Methyl octabromo-ether flame-resistant polystyrene composite material, and preparation method thereof

A technology of methyl octabromoether and polystyrene, which is applied in the field of methyl octabromoether flame-retardant polystyrene composite materials and its preparation, can solve problems such as difficulty in popularization, limited application, complex process, etc., and achieve excellent thermal The effect of stability, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0030] Example 1-6: Methyl octabromoether flame retardant polystyrene composite material and its preparation method

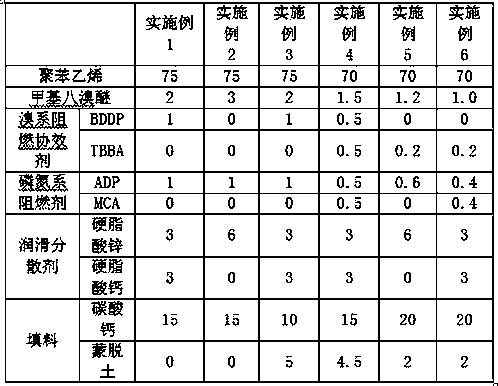

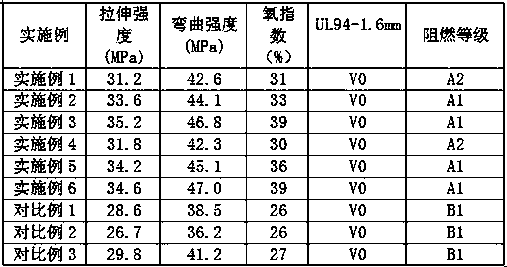

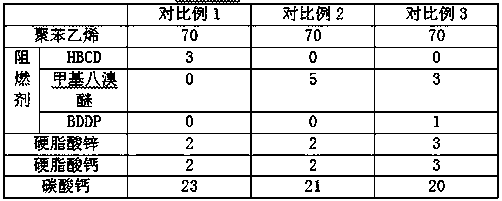

[0031] The components of a methyl octabromoether flame-retardant polystyrene composite material involved in Examples 1-6 of the present invention and the weight content of each component are shown in Table 1.

[0032] The preparation method step of methyl octabromoether flame retardant polystyrene composite material of the present invention is as follows:

[0033] (1) Weigh each component by weight fraction;

[0034] (2) After stirring each component evenly in the high-speed mixer, it is sent into the twin-screw extruder through the metering device. The temperature of the twin-screw extruder is controlled at 170-210°C. , the material is extruded, cooled, and granulated to obtain a flame-retardant polystyrene composite material of methyl octabromoether.

[0035] Table 1: Examples 1-6

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com