Compressing cold-tolerant special hydrogenated butyronitrile rubber and preparation method thereof

A technology of hydrogenated nitrile rubber and nitrile rubber, which is applied in the field of organic polymer materials to achieve excellent oil resistance, excellent compression and cold resistance, and the effect of reducing Tg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

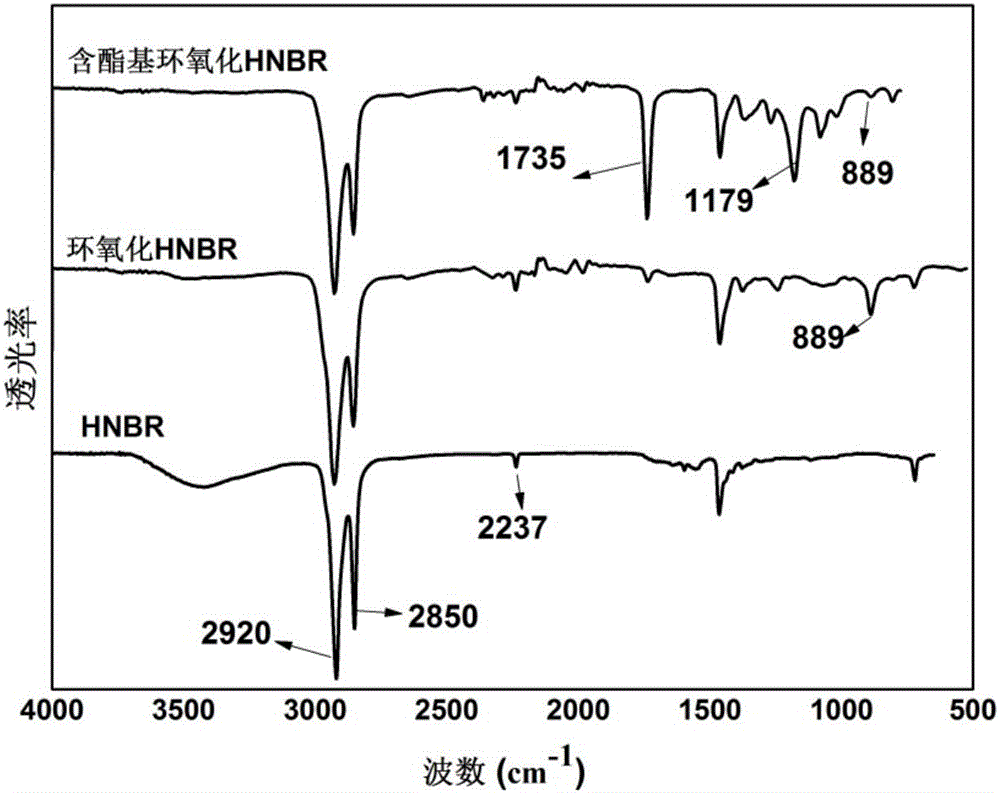

Image

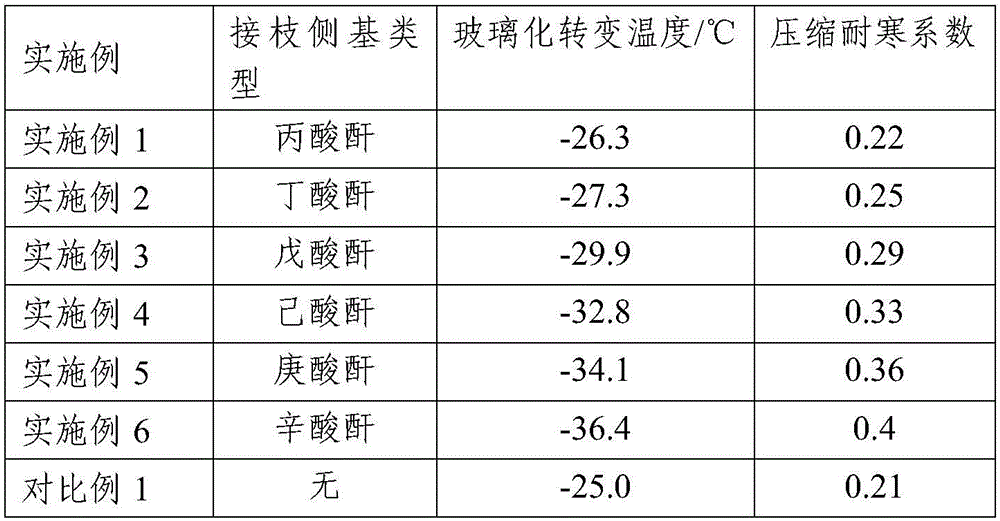

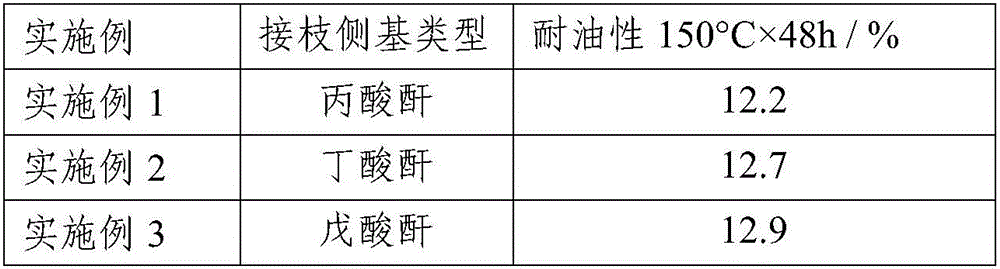

Examples

Embodiment 1

[0060] (1) Dissolve nitrile rubber with acrylonitrile content of 19wt% in xylene to prepare a solution of nitrile rubber with a solution mass concentration of 8wt%. Take 300g of the above glue solution in a 500ml three-necked bottle, add 21.6g of acetic acid, and then add hydrogen peroxide solution dropwise, react and stir at 65°C for 10h to obtain a mixed solution. The reacted mixed solution is precipitated, washed and dried to obtain epoxidized nitrile rubber. Calculated by nuclear magnetic spectrum, the epoxy degree is E%=32%;

[0061] (2) epoxidized nitrile rubber is dissolved in xylene, is mixed with the solution that solution mass concentration is 5wt%; Get solution 100g and add in autoclave, add Wilkinson catalyst 0.04g, triphenylphosphine 0.12 g. Evacuate nitrogen and hydrogen from the reactor three times each, then feed hydrogen at 4MPa, heat to 110°C, and react at medium and low speeds at 500r / min for 8 hours to obtain an epoxidized hydrogenated nitrile rubber solu...

Embodiment 2

[0065] 6.52g propionic anhydride (C 6 h 10 o 3 ) instead of 7.59g butyric anhydride (C 8 h 14 o 3 ), and other conditions remain unchanged, the hydrogenated nitrile rubber of the grafted butyl ester group is obtained.

Embodiment 3

[0067] 6.52g propionic anhydride (C 6 h 10 o 3 ) instead of 11.17g valeric anhydride (C 10 h 18 o 3 ), and other conditions remain unchanged, the hydrogenated nitrile rubber of the grafted pentyl ester group is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com