Sulfation binary metallic oxide solid acid catalyst and preparation method and application thereof

A solid acid catalyst and binary metal technology, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of low conversion rate of reaction raw materials and product selectivity, long reaction path, short catalyst life, etc. , to achieve the effects of low production cost, high selectivity, and low equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

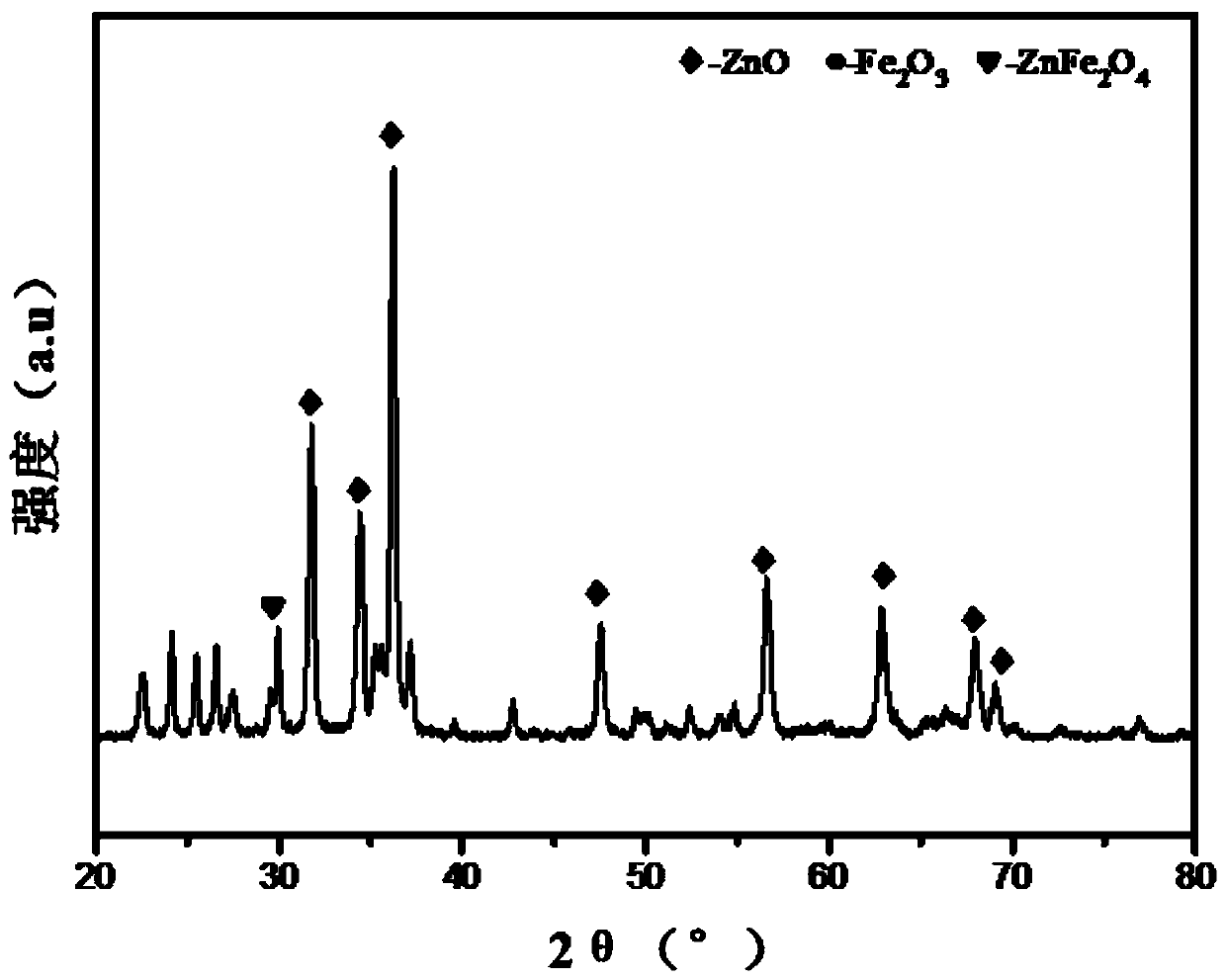

[0040] 0.1mol Fe(NO 3 ) 3 9H 2 O and 0.4mol Zn(NO 3 ) 2 ·6H 2 O was added to 500mL deionized water, heated and stirred in a water bath at 60°C for 30min to dissolve, and then 10% NH 3 ·H 2 O adjust the pH to 8, continue to stir the resulting solution in a water bath at 60°C for 2h, age at room temperature for 4h, filter the precipitate, wash the precipitate with deionized water until the washing liquid is neutral, and place the precipitate in an oven at 100°C Dry in medium for 12 hours to obtain the hydroxide precursor; grind the hydroxide precursor into particles with a particle size of 40-80 mesh, soak the particles in 1.0mol / L sulfuric acid solution and stir for 3 hours (1g powder corresponds to 10ml sulfuric acid solution) , filtered and dried at 100°C for 12 hours, placed in a muffle furnace at 500°C for 5 hours to obtain a sulfated binary metal oxide solid acid catalyst. The catalyst is SO 4 2- / Fe 2 o 3 -8ZnO. figure 1 For the sulfated binary metal oxide sol...

Embodiment 2

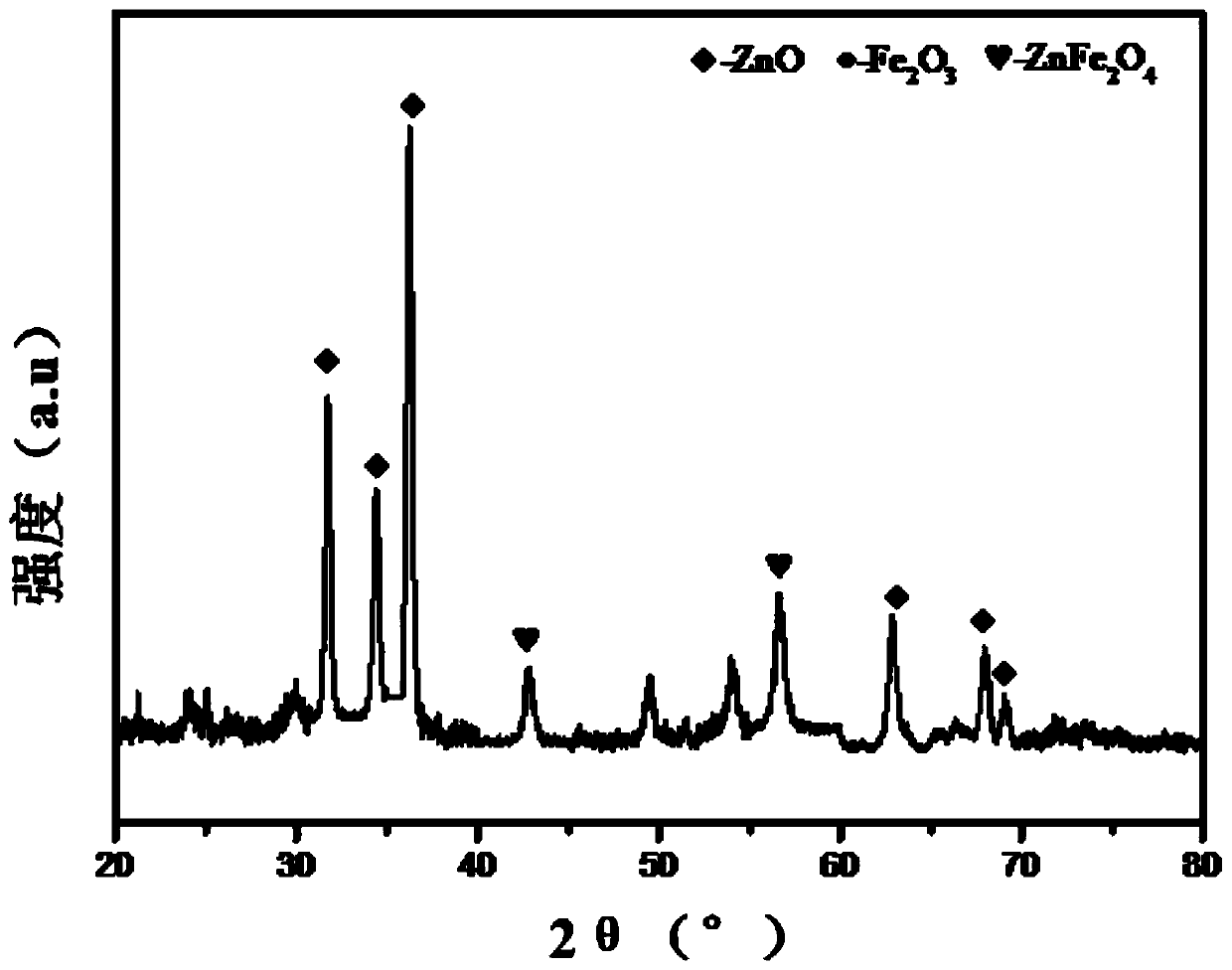

[0044] 0.167mol Fe(NO 3 ) 3 9H 2 O and 0.333mol Zn(NO 3 ) 2 ·6H 2 O was added to 500mL deionized water, heated and stirred in a water bath at 60°C for 30min to dissolve, and then 10% NH 3 ·H 2 O adjust the pH to 8, continue to stir the resulting solution in a water bath at 60°C for 2h, age at room temperature for 4h, filter the precipitate, wash the precipitate with deionized water until the washing liquid is neutral, and place the precipitate in an oven at 100°C dry in medium for 12 hours to obtain the hydroxide precursor; grind the hydroxide precursor to particles with a particle size of 40-80 mesh, immerse the particles in 1.0mol / L sulfuric acid solution and stir for 3 hours (1g powder corresponds to 10ml sulfuric acid solution), After filtering, it was dried at 100° C. for 12 hours, placed in a muffle furnace and calcined at 500° C. for 5 hours to obtain a sulfated binary metal oxide solid acid catalyst. The catalyst is SO 4 2- / Fe 2 o 3 -4ZnO. figure 2 For th...

Embodiment 3

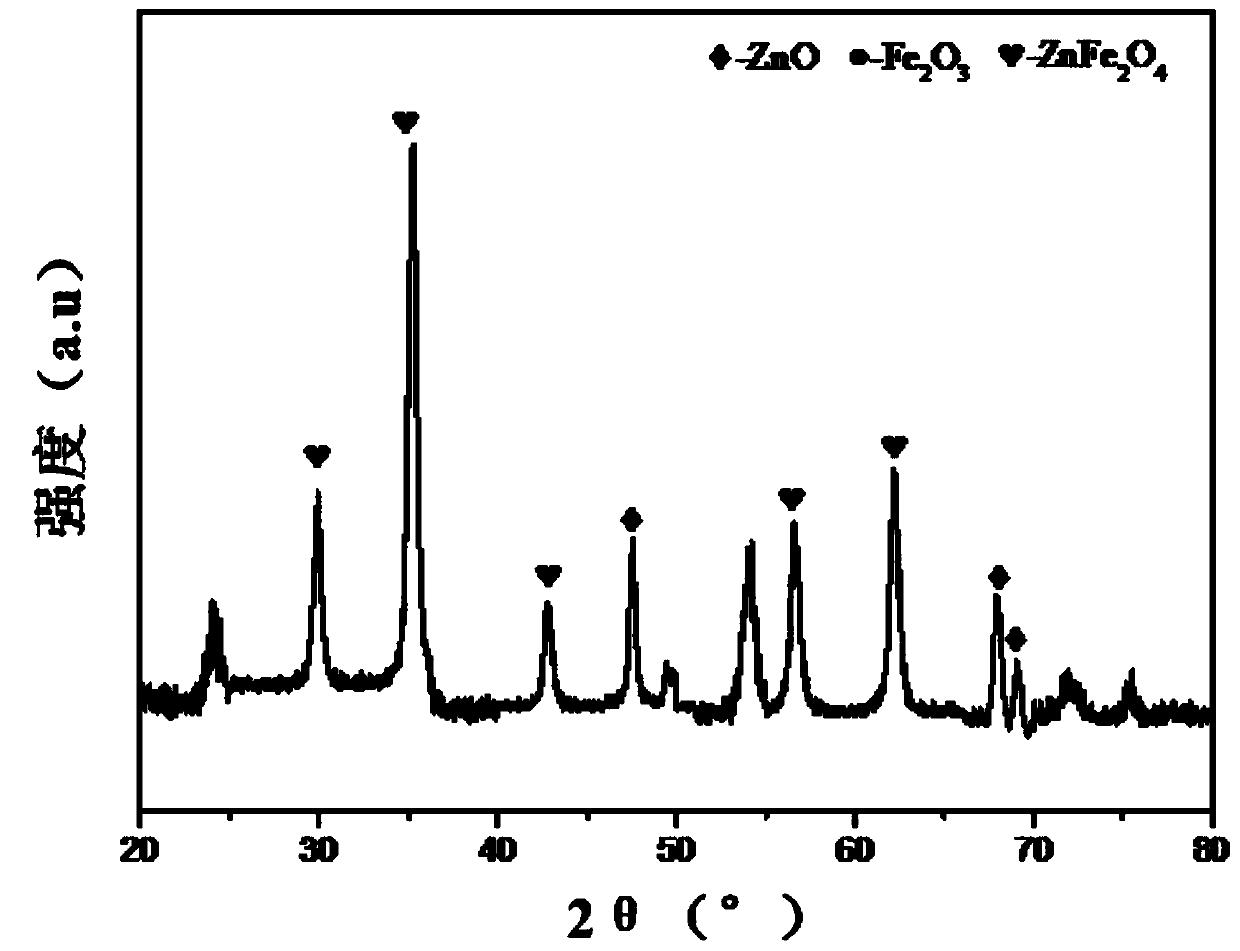

[0048] According to the metal atom molar ratio Fe:Zn=1:1, 0.25mol Fe(NO 3 ) 3 9H 2 O and 0.25mol Zn(NO 3 ) 2 ·6H 2 O was added to 500mL deionized water, heated and stirred in a water bath at 60°C for 30min to dissolve, and then 10% NH 3 ·H 2 O adjust the pH to 8, continue to stir the resulting solution in a water bath at 60°C for 2h, age at room temperature for 4h, filter the precipitate, wash the precipitate with deionized water until the washing liquid is neutral, and place the precipitate in an oven at 100°C Dry in medium for 12 hours to obtain the hydroxide precursor; grind the hydroxide precursor into particles with a particle size of 40-80 mesh, soak the particles in 1.0mol / L sulfuric acid solution and stir for 3 hours (1g powder corresponds to 10ml sulfuric acid solution) , filtered and dried at 100°C for 12 hours, placed in a muffle furnace at 500°C for 5 hours to obtain a sulfated binary metal oxide solid acid catalyst. The catalyst is SO 4 2- / Fe 2 o 3 -2Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com