Devolatilization method and equipment of thermoplastic elastomers

A thermoplastic elastomer and equipment technology, which is applied in the post-treatment devolatilization field of thermoplastic elastomers, can solve the problems of large equipment occupation, small bulk density, incomplete devolatilization, etc., and achieve the effect of preventing loss and smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

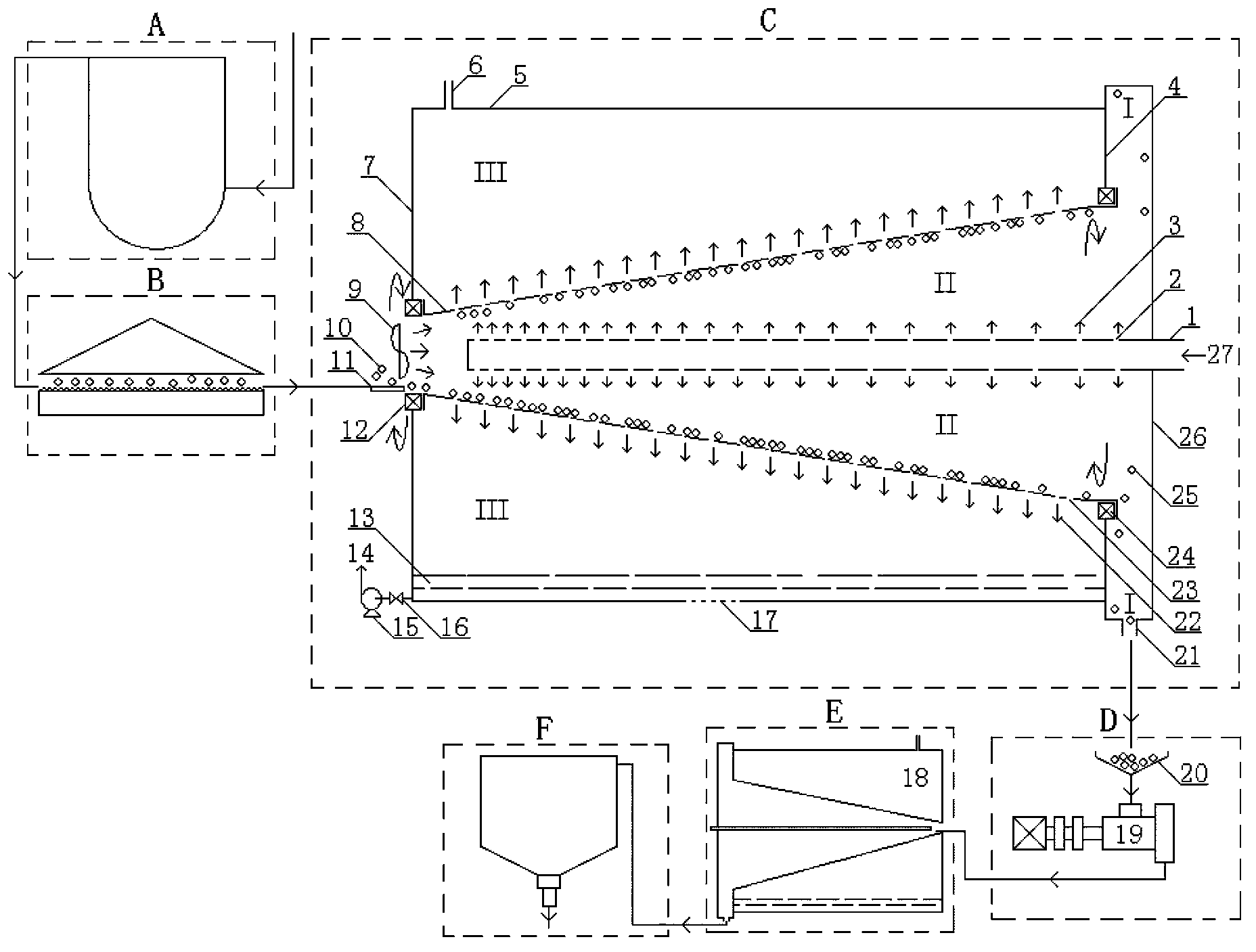

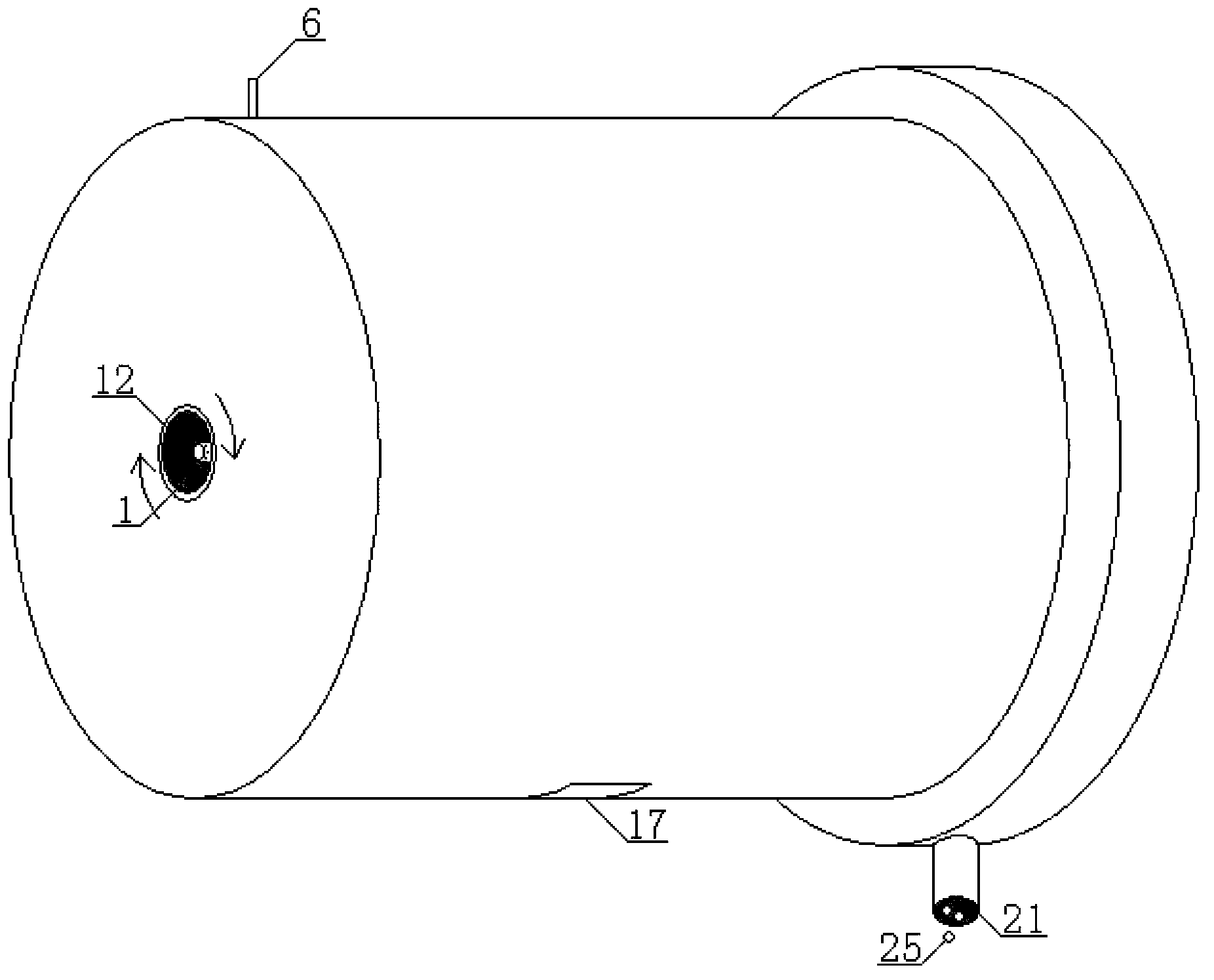

[0058] Take the horizontal conical centrifugal sieve as an example to describe it in detail.

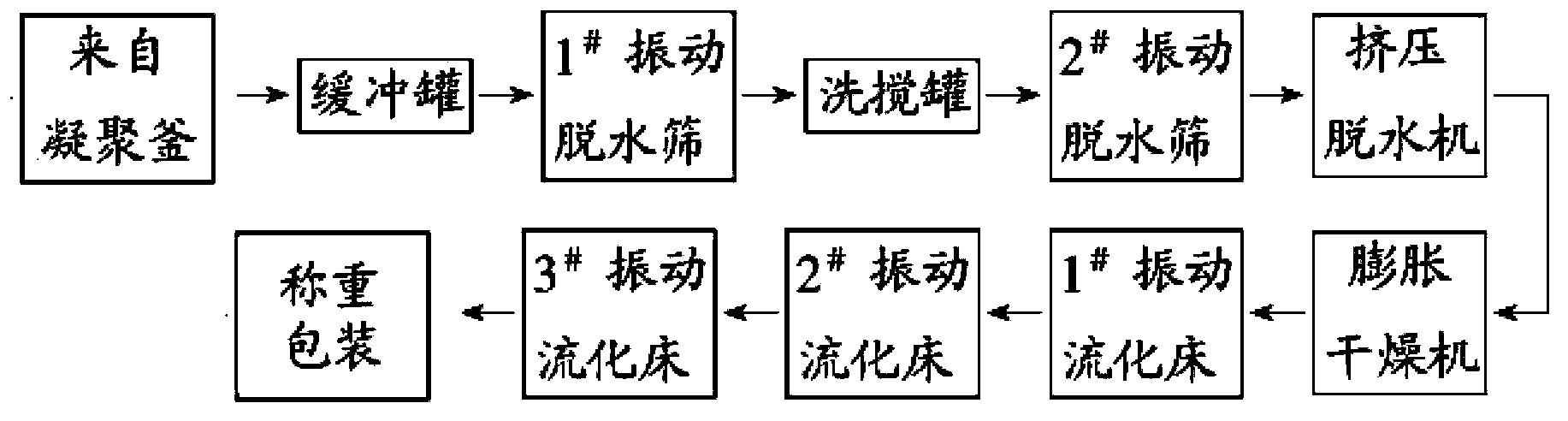

[0059] A star-shaped SBS glue with a weight average molecular weight of 300,000, a block ratio of 30 / 70, and a vinyl content of 16% (m / m) was obtained by polymerization. The glue contained 82% (m / m) of cyclopentane and 18% (m / m) polymer molecule. The glue passes through the water precipitation coagulation section A, and after the cyclopentane is cooked and removed, very fluffy colloidal particles are obtained, and these colloidal particles contain 85% (m / m) of water and a small amount of solvent. The colloidal particles are first sent to the vibration dewatering section B for preliminary water removal, so that the volatile content is reduced to about 51% (m / m).

[0060] The hydrocolloid particles 10 sent from the vibration dewatering section B are sent to the primary drying section C at a delivery rate of 55kg / min, the pressure balancer 9 is activated, and the air is blown to the le...

Embodiment 2

[0064] Take the vertical conical centrifugal sieve as an example to describe in detail.

[0065] The polymerization reaction obtained a syndiotactic 1,2-polybutadiene glue solution with a weight average molecular weight of 410,000, a syndiotactic degree of 72%, and a 1,2-structure content of 83%. The glue solution contained 84% (m / m) Cyclohexane and 16% (m / m) polymer molecules. The glue passes through the water precipitation coagulation section A, and after the cyclohexane is cooked and removed, very fluffy colloidal particles are obtained, which contain 75% (m / m) of water and a small amount of solvent. The colloidal particles are first sent to the vibration dewatering section B for preliminary water removal, so that the volatile matter content is reduced to about 45% (m / m), and the water colloidal particles sent by the vibration dewatering section B are sent to the primary drying section Dry in a vertical conical centrifugal dryer in C.

[0066]Vertical conical centrifugal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com