Urea formaldehyde (UF) sustained-release fertilizers and production process thereof

A technology for urea-formaldehyde and slow-release fertilizers, which is applied in the field of urea-formaldehyde (UF) slow-release fertilizers and chemical slow-release fertilizers. Less problems, to achieve the best fertilizer effect period and utilization rate, simple production method, slow release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

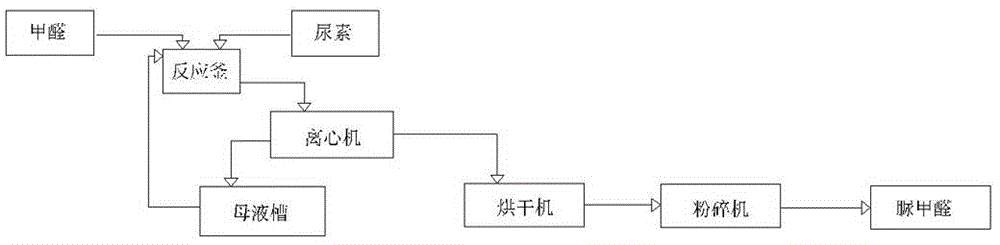

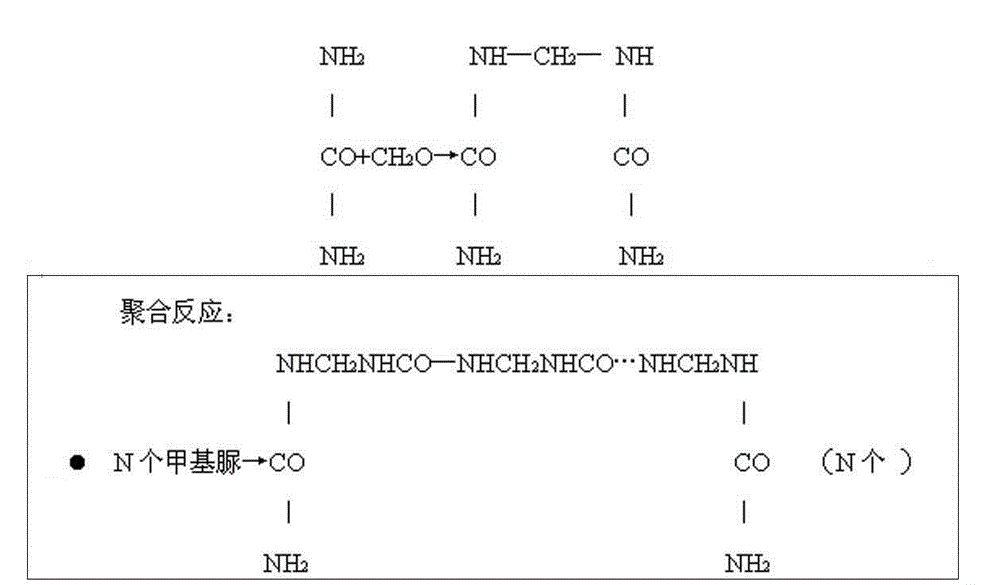

[0019] A urea-formaldehyde slow-release fertilizer is composed of the following molar ratios of raw materials: urea: formaldehyde = 1:1, and its production process is as follows:

[0020] Take 100 kg of urea (with a nitrogen content greater than or equal to 46%) and 100 kg of formaldehyde (with a content greater than or equal to 36%) according to the above ratio, add them to the reactor, and proceed under the following reaction conditions: addition reaction pH 8.0, temperature 80 ° C, The time is 30 minutes, the polymerization reaction pH is 4.5, the temperature is 55°C, and the time is 1 hour; then it can be centrifuged, dried and pulverized.

[0021] The main technical indicators of the produced urea-formaldehyde are:

[0022] Total nitrogen content: 38.5%; cold water insoluble nitrogen 25.5%; activity coefficient: 52%; biuret 0.4%; moisture: 2.6%.

Embodiment 2

[0024] A urea-formaldehyde slow-release fertilizer is composed of the following molar ratios of raw materials: urea: formaldehyde = 2:1, and its production process is as follows:

[0025] Take 200 kg of urea (with a nitrogen content greater than or equal to 46%) and 100 kg of formaldehyde (with a content greater than or equal to 36%) according to the above ratio, add them to the reactor, and proceed under the following reaction conditions: addition reaction pH 8.5, temperature 78 ° C, The reaction time is 40 minutes, the polymerization reaction pH is 4.2, the temperature is 50°C, and the time is 55 minutes; then it can be centrifuged, dried and pulverized.

[0026] The main technical indicators of the produced urea-formaldehyde are:

[0027] Total nitrogen content: 39.0%; cold water insoluble nitrogen 26.1%; activity coefficient: 48%; biuret 0.35%; moisture: 2.3%.

Embodiment 3

[0029] A urea-formaldehyde slow-release fertilizer is composed of the following molar ratios of raw materials: urea: formaldehyde = 1.5:1, and its production process is as follows:

[0030] Take 150 kg of urea (with a nitrogen content greater than or equal to 46%) and 100 kg of formaldehyde (with a content greater than or equal to 36%) according to the above ratio, add them to the reactor, and proceed under the following reaction conditions: addition reaction pH 7.8, temperature 65 ° C, The reaction time is 2 hours, the polymerization reaction pH is 5.6, the temperature is 45°C, and the time is 42 minutes; then it can be centrifuged, dried and pulverized.

[0031] The main technical indicators of the produced urea-formaldehyde are:

[0032] Total nitrogen content: 38.8%; cold water insoluble nitrogen 26.8%; activity coefficient: 51%; biuret 0.41%; moisture: 1.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com