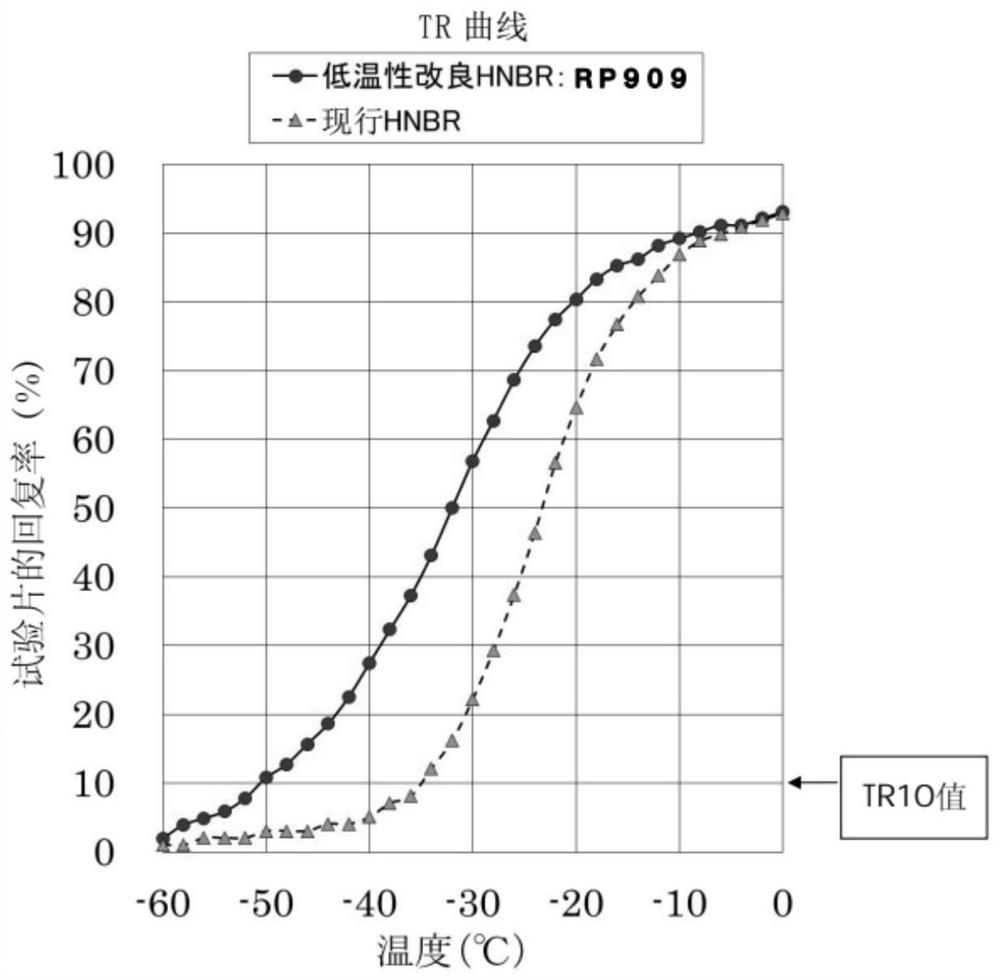

Cold-resistant hydrogenated nitrile rubber

A technology of hydrogenated nitrile rubber and oxidative hydrogenated nitrile, which is applied to pressure vessels used in chemical processes, etc., can solve problems such as being unable to cope with the requirements of high-cold use environments, achieve excellent compression cold resistance, improve low temperature resistance, and improve safety. level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A cold-resistant hydrogenated nitrile rubber, the formula of which includes the following materials: 100 parts of hydrogenated nitrile rubber, 3 to 5 parts of zinc oxide, 1 to 2 parts of stearic acid, 1 to 2 parts of palmitic acid; 0.5 to 4 parts of disperse agent, 10-12 parts of zinc borate, wherein the acrylonitrile content of the hydrogenated nitrile rubber is 39-41%. It includes 20-40 parts of aliphatic phosphate, 1-5 parts of vulcanizing agent and 4-6 parts of vulcanizing assistant. It includes 20-40 parts of aliphatic phosphate, 1-5 parts of vulcanizing agent and 4-6 parts of vulcanizing assistant.

[0032] It includes: the Mooney viscosity of the hydrogenated nitrile rubber is ML1+4, @100°C 60-70.

[0033] The present embodiment detects according to the following national standards:

[0034] GB / T 6034-1985 Determination of compression cold resistance coefficient of vulcanized rubber;

[0035] GB / T 6035-1985 Determination of tensile cold resistance coefficient ...

Embodiment 2

[0051] The preparation method of its hydrogenated nitrile rubber comprises the following steps:

[0052] 1) Epoxidation reaction: nitrile rubber is dissolved in xylene to make a nitrile rubber solution with a mass concentration of 11wt%, to which acetic acid and hydrogen peroxide are added successively, and the epoxidation reaction is carried out at 40° C. for 6 hours to obtain the epoxidation reaction Epoxidized nitrile rubber with an oxygen degree of 30%;

[0053] 2) hydrogenation reaction: the prepared epoxidized nitrile rubber is dissolved in xylene to make a mass concentration of 10% epoxidized nitrile rubber solution and put it into a hydrogenation kettle, to which Wilkinson Catalyst and ligand triphenylphosphine, at a temperature of 80 ° C and a hydrogen pressure of 1-3 MPa, hydrogenation reaction for 10 hours to obtain epoxidized hydrogenated nitrile rubber;

[0054] 3) ring-opening grafting reaction: add an acid anhydride and an epoxy group ring-opening catalyst to t...

Embodiment 3

[0056] The preparation method of its hydrogenated nitrile rubber comprises the following steps:

[0057] 1) Epoxidation reaction: nitrile rubber is dissolved in xylene to make a nitrile rubber solution with a mass concentration of 15 wt%, to which acetic acid and hydrogen peroxide are added successively, and epoxidation reaction is carried out at 40° C. for 8 hours to obtain epoxidation Epoxidized nitrile rubber with an oxygen degree of 50%;

[0058] 2) hydrogenation reaction: the prepared epoxidized nitrile rubber is dissolved in xylene to make a mass concentration of 16% epoxidized nitrile rubber solution and put it into a hydrogenation kettle, adding Wilkinson Catalyst and ligand triphenylphosphine, at a temperature of 120°C, hydrogen pressure slowly increased from 1MPa to 3MPa, hydrogenation reaction for 12h, to obtain epoxidized hydrogenated nitrile rubber;

[0059] 3) ring-opening grafting reaction: add an acid anhydride and an epoxy group ring-opening catalyst to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com