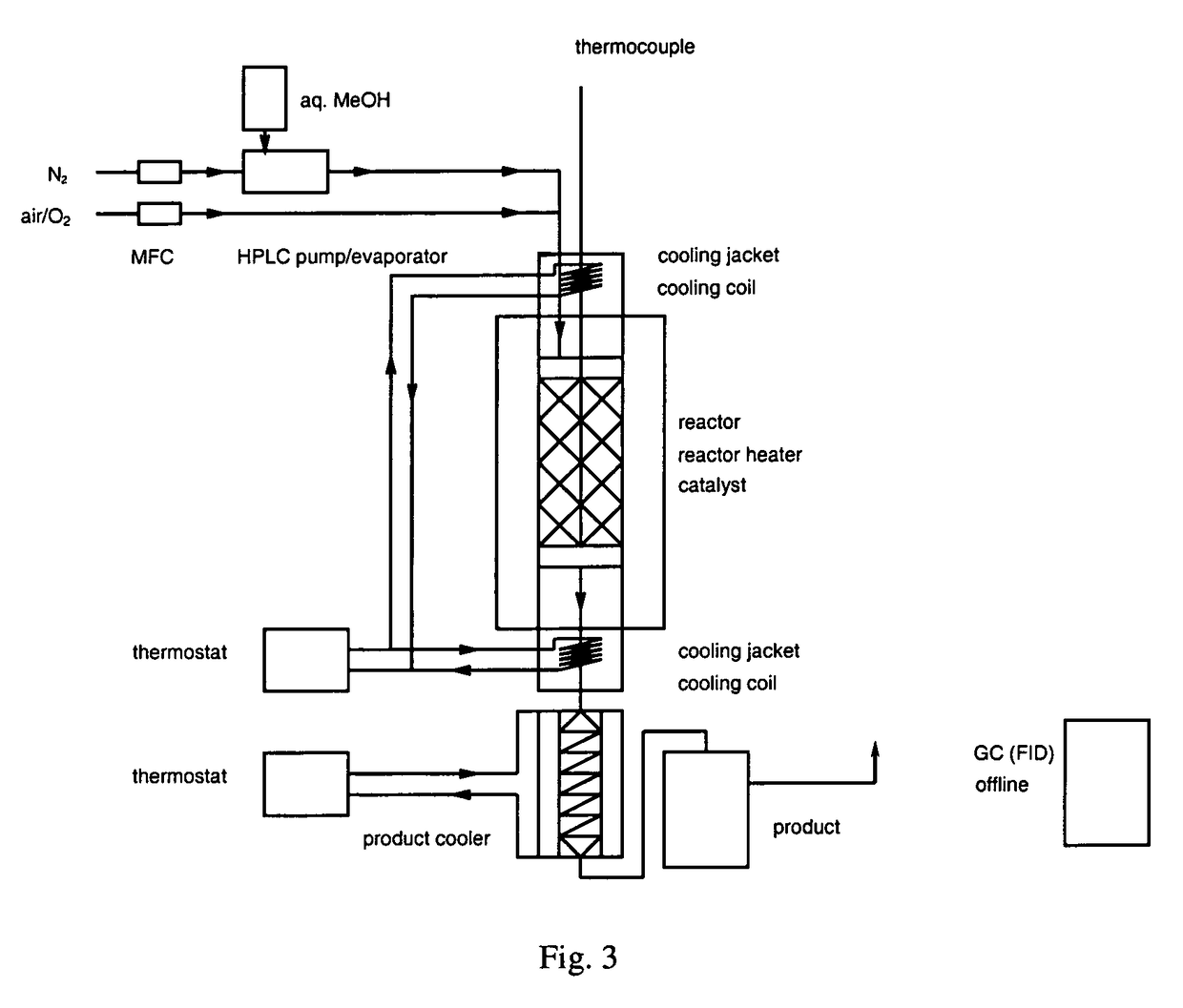

Silver catalyst for formaldehyde preparation

ActiveUS8471071B2Extended service lifeOrganic compound preparationCatalyst activation/preparationFormaldehyde synthesisSilver catalyst

The present invention relates to a process for producing coated silver catalysts. The invention further addresses the silver catalysts themselves and the advantageous use thereof in formaldehyde synthesis.

Owner:AGOSI AG

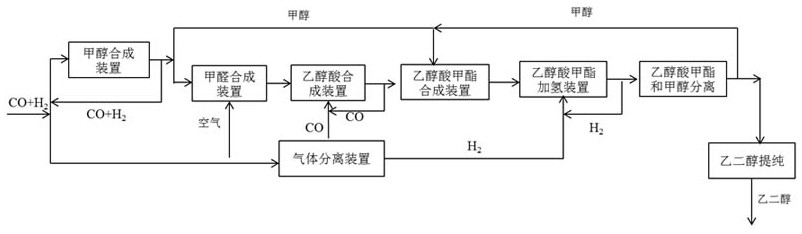

A process for producing ethylene glycol from syngas

ActiveCN111039753BReduce manufacturing costReduce refining costsOrganic compound preparationChemical industryFormaldehyde synthesisPtru catalyst

The invention relates to a process for producing ethylene glycol from synthesis gas, a process for producing ethylene glycol from synthesis gas. Synthesis gas and methanol synthesis tail gas are mixed into methanol synthesis raw materials, and methanol and methanol synthesis are produced under the action of a methanol synthesis catalyst Exhaust gas: a part of methanol is mixed with air to generate formaldehyde and formaldehyde synthesis tail gas under the action of formaldehyde synthesis catalyst, and another part of methanol is mixed with methanol recycled from hydrogenation reaction and then esterified with glycolic acid to form methyl glycolate; synthesis gas separation H obtained 2 After mixing with methyl glycolate hydrogenation tail gas, it will generate ethylene glycol, methanol and hydrogenation tail gas with methyl glycolate under the action of hydrogenation catalyst; separate ethylene glycol and methanol.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

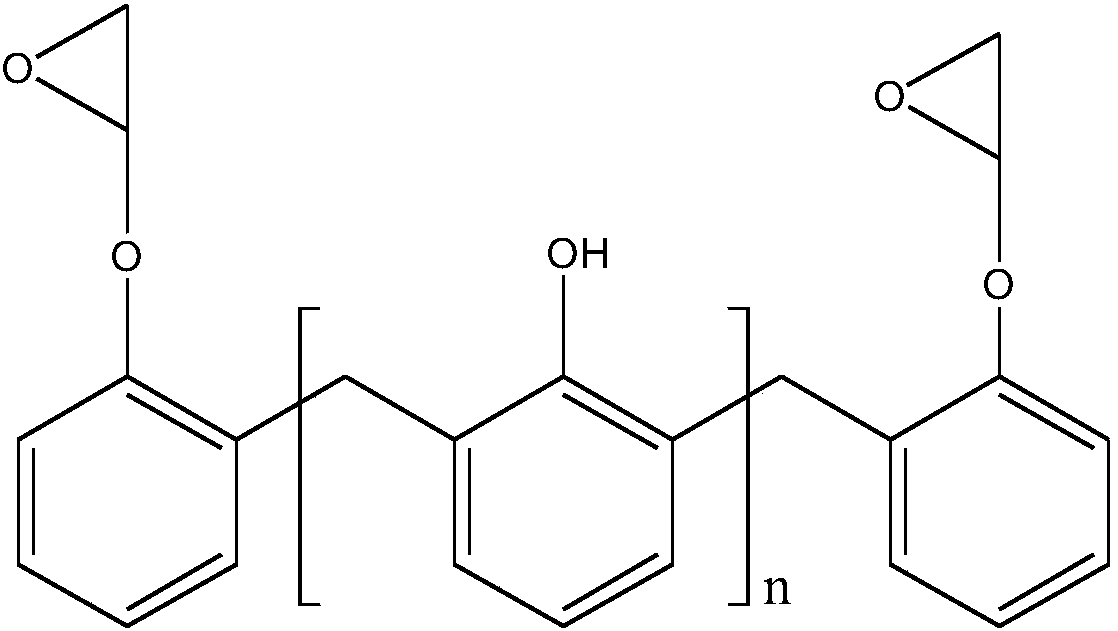

A kind of epoxy resin containing phenolic hydroxyl group and preparation method of flame-retardant foaming material thereof

Owner:WUHAN UNIV OF TECH

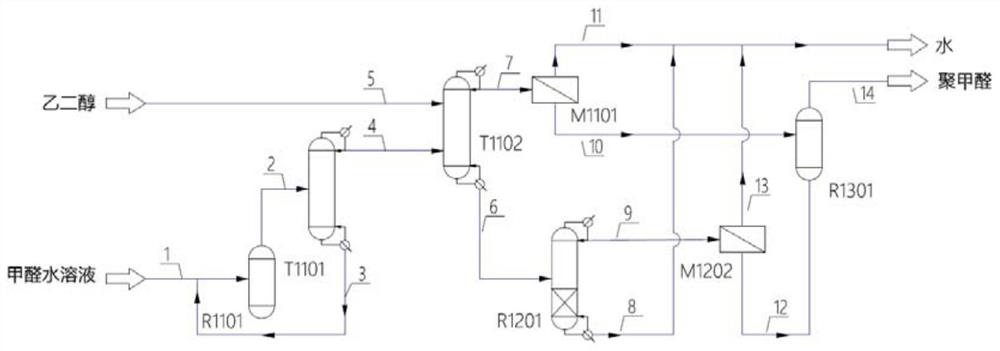

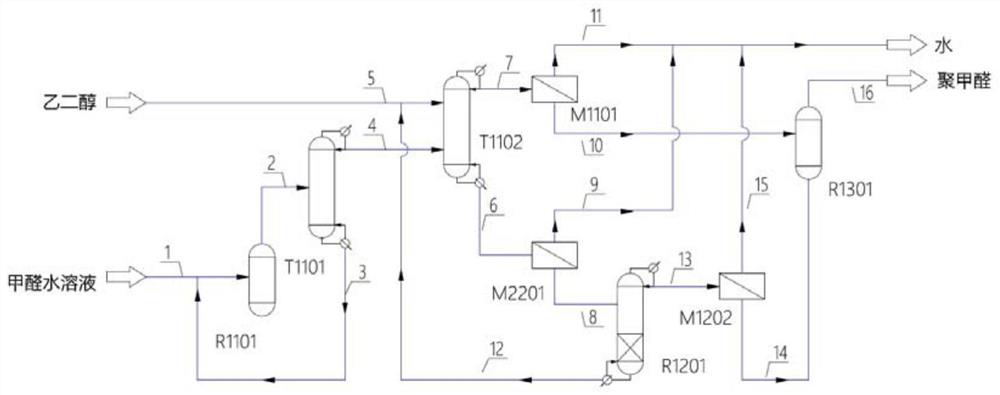

Method for preparing polyformaldehyde through co-production of trioxymethylene and dioxolane

ActiveCN111848889AHigh utilization rate of raw materialsImprove separation efficiencyOrganic chemistryChemical industryFormaldehyde synthesisPolyoxymethylene

The invention relates to a method for preparing polyformaldehyde through co-production of trioxymethylene and dioxolane. The method comprises the following steps of: synthesizing ethylene glycol and formaldehyde in a trioxymethylene crude product into hemiacetal, performing separation, and synthesizing dioxolane, thereby simplifying the subsequent separation and refining process of the dealdehydedtrioxymethylene crude product. According to the process, the amount of dilute aldehyde in the polyformaldehyde monomer preparation process is reduced, the energy consumption of the preparation process is reduced, and the product quality of the polyformaldehyde monomer is improved.

Owner:CHINA CHEM TECH RES INST +1

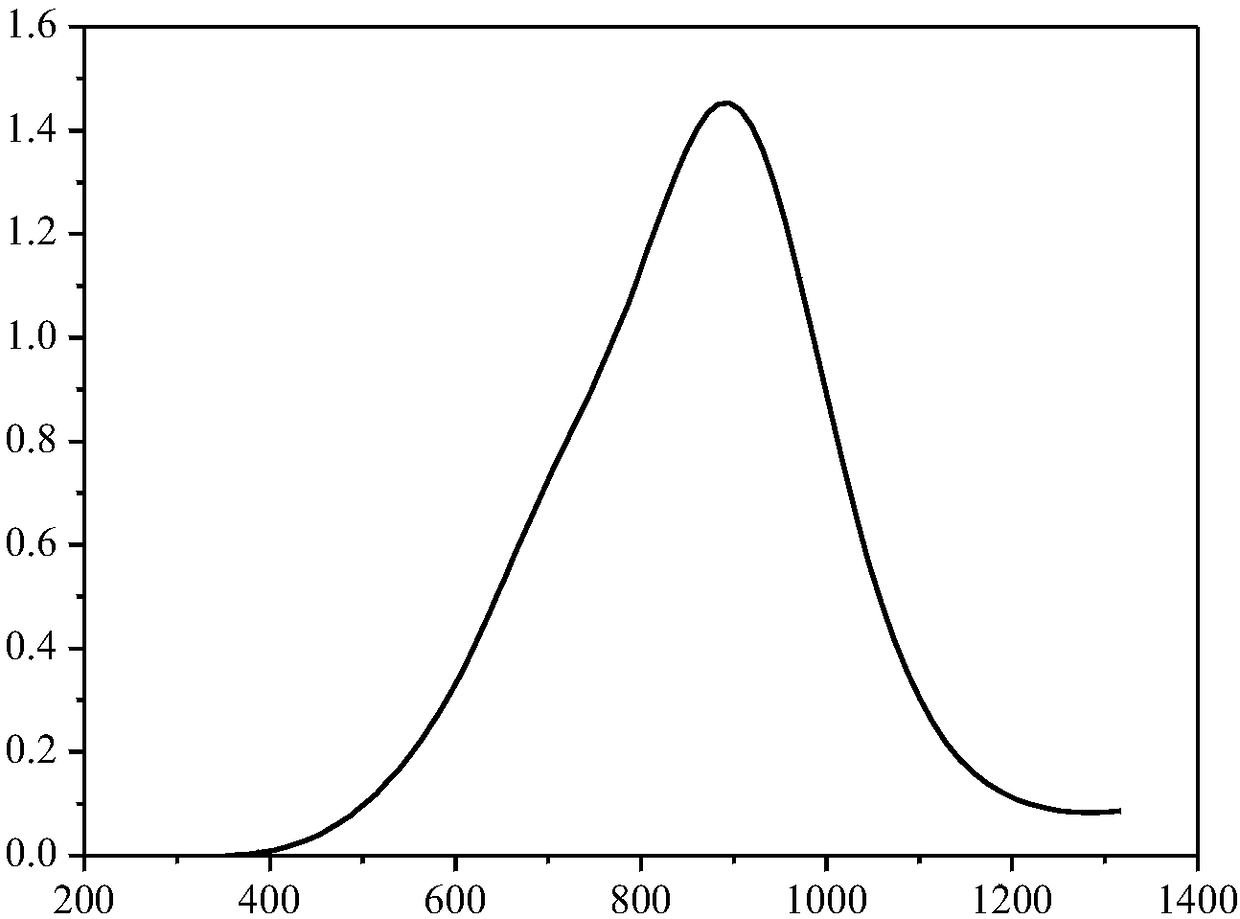

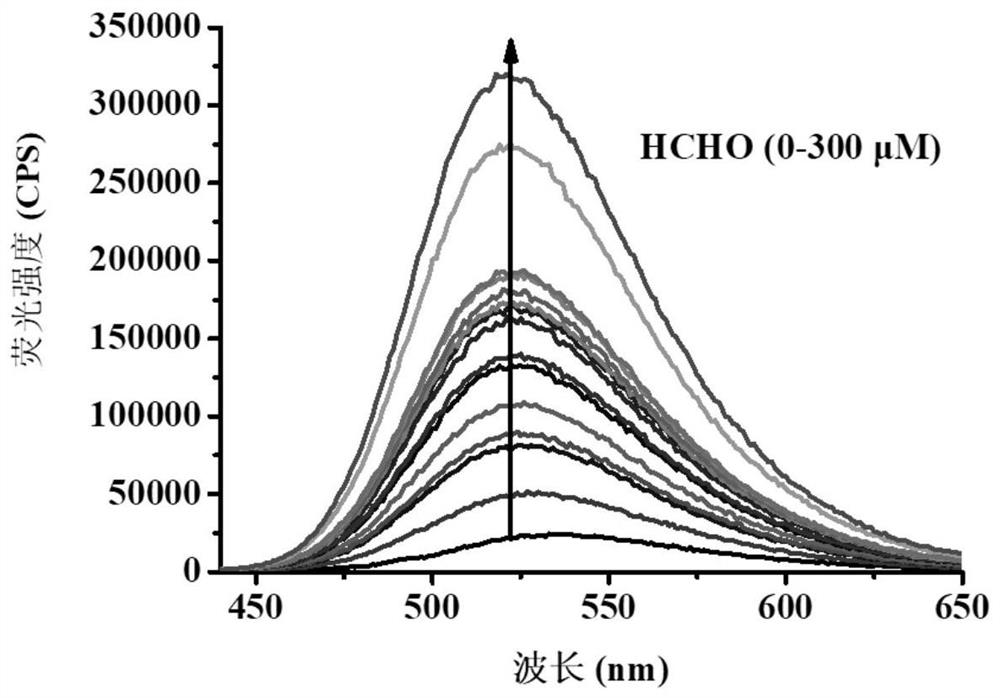

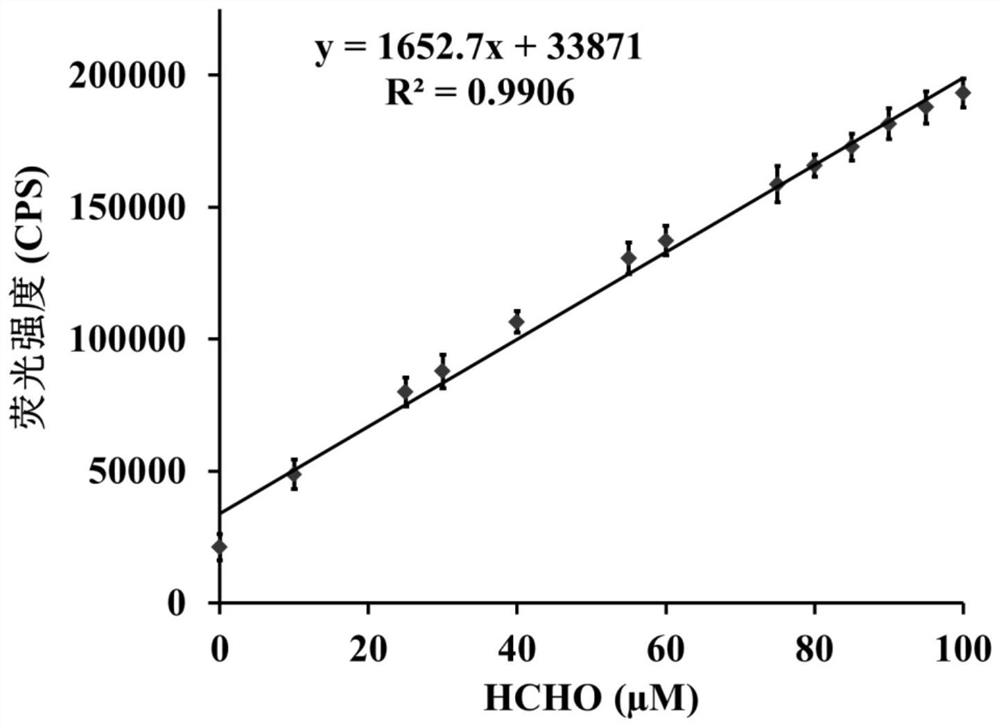

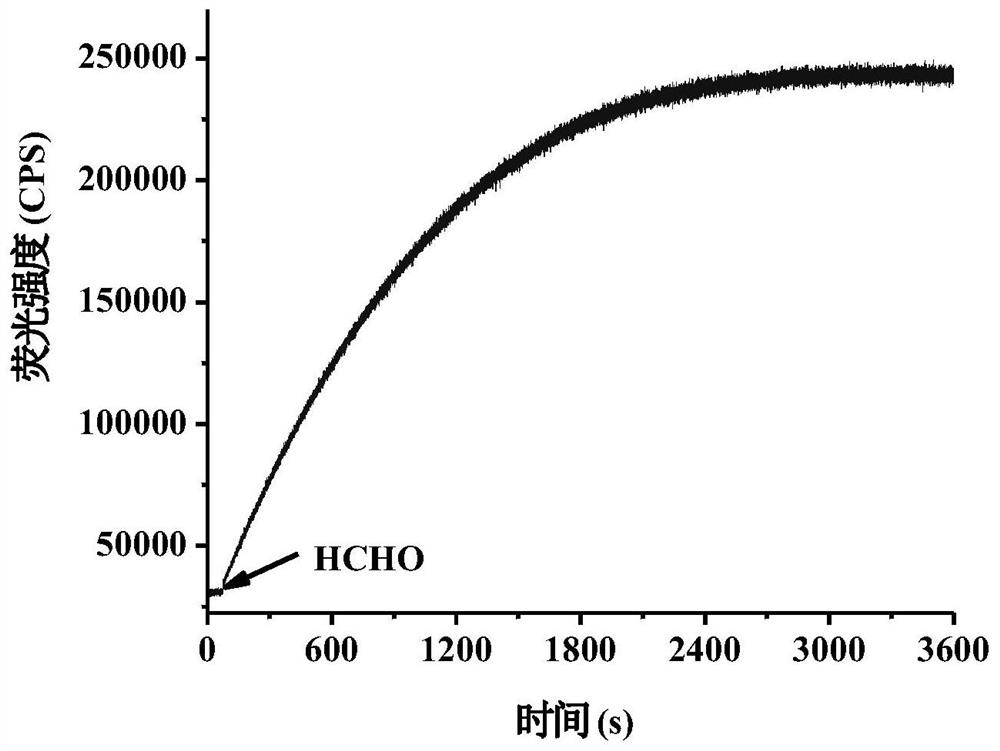

Novel cell membrane specific formaldehyde fluorescent probe as well as preparation method and application thereof

ActiveCN112457249AEffective targetingDistinguish detectionOrganic chemistryFluorescence/phosphorescenceFluoProbesFormaldehyde synthesis

The invention relates to a novel cell membrane specific fluorescent probe as well as a preparation method and application thereof; particularly, the novel cell membrane specific fluorescent probe canbe used for measuring, detecting or screening formaldehyde and living cell fluorescence imaging, and particularly can be applied to distinguishing and detecting endogenous formaldehyde and exogenous formaldehyde and imaging. The probe can realize at least one of the following technical effects: targeting and positioning cell membranes, distinguishing and detecting endogenous formaldehyde and exogenous formaldehyde, identifying formaldehyde with high selectivity, quickly responding to formaldehyde, sensitively analyzing formaldehyde, detecting formaldehyde under physiological level conditions,and being simple to synthesize and stable in property.

Owner:UNIV OF JINAN

A kind of wood adhesive resin and preparation method thereof

ActiveCN109867761BReduce usageReduce releaseAldehyde/ketone condensation polymer adhesivesFormaldehyde synthesisPolymer science

The invention provides a novel wood adhesive resin and a preparation method thereof, belonging to the technical field of wood adhesives. The name of the prepared adhesive resin is urea-ethylenediamine-formaldehyde resin. The preparation raw materials include: ethylenediamine, urea and formaldehyde; the molar ratio of urea to ethylenediamine is 2.0-2.5; the molar ratio of formaldehyde to urea is 0.85-1.0. In the preparation process, firstly, ethylenediamine and urea are subjected to deamination condensation reaction under solvent-free and catalyst-free conditions to synthesize urea-ethylenediamine polyamide, and then urea-ethylenediamine polyamide and formaldehyde are synthesized to obtain the product. The final wood adhesive resin; the appearance of the finally prepared wood adhesive resin is a milky white uniform liquid, the solid content is 60-65%, and the storage period is more than 7 days. The urea-ethylenediamine-formaldehyde resin wood adhesive provided by the invention has a simple synthesis method, and has the advantages of low curing temperature, excellent performance, low formaldehyde emission and the like, and can be used for the production of wood-based panels such as plywood and particleboard.

Owner:SOUTHWEST FORESTRY UNIVERSITY

A kind of preparation method of oil-soluble high-efficiency electric desalting demulsifier for ultra-heavy oil refining

ActiveCN103865070BReduce manufacturing costIncrease profitDewatering/demulsification with chemical meansFormaldehyde synthesisDemulsifier

The invention discloses a preparation method of an oil-soluble high-efficiency electric desalination demulsifier for ultra-heavy oil refining. The preparation method comprises the following steps: synthesizing phenolamine resin, and successively condensing the phenolamine resin with propylene oxide and ethylene oxide Reaction to obtain block polyether, then use phenol, hydrochloric acid and formaldehyde to synthesize thermoplastic phenolic resin, and finally carry out phenolic resin graft modification reaction on the obtained thermoplastic phenolic resin and block polyether to obtain ultra-heavy oil refining oil-soluble high-efficiency electric desalination Demulsifier products. The preparation method of the present invention can efficiently prepare an oil-soluble high-efficiency electric desalination demulsifier, reduce production costs, and improve the utilization rate of raw materials. The demulsifier produced by the method can greatly increase the desalination and dehydration speed of super heavy oil, save limited time, and can effectively Make up for the shortcomings of the processing device in the processing of super-heavy oil.

Owner:克拉玛依市天明化工有限责任公司

A core-shell sic@c catalyst for microwave-assisted catalytic depolymerization of solid waste and its preparation method

ActiveCN110368972BIncrease the areaIncrease loadCatalyst carriersCatalyst activation/preparationCarbon layerFormaldehyde synthesis

The invention discloses a core-shell SiC@C catalyst for microwave-assisted catalytic depolymerization of solid waste and a preparation method thereof. The core-shell SiC@C catalyst includes a carrier, an active component and a catalytic component. The carrier is SiC@C core-shell composite material, SiC@C core-shell composite material specifically uses resorcinol and formaldehyde to synthesize phenolic resin as a carbon precursor, and coats the surface of SiC to form a carbon layer; the catalytic promoter component is a transition metal The oxide is loaded in the surface pores of the carbon layer; the active component is a noble metal, which is loaded in the surface pores of the carbon layer; and the mass ratio of the carrier, the catalytic promoter component and the active component is 1:(0.005~0.01): (0.01~0.05). The core-shell SiC@C supported catalyst prepared by the invention is used in the microwave-assisted depolymerization process of solid waste, which effectively improves the depolymerization degree and depolymerization efficiency of solid waste, and at the same time improves the orientation of microwave-assisted depolymerization products Regulation has greatly promoted the efficient and high-value utilization of solid waste.

Owner:SHAANXI UNIV OF SCI & TECH

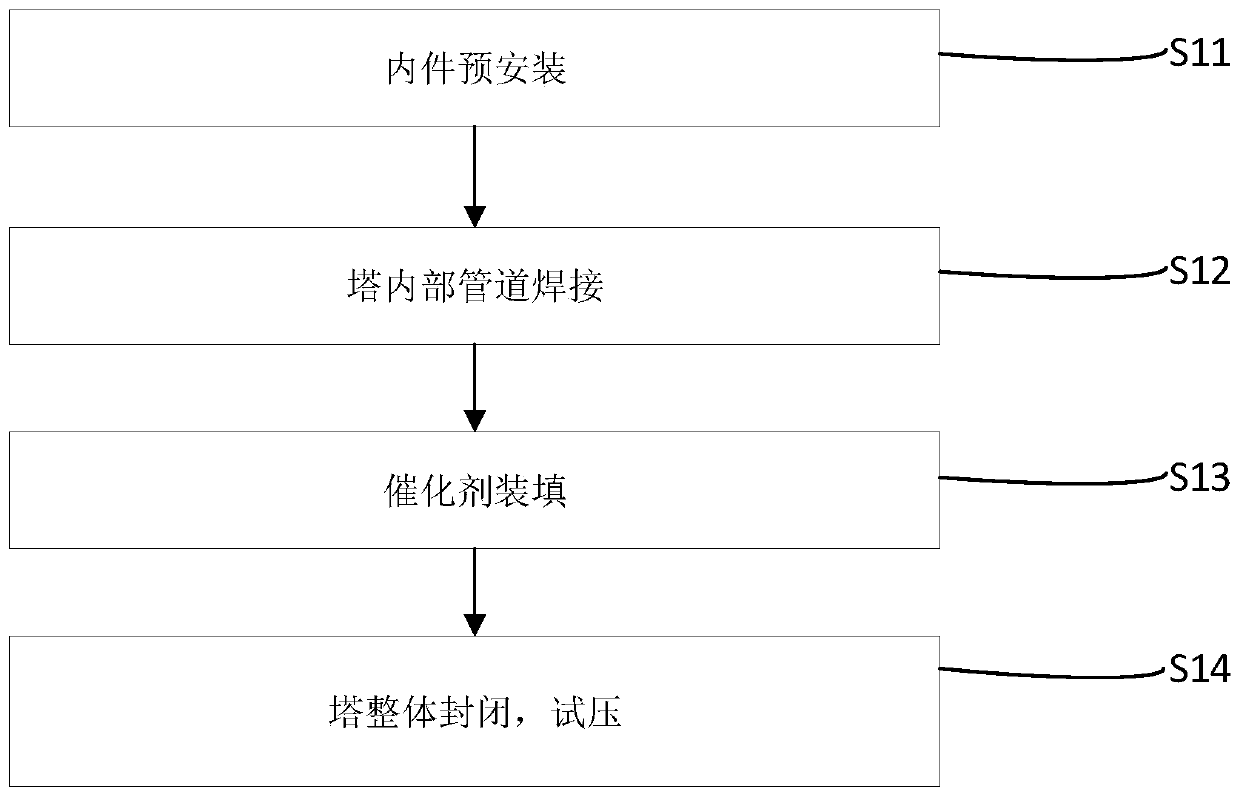

Method for accurately installing formaldehyde synthesis tower internals

InactiveCN111013513AEfficient connectionSolve alignment difficultiesChemical/physical/physico-chemical processesMetal working apparatusFormaldehyde synthesisPtru catalyst

The invention discloses a method for accurately installing formaldehyde synthesis tower internals. The method comprises the following steps: 1, pre-installing the internals: arranging auxiliary mounting devices between tower trays, wherein the auxiliary mounting devices comprise an upper fixing and adjusting device, a connecting supporting leg adjusting device, a longitudinal sliding adjusting device and a radial sliding adjusting device which are connected in sequence, the internals are clamped and fixed on the radial sliding adjusting device through fastening pieces of the radial sliding adjusting device, the radial sliding adjusting device adjusts the radial sizes of the synthesis tower internals according to the internal size of the formaldehyde synthesis tower, the connecting supporting leg adjusting device adjusts the distance between the internals and the coaxiality of the internals through an adjusting rod, and the internals are fixed through fastening bolts after the auxiliarydevices position the positions of the internals; welding pipelines in the tower; filling with a catalyst; and integrally closing the tower, and performing pressure test. The method for accurately installing formaldehyde synthesis tower internals is simple and low in cost.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

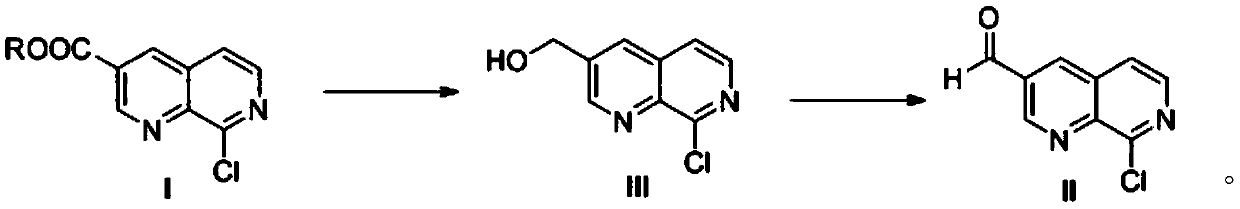

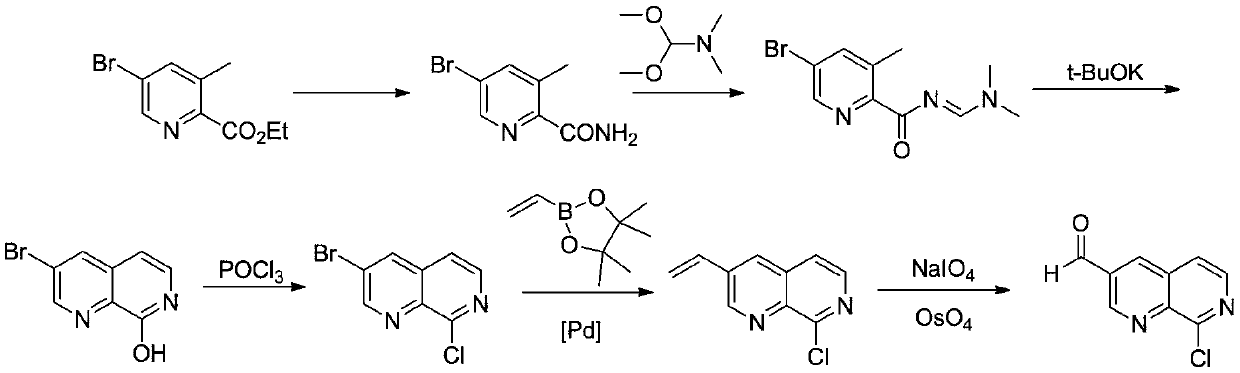

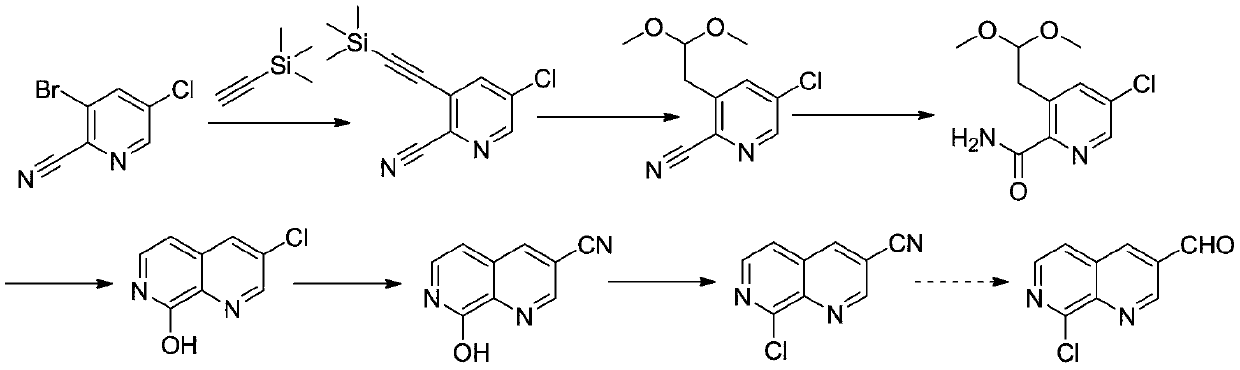

Preparation method of medical intermediate 8-chloro-1, 7-naphthyridin-3-formaldehyde

ActiveCN110950865AThe synthetic route is simpleSave raw materialsOrganic chemistryBulk chemical productionFormaldehyde synthesisFormate

The invention discloses a preparation method of a medical intermediate 8-chloro-1, 7-naphthyridin-3-formaldehyde and belongs to the field of synthesis and preparation of medical intermediates. The preparation method comprises the following steps: step 1) dissolving a compound I 8-chloro-1, 7-naphthyridin-3-formate as an initial raw material in a solvent, and under the catalysis of Lewis acid, performing reduction to obtain 2-chloro-1, 7-naphthyridin-3-methanol, namely a compound III, and 2) carrying out TEMPO oxidation on the compound III 2-chloro-1, 7-naphthyridin-3-methanol to obtain 8-chloro-1, 7-naphthyridin-3-formaldehyde, namely a compound II. The preparation method disclosed by the invention is suitable for industrial production, relatively low in cost and simple to operate, and canbe used for producing active compounds of various novel immunomodulators.

Owner:CHENGDA PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com