Prevention, actuation and control of deployment of memory-shape polymer foam-based expandables

A technology of polymers and copolymers, applied in wellbore/well components, machines/engines, mechanisms for generating mechanical power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] attached Figure 5 The effect of polar and non-polar deployment fluids on shape memory polymer foam based expandables is shown. Two cylindrical samples of polyurethane-polycarbonate rigid open-cell foam (h=4mm, d=7mm) were immersed in vegetable oil and water at 65°C and compressed to 35.2% and 39.4% of their original height, respectively. After removing the compressive load on the sample, the sample immersed in vegetable oil expanded to 39.9% of its original height in 21 seconds, and then further expanded to only 40.9% of its original height in 2468 minutes after that, while the immersed The sample in water rapidly expanded to 50.8% of its original height within 62 seconds, and then further gradually expanded to 67.2% of its original height over the next 2500 minutes. Note that the initial rapid expansion of the foam samples reflects the elastic response of the foam to removal of the compressive load and could have been avoided if the pre-compressed samples were immers...

Embodiment 2

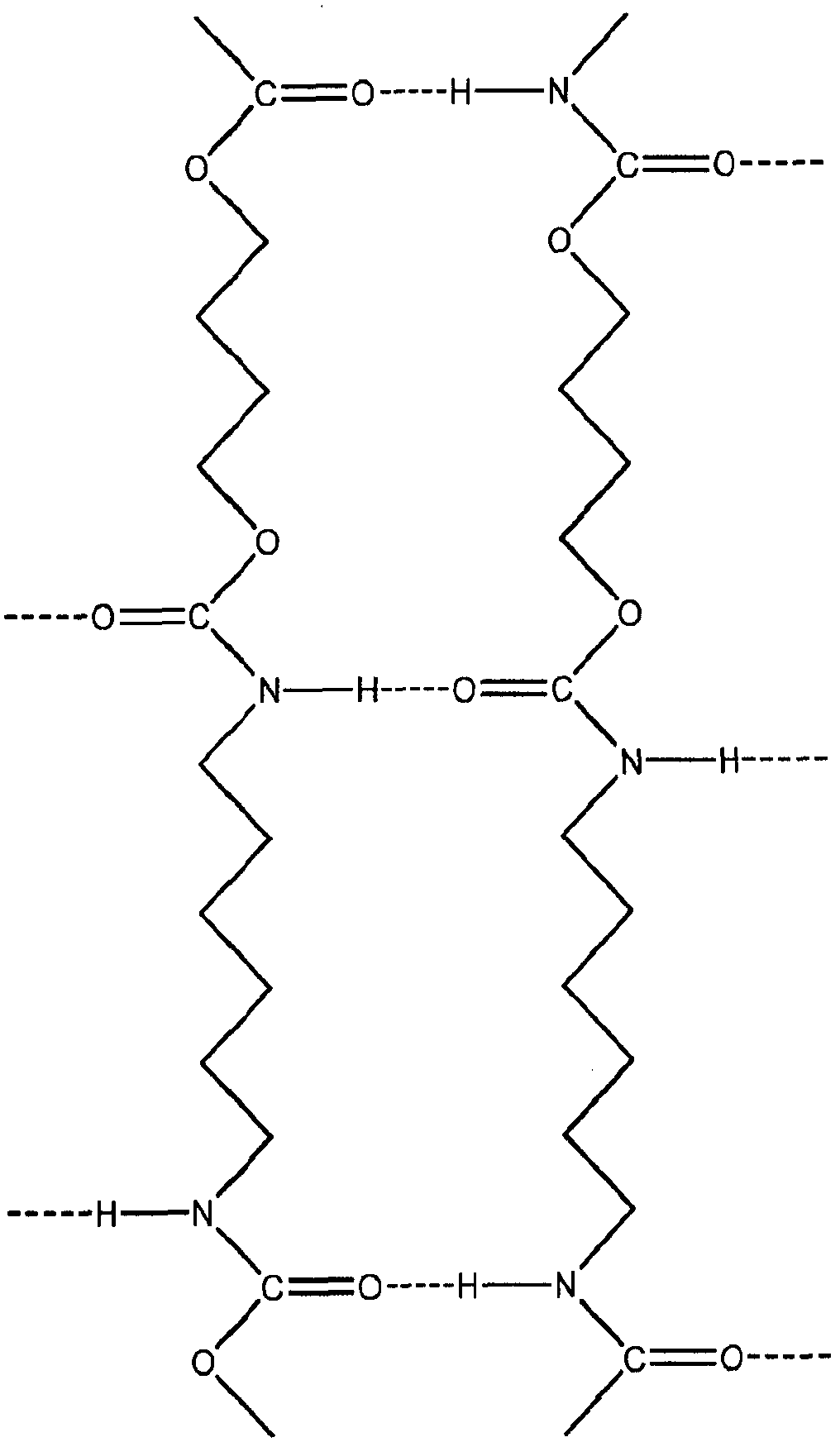

[0046] In the specific case of polycarbonate-polyurethane shape memory foam materials, it is believed that relatively light and mobile water molecules are linked to the negatively charged oxygen atoms and carbamate (urethane) of the polycarbonate chains. The positively charged hydrogen atoms form hydrogen bonds, which cause them to move and, as discussed previously, potentially act as "internal lubricants" between polymer chains. A comprehensive molecular level understanding of water molecules and polymer interactions is provided in Molecular Dynamics simulations (described by Tamar Schlick in "Molecular Modeling and Simulation", Springer-Verlag, New York, 2002).

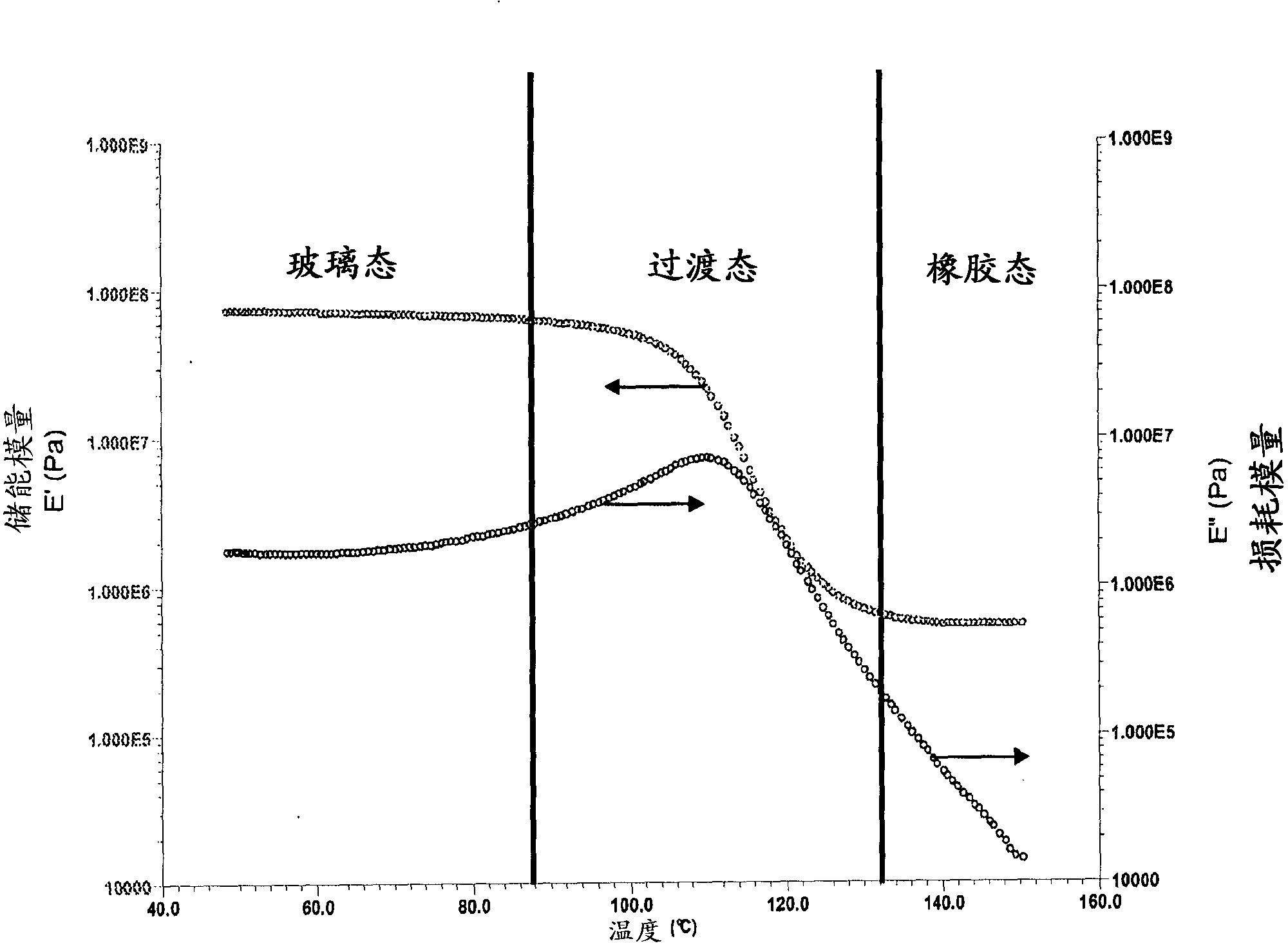

[0047] attached Figure 6 As can be seen in , this phenomenon effectively reduces the glass transition temperature Tg of polyurethane / polycarbonate foam immersed in water by a ΔTg of about -17°C compared to the Tg of the same material immersed in vegetable oil. attached Figure 6 is a plot of storage modulus (E') ...

Embodiment 3

[0050] as attached Figure 7 As shown in , by varying the temperature of the circulating fluid, it is possible to simultaneously control the speed and extent of deployment of shape-memory polymer foam-based expandables. as attached Figure 7 As shown in , increasing temperature increases the speed and extent of expandable deployment. It should be noted that this effect holds true for foams submerged in both more polar deployment fluids and non-polar deployment fluids.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com